Dry washers have been used for many years in the Southwestern United States, where water is scarce, and especially in New Mexico where several million dollars in gold has been produced during the last century by dry washing. The Cerrillos, Golden, and Hillsboro districts are among those having produced gold by dry washing. In years when other employment is scarce such production may take place widely. In the 1930’s a considerable number of men also used dry washers in Nevada, southern California, and Arizona.

If gravel is to be treated successfully by dry washing, it must be completely dry and disintegrated. For instance, after rainstorms, operations must be stopped until the ground dries out again. Even in very dry climates the gravel is slightly damp below the surface, and must be dried before it can be treated in a dry washer. Spreading the material to sun-dry or putting it through dryers adds to the cost of mining. In small-scale work, however, the gravel will dry out about as fast as it can be treated.

Dry washers are usually run by hand and have about the same capacity as rockers of corresponding size, but the work of operating the dry washer is much harder. The workers select the material they are to treat with regard to both dryness and probable gold content. It is difficult to do this on a large scale with hired labor. Plants with mechanical excavators and complex power-driven dry-washing machinery have been tried, but in the United States, at least, virtually all were commercial failures, primarily because the gravel was dug faster than the sun could dry it out. Also, in large-scale work, particularly with mechanical excavation, the cost of sizing the material is quite great. Clay and cemented gravel introduce even further difficulties.

When the gold-bearing material is completely dry and disintegrated, panning tests of the tailings should show that a good saving can be made, except perhaps with extremely fine or flaky gold. Completely disintegrated material, however, is seldom obtained. The tops of clay streaks in the gravel are likely to be richer in gold than the gravel itself. Clay or cemented gravel seldom can be broken up sufficiently by hand to free all the gold without the use of some form of pulverizer. In a dry washer all gold included in a lump of waste passes out of the machine. As water usually will break up all the gravel and separate the gold from the other material, a better saving usually can be effected with the rocker or sluice-boxes than with a dry washer.

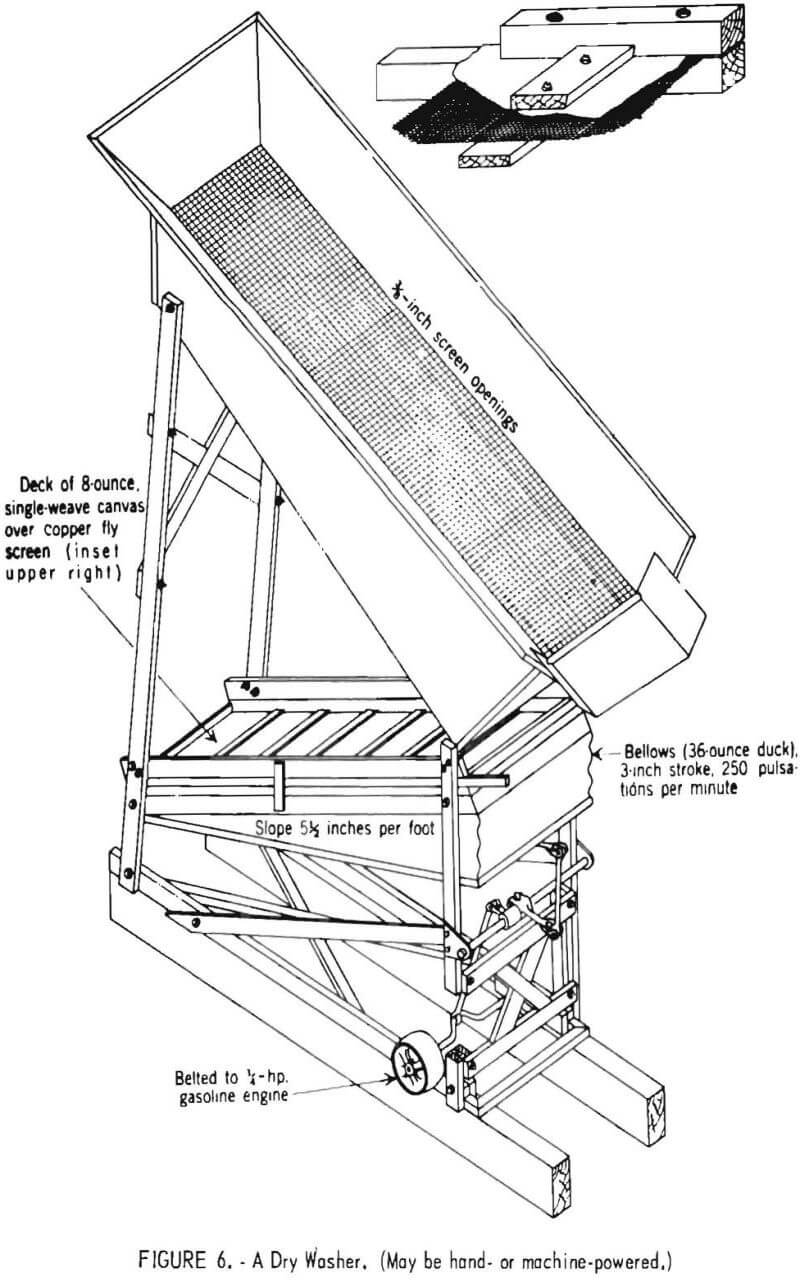

Basically, the dry washer separates gold from sand by pulsations of air through a porous medium. The screened gravel passes down an inclined riffle box with cross riffles. The bottom of the box consists of canvas or some other fabric. Under the riffle box is a bellows, by which air in short, strong puffs is blown through the canvas. This gives a combined shaking and classifying action to the material. The gold gravitates to the canvas and in held by the riffles, while the waste passes out of the machine.

The gravel is shoveled into a box holding a few shovelfuls at the head of the washer, from which it runs by gravity through the machine. A screen with about ½-inch openings is used over the box. All stones over about 1 inch in diameter generally are discarded in mining. A dry washer usually is run by a small gasoline engine which saves the labor of one man. The capacity of such machines is considerably greater than that of hand-operated ones. For instance, one man working alone must fill the box, then turn a crank which runs the bellows until the gravel runs through. The process is then repeated. With two men working, one shovels and the other turns the crank. One man can treat ½ to 1 cubic yard per day with a hand-operated washer, where the gravel lies close to the machine.

When cleaning up, the material behind the riffles usually is dumped into a pan and washed out in water. If water is very scarce, the accumulated material from the riffles may be run through the machine a second time and then further cleaned by blowing away the lighter grains of sand in a pan. Dry washers are usually handmade and have been built in a large number of designs and sizes. Figure 6 shows an example of one type. The bellows of the

canvas. In contrast to the single-weave canvas, silk or rayon permits a good extraction of gold, but too much dust goes through into the bellows. Heavier canvas is too tight for good separation. Copper-wire fly screen is used under the canvas. The riffle box is 11 inches wide and 40 inches long and contains six riffles. The slope of the riffle box is 5½ inches to the foot. (Hand-operated machines are usually much smaller and the riffle box is set at a steeper angle than with powered machines.) The gravel and sand are shoveled onto a screen with 3/8-inch openings at the top of the washer. The bellows is operated at 250 pulsations per minute; the stroke is 3 inches. The capacity of the machine is about 4/5 yard per hour, which probably would correspond to 1½ or 2 cubic yards, bank measure. (The plus 1-inch material was previously discarded.)

In cleaning up after treating approximately 1 cubic yard in the washer, the riffle box is lifted out and turned over on a large, flat surface, such as a baking tin. The concentrate from the upper three riffles is first panned, and the gold is removed. Usually both the coarse and the fine gold can be saved here. The lower riffles may contain a few colors, but nearly all the gold is normally caught in the upper riffles.