Air tables use a shaking motion similar to that of shaking tables, but instead of water, air is used to separate heavy minerals. The table deck is covered with a porous material and air is blown up through the deck from a chamber underneath. The chamber equalizes the pressure from the compressor and thus ensures an even flow of air over the entire deck surface. Generally, air tables consist of a riffled top deck mounted over a base that contains a compressor. The deck is tiltable and the riffles are tapered, much like a wet shaking table. An attached motor powers the system.

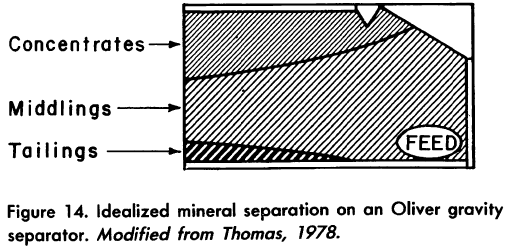

Dry feed is introduced at one comer of the deck. The deck is shaken laterally and air pressures are regulated to keep lighter particles suspended. The lighter material moves down slope along the shortest route. Heavier particles move upslope due to the movement of the table. Splitters allow an adjustable middlings fraction to be collected (Figure 12).

The sizing effects of air tables cause fine material to be lost as tailings, thus requiring careful prescreening of the ore. The feed rates, deck angles, and slopes are all adjustable for maximum separation efficiency. Air tables are capable of processing up to 7 tons per hour of feed.

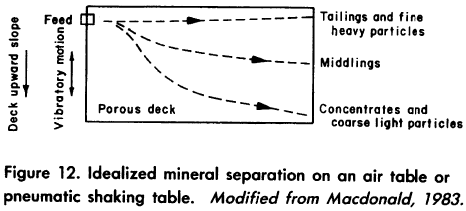

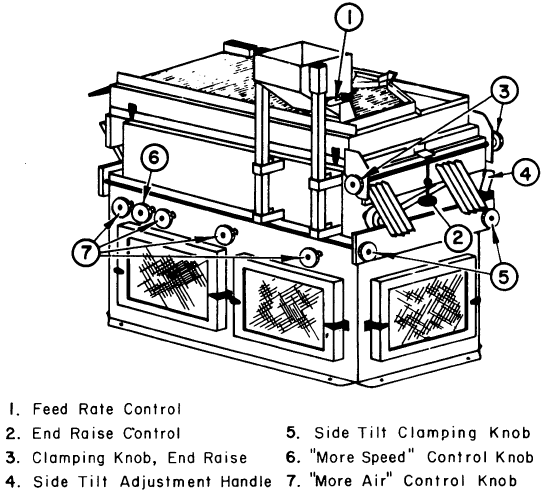

The Oliver gravity separator is a portable, self-contained air table suitable for use in dry placers. The separator is a box shaped device with a screened deck and feed box on top (Figure 13). The drive and air bellows are located inside the enclosed box. The deck area is 20 by 36 inches; the unit is roughly 54 inches high, 55 inches long, and 47 inches wide; it weighs 555 pounds. It works by forcing air through the particle mixture so that the particles rise or fall by their relative weight to the air.

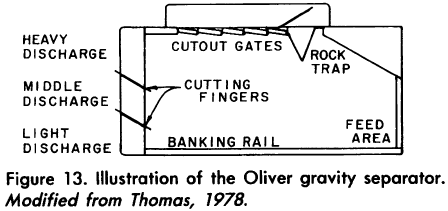

The tilt of the deck and the vibrating action of the drive create a stratification of heavy materials (Figure 14). It should be noted that this device is designed for pre-processed material that should be of a very uniform particle size. The machine includes controls for adjustment of feed rate, air flow, deck tilt, and vibration speed. The unit can process up to 100 pounds of sand-sized material per hour.