Table of Contents

Mining Companies employ the use of mine hoists to transfer ore, men and materials through a vertical shaft or slope. With varying depths, payloads and equipment, it is necessary to select a rope construction that is best suited for these parameters and that can also provide the most economical cost per ton hoisted.

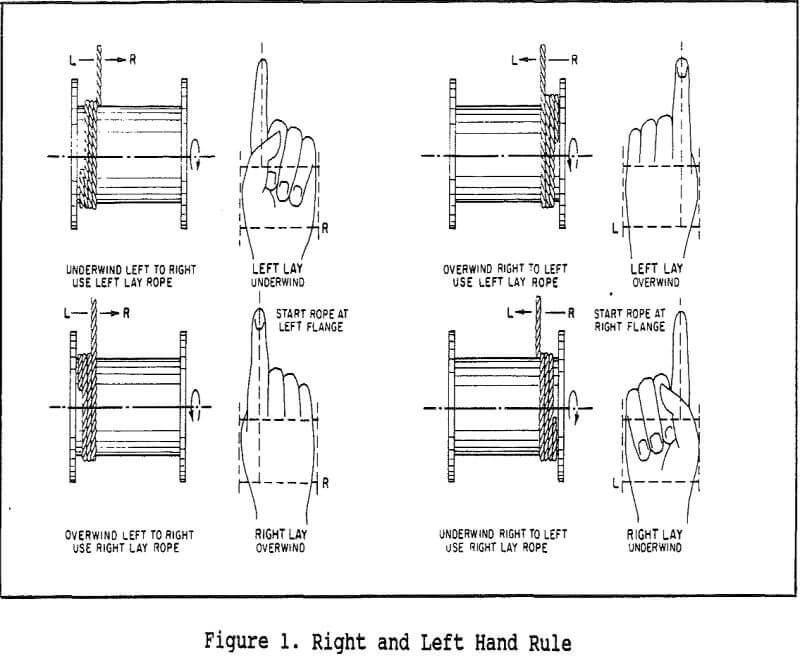

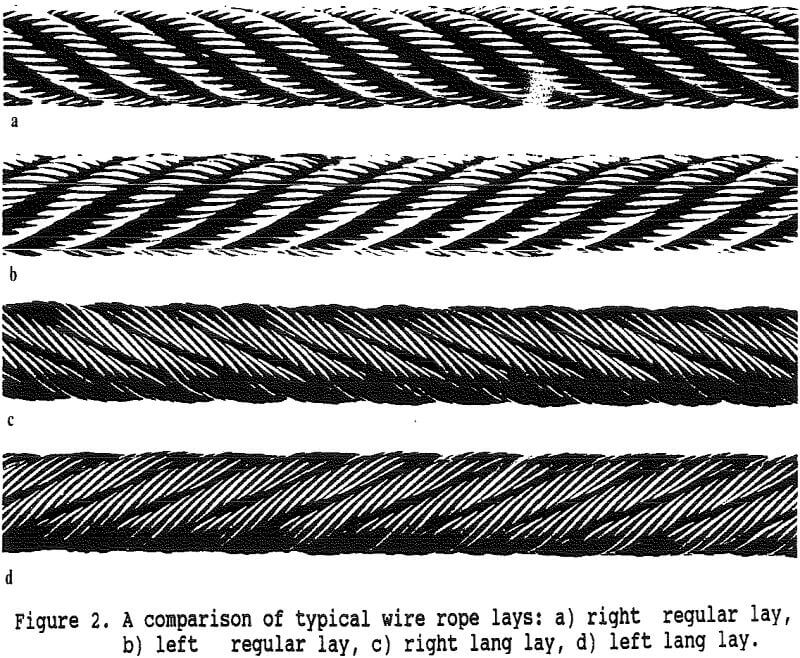

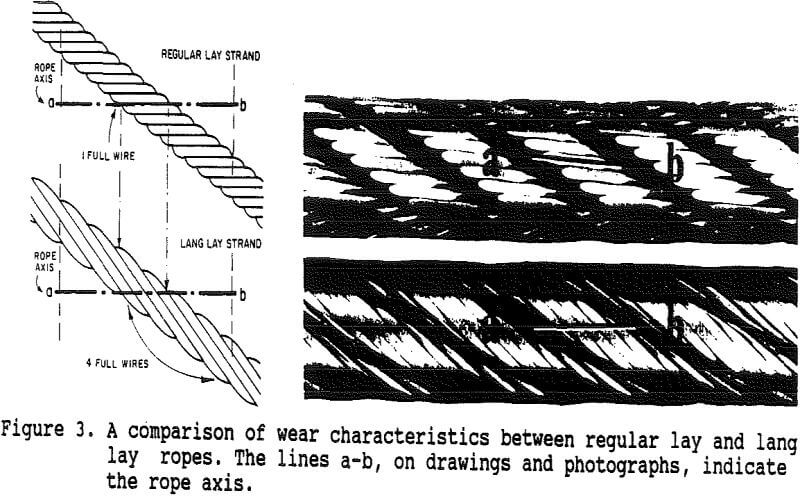

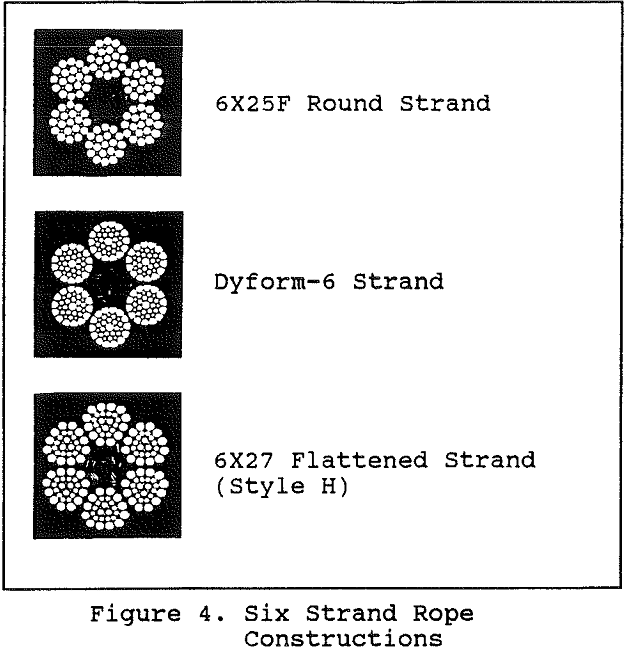

If the shaft conveyance is operating on fixed guides, then a 6 strand rope construction is the most suitable choice (This is based on the hoisting depths in the United States. Greater depths would have to take greater torque loads into consideration, hence, a different recommendation). These available 6 strand rope constructions are reviewed below. A few things that apply to all these rope constructions are the direction and type of lay; and the rope core.

Round Strand

The most common type of rope construction used for drum hoisting is the 6×19 Classification Round Strand and of this classification, the most popular construction is the 6x25F. The 6×19 classification is an equal layed construction that contains 6 strands with 15 to 26 wires per strand. This construction performs best on single layer drum hoists with the conveyance on fixed guides.

Flattened Strand

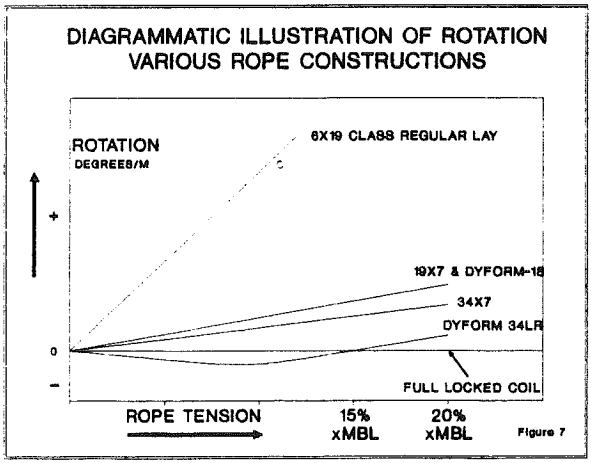

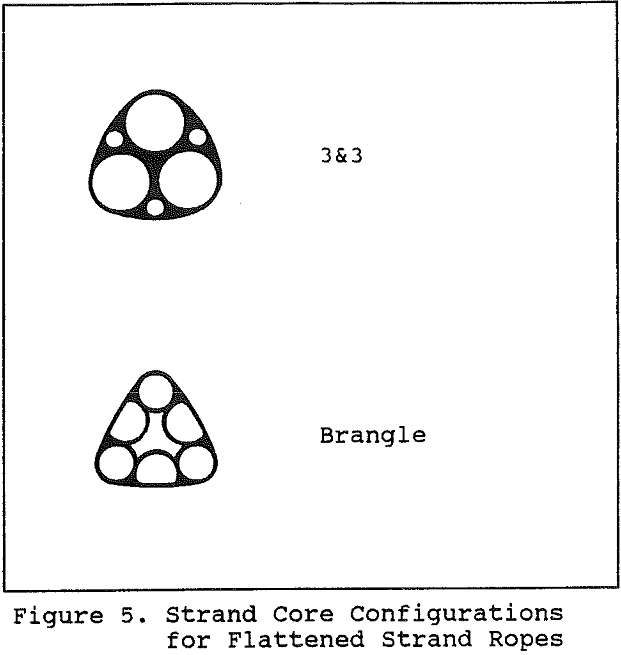

This is the construction that provides the best service for multi-layer windings. It is a cross layed construction, hence, it does not do as well as round strand on single layer winding from a fatigue stand point. However, the triangular design of the strand as shown on the 6×27 Style H, provides the rope with a larger bearing surface than even Dyform and superior crush resistance properties. When the shaft conveyance is running on rope guides, it is necessary to employ the use of a rope construction that has excellent rotation resistant qualities.

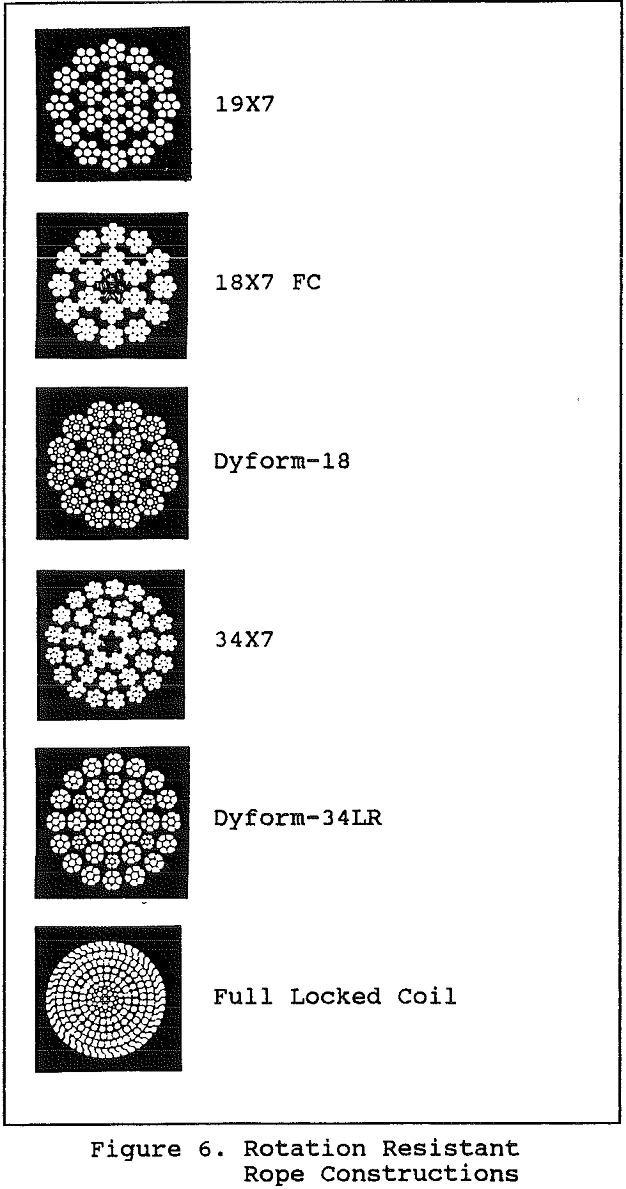

The Full Lock Coil construction provides the best all round features of rotation resistant ropes. It is virtually rotation free, has the greatest bearing surface of any construction and has a 53% higher breaking strength than 19×7. It also can employ a swivel in a sinking operation without reducing the rope’s breaking strength. These qualities make it the choice for deep sinking applications as well as for use with either fixed or rope guided conveyances. The greatest drawback is that full lock coil requires a large operating bending ratio of 100 to 120:1 depending on rope diameter.

How to Select a Drum Hoist Rope

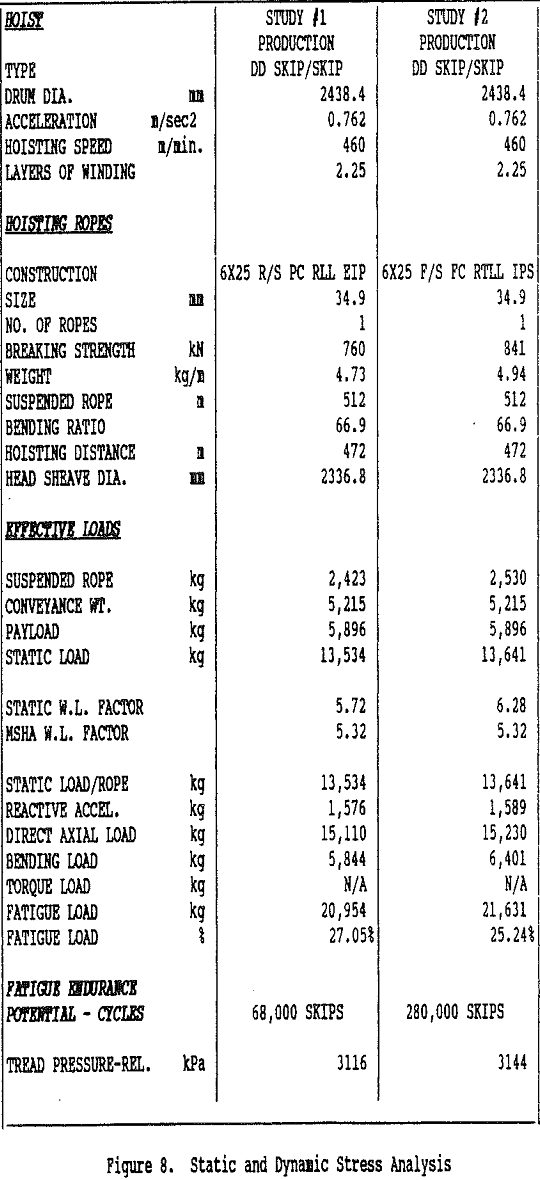

The theoretical calculations shown on this form are a summation of the static and dynamic loads experienced by the hoist ropes during the hoisting cycle; the fatigue endurance potentials predicted on the bottom of this form are based on these theoretical calculations, however, they do not take into account the adverse effects of shaft environment and/or a poor or inadequate maintenance program.

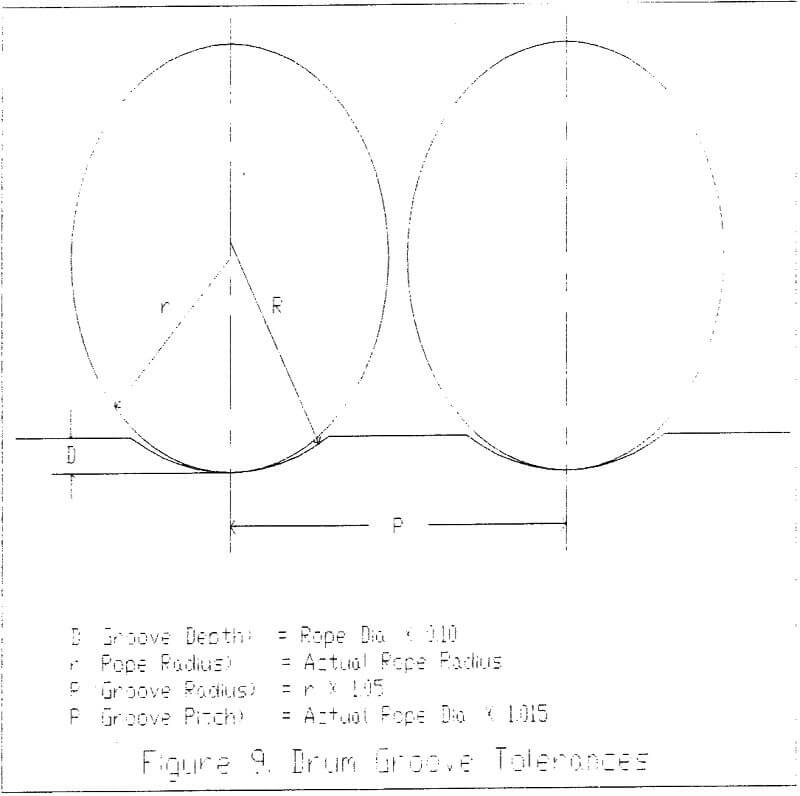

Spiral grooving is acceptable for single layer winding. Where multi-layer winding is used, then parallel grooving or one of the patterned coiling systems should be used.

Our recommendation for Headsheave & Drum to rope ratios using stranded ropes is 80:1. Some instances may allow smaller bending ratios like slope hoists where abrasion is the deciding rope removal factor, however, any decrease in this ratio will result in rope life reduction. Additionally, different rope constructions would have to be considered for these smaller bending ratios.

Drum Hoist Rope Maintenance

To achieve close to the optimum fatigue endurance potential of the ropes, they must be maintained in a proper manner. The list below highlights the areas that are the leading preventable causes of premature rope removal.

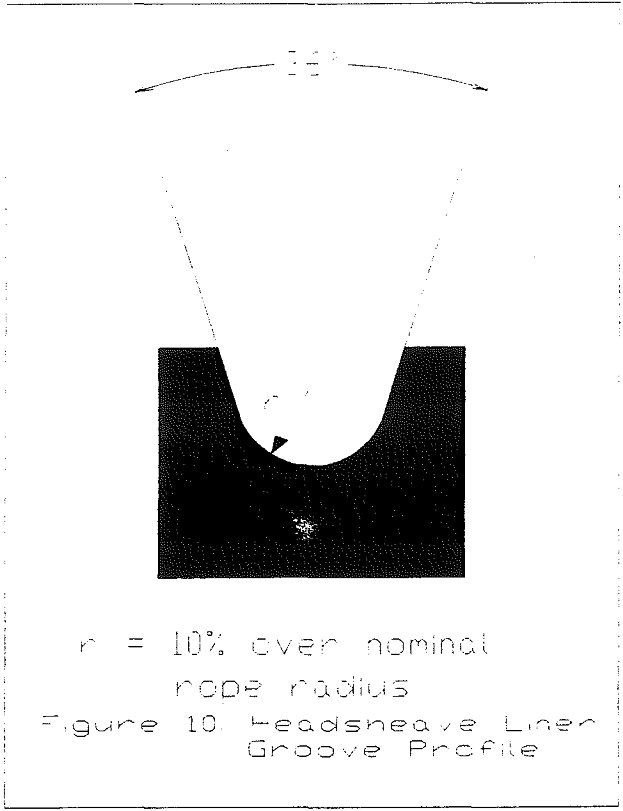

The optimum profile is 10% over nominal rope diameter with a 36° included angle. The minimum acceptable profile would be 7.5% over nominal rope diameter for a newly installed rope.

If it is less than 7.5%, then the chances for structural upset of the rope construction in the form of a high strand or strands is highly probable. This distortion would be found on the rope at the headsheave going towards the drum with the conveyance in the lowermost position. The tight profile reduces the natural rotation of the rope in the headsheave and causes a milking action which pushes a buildup to the above mentioned area.

This is the same procedure that should be used for the initial rope installation. This allows the dead wraps to be wrapped with the highest amount of tension. Though the dead wraps do not come off the drum during the normal winding cycle, the dead wraps will still stretch constructionally and suffer from secondary bending as the subsequent layers are wound. This leads to classic step fatigue wire breaks on the dead wraps. The above procedure puts the dead wraps on with sufficient tension to avoid this condition. A full conveyance is used during the procedure to obtain as much tension as possible.

Shortly after installation, a new rope experiences constructional stretch which is permanent elongation of the rope. The majority of this stretch happens early in the rope’s life and due to its helical nature, rope turn must accompany this elongation. Since both ends are fixed, the turn cannot come out of the rope and will build up directly above the conveyance.

The first step in proper lubrication is to ensure that the rope ordered comes with a lubricant that will protect the rope for a long period of time while it is being stored (spare rope) and be suitable for the particular shaft environment it is intended for. Talk to the rope manufacturer for specific brand recommendations.