Table of Contents

- A Modern Idea of Service

- Placer Dredging

- Dredging Conditions

- Proper Design of Dredge

- Dredging Dry Ground

- Dredging High or Deep Ground

- Dredging Frozen Ground

- The Right Way to Proceed

- Amortization

- Freak Dredges

- A Placer Dredge

- Wood or Steel Hulls

- The First All-Steel Dredge

- Construction Work

- Size of Dredge

- A Typical or Standard Dredge

- Description

- A Problem of Great Variations in Digging Depth

- Tin Dredging

A Modern Idea of Service

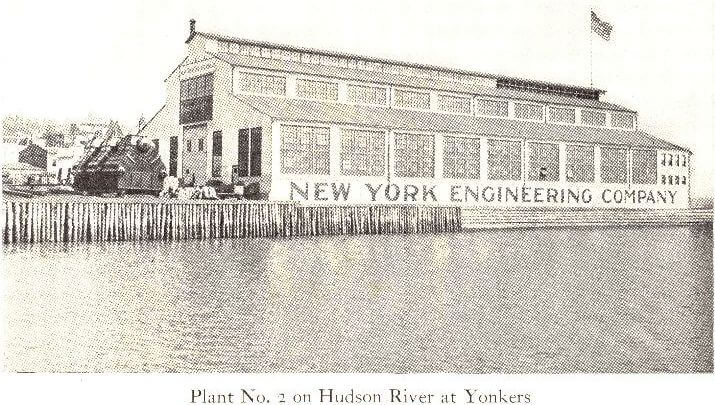

Our present plant was designed and built by ourselves and we have also designed and built much of our special machinery in order to take care of the operations peculiar to our line of work. Our plant is electrically operated throughout and every modern method and apparatus has been installed in order that we might lead all others in this particular industry.

The location of our plant at Yonkers, N. Y., directly on the Hudson River, provides great advantages both to ourselves and to our clients, as it gives us both rail and water transportation. We are located in the center of production of all the materials entering into the construction of our dredges. Almost all parts of the modern dredge are of cast, wrought, or manganese steel, all of which are produced in the East and at our very door. Our location on tidewater again provides exceptional shipping facilities as our dredge machinery can be loaded directly into vessels at our dock for shipment to any part of the world. A switch from the New York Central Railroad runs through the center of our plant.

We have provided the above advantages in order that we may render the highest possible service to our clients, who may always depend upon our promises being kept and our methods being fair and businesslike.

The New York Engineering Co. was founded in 1906 by A. C. Ludlum, its President, who is still actively in charge of its affairs. Our personnel has been maintained intact from the beginning to the present which accounts for much of the Company’s success. Our credit and responsibility are beyond question.

It is important that one deals with a responsible Company, but it is of vital importance that one secures a dredge that is correctly designed and has the greatest earning capacity and on this basis, we earnestly solicit an opportunity to submit plans and specifications.

Placer Dredging

Industrial or commercial enterprises are generally supposed to give a moderate but sure return on the investment; whereas the popular conception of mining enterprises is one of fabulous return or else nothing at all; in other words, a gamble where luck and chance govern all. It has remained for the dredging of gold to upset this conception and to demonstrate beyond a question that such mining is as much a business enterprise as any manufacturing industry, and in addition it has the great advantage of having an absolutely unlimited and unfluctuating demand for its product. These conditions are found in no other business but that of producing gold—the standard of all values.

- Steam Electric Dredge

- Steam Electric Dredge

- High Efficiency

- Low Operating Costs

- Dredging Clay and Barren Overburden

- Dredging Large Boulders

- A Successful Enterprise

- A Resoiling Dredge

- Thorough Prospecting Work

- Another All-Steel Dredge

- The Road to Success

- Data That Should Be Given When Writing To Us

- Specifications of Empire Dredges

- Placer Prospecting Practice

- Drill Boats

- Special Drilling Apparatus

- Placer Prospecting Practice

- Exploiting the Property

- Hydraulic Mining

- Hydraulic Elevators

- Successful Hydraulic Mining in Colombia, S. A.

- The Empire Hydraulic Elevator

- Other Things That We Do

- Hydraulic Equipment

- Diamond Mining Machinery

- Boilers

- Construction Work

- Dredge Parts

- Portable Power Plants

- General Plate and Machine Work

- Foreign Correspondence

- Patents

- Financing Placer Enterprises

When the ground is properly prospected and equipped with a skillfully designed and well-built dredge, the returns can be predicted with an exactness that challenges belief. Corporations operating gold dredges have calculated returns for years in advance and results have shown an accuracy in forecasting the returns that is not to be equalled in manufacturing or in the marketing of any other products; for market conditions and many other changeable factors introduce uncertain figures and features that set all calculations at variance, while gold—the product of gold dredging—has a market and a value absolutely unwavering and a demand unlimited.

The government always stands ready to buy the entire product at a fixed price of $20.67 per ounce. Another favorable point in gold  dredging is the fact that the entire area can be prospected and all conditions predetermined, and there are less chances of the unexpected happening, as in lode mining where the ore changes its character with depth or the vein faults or pinches out. In fact, it would seem that there is no one form of mining enterprise in which one needs to take less chance than in gold dredging. If the investor will only protect himself by securing the best possible talent in gold dredge engineering before making any heavy commitments, success will be assured, or at least failure averted. For these reasons, gold dredging has attracted widespread attention among investors and business men.

dredging is the fact that the entire area can be prospected and all conditions predetermined, and there are less chances of the unexpected happening, as in lode mining where the ore changes its character with depth or the vein faults or pinches out. In fact, it would seem that there is no one form of mining enterprise in which one needs to take less chance than in gold dredging. If the investor will only protect himself by securing the best possible talent in gold dredge engineering before making any heavy commitments, success will be assured, or at least failure averted. For these reasons, gold dredging has attracted widespread attention among investors and business men.

Dredging Conditions

It is not easy to state in exact terms just what conditions are essential for success in placer dredging, but there are a number of factors which have such an individual importance that the lack of any one of them may result in failure where otherwise success should have been attained.

Proper Design of Dredge

There is no one governing condition more important than machinery of design and construction suitable for working in the area chosen for exploitation by the dredging method. Thus there are several instances where faulty design or construction have wrecked undertakings which otherwise would have furnished rich reward. Therefore, we emphasize not only the advantage of care in selection of the dredging plant, but also the importance of thorough and careful investigation of the dredging ground under consideration so that the dredge may be designed and built to meet the existing conditions.

Dredging Dry Ground

It is often assumed that it is necessary to have plenty of water in order to make a dredging project practicable. This is quite erroneous since dredging may be carried on in arid areas devoid of any running water. To accomplish this it is only necessary to have a small pond about two hundred feet in size to float the dredge and a small supply of water, which can be pumped or flumed from a distance, to take care of the seepage and evaporation. In this small pond the dredge can be made to float over any part of the property and carry the pond along with it, inasmuch as the dredge fills in behind with the material that is removed from the front.

It is often assumed that it is necessary to have plenty of water in order to make a dredging project practicable. This is quite erroneous since dredging may be carried on in arid areas devoid of any running water. To accomplish this it is only necessary to have a small pond about two hundred feet in size to float the dredge and a small supply of water, which can be pumped or flumed from a distance, to take care of the seepage and evaporation. In this small pond the dredge can be made to float over any part of the property and carry the pond along with it, inasmuch as the dredge fills in behind with the material that is removed from the front.

Dredging High or Deep Ground

The dredging of benches or terraces is also possible as the pond and the dredge can be gradually and easily raised up from a lower level on to a higher level. The ultimate depth to which a dredge can dig has not yet been determined and alluvium about 100 feet deep is now being handled with great success and probably greater depths could be dredged if found to exist. Banks as high as 30 to 40 feet above the water level are also successfully handled.

Dredging Frozen Ground

The dredging of frozen ground has been successfully accomplished in the past by thawing the ground with live steam introduced through pipes or steam points driven into the gravel. While this has worked out successfully, still it has always proven expensive. In some cases ground sluicing has been resorted to or the ground flooded with running water which eventually permeates the gravel and thaws it, but this process has proved a very slow one.

A method has been developed in Alaska which is proving very successful. It consists of the driving or sinking of pipes into the ground to bed rock and water of normal temperature and under slight pressure is then forced down through the pipes and out of the bottom onto bed rock. It then flows through the gravel and thaws it quite rapidly. This has proven to be the least expensive and the most desirable way of preparing frozen gravel for dredging.

The Right Way to Proceed

The right way to determine the desirability of a dredging project seems so simple that one often wonders how any one can go wrong in this industry—that is, assuming that the promoter or prospector is serious and honest in his intentions and has no idea of promoting a wildcat scheme; and in this connection it is most satisfactory to note that there have been few wildcat companies promoted in the dredging field in recent years.

There have been failures in gold-dredging enterprises, and most of these might have been prevented if the proper steps had been taken in the beginning. There is still too much of a tendency to regard gold dredging in the light of a gamble, instead of applying to it conservative business methods, such as any one should apply when contemplating an investment in a manufacturing or contracting business.

The prospector and promoter must be born optimists, but the investor should be the stabilizer, by applying the test of business and engineering methods to the project. The first step to be taken when considering any gold-dredging project is to secure the services of a competent engineer experienced in this particular line of work. This may not always prove as easy as it sounds. However, there are many channels through which the name of a competent engineer can be secured.

Often the engineer can observe conditions on the surface of the ground that will condemn the enterprise to failure, and thus can save the investor from further loss. It sometimes occurs that rough, hard bedrock will be visible in many places, or it can be readily seen that the gravel deposit is extremely shallow. Numerous boulders may be in evidence so large as to make the cost of mining prohibitive. Large boulders are not always prohibitive to successful mining, but they do make for high operating costs and can be handled only by certain methods.

The cut on opposite page shows the La Clara Mines, in Colombia, South America, successfully operated for the last ten years. Note the enormous boulders. It is doubtful whether this ground could be successfully handled by any other method than with the combination of giants and hydraulic elevators.

If the physical conditions appear to be favorable for successful operations, it is then a comparatively simple matter to prospect the ground either by shafts or drill holes, or open cuts across the deposit may even sometimes be run. This work, which can be done at comparatively small expense, will determine whether the ground is worthy of an exhaustive examination; in other words, a complete proving of the entire area may be made before the expensive dredging equipment is purchased.

It is to be regretted that there is so little literature available to the average inquirer on gold dredging. Only a few books have been published on this subject. The U. S. Bureau of Mines publishes a bulletin No. 121, entitled “The History and Development of Gold Dredging in Montana.” This contains much valuable data and many interesting photos. The Bureau also publishes another Bulletin No. 127, entitled “Gold Dredging in the United States,” by Charles Janin. This book also contains much valuable information and will prove of great benefit to any one interested in this industry.

Dredging is a comparatively new industry, dating back only about twenty-five years in this country. For the first few years, it “just growed” like Topsy, with no systematic development. This growth is well illustrated in the Bureau of Mines bulletin No. 121 previously cited. In this pamphlet is shown the struggle of a company during a number of years, with the expenditure of many thousands of dollars, in order to develop a successful dredge for their existing conditions. Later, engineering ability came more fully into play in the dredging industry and today the American type of dredge may be said to be standardized, variation in the details of a design and construction being made only to fit the particular conditions under which the dredge is to operate. With dredges standardized and with a number of responsible gold-dredge engineering and construction companies in the field, there is little need for any one making a complete failure by securing the wrong type of dredge.

Amortization

In considering a dredging enterprise, special attention must be given to amortization; it must be borne in mind that the initial cost of the ground and the dredge installation must be recovered before any real profit is earned, as the ground when dredged is practically useless. Attempts have been made to resoil or to render the ground useful after dredging, and this is now meeting with some success. In Australia it is compulsory by law, and the dredges are designed and their operations conducted so as to resoil all the dredged ground. In Korea this is successfully being done by a dredge designed and built by us.

Dredging equipment is of little value after the ground is dredged out. Therefore, the capital investment is a diminishing asset, probably disappearing during the operation of the enterprise. It is necessary, therefore, to prove up a sufficient area to cover the cost of the ground, the equipment and the operating expense and to leave a balance for a profit commensurate with the capital invested.

Freak Dredges

Many failures were made in the earlier days by attempting to use the suction and the dipper types of dredges; also many peculiar engineering freaks were tried out and proved inefficient, such as sinking caissons, using divers in connection with suction dredges. Many so-called dry-land dredges, as well as the steam shovel, combined with sluicing apparatus have also demonstrated their inefficiency and

have caused failures, whereas with proper equipment a success might have been made. While there are many records of these failures, it is to be regretted that there is no compilation of them in any one particular form and therefore, nothing to warn the average outside inquirer from these pitfalls. There is, however, less tendency nowadays for new companies to go wrong by attempting any of these experiments, which have demonstrated their failure in the past.

have caused failures, whereas with proper equipment a success might have been made. While there are many records of these failures, it is to be regretted that there is no compilation of them in any one particular form and therefore, nothing to warn the average outside inquirer from these pitfalls. There is, however, less tendency nowadays for new companies to go wrong by attempting any of these experiments, which have demonstrated their failure in the past.

There is not only a standard type of successful dredge, but working costs have been accurately and closely determined, and many records of them are published in pamphlet form and in the various mining journals. Therefore, there is little reason for any enterprise making a failure by underestimating their working costs.

Where it is practicable, hydraulicking is the simplest and most economical method of placer mining. We treat of the hydraulic method of mining in the latter part of this booklet, but here it may be assumed that the project is one requiring a dredge, and the following pages accordingly treat of dredging methods.

In dredging for gold and platinum, there is practically no difference in the details of design of the dredge or in the recovery apparatus, but in the dredging of tin, the tables and sluices are quite different and a jigging apparatus is sometimes introduced and ample provision must be made for frequent clean-ups of the tin concentrate.

A Placer Dredge

While it is assumed that the reader is fairly familiar with placer dredging apparatus, still we will briefly describe the elements of a placer dredge.

A digging apparatus at the bow, consisting of an endless chain of buckets operating on a steel digging ladder, raises the material and delivers it to the screen— a revolving perforated cylinder. The screen washes and sizes the material, over-size material passing through to the stacker and the smaller material passing through the perforations and on to the tables for recovering the gold, platinum or tin. The stacker is a conveyor at the stern, which carries the over-size material from the screen to a distance behind the dredge and on to the tailing pile, thereby disposing of the waste. A pumping apparatus furnishes water for washing and sluicing the screened gravel and for recovering the gold therefrom. A winch controls the spuds and lines that manipulate and hold the dredge in position. This completes the essential elements of the dredge. Each element is complete in itself, is combined in regular co-ordination,  and the whole is mounted on a scow, forming a complete simple and practical excavating, screening, washing and stacking apparatus, the operation of which is practically automatic and continuous. All of these operations, and in fact every piece of apparatus on the dredge is controlled by one man, who is located in the pilot house of the dredge.

and the whole is mounted on a scow, forming a complete simple and practical excavating, screening, washing and stacking apparatus, the operation of which is practically automatic and continuous. All of these operations, and in fact every piece of apparatus on the dredge is controlled by one man, who is located in the pilot house of the dredge.

While the prototype of the American dredge came from New Zealand, it remained for American engineers to develop and perfect it to its present high state of efficiency. The gold dredge of today is a truly marvelous piece of mechanism, that will handle over 15,000 yards of material a day; washing, sizing and concentrating it, recovering the gold therefrom, and disposing of the waste or barren gravel, and all of this is accomplished with the labor of only three or four men per shift.

If we stop to consider that it would require fifteen to twenty thousand men to do the same work; we may form some conception of the wonderful performance of these great machines, which have been picturesquely called the “Gold Ships of America.”

These gold ships have plowed their way through the western mountains and plains and through the ice-bound fields of Alaska for the past twenty years, and have taken out over one hundred and seventy-five millions in gold for the enrichment of their owners.

Wood or Steel Hulls

One of the first things to be determined is whether the dredge should have a wooden or a steel hull. If suitable timber is close at hand and can be secured at an attractive price, the saving in first cost may prove an incentive to use a wooden hull. Quite often one concludes that suitable lumber may be readily obtained in the vicinity of the dredging operations only to find later on that this is not true. The lumber required for a dredge is of large dimensions and unusually long lengths are necessary in order to build a stiff and durable hull. Moreover, the timber must be of first-class quality. All of these conditions are rarely ever fulfilled in a tropical country and in many instances it becomes necessary to import the lumber from the United States. The final result is that the wooden hull proves more expensive than originally estimated and much time is lost in securing the lumber. If a wooden hull is finally decided on, great care must be exercised in order that the hull be well designed and built by competent ship carpenters. The hull is the foundation of the dredge and should be built to last as long as the machinery. In building a wooden hull in the tropics, extra care must be taken to ventilate it properly on the inside in order to prevent dry rot, and to protect it on the outside against damage by the toredo and other wood-boring insects.

One of the first things to be determined is whether the dredge should have a wooden or a steel hull. If suitable timber is close at hand and can be secured at an attractive price, the saving in first cost may prove an incentive to use a wooden hull. Quite often one concludes that suitable lumber may be readily obtained in the vicinity of the dredging operations only to find later on that this is not true. The lumber required for a dredge is of large dimensions and unusually long lengths are necessary in order to build a stiff and durable hull. Moreover, the timber must be of first-class quality. All of these conditions are rarely ever fulfilled in a tropical country and in many instances it becomes necessary to import the lumber from the United States. The final result is that the wooden hull proves more expensive than originally estimated and much time is lost in securing the lumber. If a wooden hull is finally decided on, great care must be exercised in order that the hull be well designed and built by competent ship carpenters. The hull is the foundation of the dredge and should be built to last as long as the machinery. In building a wooden hull in the tropics, extra care must be taken to ventilate it properly on the inside in order to prevent dry rot, and to protect it on the outside against damage by the toredo and other wood-boring insects.

A steel hull, while costing a little more in the beginning, proves an economy in the end. When properly designed it will last for many years and no additional expense is involved for maintaining it. The steel hull should be assembled in the shop before shipment and when it is transported to the buildingsite, it is then readily reassembled and riveted up in a very short time. We have always been strong advocates of the steel hull and super-structure because it affords a good rigid foundation for all the operating

machinery and it is not subject to the rapid deterioration that occurs in wooden hulls. Another advantage of the steel hull and housing is the freedom from fire risks. Quite a few of the wooden dredges in the western fields have been destroyed by fire and the additional first cost of the all steel form of construction is an item of insurance that is well warranted. Quite a few steel hulls that have been built in the past have not had sufficient depth and have therefore, lacked proper freeboard. Great care must be exercised in estimating the weight of all machinery and of the dirt and gravel load; even the specific gravity of the pond water should be taken into consideration, since this affects not only the flotation of the dredge but also the power required to operate the centrifugal pumps.

The First All-Steel Dredge

We illustrate the first all-steel dredge designed and built in this country. It was constructed by us for the Orsk Gold Fields Ltd., and was designed for operation in Eastern Siberia under severe climatic conditions. Suitable timber for hull construction was difficult and expensive to obtain. Many of the wooden hulls in this country had caused no end of troubles through leakage; in many cases sinkings and disasters had resulted. Furthermore, a wooden hull frequently proves difficult to keep in alignment and consequently interferes with the smooth operation of the driving machinery. All these considerations taken together led us to decide that a steel hull would provide the Orsk Gold Fields with the most satisfactory foundation for the dredging machinery. This dredge, which is usually known as the Kolchan Dredge, soon proved the numerous advantages of steel hull construction, and today this form of construction is generally followed.

Construction Work

This dredge was built by us some twelve years ago. We contracted to design, build and make shipment in four months and fifteen days. We completed it and made shipment in four months and ten days, and we took charge of the transportation and erection of the dredge which involved many problems and difficulties. All the machinery was first shipped to Vladivostok, and from there it was reshipped to Nikolaievsk about six hundred miles north on the Siberian Coast. From this point it was transported in punts sixty miles to a landing spot. It was then hauled by wagon 10 miles to the building site. We had entire charge of the erection of the dredge, a large power plant, together with machine shop equipment and various other accessories. We erected and put this entire plant in operation in three months and twenty-four days. The above record has never been equalled by any other dredge building company. When one considers the great difficulties under which we labored in carrying out this work, they cannot help but conclude that it was a most remarkable performance.

This dredge had buckets of 7½ cubic feet capacity and was electrically driven, receiving its power from the generating station built by us. Provision was made for heating the dredge and the stacker for winter operations. This dredge operated successfully for nearly ten years under very difficult conditions, such as severe climate, great distance from a base of supplies, with no established transportation—inexperienced foreign labor—Russians, Koreans, Japanese, etc. Notwithstanding all these trying conditions, it established an excellent record for large yardage and low working costs.

This dredge averaged 88.72% working time during one of its years of operation, which is a record that has never been equalled by any other dredge under such extraordinarily difficult operating conditions. It was badly damaged and put out of commission during the latter part of the Russian Revolution; but it is expected that it will be repaired and put in operation again in the near future.

Size of Dredge

The size of a dredge is usually determined by the total number of yards one desires to dig per day or month, still it is also governed by other conditions such as digging depths, size of boulders, etc. It is not practical to build the smallest size of buckets for the greatest digging depth, neither is it practical to use small buckets in very hard cemented gravel or where numerous large boulders are present. Consideration must also be given to the total number of cubic yards contained in the piece of ground in question and the number of years required to work out the ground with a certain size of dredge. This is generally calculated by assuming the life of the dredge as of ten years duration.

The size of the buckets, that is, their contents in cubic feet is always taken as a standard for the size of dredge.

A Typical or Standard Dredge

Almost every placer project presents different conditions; every dredge we build is adapted to meet the specific conditions existing in the property for which it is built. Occasionally, however, a property is found which presents no special difficulties and a dredge constructed for such a property while specially designed and built with the utmost care, still it might be considered as a typical or standard dredge.

The dredge that we built for the Rimu Gold Dredging Co. Ltd., of New Zealand, might be offered as an example of a standard dredge. Their property is located near Hokitika on the west coast of New Zealand, close to a seaport and with a railroad running directly to the ground. A hydro-electric power plant a short distance away furnished electric power for the operation of the dredge.

The dredge that we built for the Rimu Gold Dredging Co. Ltd., of New Zealand, might be offered as an example of a standard dredge. Their property is located near Hokitika on the west coast of New Zealand, close to a seaport and with a railroad running directly to the ground. A hydro-electric power plant a short distance away furnished electric power for the operation of the dredge.

The drilling proved the presence of a few large boulders in some spots and accordingly the main dump hopper opening to the screen was made a little larger than usual and the screen itself was made somewhat heavier; the stacker was built especially wide and the stacker motor house was raised a little higher than usual in order to allow the large boulders to pass safely underneath it.

Description

This dredge was electrically driven and had an aggregate of 560 horse power motors on board all operating on a 2200 volt circuit. The main drive motor was a 200 H.P. variable speed running 540 R.P.M. while the high pressure pump motor was 125 H.P. constant speed running at 900 R.P.M. and direct connected to the pump. The low pressure pump motor was 75 H.P. at 900 R.P.M. and was direct connected to its pump. A 50 H.P. motor at 1200 R.P.M. was direct connected to a centrifugal pump for furnishing water under high pressure to two nozzles located in the main dump hopper. These nozzles were for the purpose of washing the buckets clean as they dumped into the hopper. The screen drive motor was a 50 H.P. variable speed running at 700 R.P.M. The stacker drive motor was 40 H.P. variable speed running at 720 R.P.M. The winch motor was 30 H.P. variable speed, 600 R.P.M. with special grid resistance for reducing the speed to one-third of normal.

The main winch itself contained seven drums—one long one for operating a head line when it was desirable; four of the regular size drums were used for operating the corner lines and the other two were each for operating one of the two steel spuds. This dredge was equipped with double banks of tables, fourteen tables being located in each bank on each side of the dredge making a total of fifty-six tables with a total gold saving surface of 4800 square feet.

This dredge was equipped with all manganese steel buckets of ten cubic feet

capacity, digging to a maximum depth of about forty-five feet below water level and carrying a bank about fifteen feet in height. While containing no radical innovations it had several new and interesting features. Among these was an underhung screen drive; the screen was mounted on one large roller at each end and was held in place by two side guide rollers at each end. The large rollers carrying the weight of the screen were hung from the bottom side of the supporting timbers. This makes a very simple arrangement for permitting the renewal of bearings or rollers. With the bearings mounted on the tops of the timbers as has heretofore been the practice, such renewals are quite difficult. These underhung bearings also prevent the accumulation of dirt on and around them, and the fact that they are thus kept clean makes them far more durable. The screen itself was seven feet in diameter and forty feet long, so as to give ample screening capacity.

The main bucket line drive contained a spring cushion effect as shown in the accompanying illustration. These cushion springs are located in separate housings on each side of the main drive pinion, and they serve to reduce the shocks throughout the entire driving system, including the main drive motor.

The lower tumbler was also equipped with a new improvement or ours, consisting of a water-and-grit-proof bearing which absolutely prevents any water or grit from entering the lower tumbler bearings. Bearings of this type were first applied by us on the Gumoas Dredge in the Philippines, where they were in operation for three years without any renewals or repairs.

All these new features are proving eminently satisfactory in this dredge which began operations late in 1921.

A Problem of Great Variations in Digging Depth

Usually a placer property is workable to a fairly even depth over its entire extent, and the length of the digging ladder for the dredge is simply determined by the maximum depth to be worked, but the Philippine Exploration Company’s ground was divided into two pieces— one of comparatively shallow depth averaging about 25 feet with a maximum depth of 35 feet. The balance of the ground averaged 55 feet depth. It is not economical to operate a deep digging dredge in very shallow ground. Therefore, we designed and built a steam driven dredge for them which had a maximum digging capacity of only 35 feet, but the dredge was so designed that an extension ladder piece with additional buckets, etc., was installed when the deeper ground was encountered. This might seem to be a very simple problem at first, but one must consider that the digging ladder must project far enough beyond the bow to enable one to dig the corners and yet it must not be hung so far

aft as to cut down the deck space at the stern of the dredge and thus curtail the gold saving table area which is so essential.

We not only built this dredge, but we took charge of the transportation and erection of it in the field under some of the most difficult conditions that are to be found in a tropical country like the Philippines where typhoons and floods are very frequent at certain seasons of the year. All this work was carried on economically and expeditiously by us and the dredge put in successful operation.

The Gumoas Dredge had 5½ cubic foot buckets and was steam driven. The boiler was 250 H.P. of the water tube type having an extra large furnace arranged for burning wood. This boiler was set in a complete steel housing lined with asbestos and the furnace being lined with fire brick. The main drive engine was of the compound condensing type having cylinders 12 inches x 20 inches in diameter with 14-inch stroke rated at 150 H.P. The high pressure centrifugal pump was direct connected to a compound engine having 8-inch x 16-inch cylinder with 8-inch stroke, while low pressure pump was also direct connected to a duplicate of the engine that operated the high pressure pump thereby making the parts of the two engines interchangeable.

The main winch contained nine drums—four of these were for the corner lines of the dredge, two were for lifting the two spuds and the two extra drums were used for handling the many stumps that were encountered in the digging and for various other purposes around the dredge and they also afforded spare drums in case of accident to any of the others. One extra large drum was used for a head line when it was desirable to operate on same. This winch was driven by a pair of 7 x 7 reversible engines. A 60 H.P. engine located at the stern of the dredge operated the revolving screen as well as the stacker. A surface condensing system maintained a high vacuum and greatly aided in the economical operation of this plant. The

condenser was of the vertical type so as to prevent the settling or accumulation of dirt, leaves, etc. in the tubes, inasmuch as the wash water for the gold saving tables was all pumped through this condenser to serve as condensing water. The tubes were of larger diameter than usually furnished so that they might readily be kept clean. These particular features added much to the steady and efficient operation of the plant.

The Philippines Exploration Co.’s Gumoas Dredge began operations in November, 1912, and during its first six months’ run it produced $164,380 and paid out $87,500 in dividends. In August, 1913, the dredge operated 517 hours out of the possible 576. (It was shut down on Sundays according to law.) This was equal to 90% running time and during this one month it dug 92,000 yards and

produced $36,642. It paid many dividends of 10% a month and averaged dividends at the rate of 60% a year during its life. Summing up its entire operations, it handled about 900,000 yards of gravel per year, averaging about 30 cents per yard, while the operating costs averaged slightly under 10 cents per yard. This dredge made an average working time record of 84.38% during one of the years of its operation. The Gumoas Dredge after six years successful operation, during which time it worked the ground out, was then dismantled and removed to Ipoh in the Federated Malay States where it was reassembled and is now in successful operation as a tin dredge; the tables and sluices having been modified in order to successfully handle the tin concentrate.

Tin Dredging

While the machinery for the tin and the gold dredge is about the same, still there is quite a difference in the general design of the dredge itself. The hull must be quite a little deeper in order to provide sufficient freeboard with the added weight of the large amount of tin concentrate that accumulates on the tables and in the sluices.

In many instances the stacker is omitted and this can be done successfully if the ground is not too deep or the banks too high. When the stacker is omitted the upper tumbler and the screen are placed higher than usual so that the sluices may project a long ways beyond the stern of the dredge in order to enable one to properly distribute the tailings. The tables and sluices must be arranged so that frequent clean-ups can be made without shutting down the dredge.

Prospecting methods employed in the tin fields are very similar to those of the gold fields and the Empire Hand Prospecting Drill is extensively used in all parts of the world for this particular purpose. There is no apparatus equal to the Empire Drill for cheap, rapid and accurate prospecting of alluvial tin deposits.