Table of Contents

As well as metal working, welding or cutting, downdraft tables are also used for human dissection tables although rim exhausts are usually used for this purpose. For manual shoe repair and during application of artificial fingernails, downdraft tables are the only type of exhaust possible.

As well as metal working, welding or cutting, downdraft tables are also used for human dissection tables although rim exhausts are usually used for this purpose. For manual shoe repair and during application of artificial fingernails, downdraft tables are the only type of exhaust possible.

Larger versions are used for sanding, grinding, polishing, and welding. Since welding generates large amounts of heat together with the contaminants, a downdraft table, although handy, is not suited for this use. There could be problems with grinding, since the contaminants are generated with a high velocity in different directions and a downdraft table is only suited for capturing contaminants with low velocity and a temperature equal to or lower than room temperature. A partial solution to this is to surround the table on three sides with walls (0.2 to 0.5 m high) to deflect the generated contaminants and to diminish the amount of air pulled in from the sides.

Very large downdraft rabies have been used for sources such as electrocutting and welding of large steel sheets.

Modification to processes can also indirectly reduce pollutant emissions. Using the histology labs as an example once again, special exhaust enclosures were designed to reduce energy consumption and employee exposure to chemical vapors. Histology staining dishes require a large amount of bench space, and as a result, employees will remove staining dishes from cramped fume hoods. Down draft tables are typically installed to protect the employees from chemical fumes, but these tables require an air flow of approximately 2000 cubic feet per minute (cfm) for proper operation. The air from the down draft tables cannot be recirculated and must be exhausted directly to the roof vent. Make-up air must be tempered and supplied to the histology labs. The University of Minnesota designed modular exhaust enclosure boxes to protect employees from exposure to the histological chemicals and to reduce air flow (and energy) requirements. These exhaust enclosure boxes reduce air flow requirements by 10 to 40 times over equivalent space used by down draft tables.

Modification to processes can also indirectly reduce pollutant emissions. Using the histology labs as an example once again, special exhaust enclosures were designed to reduce energy consumption and employee exposure to chemical vapors. Histology staining dishes require a large amount of bench space, and as a result, employees will remove staining dishes from cramped fume hoods. Down draft tables are typically installed to protect the employees from chemical fumes, but these tables require an air flow of approximately 2000 cubic feet per minute (cfm) for proper operation. The air from the down draft tables cannot be recirculated and must be exhausted directly to the roof vent. Make-up air must be tempered and supplied to the histology labs. The University of Minnesota designed modular exhaust enclosure boxes to protect employees from exposure to the histological chemicals and to reduce air flow (and energy) requirements. These exhaust enclosure boxes reduce air flow requirements by 10 to 40 times over equivalent space used by down draft tables.

|

|

|

|

“We at Cuming Microwave have several Belfab downdraft tables and are highly pleased with them. We use them in several different production floor areas. We have large and smaller models in every division of our company. The Belfab downdraft tables are essential to our operation and serve a very integral part of our production line”. Kevin Frost, Facilities Manager, Cuming Microwave Corp.

“When we first started we bought similar machines from several different manufacturers, and after 8 years, we now use exclusively Belfab to get the job done. We find them to be reliable and easy to clean. Whenever we need to buy another downdraft table, we do not even look anywhere else, it is going to be a Belfab downdraft table. Nothing can compare.”

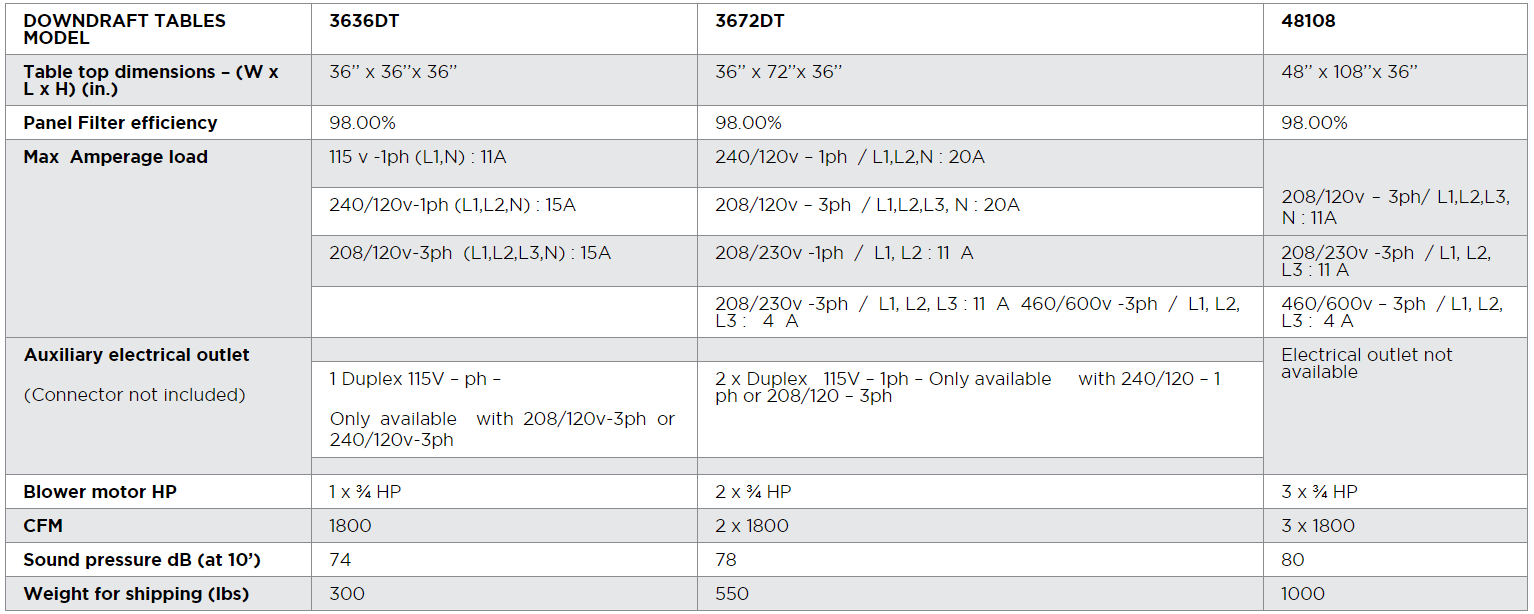

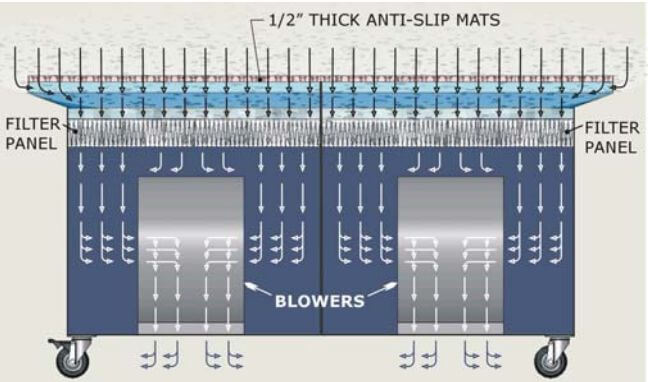

Blower Features

- Located on the clean side of filters for trouble free extended life.

- Energy efficient : more suction with 50% less HP.

- Revolutionary design: dual inlet blowers generating over 1800 CFM each.

- Airflow design generating even suction distribution across the whole top area.

Table Top Features

- Innovative anti-slip and non-scuffing mats: These robust half-inch thick mats secure parts in place and protect work from denting.

- Ergonomic: Special recessed base design offers foot clearance for workers comfort .The tabletop surface is accessible from 360° around.

- Ease of maintenance: The gas-cylinder assisted tabletop is fully counter balanced and auto-blocking for easy opening with one hand. This unique feature gives easy access to filters and inner chamber for maintenance.

Filter Features

- Innovative design: Filters act as dust trays to capture 100% of collected dust particles. They can be easily emptied, cleaned and replaced in less than one minute!

- Flexible concept: Can integrate a variety of panel filter types and thicknesses that can be selected to optimize both filtration performance and durability for your application.

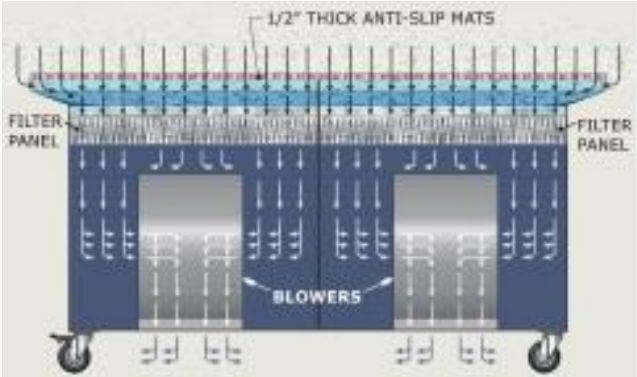

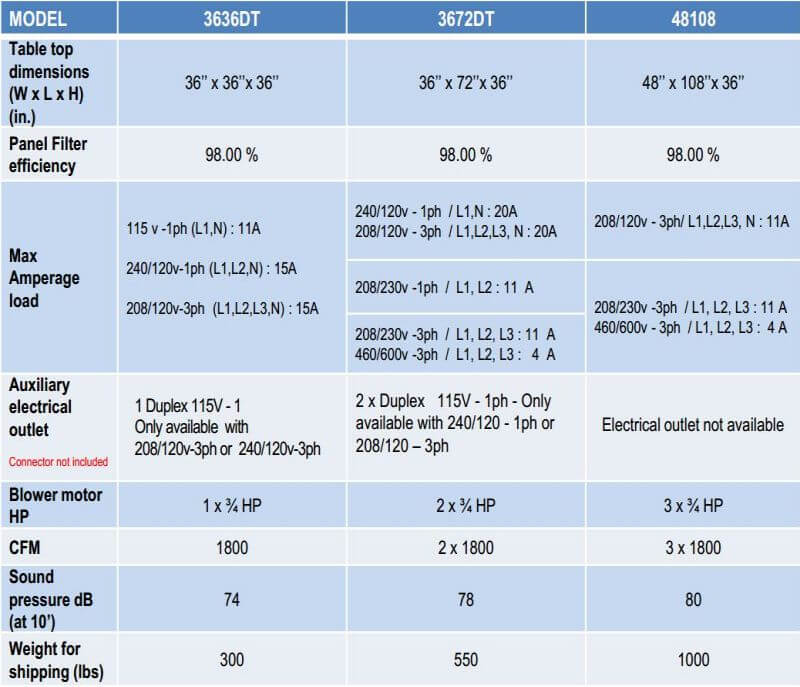

Downdraft Tables : Specifications

Options

- Filter cleaning hood

- Back & side shield

- Tabletop mat replacement

Warranty

- 12 month warranty

Downdraft Tables

Cuming Microwave Corporation – Avon, MA – is a global supplier of Microwave Absorbers, Radar Absorbers, Dielectric Materials, Anechoic Chambers, EMC Chambers for the Defense, Electronic, Telecom, Medical & Automotive Industries – A Complete Line of EMI Absorbers and EMI Suppression Materials. The organization has been using downdraft tables from Belfab for many years. Continue to read why below.

“We at Cuming Microwave have several Pyradia Belfab downdraft tables and are highly pleased with them. We use them in several different production floor areas. We have large and smaller models in every division of our company. The Pyradia Belfab downdraft tables are essential to our operation and serve a very integral part of our production line”. Kevin Frost, Facilities Manager, Cuming Microwave Corporation.

“When we first started we bought similar machines from several different manufacturers, and after 8 years, we now use exclusively Pyradia Belfab to get the job done. We find them to be reliable and easy to clean. Whenever we need to buy another downdraft table, we do not even look anywhere else, it is going to be a Pyradia Belfab downdraft table. Nothing can compare.”

Tabletop Features

Innovative anti-slip and non-scuffing mats: These indestructible half-inch thick mats secure parts in place and protect work from denting.

Ergonomic: Special recessed base design offers foot clearance for workers comfort. The tabletop surface is accessible from 360°around.

Ease of maintenance: The gas-cylinder assisted tabletop is fully counter balanced and auto-blocking for easy opening with one hand. This unique feature gives easy access to filters and inner chamber for maintenance.

Filter Features

Innovative design: Filters act as dust trays to capture 100% of collected dust particles. They can be easily emptied, cleaned and replaced in less than one minute!

Flexible concept: Can integrate a variety of panel filter types and thicknesses that can be selected to optimize both filtration performance and durability for your application.

Blowers features

– Located on the clean side of filters for trouble free extended life.

– Energy efficient: more suction with 50% less HP

– Revolutionary design: dual inlet blowers generating over 1800 CFM each

– Airflow design generating even suction distribution across the whole top area