Table of Contents

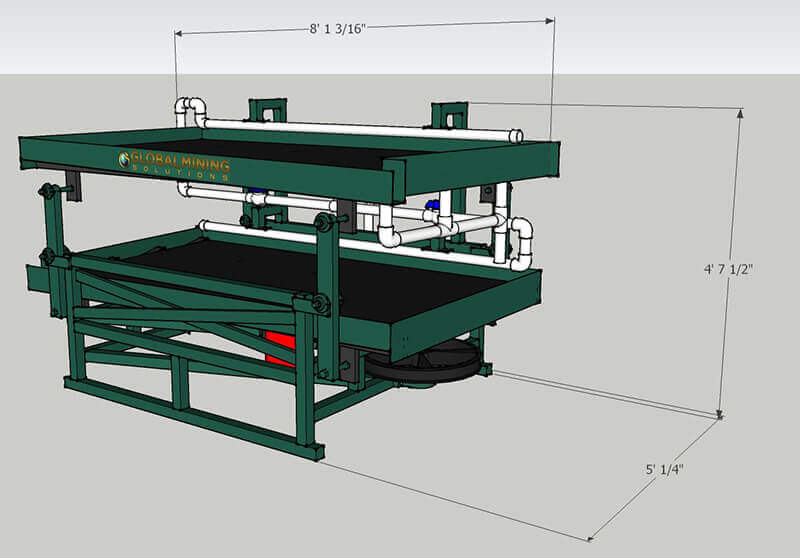

The 911MPEGMS-2DST double deck “DUPLEX” gold shaker table is effectively 2 super-imposed 4′ x 8′ decks and processes 2 tons per hour of -200 minus to 4 tons or more of sand size material. This provides you with 64 square feet of tabling area. The same gold recovery area a 12′ X 5′ 4″ table would provide you.

- Two 4’ x 8’ oscillating cleaning decks

- 16 feet of effective tabling length

- Feed size material ¼ “ to 1 micron of placer concentrates or pulverized rock.

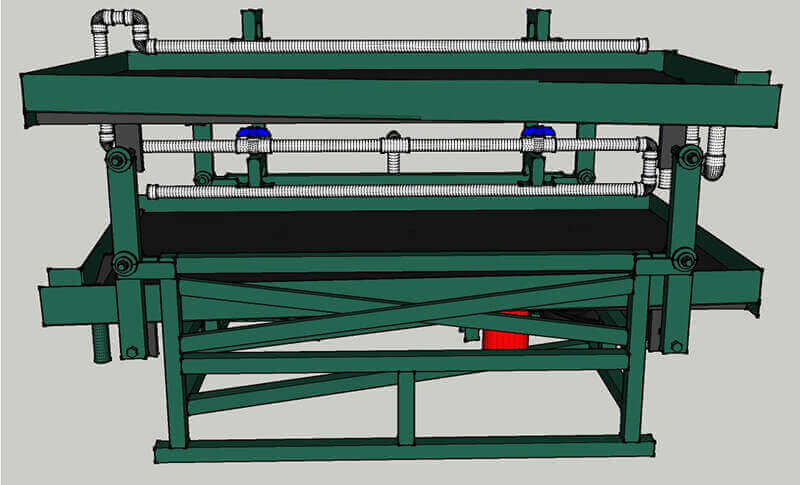

- Requires 50-60 GPM of water (includes both decks).

- Uses ¾ hp or 0.56 kw motor

The 911MPEGMS-2DST is our large high capacity gold shaker best seller. More miners buy the 911MPEGMS-2DST than the classic single-deck 911MPEGMS-1DST. The 911MPEGMS-DST operates at 1000s of gold mining operations around the World.

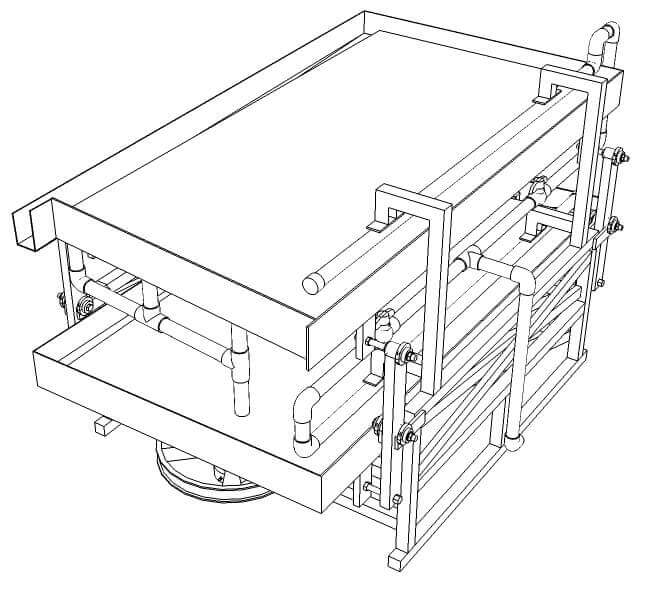

The high-capacity double-deck shaker table is self-balancing and does not need to be bolted down. By double stacking its 4’ x 8’ decks, the 911MPEGMS-2DST offers you 16 feet of tabling length in 50% less footprint with the added stability of the self-balancing motion.

The shaking motion of the high production concentrating table is such that the top and bottom tables move in opposite directions at the same time. The weight and simultaneous opposite motions of each deck effectively counterbalances the energy to nil. This cancels out any vibrations that typically makes a “table walk” and forces you to bolt it down securely.

The only installation requirement for the double-deck gold shaker is it be sitting on level ground. We have some of our tables are standing free (flat) on wood timbers in the jungle!

No gearbox to lubricate or repair.

|

|

|

|

|

|

|

|

Duplex Concentrator

The double deck concentrating tables was originally developed for the recovery of tin from low-grade feeds, but has a wider application in the recovery of tungsten, tantalum, gold, chromite, and platinum from fine feeds. Two decks are used alternately to provide continuous feeding, the feed slurry being fed onto one of the decks, the lower density minerals running off into the discharge launder, while the heavy minerals remain on the deck. The deck is washed with water after a preset time, in order to remove the gangue minerals, after which the deck is tilted and the concentrate is washed off. One table is always concentrating, while the other is being washed or is discharging concentrates. The concentrator has a capacity of up to 5 tph of -100 um feed producing enrichment ratios of between 20 and 500 and is available with various sizes and numbers of decks.

Gold miners are very much enjoying the invention.

Gold Shaker Table Working Principle

Separation of particles on a table deck is not merely the result of their differences in specific gravity, but rather there are numerous interrelated phenomena. A decided advantage of tabling over some other known processes is the fact that a great many variables can be made to aid and assist in effective separation.

Basically the separation of different minerals on a concentrating table are the result of the following factors:

- Specific gravity of the particles,

- size of particles,

- shape of particles,

- stratification (or consolidation trickling), and

- hindered settling.

The effective use of these factors may be controlled and aided by the following table adjustments:

- Differential action of the drive or head motion,

- speed of motion,

- length of stroke,

- side tilt,

- end elevation,

- size of deck area,

- shape of deck,

- character of deck surface,

- riffle design,

- amount and distribution of wash water,

- feed water-solids ratio,

- feed rate, and

- feed uniformity.

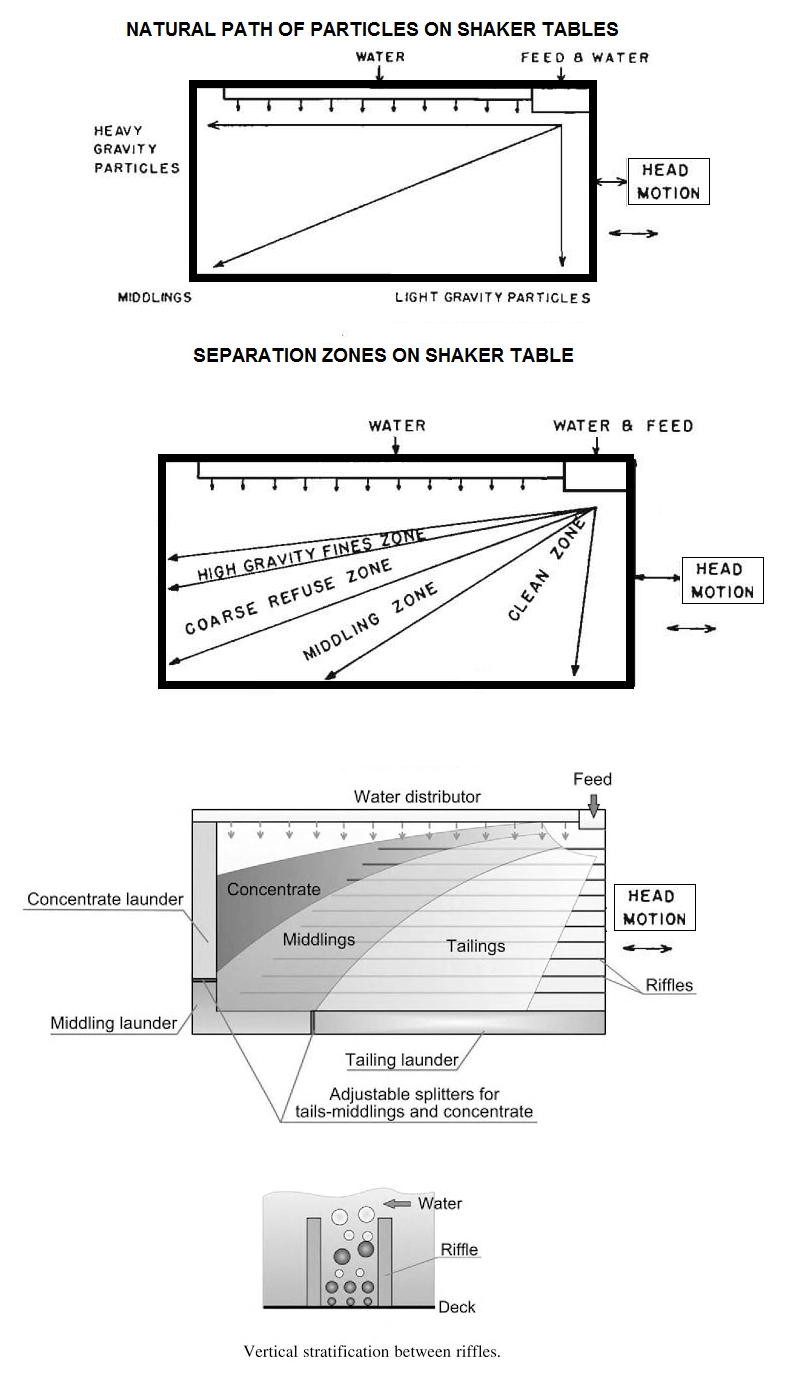

The more generally accepted explanation of the action of a concentrating shaker table is that, as the material to be treated is fanned out over the table deck by the differential motion and gravitational flow, the particles become stratified in layers behind the riffles. This stratification is followed by the removal of successive layers from the top downward by cross-flowing water as the stratified bed travels toward the outer end of the table. The cross-flowing water consists partly of water introduced with the feed and partly of dressing water fed separately through troughs along the upper side of the table. The progressive removal of material from the top toward the bottom of the bed is the result of the taper in the height of the table rimes toward their outer end, which allows a successively deeper layer of material to be carried away by the cross-flowing water as the outer end of the table is approached. By the time the material reaches the end of the table, only a thin layer, probably not much thicker than one or two particles deep, remains on the surface of the deck, this layer being discharged finally over the end of the table.

The physical and mechanical principles involved in the concentration action of a table are somewhat more complicated than this cursory explanation implies. A mathematical analysis of flowing film concentration, while of fundamental value, pertains mostly to smooth deck surfaces and does provide details concerning the phenomena surrounding the use of riffles. Such mathematical calculations are prerequisite to an understanding of basic principles, but they do not begin to explain the sharp separations that tables are capable of achieving.

Unless the table feed contains a high percentage of near-gravity material, high tabling efficiencies may be expected. If a table could be operated on feed consisting of nothing but a mixture of individual fine particles with a size range of approximately 1/4″ to 50 mesh (6.3 to 0.3 mm), a near-perfect separation could be obtained. With such a feed, a well-operated table would probably recover 99.5% of the fine while eliminating not less than 95% of the shale. This implies almost perfect stratification according to specific gravity without regard to particle size. However, it is improbable that such stratification could be attained entirely as a result of the motion of the deck and the flow of water in a plane parallel to the deck surface. The question then arises as to the other forces or factors that are involved which contribute significantly to the efficiency of the separation on a table.

No exhaustive study has been made of the principles involved in table concentration by either ore-dressing or ore preparation engineers. Engineers probably have given more attention to the subject than anyone else, even though their experimental work was of a preliminary nature. It was their aim “to bring out the fact that stratification, contrary to the common belief, will not account for the separation effected by the fine gold washing table, and that cross-flowing water, in addition to removing the top strata found on the table, must also have an important selection action in completing the separation according to specific gravity, both in the upper and in the lower strata found between riffles.”

Metallurgists developed a theory as to the selective action of the cross-flowing water postulates that only a part of the water flowing across the table flows over the top of the bed between the riffles; the remainder flows through interstices in the bed. These interstices are comparatively large near the top of the bed, but become progressively smaller toward the bottom, thus forming, in effect, V-shaped troughs. Under these conditions the water currents are relatively swift near the top of the bed and become progressively slower toward the bottom. According to them, “With paths for the water such that the top strata are subjected to relatively swift currents and the lower strata are subjected to progressively slower currents, the separation actually occurring on the table can be explained. As the coarse particles at the top receive swift currents and each successively finer size at the lower levels receives slower currents, the velocity of the water matches the size of materials comprising the different strata. Under these conditions a separation occurs in the lower strata similar to that in the top strata, only it takes place more slowly. The slow currents of water within the bed carry the fine-waste particles along from riffle to riffle at a more rapid rate than they do the fine-bone and shale particles.”

Although stratification due to the nearly horizontal action of the table deck and the flow of water in a plane parallel to it probably are not sufficient to account entirely for the sharpness of separation achieved by a table, it is, nevertheless, the fundamental principle of the table, just as hindered settling is the fundamental principle of a jig. Although these processes are of diametrically opposite characteristics, a table probably utilizes the hindered-settling principle at least to a minor extent. For convenience in this discussion, the stratification due to the more or less horizontal action of the table deck and flow of water will be referred to as table stratification. This type of stratification is illustrated by the separation that takes place when a box of large and small spheres is shaken and agitated in a horizontal plane in such a way that the large and small marbles collect into separate layers, with the small marbles collecting in a layer on the bottom, while the large marbles collect in a top layer. The principle of hindered settling can be demonstrated by placing a mixture of large and small marbles in a vertical cylinder of suitable size with a perforated-plate bottom. If water of sufficient volume and pressure is forced upward through the perforated plate so as to keep the marbles in teeter for a short interval, the marbles will separate into layers, with the large marbles in the bottom layer and the small ones on top. The separation is the opposite of that obtained by table stratification. In these illustrations of stratification and hindered settling, it is assumed that the marbles are all of the same specific gravity regardless of size. If some marbles have higher specific gravities than others, the effect will be to increase their tendency to settle toward the bottom, regardless of whether this tendency favors or opposes the stratification or hindered-settling action. The heavier the small marbles, the easier the separation by table stratification and the more difficult by hindered settling. Conversely, the heavier the large marbles, the more difficult the separation by table stratification and the easier the separation by hindered settling.

In keeping with the above principles, complete separation according to specific gravity could hardly occur on a table or any other concentrating device as a result of either table stratification or hindered settling alone when the material to be separated consists of particles varying in both size and specific gravity. In fine gold washing the objective is to separate fine gold particles from tailings particles according to specific gravity without reference to particle size. As this separation can be accomplished more effectively by utilizing the combination of table stratification and hindered settling, it is quite likely that both processes actually do play a role in the operation of a concentrating table.