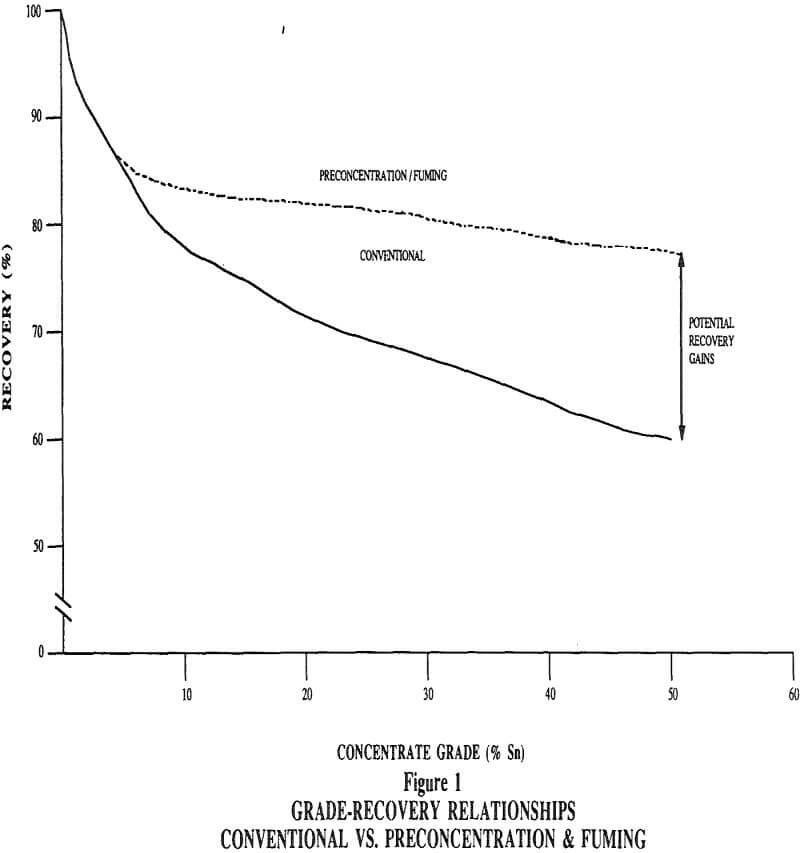

Minproc has developed a process concept of preconcentration of zinc and tin to moderate grade preconcentrates at high recovery, followed by pyrometallurgical upgrading (filming) of the preconcentrates to high grade, saleable oxide fumes. Broadly, concentrate grade is inversely proportional to recovery, and while high recoveries of zinc and tin can be achieved into low grade concentrates, attempts to produce high grade, saleable products inevitably results in recovery losses.

For moderately complex ores such as those from Colquiri, the grade-recovery relationship is relatively steep. For very complex ores, the grade-recovery curve may be so steep that economic treatment is impossible. This nexus can be broken if chemical or pyrometallurgical rather than physical concentration methods are employed. Thus, low cost physical methods can be used to produce a low grade concentrate at high recovery, and the product can then be further upgraded using a different process which does not result in any significant further loss of values.

Minproc Fuming Technology

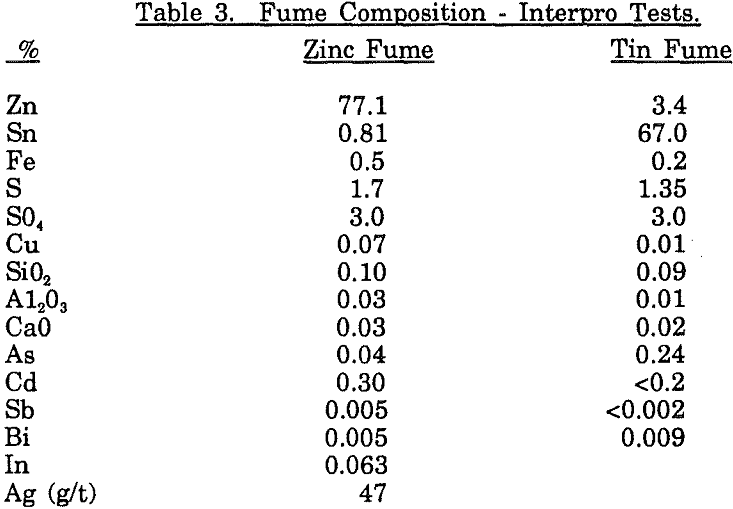

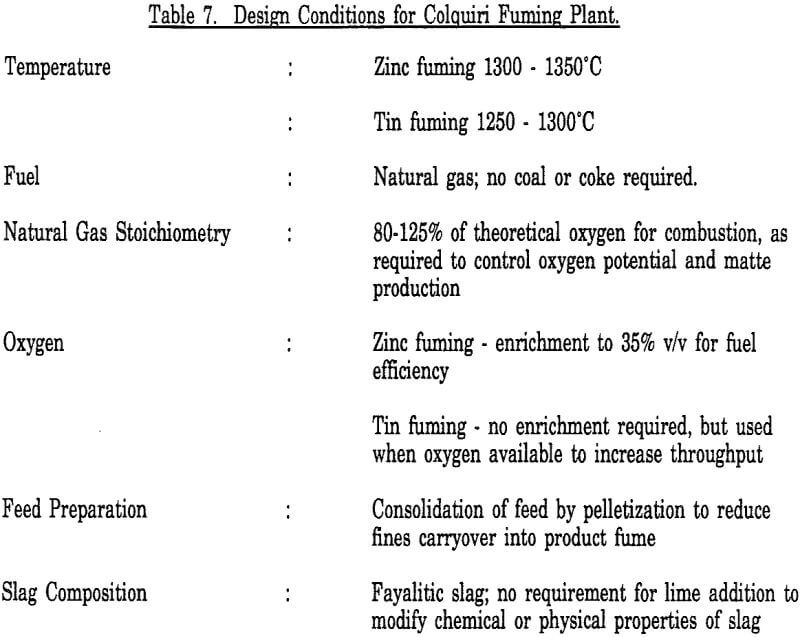

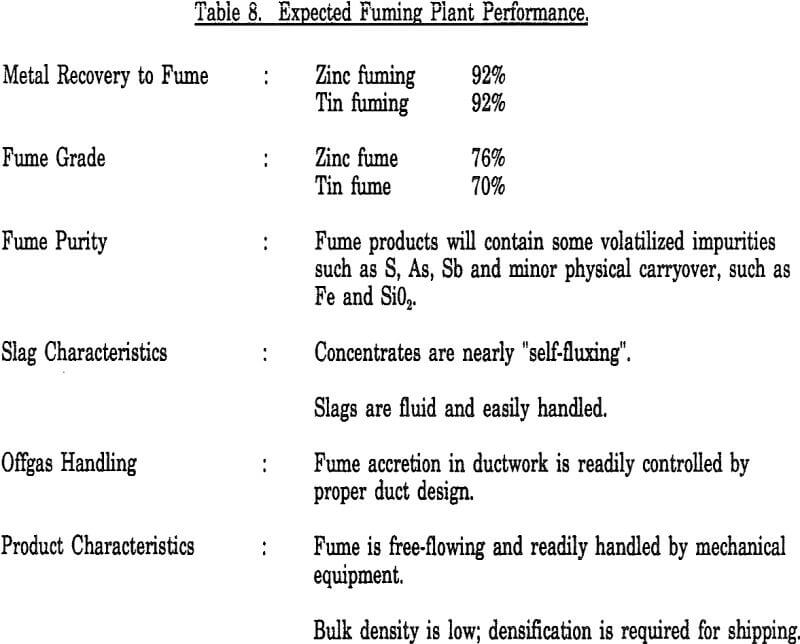

The Colquiri fuming plant will apply a pyrometallurgical upgrading process to low grade concentrates that separates zinc and tin from gangue and produces high-grade oxide fumes. Fuming is a chemical separation process based on the relative vapor pressures of the feed components. Fuming liberates zinc and tin from major impurities which are too closely associated to permit economic physical separation by conventional mineral processing methods.

Minproc Fuming Testwork

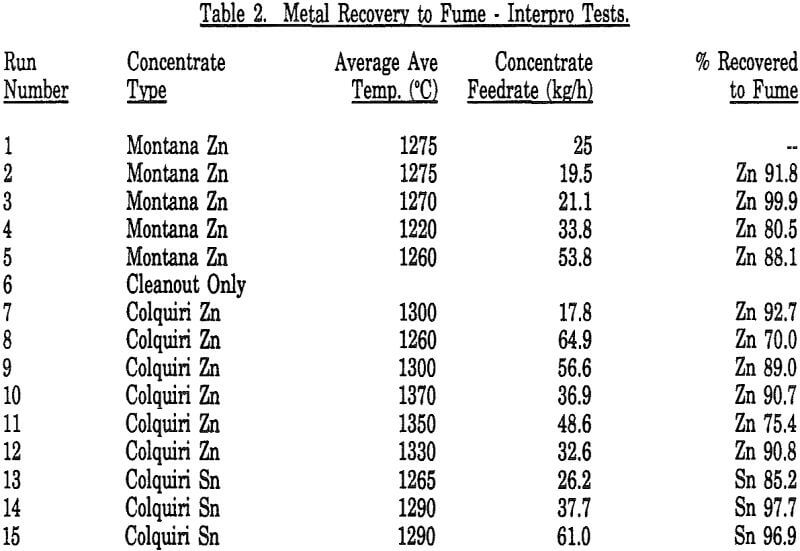

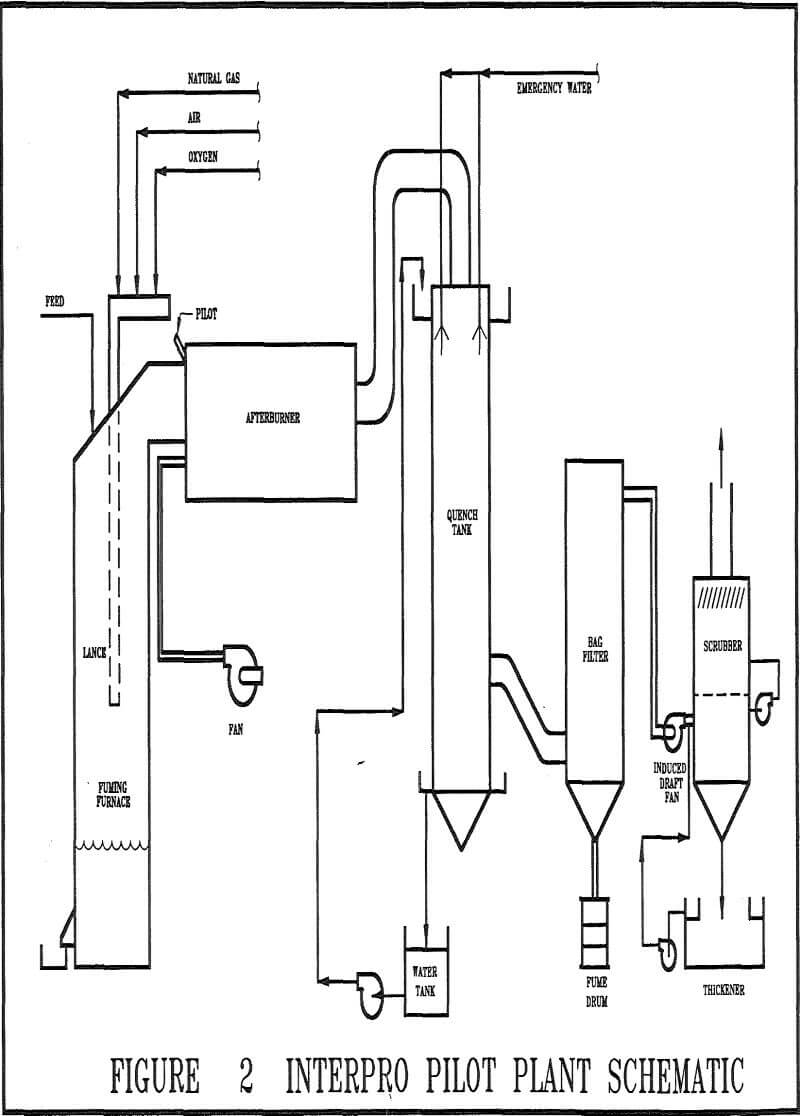

Minproc has carried out two bench-scale test programs and two pilot-scale programs for the evaluation of the pyrometallurgical upgrading of Colquiri concentrates. The testwork concentrated on the Minproc Technology proprietary, single-stage matte fuming process to produce zinc oxide fume directly from concentrates.

This work accomplished the following:

- confirmation of process chemistry,

- establishment of process conditions for commercial operation,

- establishment of key operational requirements and process results, and

- provision of essential engineering design criteria.

Test Results

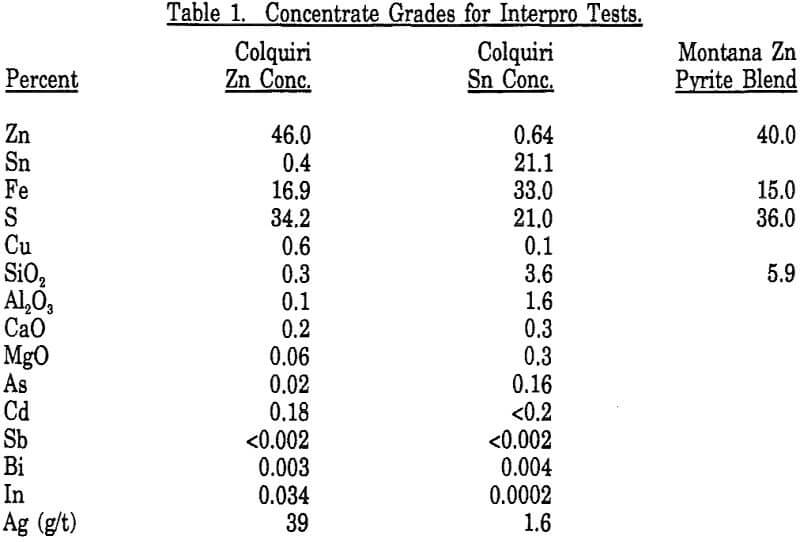

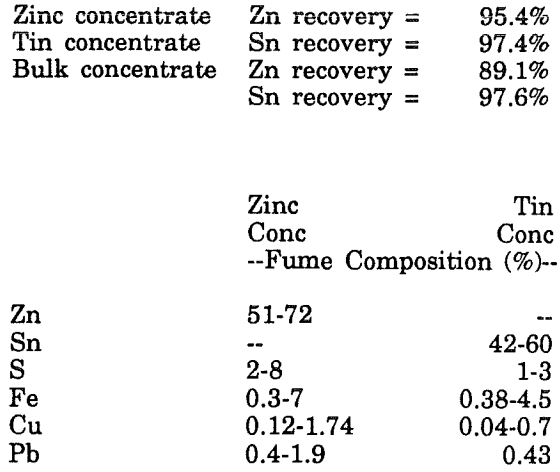

CIMM Testwork: This work demonstrated that matte fuming of zinc could be achieved under a range of operating conditions. These tests, when projected at full scale, indicated attractive economics for Colquiri. The impact of key process variables on metal recovery and grade were established on a batch basis and provided the input for subsequent pilot plant testwork. The program evaluated typically 36% zinc concentrates and 18% tin concentrate together with a bulk concentrate of mixed tin and zinc with approximately 6% tin and 29% zinc.

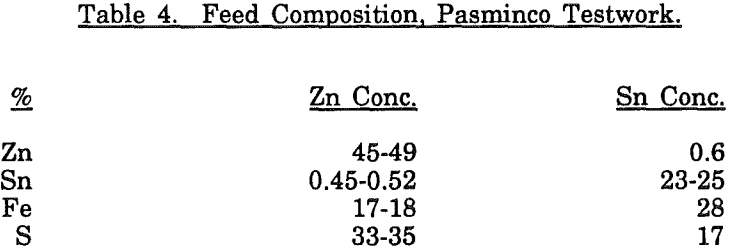

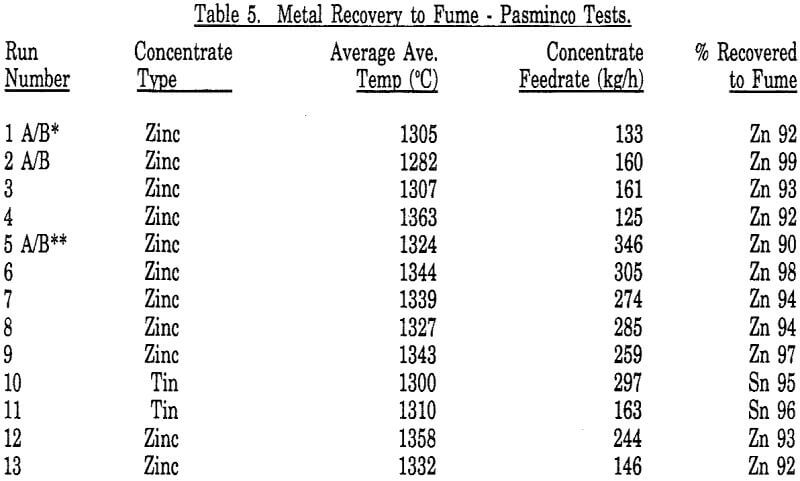

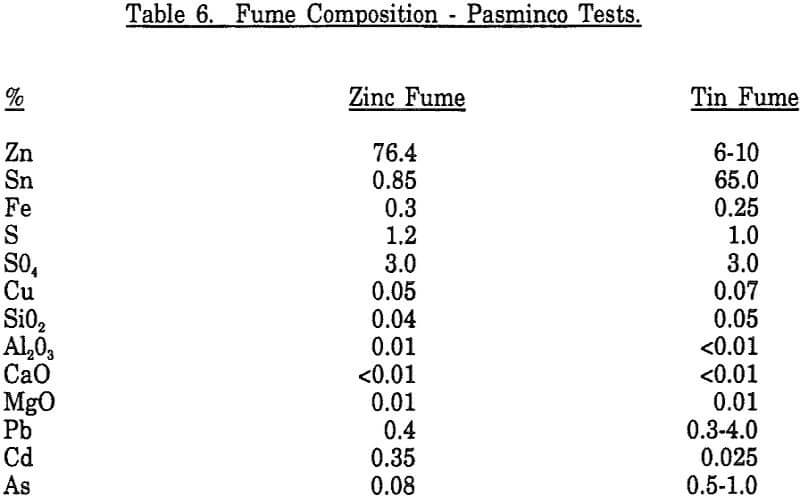

Pasminco Testwork: Two additional matte fuming test campaigns were conducted for one week periods each at the Pasminco Research Centre in Boolaroo, N.S.W., Australia, in March and May, 1991. Pasminco was selected to perform these tests because of the size of their submerged combustion smelting test facility and its experience in zinc fuming from slags. The Pasminco Research facility is well suited for handling the high off-gas solids loadings arising from fuming processes.

Feed Materials – Concentrates were from the same Colquiri batches used for the Interpro trials. In addition, pyrite tailings were added to tin trials as a source of additional sulfur. The principal analyses of feed materials are given in Table 4. Approximately 12 days continuous operation was achieved in the two campaigns, and some 40 tonnes of zinc concentrate and 5 tonnes of tin concentrate were smelted.

Discussion

The conventional hydro and pyro metallurgical routes for recovery of zinc or zinc oxide from Colquiri tailings would all suffer major technical disadvantages or be uneconomic.

Pretreatment of the tailings from Colquiri yields preconcentrates which are low in penalty-type impurities such as Pb, Cd, As and Sb but have high iron content. The need for a new approach for Colquiri tailings retreatment was evident.

Colquiri, being a remote high-aititude location, required a process that was:

- high intensity,

- simple and low in cost,

- operated only on natural gas, and

- required little or no flux.