Table of Contents

Understanding the difference between a kiln and a furnace is not so hard, once you know their true definitions.

A kiln is usually charged (filled with stuff), then heated to fuse the stuff, then cooled, and the stuff removed.

A furnace is usually heated first, then charged, then the stuff removed, and the furnace eventually cooled (though not always).

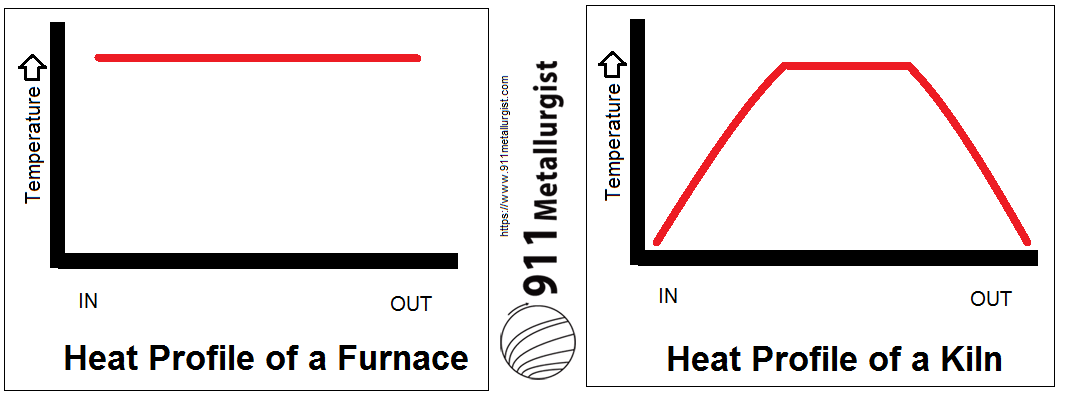

This fundamental difference between a kiln and a furnace is expressed in the charts below. A furnace has a constant heat/temperature profile while a kiln sees its profile vary from ambient to peak, holds, and back to room temperature.

Furnace Definition

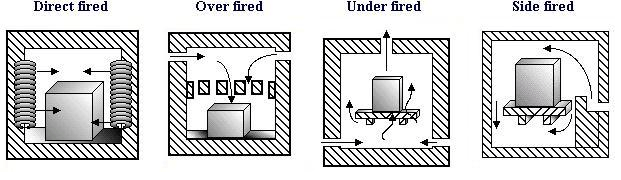

A furnace is a device used for heating. It is essentially a thermal enclosure and is employed to process raw materials at high temperatures both in solid state and liquid state.

A furnace is just a high-temperature oven. Generally, furnaces that operate at temperatures under 1000°F are called ovens. Furnaces and ovens have very similar features. Both are primarily used to heat treat metals, using gas, oil, or electricity.

Kiln Definition

A kiln is a thermally insulated chamber, a type of oven that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Various industries and trades use kilns to harden objects made from clay into pottery, bricks etc.

A kiln is an oven or furnace or a heated chamber, for the purpose of hardening, burning, calcining or drying anything; for example, or smelting ores.

In using an intermittent kiln, the ware to be fired is loaded into the kiln. The kiln is closed, and the internal temperature increased according to a schedule. After the firing is completed, both the kiln and the ware are cooled.