Objective: To separate complex mineral mixtures according to their dielectric properties.

Approach: Develop a laboratory-scale continuous dielectric separator to separate mineral mixtures by exploiting their difference in dielectric properties.

How Continuous Dielectric Separator for Mineral Beneficiation Works

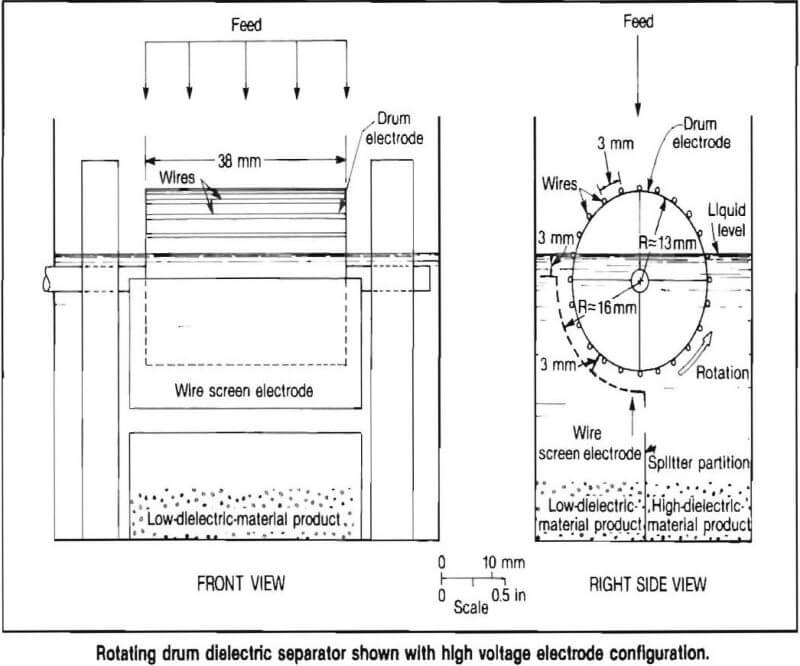

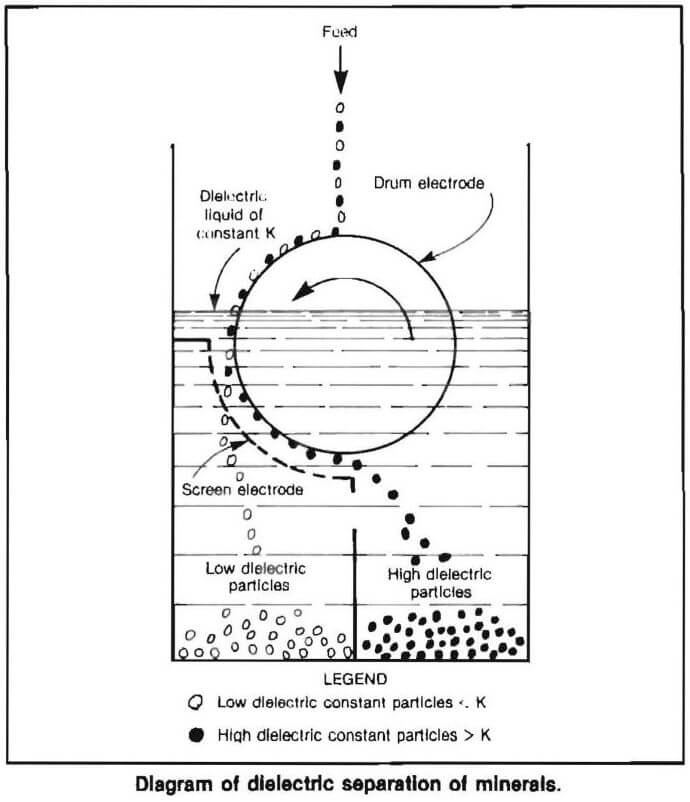

Dielectric separation is defined as the separation of particles based on their dielectric properties. The uniqueness of the Bureau’s continuous separator, called the “Rotating Drum Dielectric Separator,” is that it contains a high-voltage electrode configuration. The drum electrode consists of a series of coaxial parallel wires mounted on the outside surface of an insulated cylinder. The screen electrode is a wire mesh, quarter cylinder positioned outside and coaxially with the drum electrode. The drum electrode is placed in a liquid of dielectric constant K with the liquid level just above the drum’s axis. The screen electrode is completely immersed in the dielectric medium. A high-voltage alternating current, 1,000 volts 450 hertz, applied to both electrodes produces a high-gradient electric field in the gap between the drum and screen electrodes.

Finely divided mineral particles, 65 to 400 mesh, are fed onto the top of the drum, and carried by the drum’s rotation into the dielectric medium and into the space between the two electrodes. Mineral particles having a higher dielectric constant than that of the liquid are attracted to the drum electrode and adhere to the drum’s surface until they leave the high-gradient electric field. The particles having a lower dielectric constant than the liquid leave the surface of the rotating drum and fall through the screen electrode.

In this manner, high dielectric constant particles are continuously moved past the high electric field, and collected beyond the splitter partition while the lower dielectric constant particles are collected beneath the screen electrode.

Test Results

Results obtained with the separator were extremely promising and showed the design to be conceptually sound; however, it should be noted that these results were achieved on a very small-scale separator. Furthermore, the recovery and recycle of di-electric liquid was not investigated. To have commercial application, the capacity of the unit would have to be increased several hundred-fold.

Twenty-eight mineral mixtures were tested with the Bureau-developed, rotating drum dielectric separator. Quartz or quartz combined with feldspar were the gangue minerals for the various mineral mixtures. Minerals such as rutile, zircon, monazite, celestite, and ilmenite responded favorably to separation from quartz and to a lesser degree, from quartz- feldspar mixture. Several other minerals including barite, scheelite, witherite, and sphalerite, responded to separation from quartz.

The continuous dielectric separator for mineral beneficiation was developed in research done by Cy Jordan, Supervisory Metallurgist and Paul Weaver, Minerals Engineer, at the Bureau’s Tuscaloosa Research Center.

Patent Status

United States patents No. 4,100,068, July 1978, and No. 4,164,460, August 1979, were assigned to the U.S. Department of the Interior. For license Information write to: Department of the Interior, Office of the Solicitor, 18th and C Streets N.W., Washington, D.C. 20240