In many instances, Diatomaceous Earth (DE) filtration could be considered a relatively recent technology. In the late 1800’s there were many references to the use of DE in small scale filtrations and in most instances these were laboratory curiosities. The use of DE in the sugar industry was proposed in the 1880’s, but this was unsuccessful for two primary reasons. First, the types of filters available were not suited to DE filteraids and second, the quality of the filteraids was rather variable.

In many instances, Diatomaceous Earth (DE) filtration could be considered a relatively recent technology. In the late 1800’s there were many references to the use of DE in small scale filtrations and in most instances these were laboratory curiosities. The use of DE in the sugar industry was proposed in the 1880’s, but this was unsuccessful for two primary reasons. First, the types of filters available were not suited to DE filteraids and second, the quality of the filteraids was rather variable.

It was not until the 1910’s that DE filtration made its first real inroad into industrial filtration and this again was oriented towards the sugar industry. The only type of product available, though, was the “natural” grade which was strictly dried, milled, and classified. Consequently, the choices of grades were limited and so were the variables which would influence the economics of the process. In the mid 1920’s a breakthrough was made which would revolutionize the DE industry – the development of calcined and flux-calcined products. Up until this time the use of DE in insulation products was major and now, with greater flexibility, the DE filteraid industry would outdistance the other uses. The introduction of the calcined and flux-calcined products increased the flowrates possible by more than twenty fold which added a new dimension to filtration. The increased flowrate products would have somewhat lower clarity than the slower flowrate products, yet still substantially better than without the DE filteraid.

One of the first necessities in the development of DE filteraids was the concurrent development of filters, particularly automated and semi-automated. At present, DE filteraids are used on rotary vacuum precoat, vacuum leaf, plate and frame, and pressure leaf filters. Although, the present usage in domestic cyanide leach operations is limited to both plate and frame and pressure leaf filters, a brief discussion of the vacuum filters will be given.

The rotary vacuum precoat filter is similar to the rotary vacuum filters utilized in many hydrometallurgical operations with the primary difference being that a precoat of up to several inches (up to 15 cm) of filter aid is formed. Instead of the solids being filtered directly by the filter cloth, they are collected on the surface of the precoat. As the drum rotates a knife (doctor knife) cuts the solids, and a small quantity of filteraid, from the surface of the precoat. Rotary vacuum precoat filters are normally employed when it is necessary to remove slimey solids or solids in excess of one percent. There are several instances where rotary vacuum precoat filters are utilized in the mining industry. One of the largest at this time is the filtration of phosphoric acid produced from the vast deposits of phosphate rock located in the Southeastern United States.

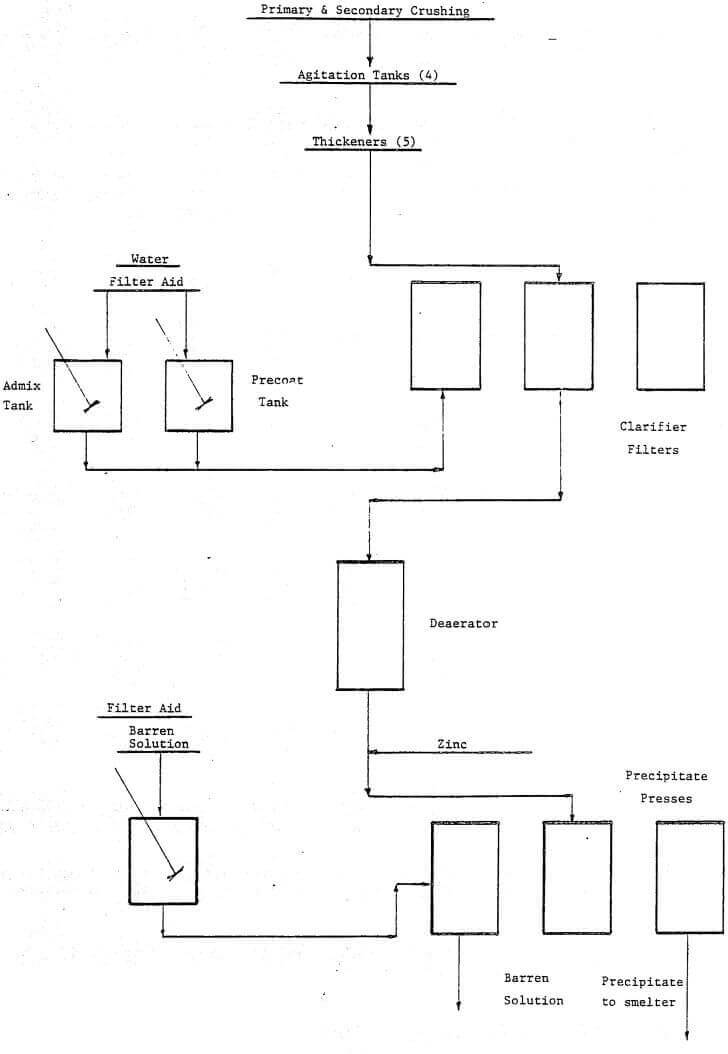

Although domestic cyanide operations appear to limit their usage to plate and frame and pressure leaf filters, some South African operations utilize vacuum leaf filters. A vacuum leaf filter is constructed with the filter elements suspended in an open tank, with the solution being drawn through the elements by a vacuum pump. These filters have the advantage of being somewhat lower in cost since no pressure vessel is required, plus an operator can easily clean, inspect or repair the elements. Throughput is, of course, limited by the attainment of atmospheric pressure.

Normal operation of a vacuum leaf filter consists of forming a precoat on the filter elements and then introducing “admix” or “body feed” with the incoming solution to be filtered. The filter is operated until either the flow drops below a required level or the maximum vacuum is obtained with a subsequent decrease in flow.

The pressure leaf filter is utilized as a clarifier filter in many cyanide leach operations. There are a considerable number of configurations yet, the horizontal tank, vertical leaf construction is the most widely used. Regardless of the design of the filter (e.g. vertical tank, horizontal leaf), the operating conditions are similar. The leaves are generally covered with either stainless steel or synthetic cloth and are normally precoated with DE or a DE/cellulose blend. An admix is then fed into the filter along with the solution to be filtered. It is necessary to “backwash” the filter and reprecoat once the flow drops off, the pressure exceeds the maximum, or the cake space has filled.

The plate and frame filter is utilized for collection of precipitate in most operations where the values are precipitated. It is used since it has a dry cake discharge and, therefore, all of the values are collected. The filter is precoated with DE, and since the DE is essentially silica, it is readily consumed during the smelting operation. No admix is used during this operation.

The use of DE has several advantages in the cyanide leach operation. One of the primary prerequisites in the clarification of the pregnant solution is sparkling clarity. If the pregnant is not clear, the colloids present will coat the zinc particles, thus reducing the reactivity of the zinc. Also, colloidal particles will plug the precoat on the precipitate filter, thus reducing the cycle length. This would, of course, necessitate more frequent press breakdown which is labor intensive, and also increase security problems with more frequent handling of precipitate.

There are several other advantages from using DE filteraids which are not necessarily specific to cyanide leach operations but any other filtration application. The formation of a precoat serves two functions – it protects the cloth and also provides instantaneous clarity. If the precoat were not formed, fine colloids would plug the cloth which would decrease the flowrates. At some point the, the cloth would have to be replaced and either be discarded or possibly washed. It has also been reported that the use of DE retards the formation of ime scale on the cloth.

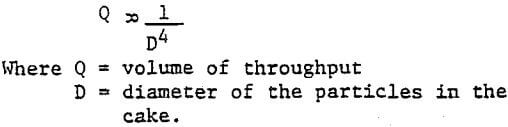

The primary advantage of using DE is obtaining high flowrates with a high degree of clarification. It is evident from classic permeability equations that

Consequently, in efficient settling operations smaller particles in the overflow would result in lower flowrates through a clarification filter. It is also apparent that the finer particles would penetrate a filter cloth and plug it, even if they could be collected. The use of the filter aid solves both problems – it protects the cloth and produces a more permeable filter cake.

The design criteria for selecting the filtration mode is indeed most difficult. The operating cost of a DE filter appears to be higher due to the cost of the filter aid, but when capital for larger filters is examined, (plus the space requirements, the necessity of more frequent cloth cleaning), the selection task becomes extremely difficult. The question arises, can the higher operating cost be offset by a reduction in capital requirements?

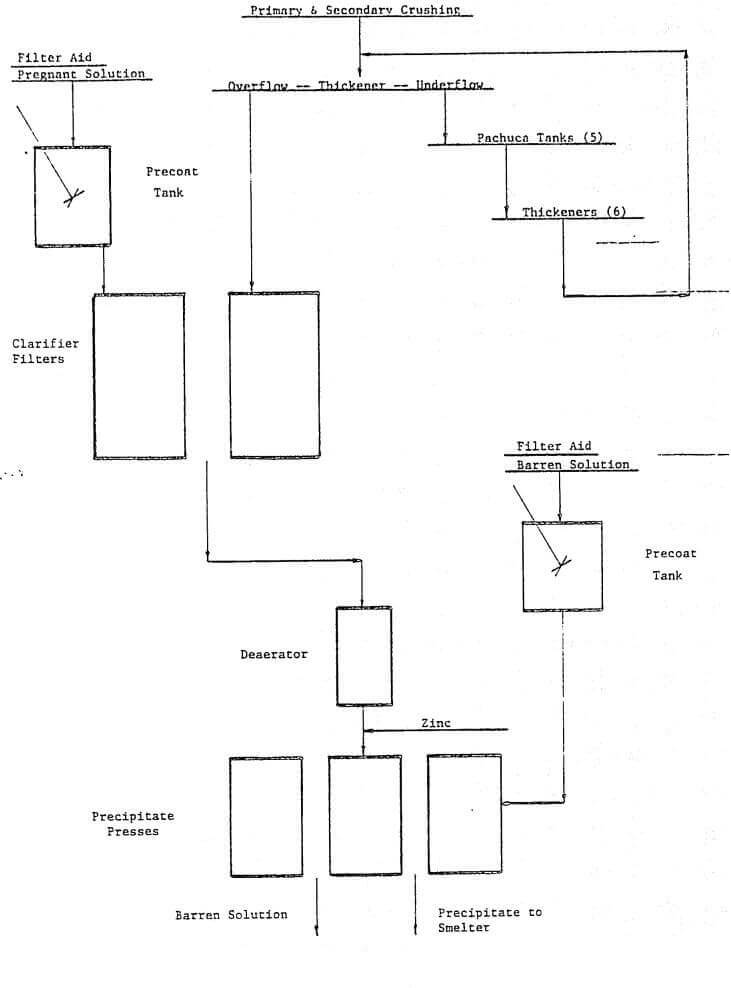

Cyanide Applications in Merrill-Crowe

Since DE filtration may be considered a relatively recent technology, particularly concerning the mining industry, it is not uncommon that documentation is also somewhat thin. Bitter (1940) referred to the use of DE to precoat the filter used to collect gold-silver precipitate. The method for precoating is far from sophisticated, although, a similar method is used now in almost all Merrill-Crowe type operations.

Dorr and Bosqui (1950) not only refer to precoating precipitate filters, but also clarifying filters with “filter aids”. No mention is made of using an admix and it is apparent that with thickener overflows that are very low in solids content, this may be satisfactory. In most instances though, the use of admix is necessary and insures extended cycles in the event of minor upsets in the thickeners.

In South Africa, DE is used to precoat clarifier filters without the use of admix and pre-clarification is obtained by the use of rotary vacuum filters. In the rotary vacuum filters “filter aids” such as polyacrylamides are used. The clarifier filters, which are vacuum leaf or pressure tube filters are precoated with DE. Since the feed is “prefiltered”, it appears no admix is necessary. Filter design for the leaf filters consists of about 50 leaves which are covered with either canvas or synthetic cloth. The dimensions of the leaves vary from 6.0 ft.(1.83m) x 7.0 ft. (2.13m) to 4.0 ft (1.22m) x 7.0 ft. (2.13m).

The tube or candle filters are generally Stellar units which have from 410-520 ft.² (38-48.5m²) of area per filter. The cycles average about twelve hours although higher solids content can necessitate more frequent backwashing. Recently Funda and Niagara filters have been introduced which are more similar to units presently used in the U.S.

The precipitate filters in South Africa are both vacuum and pressure filters and are also precoated with DE. The breakdown period occurs from seven to ten days which is similar to U.S. operations. One of the primary differences occurs with the use of the Stellar “candle” filters for precipitate collection. Since these filters do not have the dry cake discharge which plate and frame filters have, it is necessary to backwash the filters to collect the precipitate. The use of the pressure filter to collect the precipitate, whether the Stellar in South Africa or the plate and frame in the U.S. prevents the possibility of air entering the system, and, therefore, improves precipitate recovery. As with most U.S. installations, the DE precoat in the precipitate filters is followed with a secondary precoat of zinc.