To begin, let’s start the description with the Diaphragm Pump and its Working Principle. The name of the diaphragm pump is derived from the RUBBER MEMBRANE that the pump uses to achieve its pumping action. The diaphragm works on an air displacement principle. The membrane is mechanically pushed and pulled in and out of a pumping chamber.

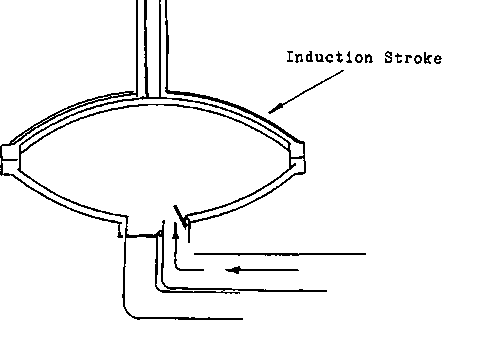

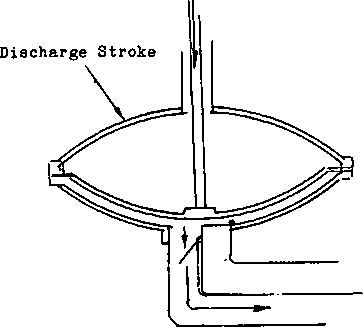

When the diaphragm is collapsed all of the air is forced out of the diaphragm chamber. When the diaphragm is extended the slurry, or whatever is being pumped, is sucked into the diaphragm chamber through the intake line. That is the INDUCTION or SUCTION STROKE, the EXPULSION or DISCHARGE STROKE is simply causing the diaphragm to collapse once more.

When the diaphragm is collapsed all of the air is forced out of the diaphragm chamber. When the diaphragm is extended the slurry, or whatever is being pumped, is sucked into the diaphragm chamber through the intake line. That is the INDUCTION or SUCTION STROKE, the EXPULSION or DISCHARGE STROKE is simply causing the diaphragm to collapse once more.

The slurry will be discharged out of the discharge line. To control the suction and the discharge, the intake and outlet lines will have a ONE WAY VALVE in each of them. They allow the material access to only the right line. On the induction, or suction stroke, the vacuum will keep the discharge valve closed. On the discharge stroke the one way valve of the intake line will not open.

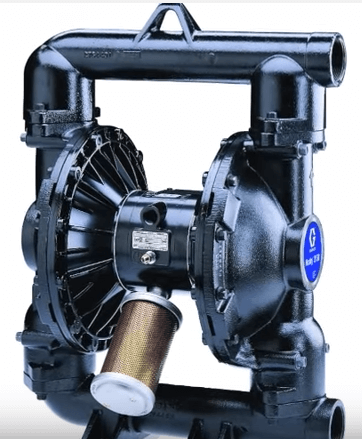

In some cases to increase speed and pumping capacity a second diaphragm may he added, this second diaphragm will be on a suction stroke while the first one is on a discharge stroke. This also makes pump vibration and movement less.

The energy necessary to cause the diaphragm to pump may be generated in a variety of ways, from an ELECTRIC or GAS MOTOR to an AIR MOTOR.

There are a large number of designs that are possible with an air motor. The Diaphragm Pump Working Principle is as simple as two valves opening and closing using air pressure to force a piston back and forth, or as complicated as delicately balanced vanes that are revolved by the air. The use of an air motor on this type of pump allows it to be used in more than one application. Air motors can be made small and light, ideal for use as a portable pump. As a submersible pump, the use of air makes it a sealed unit with no external moving parts. Because it doesn’t give off fumes or use electricity, it may be used indoors or around flammable liquids. These advantages make it a very handy pump to have around a concentrator plant, if only as an emergency piece of equipment.

You have two options you may use to control the volume through put of this pump. You may INCREASE or DECREASE the SPEED of the diaphragm stroke or you can LENGTHEN or SHORTEN the diaphragm stroke either one will increase or decrease the through put of the pump.

It handles heavy density materials well and as long as it is well maintained they are a reliable but slow pump. A disadvantage for some application is the unsteady pressure of its discharge, even double diaphragm pumps have a pause in between the discharge cycles.