This is a Diamond Processing Chart as it was done in the 1950s.

World demand and production of diamond both for gem and industrial purposes has increased nearly five-fold during the past 25 years. Improved mining and recovery methods together with the discovery and development of new fields has enabled mining operations to fill the growing demands. Producing areas in Canada, South Africa, South West Africa, The Congo Republic, Angola, Ghana, Tanganyika and Sierra Leone account for over the bulk of world production.

In mining, diamonds are recovered mainly from alluvial deposits which vary widely in character, often cemented; and usually contain large quantities of clay or a sticky slime fraction from near zero to about 50%. Substantial production also comes from Kimberlite pipes and dikes (Blue Ground), a basic igneous breccia, considered generally to be the originating source for nearly all diamonds. Diamonds have a specific gravity up to 3.52 and are associated with minerals such as magnetite, ilmenite, garnet, tourmaline, spinel, rutile, pyrite, quartz and other minerals which due to their specific gravity makes separation from the diamonds difficult and affects the ratio of concentration obtainable through gravity methods. Since the value per ton of diamondiferous gravel seldom exceeds one metric carat per ton with an average of less than 0.3 carat, a high ratio of concentration, in the order of 1: 5,000,000 or higher, is necessary.

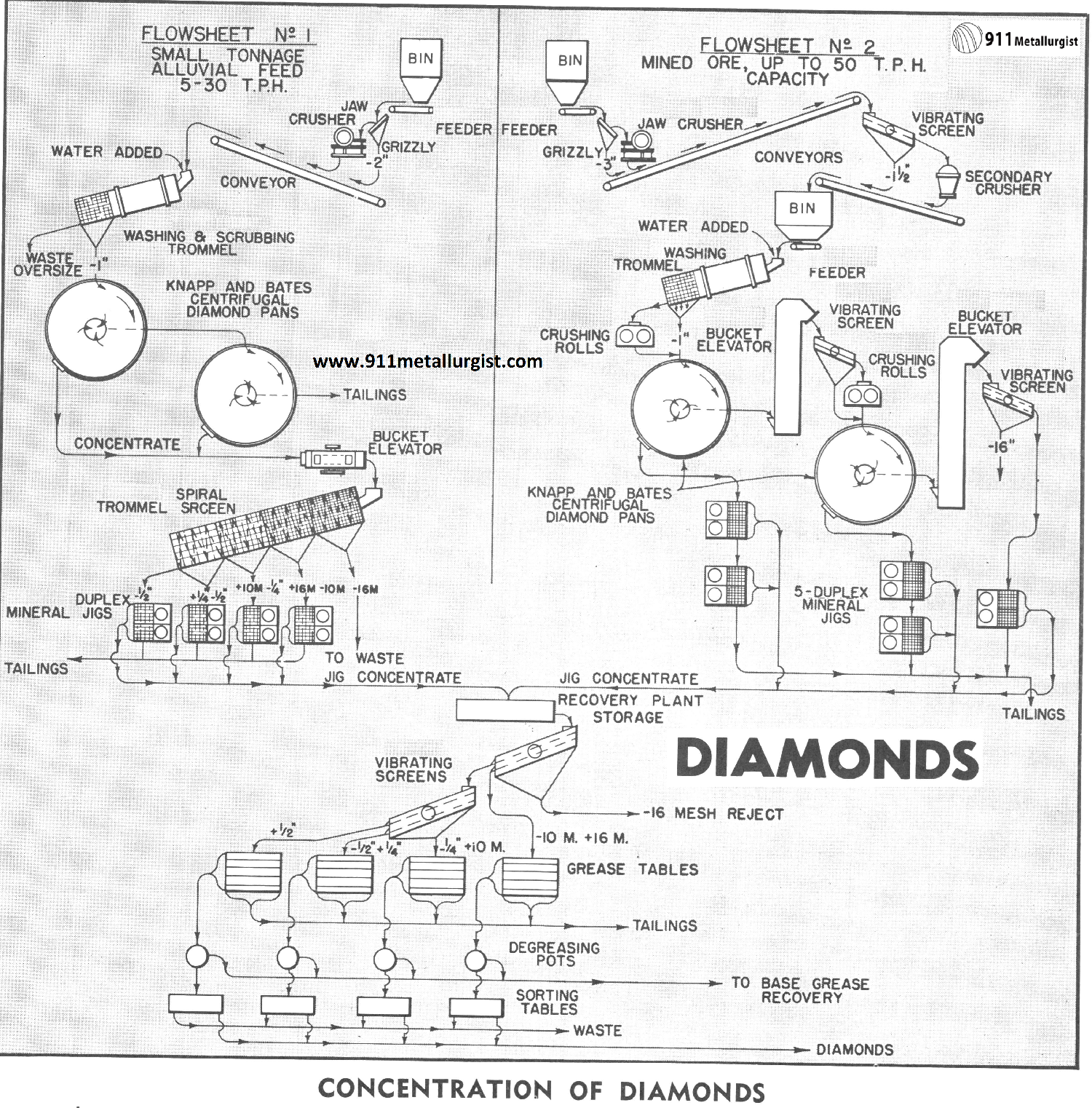

General Diamond Process Flowchart

Many recovery methods are used and methods vary depending on the location, size and nature of the deposit. The methods include production by natives using simple hand pans to more complex mechanical means employing washing, screening, stage crushing, clear water and puddle panning, heavy media separation, jigging, attrition and differential grinding, magnetic and/or electro-static separation, flotation, grease tabling and hand sorting. Certain operations use one or more field plants to supply a central plant for reconcentration and final sorting.

Diamond Process FLOW CHART #1

This flowsheet is typical for small to medium tonnages of alluvial feed (5 to 30 tons per hour). Such material is often cemented and requires crushing by either jaw or gyratory crushers. In this flowsheet a trommel screen, with a scrubbing section, is used to break down clay and cemented fractions, before screening and rejection of the oversize to waste. The trommel undersize, —1″, is fed to centrifugal diamond pans in series.

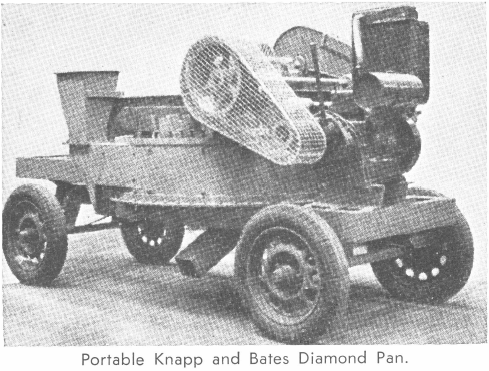

Diamond pans were developed in South Africa and have been highly successful and widely used in the recovery of diamonds. Their use for the separation of other minerals has been limited and inefficient.

A diamond pan is a shallow, flat bottomed circular pan with an inner well about 0.3 of the pan diameter and several inches lower in height than the outer pan wall. A vertical shaft is mounted to rotate in the center to which radial horizontal arms are attached above the pulp level in the pan. Tines extend downward from the radial arms and are adjustable to clear the pan bottom. These tines are triangular and so spaced and mounted on the radial arms to plow material on the pan bottom outward. The feed entry is tangential to the outer wall while the tailings discharge is through a weir in the center well. In operation the tangential entry of the feed combined with the stirring action of the tines causes a vertical swirl to the mass. The condition created in the pan simulates the heavy media process in that the lighter materials remain in suspension and are carried down the vortex to the center discharge weir while the heavier particles settle through the swirling mass to be plowed outward on the bottom to a concentrate discharge outlet in the outer wall. Feeds containing a high amount of clay and fine sands give the most effective results, however, many pans operate on feeds containing little or no clay or fines with reduced but still satisfactory recoveries. Capacity of diamond pans is normally 5 to 6 tons per square foot of effective area per 24 hours and require 1 to 1½ horsepower per ton of feed. Ratios of concentration vary, usually from 10:1 to 50:1 depending on the amounts of heavy minerals associated with the diamonds. Recoveries up to 97% are sometimes possible.

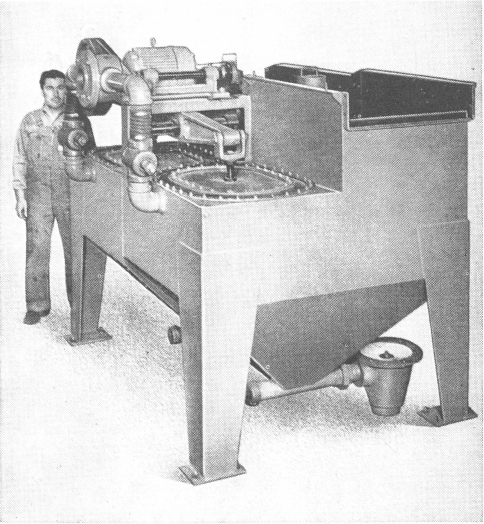

The diamond pan concentrates in Flowsheet No. 1 are elevated to a trommel screen for sizing to eliminate — 16 mesh undersize and to produce four size ranges each going to a Duplex Mineral Jig for further concentration. Mineral Jigs have proven to be very efficient in diamond treatment with recoveries near 100% being reported. The jigs are equipped with 2 mm bedding screens. No artificial bedding is added in most operations since the pan concentrates contain sufficient heavy minerals to form adequate bedding. A 2-mm hutch concentrate is produced from the jigs which are discharged to locked containers before being removed to the final recovery section. The 2-mm concentrate retained on the jig screens is removed by hand at intervals as necessary and are hand sorted for recovery of the diamonds. All phases of concentrate handling are done under conditions to insure security. All launders, jig compartments and concentrate collection points are covered, locked or protected to prevent theft.

Diamond Process FLOWSHEET #2

This flowsheet was developed for diamond recovery from Kimberlite ore as mined and with properly sized equipment is suitable for tonnages up to 50 tons per hour. The mined ore is crushed to —3″ followed by screening and secondary crushing to — 1½”. A picking belt is sometimes employed between crushing stages for removal of waste rock and possible recovery of large diamonds, but this step is generally considered uneconomical. Few, if any diamonds are broken in the crushing operations, as they are usually smaller than the crusher openings, and break free from the matrix without damage. The crushed ore goes to a bin for storage and for controlled feeding to the recovery circuit. A trommel screen with scrubbing sections is used to break down any soft portion of the ore before screening. Oversize material is reduced to — 1″ with a spring roll crusher and then joins the trommel undersize to feed a centrifugal diamond pan. The flowsheet shows one pan, however, several pans in series are sometimes found to be more effective when the ore contains high percentages of heavy minerals. The pan tailings are elevated or dewatered and conveyed to another screening and crushing step to provide a—3/8″ feed to a secondary diamond pan. The tailings from the secondary pan are elevated and screened to produce a + 1/8″ fraction as a final tailing, and a —1/8″ product which passes to a Duplex Mineral Jig for recovery of any small diamonds remaining. The concentrates from the primary and secondary pans are each separately fed to two Duplex Mineral Jigs in series for reconcentration. The use of Mineral Jigs in series on the unclassified feed eliminates the necessity of classification or screening to produce sized feed fractions often necessary when plunger type jigs are used. The ratio of concentration on jigs in this service ranges from 10:1 upward depending on the amounts of heavy minerals in the pan concentrates. Feed rates vary from 200 to 1000 pounds per square foot of compartment area per hour.

The final recovery of the diamonds from gravity concentrates is accomplished by several steps of reconcentration which differ in many cases due to the amount and nature of the associated gangue minerals. When appreciable amounts of heavy minerals are present the concentrates are sized to give a — 1/8″ fraction which is dried and passed through magnetic and/or electrostatic separators to eliminate affected materials, before being further reconcentrated on grease tables. The recovery method shown in Flowsheets No. 1 and No. 2 is frequently used when the gravity concentrates are wet screened to three or more size ranges as the feed to separate grease tables and to reject —16 or —28 mesh materials.

The grease tables are of several types being usually either mechanically or electrically vibrated with the movement normal to direction of flow. The decks are made both flat and stepped, being adjustable in slope to give proper flow velocity for the different size ranges of feed. The stepped decks have from 4 to 8 removable compartments or pans each being 8″ or more in width by 3 to 4 feet in length, each pan being mounted in steps down the table. Each step is coated with +½” thickness of a special petroleum grease which is given a surface covering of about 1/16″ of another type grease. In operation the sized feed is uniformly fed across the table into a flow of water to carry the material across and down the table steps. The diamonds being non-wettable adhere to the grease while most of the other minerals are carried off the table by the water and are rejected as waste. After 45 to 60 minutes of operation the 1/16″ surface layer of grease, together with the diamonds and some other trapped minerals, are scraped from the tables. This grease layer is placed in grease pots having perforated sides. The pots are

Duplex Mineral Jig. Over 40 large Mineral Jigs are used by one major diamond operation.

covered and placed in boiling water for removal and recovery of the grease. The diamond concentrates after degreasing are hand picked and sorted under diffused light. This final operation is very exacting work and is carried on under close observation and security conditions.

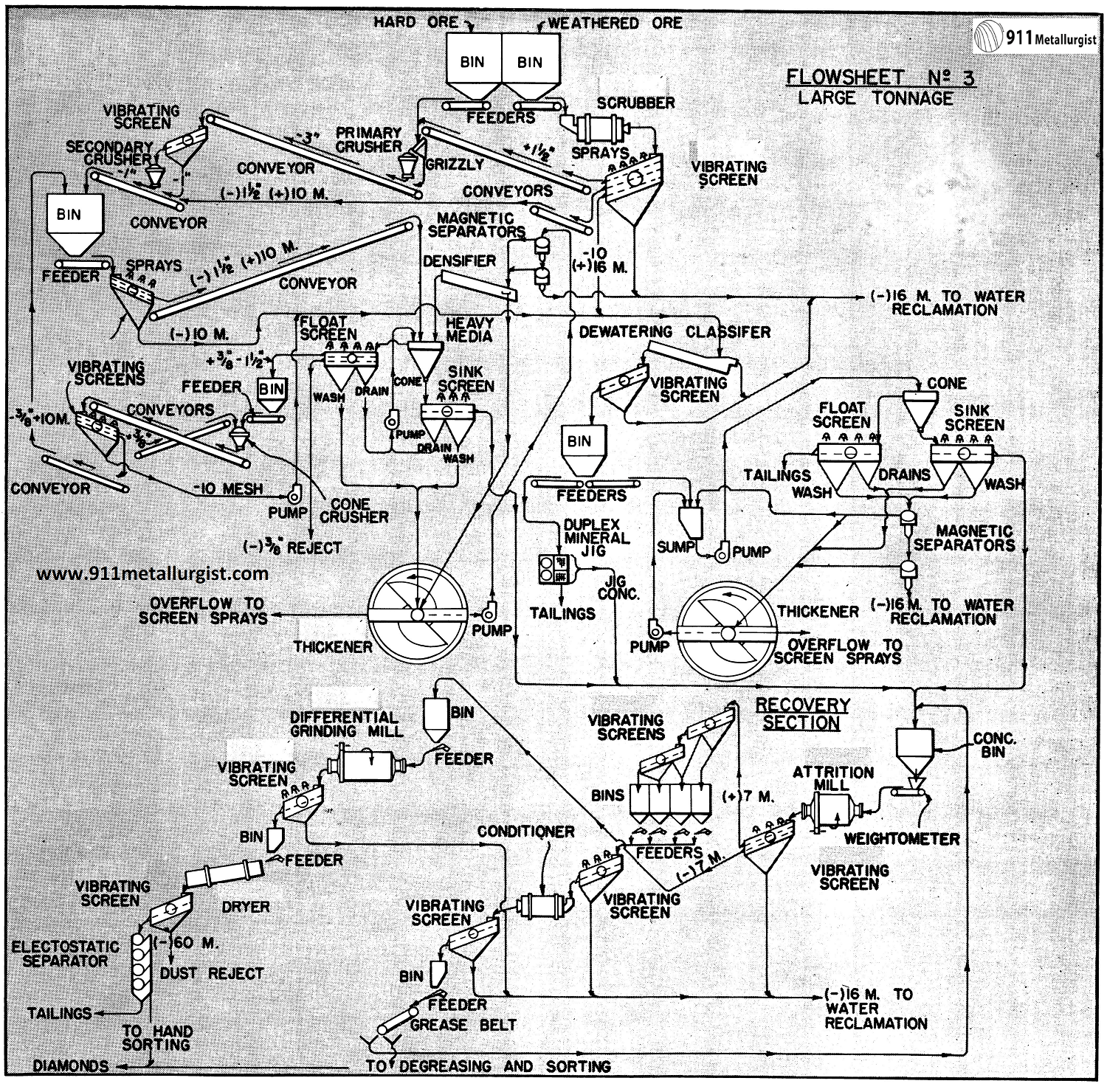

Diamond Processing Flow Chart #3

This flowsheet illustrates a more complex diamond recovery method developed in recent years. With variations it can be used to process 100 to 500 tons per hour of Kimberlite ore and is also arranged to handle weathered or soft ores. For the hard ore as mined the flowsheet follows conventional methods of stage crushing and screening to reduce the ore to —½”. The weathered ore is intensely scrubbed to break down the soft fractions and then screened as shown. All the —1½” ore is wet screened to produce +10 mesh and —10 mesh sizes. The — 1½”, +10 mesh fraction goes to a heavy media separator from which the sink product, after media screening and washing, goes to concentrate storage. The float product is washed and screened to reject all —3/8″ to waste. The +3/8″ size is crushed and screened to —3/8″ +10 mesh for retreatment to the

heavy media circuit.

All —10 mesh material from the screens ahead of the heavy media process and from the screen following the scrubber is dewatered and wet screened to give a — 10 mesh, +16 mesh size range for treatment either by heavy media separation through cyclone separators or by Duplex Mineral Jigs as illustrated.

In the recovery section a number of reconcentration methods are used. Attrition grinding using a light grinding charge at near 40% of critical speed reduces part of the heavy minerals without damage to the diamonds. The mill discharge is screened to eliminate — 16 mesh or in some cases —28 mesh and to split the remaining concentrates at about 7 mesh. These two size ranges being treated separately with the —7 mesh going to a mill to effect a differential grind to further reduce the waste materials. This product is wet screened and the oversize is dried, screened to remove dust before passing through an electrostatic separator. The diamond concentrates are then hand sorted. The +7 mesh concentrates are sized, usually to four size ranges, each separately conditioned to remove any coating from the diamonds which interfere with collection on grease tables or grease belts. Grease belts are a recent development and require less attention and labor than grease tables. They are similar to short conveyors and are mounted in a framework so that the slope can be adjusted for correct flow velocity. The concentrates are fed to spread a thin layer over the belt surface down which a stream of water flows. Grease is continually applied to the belt at the upper end and is scraped off at the lower end with the diamonds. The diamonds are degreased and processed by hand sorting.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.