Table of Contents

The processing of ores for the recovery of minerals such as phosphate (U.S. Bureau of Mines, 1975), potash (C. E. Jordan, 1977), bentonite (S. G. Amplan, 1975), and coal (R. E. Zimmerman, 1978) generally results in the production of ultrafine waste materials, which respond poorly to conventional physical separation and dewatering techniques. In many cases these ultrafine waste materials contain mineral values that represent a major loss of natural resources. Current mineral practices usually dispose of these fine-particle wastes by impoundment in settling ponds because current technology, in most cases, can recover neither ultrafine mineral values nor the water associated with these wastes. The settling ponds cover large land areas that are difficult to reclaim. The tremendous losses in resources—minerals, water, and land—have created the need for an alternative disposal system.

The Bureau of Mines, U.S. Department of the Interior, is investigating techniques for dewatering a variety of fine-grain waste materials (B, J. Scheiner, 1982, J. R. Zatko, 1982, and A. G. Smelley, 1980). The technique consists of mixing fine-grain waste with a flocculant, PEO, and dewatering the resulting agglomerate on static and/or rotary screens. This report describes the results obtained from field tests and small-scale continuous dewatering tests on coal-clay waste, bentonitic waste, and phosphate clay waste.

Dewatering of Ultrafine Bentonitic Waste

Bentonites are used in drilling muds, foundry sands, and pelletizing of taconite iron ores (S. G. Amplan, 1975). The major source of raw bentonite is in Wyoming. Raw bentonite is mined and then refined to remove roots, coarse quartz, and bentonite particles larger than several micrometer. The rejected material from the refining process is discharged from the plant as an aqueous slurry and disposed of by impoundment. This waste slurry settles poorly, thus requiring large impoundment areas.

A sample of bentonitic waste containing 12 percent solids was obtained from a refiner located in Texas. X-ray analysis of the material showed that it had major amounts of quartz and bentonite, with minor to trace amounts of calcite and mica and/or illite. It also contained trace amounts of plagioclase, zeolite, and cristobalite. The material was 100 percent minus 400-mesh.

PEO, available commercially, was used as the flocculant in all dewatering tests described in this report. The polymer is a linear, nonionic, water-soluble molecule composed of repeating units of (CH2-CH2-O) groups. For dewatering with bentonitic and coal-clay waste, an 8-million-molecular-weight polymer was used.

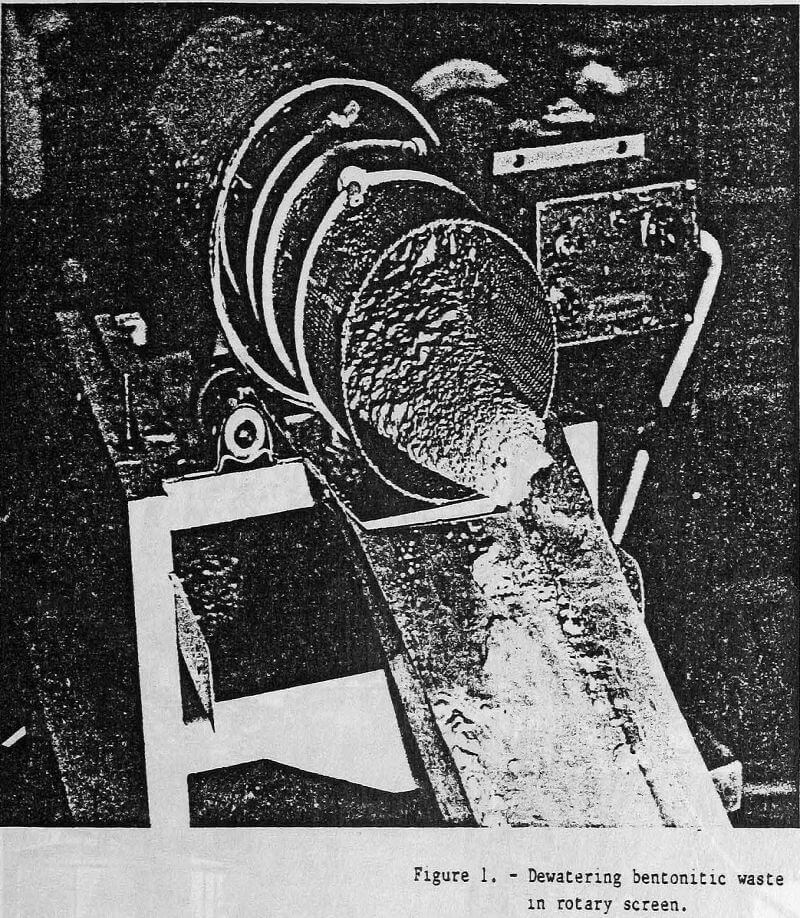

The procedure for small-scale continuous testing consisted of pumping the slurry at the rate of 1 gallon per minute to an agitator-type mixer unit where PEO was added. The flocculated material flows from the mixer into a rotary trommel screen, where water is removed through the screen; the solids form a roll and move down the screen as shown in figure 1. The trommel screen was constructed of type 304 stainless steel mesh; it was 36 inches long and 8 inches in diameter and had screen openings of 10 mesh.

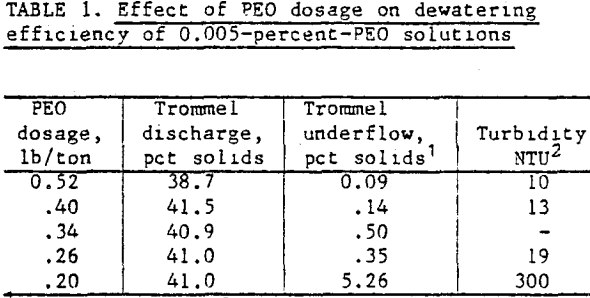

Initial batch experiments indicated that PEO formed weak flocs with the bentonite sample, which was a sodium form of montmorillonite. Previous research (D. A. Stanley, 1982) indicated that PEO forms stronger bonds with a Ca-montmorillonite than with sodium montmorillonite. Therefore, the bentonite slurry was treated with calcium ion in the form of lime or calcium chloride, and strong flocs that dewatered readily were produced when PEO was added to the slurry. Based upon these preliminary batch experiments, small-scale continuous tests were conducted. In these experiments the amount of calcium chloride used was 20 pounds per ton based on the dry solids content of the bentonite slurry, and the PEO solution was 0.005 percent. The results are shown in table 1.

As can be seen from table 1, all dosages investigated produced a trommel discharge ranging from 38.7 to 41.5 percent solids. The water recovered from the trommel had flocculated solids which settled rapidly to produce water containing a turbidity of 10 to 19 NTU except for the dosage of 0.2 pound per ton, which produced a water containing 300 NTU turbidity. Discharge into a pristine environment usually requires the water to have a turbidity of 10 NTU or less.

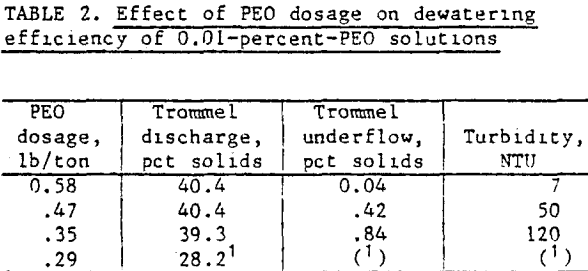

The series of tests summarized in table 1 was repeated except that 0.01 percent PEO was used. The results are summarized in table 2.

The results indicate that the 0.01-percent-PEO solution requires a larger dosage and more solids pass through the screen then with 0.005-percent-PEO solutions.

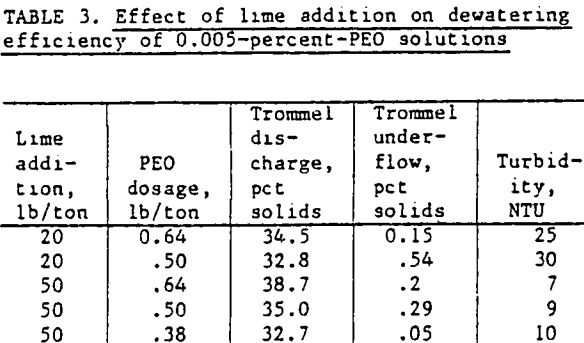

Another series of tests was conducted to determine the effect of using lime instead of calcium chloride. The results, shown in table 3, indicate that lime will work but the overall efficiency is not as good as that obtained with calcium chloride. For the tests described, the optimum results were achieved when 20 pounds of calcium chloride were added to the waste, followed by flocculation with 0.26 pound per ton of PEO as a 0.005-percent solution.

Dewatering of Coal-Clay Waste

In the preparation of coal to produce low-ash material, a waste product containing fine coal and clay is generated. This waste product, generally minus 23 mesh in size with the major portion being minus 325 mesh, is difficult to handle owing to the slow settling of the fine-sized clay particles. The material is usually processed in a thickener to produce a slurry containing about 30 weight-percent solids that is impounded behind earthen dams. It has been estimated that about 16 million tons of these waste solids are generated annually (R. E. Zimmerman, 1978).

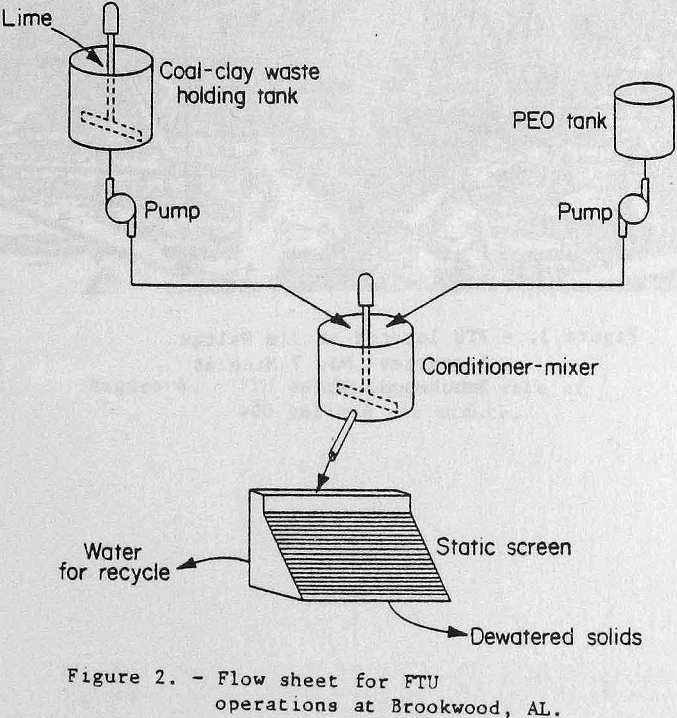

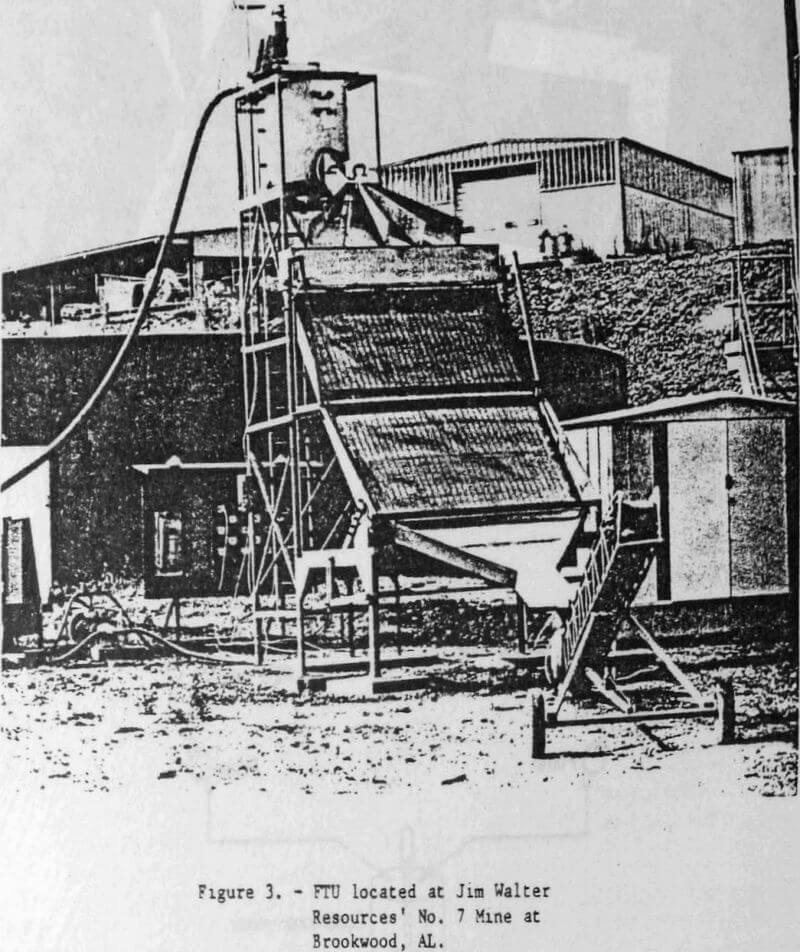

Small-scale continuous tests were conducted on coal-clay waste from West Virginia and Alabama (J. R. Zatko, 1982). Coal-clay waste slurry was dewatered from a nominal 7 percent solids to greater than 50 percent solids using 0.3 to 0.5 pound of 8-million-molecular-weight PEO per ton. Solution concentrations ranged from 0.025 to 0.25 percent PEO. Based upon the encouraging results of the small-scale continuous tests, a larger scale field test unit (FTU) was designed and installed at Jim Walter Resources No. 7 Mine at Brookwood, AL. The flow sheet for the FTU is shown in figure 2. Coal-clay waste is supplied to the FTU from the underflow of the minus 28-mesh flotation circuit. The dewatering screen consists of two 8-foot-wide and 4-foot-long screens combined to form an 8- by 8-foot unit. The upper section of the screen (8 feet wide and 4 feet long) has slot openings 2.75 inches long and 0.02 inch wide. The lower screen has slot openings 2.75 inches long and 0.01 inch wide. The expected capacity of the screen is 400 to 600 gallons a minute, producing a product of 50 to 60 percent solids. A view of the FTU is shown in figure 3. Dewatered material from the screen was conveyed to a pit to determine its stability and dewatering characteristics.

The FTU has been operated for several months at the rate of 400 gallons per minute. Solids of 55 to 60 percent have been obtained using 0.15 to 0.30 pound of PEO per ton. The FTU during operation is shown in figures 4-5.

Dewatered material exiting the screen was conveyed to a pit where it continued to dewater. In the pit the material went from 55 weight-percent to 65 weight-percent in 2 to 3 days and 70 percent in several days. Figure 6 shows an operator standing on the dewatered material 3 days after the FTU was last operated. Further tests are being conducted in which the dewaterd material is mixed with the preparation plant refuse to determine if a stable mixture can be obtained for disposal, thus eliminating the need for ponding of coal-clay waste.

Dewatering of Phosphatic Clay Waste

Phosphatic clay waste generated during the mining and beneficiation of phosphate ore is disposed of by impoundment behind earthen dams. The overall natural settling rate of phosphatic clay waste is extremely slow (U.S. Bureau of Mines, 1975). Generally, the clay wastes have a rapid initial settling rate, thickening from a nominal 3 percent solids to 10 percent solids in a week and to 15 percent solids m about 3 months. Densification to about 18 percent solids generally requires a year, and to reach solids contents of 20 percent or higher requires several years. The initial settling rate is fast enough to allow for recovery of approximately 90 percent of the water pumped to the settling pond. But the 10 percent of the water lost with the slimes and by evaporation is estimated to be about 5 tons for each ton of phosphate concentrate produced (J. E. Lawver, 1978).

The flow rate of phosphatic clay waste to settling areas usually ranges between 20,000 and 80,000 gallons per minute for each phosphate mine. To accommodate the waste, large impoundments covering 400 to 600 acres, with dam heights ranging from 20 to 40 feet, are required (J. E. Lawver, 1978 and J. R. Boyle, 1969). When these impoundments become filled with phosphatic waste, new impoundments must be built in order for the mining company to continue to operate. Both abandoned and operating impoundments are potential environmental hazards because of possible dam failure. Reclaiming impoundment areas for use in such activities as agriculture is difficult and often requires decades.

New technology is needed to overcome the problems caused by phosphatic clay waste. One approach is to develop technology that results in rapid consolidation of the waste, with subsequent disposal in mined-out areas. To accomplish this, the clay waste would have to be dewatered to approximately 30 to 38 percent solids. At this degree of consolidation, the volume of clay waste, plus the sand from the phosphate beneficiation sequence, would fit back into the mine cut, thus eliminating the need for above ground storage.

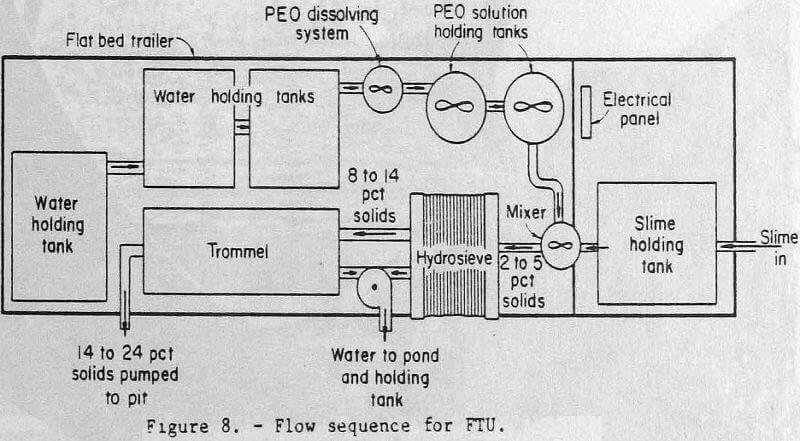

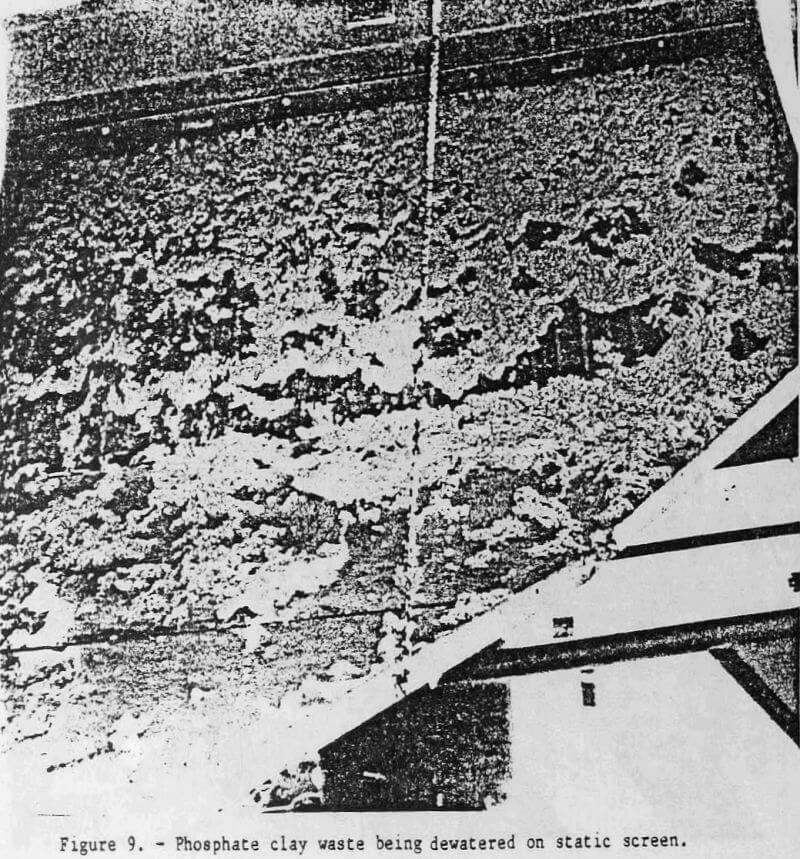

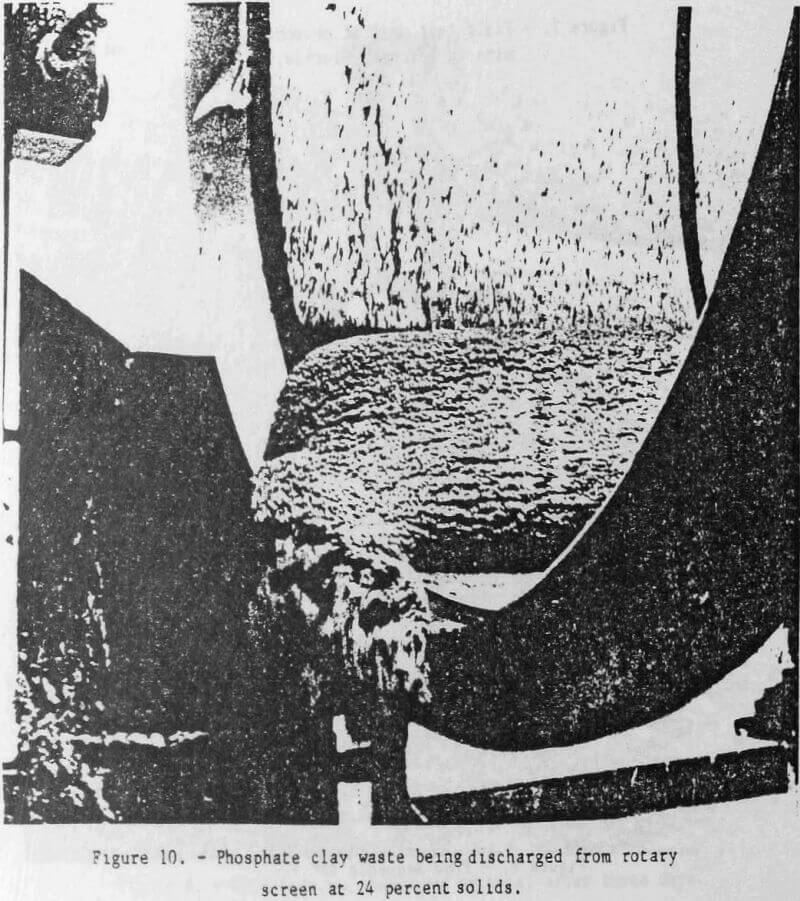

In tests conducted by the Bureau, the PEO dewatering technique immediately consolidated phosphate clay waste from 3 percent solids to 20 percent solids (A. G. Smelley, 1979). Based upon these results a FTU was constructed and tested at Occidental’s Suwannee River Mine, located in White Springs, FL. The trailer-mounted FTU is shown in figure 7, and its flow sequence is shown in figure 8. In addition to the dewatering screens, the equipment included an automatic dissolving system for making PEO solutions; holding tanks for PEO solutions, slimes, and makeup water; a stirred vessel for mixing PEO solutions with the clay waste; and various, pumps to transport solutions, slurries, and consolidated material. The hydrosieve screen is 8 feet wide and 4 feet high. The screen openings were run horizontally and were 2.75 inches long and 0.03 inch wide. The trommel screen is 3 feet in diameter and 12 feet long. The trommel screen was constructed of 10-mesh stainless steel and lined with a second screen of 48-mesh stainless steel in the first 4 feet from the feed end to prevent loss of solids as the flocculated material flowed onto the screen. Clay waste was pumped to the FTU and held in a 1,200-gallon-capacity holding tank. From there the slime was pumped to the mixer where PEO solution (PEO molecular weight of 5 million) was mixed with the slime, and the resulting flocs were discharged into a trough that overflowed onto the hydrosieve screen. The flocculated material moved down the hydrosieve by gravity flow. Water released during the flocculation passed through the screen, and the consolidated material moved down the screen, as shown in figure 9. The material flowed into the trommel screen where a roll was formed and more dewatering occurred. The dewatered material was discharged from the trommel as shown in figure 10; and flowed into an auger-feed positive displacement:pump to a pit where further dewatering occurred.

The phosphate clay waste indigenous to the Suwannee River Mine contains clays that are not fully calcium exchanged and not fully oxidized. To treat these type clays using PEO as a flocculant requires addition of lime and aeration prior to PEO addition (D. A. Stanley, 1981). Using this pretreatment method, over 2 million gallons of phosphate clay waste were treated in the FTU operating at a flow rate of 165 to 275 gallons per minute. Typical results obtained from the FTU operation were dewatered products containing 20 to 24 percent solids using a 0.25 percent PEO solution at a PEO dosage of 1.0 to 1.1 pound per ton. Dewatered solids from the FTU continue to dewater when placed in a pit below the groundwater level to 29 percent in 127 days.

To obtain the necessary engineering data to scale up the technique, a prototype unit with a capacity of 2,000 to 4,000 gallons per minute will be tested in central Florida during 1983-04.

Conclusions

A dewatering method using PEO as a flocculant has been successfully used to dewater bentonite clay waste, coal-clay waste, and phosphate clay waste. In field tests, phosphate clay waste has been dewatered from 2.5 percent solids to greater than 20 percent solids. In other field tests, coal-clay-waste has been dewatered from 3 percent solids to greater than 55 percent solids. In addition, small-scale continuous tests have shown that bentonitic clays can be dewatered from 12 percent solids to 40 percent solids. Investigations are continuing on the PEO technique to obtain engineering data required for scale-up.