Phosphatic clay waste is one of the principal waste products resulting from the mining and benefication of Florida phosphate ore. This waste material, which is comprised of ultrafine particles (70 pct less than 1 µm), responds poorly to conventional solid-liquid separation techniques and is currently disposed of by impoundment behind earthen dams.

The overall natural settling rate of phosphatic clay waste is extremely low. Generally, impounded clay wastes thicken from a nominal 3 pct solids to 10 pct solids in about 3 months. Densification to about 18 pct solids may require a year, and to reach solids contents of 20 pct or higher may require several years. Data indicate that approximately 90 pct of the water pumped to the settling pond is eventually recovered. The remaining 10 pct of the water lost by storage with the waste clays and by evaporation amounts to about 5 st for each short ton of phosphate concentrate produced.

The discharge rate of phosphatic clay waste to settling areas ranges between 20,000 and 80,000 gal/min. To accommodate the waste, impoundments covering 400 to 600 acres, with dam heights ranging from 20 to 40 ft, are required. At present, there are approximately 80,000 acres of active and inactive clay settling areas in Florida.

To eliminate the use of aboveground disposal, which appears to be the ultimate goal of the State of Florida, new technology is required to process the wastes generated by most of the Florida phosphate mines. To use only mined-out areas for disposal of the clay wastes requires that the solids content of the material be consolidated from a nominal 3 pct to a final 30 to 38 pct. Generally, at this degree of consolidation, the volume of clay waste mixed with the sand from the phosphate beneficiation sequence would fit into the mine cut and eliminate the need for aboveground storage.

The Bureau of Mines has tested a dewatering technique for phosphatic clay waste that may assist in eliminating storage by impoundment. A portion of the water now being lost using conventional waste disposal methods also can be recovered, and at the same time the dewatered solids produced may be more suitable for land reclamation. The procedure consists of flocculating the clay waste with a long-chain polymer, polyethylene oxide (PEO). Combining the phosphatic clay waste with PEO forms strong flocs which are tough enough to be dewatered on a screen. In previously reported work, this technique was tested using a field test unit (FTU) at Estech General Chemical Corp.’s Silver City Mine, near Bartow, FL, and at Occidental Chemical Co.’s Suwannee River Mine, near White Springs, FL. At feed rates between 60 and 165 gal/min, the FTU was able to consolidate clay waste from a nominal 3 pct solids to 20 pct solids. To determine if the PEO-treated material continued to consolidate, the treated clay wastes were pumped into storage pits. The pits were sampled over a period of time to deter¬mine the solids content. At both sites, the clay waste consolidated to approximately 27 pct solids in 60 days. At the Silver City Mine, an additional 30 days was needed to attain 30 pct solids. The clay waste at the Suwannee River Mine needed an additional 80 days to consolidate to 30 pct solids.

This report describes further testing of the PEO dewatering technique. At the request of the Mobil Chemical Co., the small-scale unit (8 to 18 gal/min) and the FTU (200 gal/min) were operated at Mobil’s Fort Meade Mine. The small unit was used to develop the parameters of operation for the FTU. The FTU was used to fill a pit with dewatered clay waste so that any further consolidation of the waste with time could be monitored.

Small-Scale Dewatering Experiments

Commercially manufactured PEO was used as the flocculant in all dewatering tests. The polymer is a linear, non- ionic, water-soluble molecule composed of repeating units of CH2CH2-O and having a molecular weight of approximately 5 million. Solutions containing 0.25 pct PEO were, prepared from the solid polymer. These solutions were then diluted to concentrations between 0.01 and 0.05 pct. Deep-well water was used for preparation and dilution of the PEO solution.

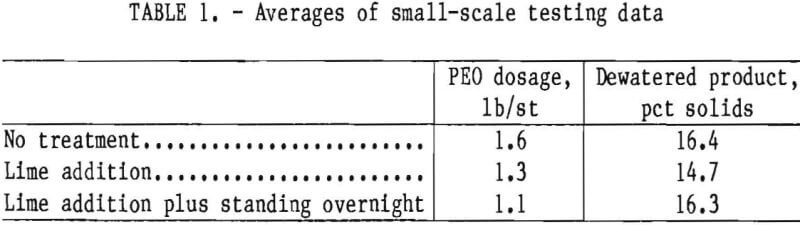

Initial tests were conducted, using small-scale equipment with a throughput capacity of 8 to 18 gal/min, to determine how this clay waste responds to floccula- tion with PEO. Clay waste used in these experiments was obtained from the pumping sump at the Fort Meade plant. The clay waste entered a 400-gal tank and was then pumped to a mixer, where PEO was added. The resulting flocs were dewatered on a static screen, followed by further dewatering in a trommel screen. Tests were conducted to determine how variables such as lime addition, aging time, PEO dosage, PEO concentration, flow rate, and mixer speed affected the dewatering. Since the character of clay waste changed from hour to hour, the results of individual tests were grouped together to obtain a trend. The data were divided into three major groups: (1) dewatering the clay waste from the sump without any treatment, (2) addition of lime prior to PEO flocculation, and (3) addition of 3 to 10 lb/st lime, mixing, and allowing the lime- treated clay waste to stand overnight. For each of these groups all the test results were averaged to obtain a single number for dosage and solids content. The average results are shown in table 1. The averages given in table 1 represent a wide range of results; for example, the solids content ranged from 7 to 21 pct and the PEO dosage from 0.88 to 2.53 lb/ st. The results indicate that PEO will flocculate this clay waste and that the resulting floc could be dewatered on the trommel screen. Also, the addition of lime lowers the PEO dosage.

Large-Scale Clay Dewatering Experiments

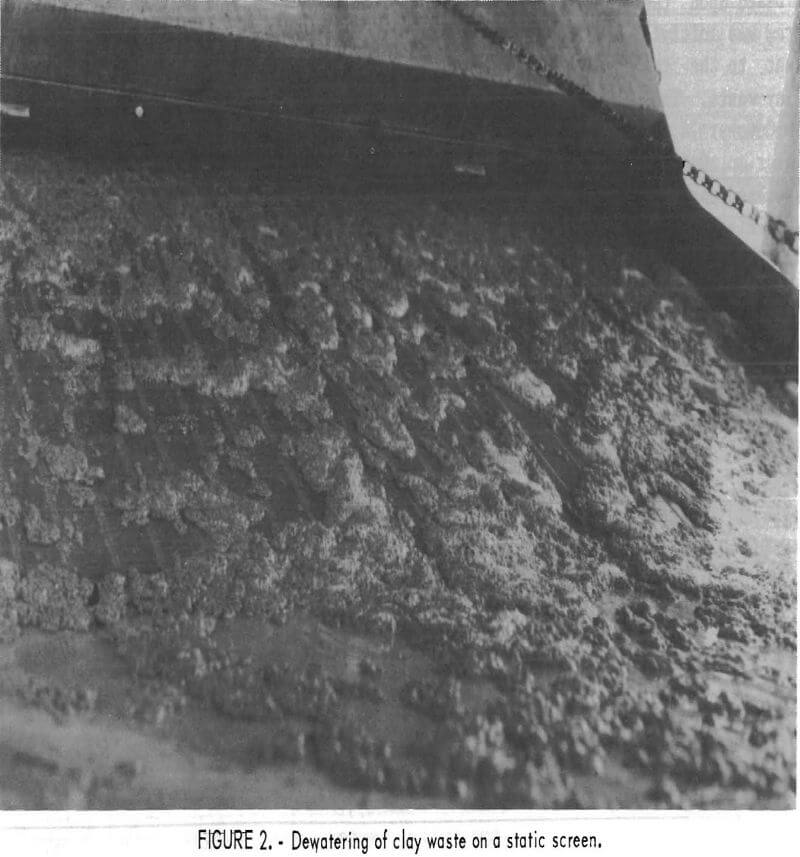

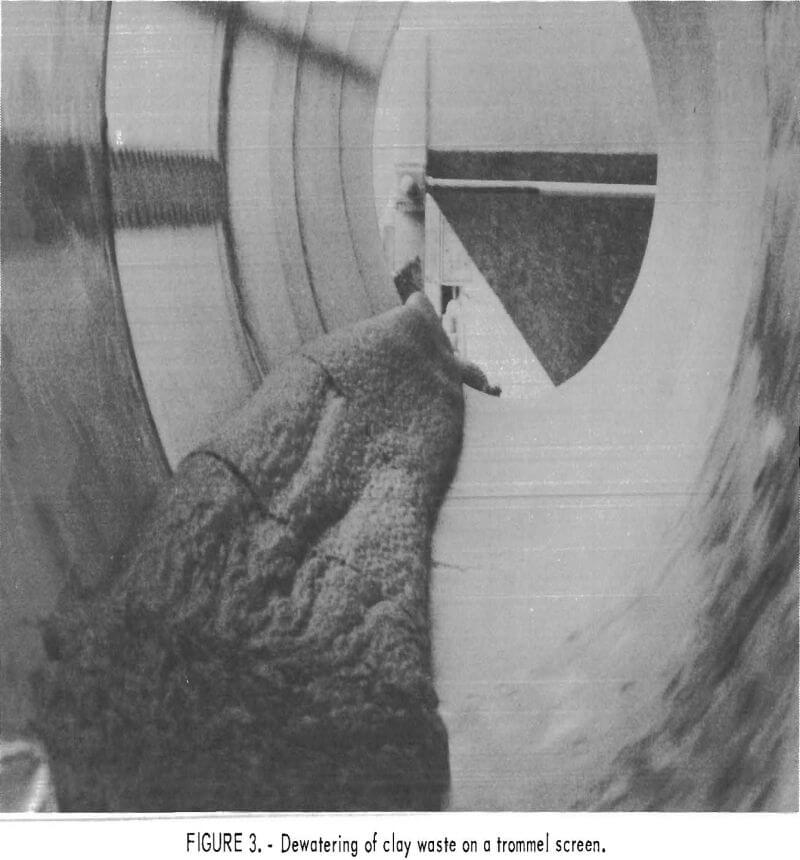

Based on results of the small-scale experiments, the mobile FTU was moved to the test site. Figure 1 shows the flow sequence for the FTU. Clay waste was supplied to the unit from the plant clay waste pipeline. The clay waste from the pipeline flowed to a holding tank. From this tank it was pumped to the FTU at a predetermined rate. The static screen, shown in operation in figure 2, is 8 ft wide by 4 ft high and has openings 0.03 in wide. The trommel screen has a 3-ft diam, is 12 ft long, and was constructed of 10-mesh stainless steel. The first 4 ft from the feed end was lined with a second screen of 48-mesh stainless steel

to prevent loss of solids as the flocculated material flowed onto the screen. During operation, the clay waste forms a roll in the trommel, as shown in figure 3. In addition to the dewatering screens, the equipment includes a system for making PEO solutions; holding tanks for PEO solutions and the clay waste; and various pumps to transport solutions, slurries, and consolidated material.

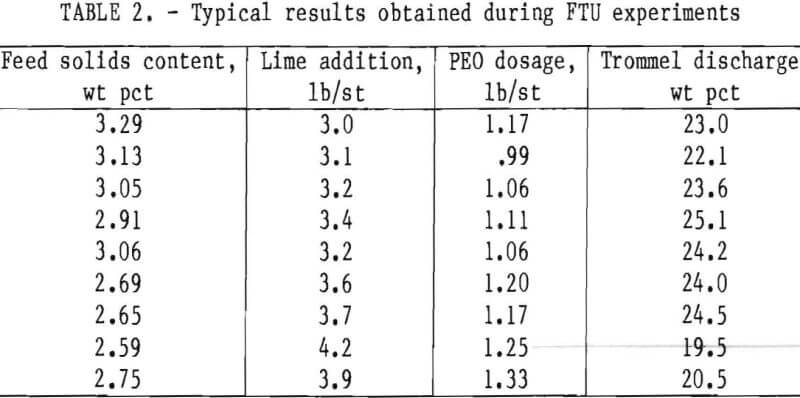

Initial experiments were conducted to determine the optimum mixing speed for the clay waste-PEO mixer. It was determined that 45 r/min gave the best results. Based upon this information, the FTU was operated at 45 r/min. Results of a series of tests, shown in table 2, indicate that 19.5 to 25.1 pct solids can be obtained with 0.99 to 1.33 lb/st PEO.

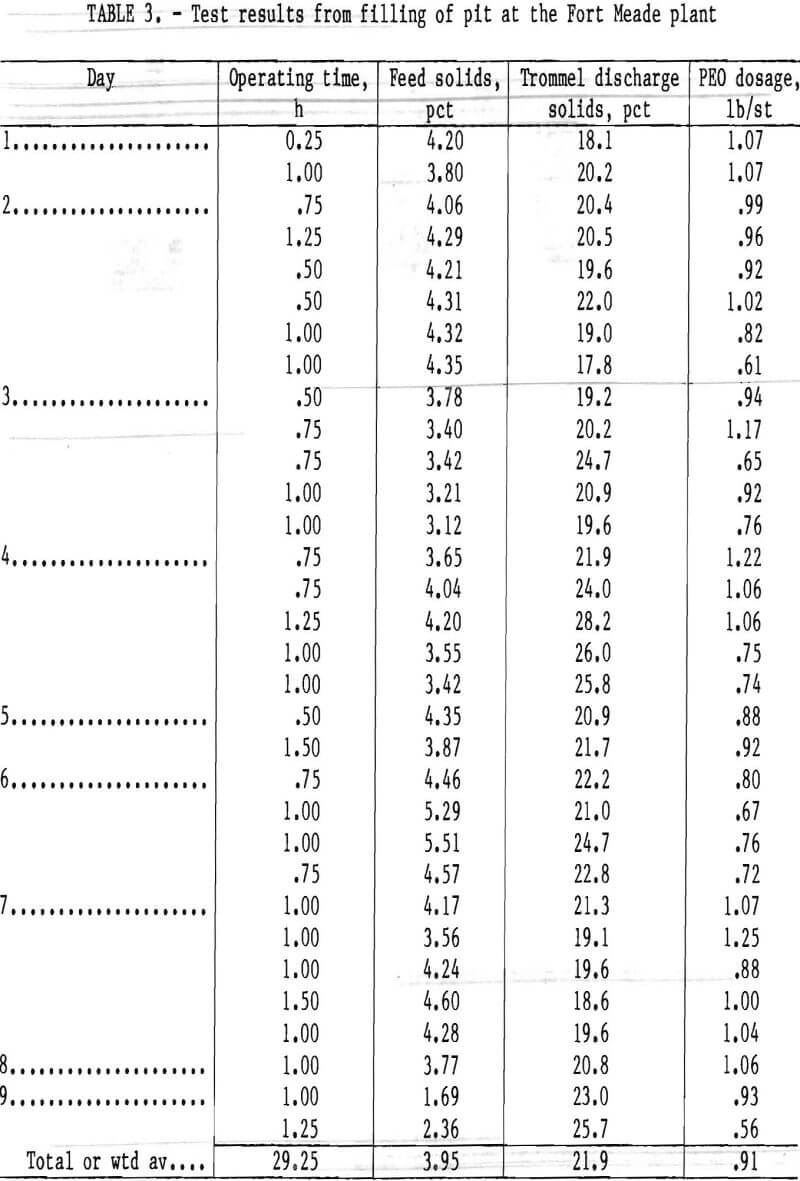

Based upon these results, a test program was initiated to fill the pit adjacent to the test unit with dewatered clay waste. The pit was filled beginning on October 14, 1983, and ending 10 days later on October 24, 1983. The unit was operated each day as long as clay waste was discharged from the plant. On some days clay waste was available only for short periods of time. The unit was operated at a flow rate of 200 gal/min in the following manner.

Clay waste from the plant was placed in the holding tank, and lime was added. For the test, the average solids content of the feed was 3.95 pct, as shown in table 3, and the lime dosage averaged 3.8 lb/st. Clay waste from the plant was added to the tank at the rate of 200 gal/ min and was pumped out of the tank at about 300 gal/min, with 200 gal being sent to the dewatering unit and 100 gal recycled back to the top of the tank. This kept the tank stirred. The feed to the tank from the slime line varied in solids content; recycling a portion of the slime back to the tank provided a more uniform feed to the dewatering unit. The operating volume of the tank was approximately 14,000 gal.

Results of the tests, summarized in table 3, show that the average solids content placed in the pit was 21.9 pct, with an average dosage of 0.91 lb PEO per short ton of solids.

The volume of dewatered material pumped to the pit during the test program was approximately 53,000 gal. The water table in the center of the pit was 44 in above the bottom, and the pit was filled to a depth of 86 in. During the filling the water was not pumped from the pit, but was allowed to flow into the ground through the walls of the pit as dewatered material was placed into the pit. At the end of the filling, the water level on top of the solids was 1 to 2 in.

The amount of dewatering that occurred in the pit was determined by taking samples from the middle of the pit. Results are shown in table 4.

The data indicate that 30 pct solids will be reached in less than 3 months. In figure 4, a view of the pit 22 days after filling shows that the outside edge of dewatered material developed cracks as it dewatered.

Conclusions

The phosphate clay waste from the Fort Meade Mine was successfully dewatered in the FTU to greater than 20 pct solids. These results were achieved by adding 3.8 lb lime per short ton of dry solids and stirring for approximately an hour prior to PEO addition. PEO dosages averaged 0.91 lb/st for the operation of the unit. The dewatered clay waste continued to consolidate when placed in a pit and reached 29.9 pct solids in 80 days.