Table of Contents

This paper is intended, in the light of recent investigations, to call attention to some of the essential features of good practice in sampling and mine-valuation. Mine sampling may be divided broadly into two classes:

- development-sampling and computation of ore-reserves; and,

- stope-sampling and estimation of stope-values.

Development Sampling

It is with development-sampling only that this paper deals—the term development being taken to mean the opening-up of a mine by cross-cuts, drives, connections, etc., preparatory to actual extraction of the ore for milling. In development-sampling the work of the sampler and the consequent estimation of the probable value of the mine or portions of the mine, as the case may be, cannot be verified until a later period, when the ground thus sampled has been exploited; hence, extreme care and accuracy are essential. Moreover, the development-sampler has to foresee and allow for contingencies which may arise when stoping is started. It follows that the sampling, in development-work, demands familiarity with the conditions likely to be encountered later in actual mining. In stopes, on the other hand, sampling is done under actual working-conditions, and the sampler’s valuations are immediately checked by the gold-output, or in some cases by a second sampling of the broken ore. A stope-sampler therefore need not be an experienced miner, though he should possess sound technical training and work accurately. Should he be somewhat inexperienced, he soon has his errors discovered for him, and learns to avoid them. Taking these facts into account, it is obvious that a mining company employing two or more samplers should choose for the sampling of development-work the man who is most experienced in the general and local conditions of mining.

The earliest stages of mine-development often consist of shaft-sinking and cross-cutting. If the shaft be sunk on the lode, ore-sampling of course commences at once. In any case, in a vertical shaft particular attention to the formation should be paid by the person in charge of the sinking. We know of a recently-sunk vertical shaft in which the reef was passed through unnoticed, and much money and valuable time were wasted in sinking to a considerable depth below the reef before it was discovered. Detailed information of the ground passed through, accompanied by illustrative specimens, should be preserved, although frequently too little attention is paid to this matter. It is usually the duty of the person in charge of development-sampling to note all dislocations, faults, and dikes as they occur, and this work cannot be done efficiently without a knowledge of the local formations. At times the condition of the country-rock can only be determined by shafts and cross-cuts. A strict watch of the conditions as they develop may sometimes result in the discovery of a fresh payable deposit. Mining history is replete with many instances of adventitious finds of a mineral or vein resulting while searching for others.

A remarkable instance of recent date was the discovery on the Rand of a pyritic seam in the quartzites behind the main reef that, in places, was of economic value. During the past 20 years that this seam has been known its importance was not appreciated. On some mines on the Rand, in cross-cutting, every foot is sampled and assayed as the work proceeds, and under this careful method of working no auriferous rock of any kind is likely to be overlooked. Cross-cuts should be examined, not merely on one side, but on both. It is very important that information gained during the early progress of a mine should be recorded for reference, since too often the geological story told in the early stages of development is lost, the unrecorded testimony being hidden in lagged-up shafts and cross-cuts.

Development-sampling should proceed pari passu with the development-work; if the former lags money is too often wasted on work in unprofitable ground.

An important point in the exploration of an ore-body is that it should be continuously examined throughout its entire course. By taking samples at occasional points only, the presence of intervening irregularities, horses, forks, or branches, may be overlooked.

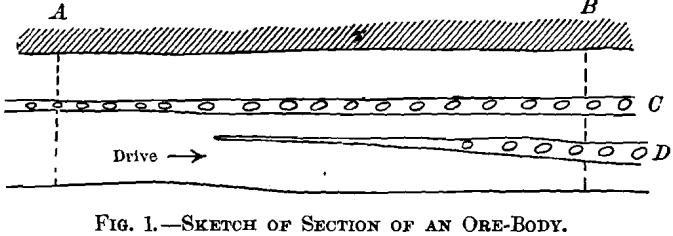

Attention should also be paid to the formation outside of the pay-streak, so that new ore-bodies will not be passed unnoticed. Fig. 1 represents an occurrence not uncommon on the Rand— namely, a reef, D, which has “ made ” under reef C, between the points A and B. The examples above given may seem to some to belong to the rudiments of practical mining, but the precautions mentioned are so often neglected that we do not apologize for emphasizing them here.

With regard to the taking and ticketing of samples, numerous ideas have been suggested and adopted for this work, varying with the requirements of particular circumstances. So much has been written on the subject that it is unnecessary to deal with it at length in this paper. It may, however, be as well to remark that in taking a sample the bag or other receptacle should be clearly numbered, or else a numbered ticket be inserted. The latter method is preferable if there is any danger of salting. All details of each sample should be entered with the reference number in the sampler’s notebook, on the spot, at the actual time of taking the sample, and should generally be accompanied by a sketch-section, also made at the time, giving the position relative to some known point.

The results obtained by sampling should be carefully recorded for reference. It is by no means common to find records that have been well kept. At one mine the sampling results are filed carelessly on slips of paper; at another, a bewildering array of columns and figures are inclosed in a library of leather-bound volumes. In such books are specified the date of taking the sample, the number of the level or stope, as well as of the sample, the sampler’s name, the thickness of reefs, the thickness of waste, the total, thickness of reef, the total thickness of waste, and so on ad infinitum— in fact, so much indigestible detail that the main issues are obscured.

In both of the cases above described any required information is readily obtained if those responsible for the records are at hand. What is wanted, however, is a record that explains itself, just as a merchant’s book shows clearly the nature of that merchant’s business to an examining auditor.

In a mine in which numerous samples are taken daily, it is desirable that particulars of these samples should be recorded at once, in order that they be not lost or forgotten, and that the assays should be done and the results entered up as soon as possible, so that the latest sample-details are available at the earliest possible moment for those whose business it is to know them. For the purpose of recording these particulars a sort of sample day-book should be kept in the office, in which is entered the sampler’s name, the date, the number of the sample, and such details with regard to the latter as may have been obtained. This day-book should have the pages numbered so that it can be referred to in the stope- or development-sample record-books. Postings, of essential summaries only, to the latter books should be made from time to time. By this system the record-books are not obscured by unnecessary details, while further information, if required, can be obtained at once by referring to the day-book. The data in the day-book would, of course, be arranged chronologically, and the record-books should have as their basis of reference the locality from which the samples were derived.

In sampling-memoranda, distances should be referred to common starting-points when possible. This is not always done, and it is by no means rare to find books in which one sample-section is described as being 13 ft. east of, say, peg 25 W, while the next section is measured from some other peg, or even from a pillar. However lucid such observations may be to the sampler, they convey little information to others.

At the foot of every page the number of sections and the totals of such columns as can be added should be entered. These totals will be found to save much work in estimating the ore-reserves.

Clearness and simplicity should be a characteristic of the records thus described. At some mines a special clerk, known as the sampler’s clerk, attends to the records, thus enabling the samplers to devote more attention to the careful taking of samples.

Pictorial information is, perhaps, best supplied to the records by means of the continuous-section method, an excellent system that has been well described by M. H. Burnham. This method of illustration shows readily the position of the pay-rock in a drive or stope-face. The drawing need not be so elaborate as to preclude its insertion in the record-book alongside of the written data.

Record-books, however excellent, are not the best means of conveying geological information, and it is not easy to picture the distribution of ore-shoots by their aid. This is best done by means of the assay-plan.

The object of the assay-plan is largely to separate the sheep from the goats—to point out payable and unpayable zones. The assay-plan generally conveys most information when made on the plane of the reef. On the Rand very neat assay-plans are made, though in many mines there is a tendency to crowd the plans with individual assays. Payable blocks should be tinted with a slight wash of distinctive color. While in some mines there is a prejudice against indicating values by tints, other mines, on the contrary, have plans resembling Joseph’s coat, each grade having its own special shade. The latter extreme seems unnecessary, since the figures should tell their own tale, the distinction between “ payable” and “ unpayable” being usually a sufficiently graphic illustration.

As soon as ground has been blocked out and included in ore reserves, the value of these blocks should be plainly indicated on the assay-plans. All faults and dikes should be shown on the plan, and it is sometimes advisable to indicate important changes of the foot- or hanging-wall.

The computation of average value from assays has been thoroughly discussed recently by Mr. Crosley, T. A. Rickard, and others. That the somewhat crude methods of averaging sample- values at present in vogue are not theoretically precise has been proved beyond doubt. At the same time the exact rules governing the deposition of ores remain unknown. Let it also be remembered that the present “ inch-dwt.” method of taking a geometrical mean has been proved to yield an excellent approximation in averaging stope-values. Some of the reasons why faulty estimations of ore-reserves are so frequent will be referred to later. The present geometric-mean method is also very widely used, and to abolish it would be to condemn the method by which most of the world’s gold-mines have been valued. As the case now stands, the exact method of averaging sample-values yet remains to be discovered. All known methods yield only approximate results, which is not surprising when one reflects that each sample often represents more than 100 tons of ore blocked out. We therefore prefer to use for the present the simple “ inch-dwt,” method, which, after wide usage, has proved fairly satisfactory, to other methods, which are more cumbersome, less used, and which have not yet been shown by practice to give a greater approach to accuracy.

The problem of dealing with abnormally high assays is of lasting interest. The general consensus of opinion is that abnormal values should not be retained. From experience we consider the best plan is to obtain the average value including the abnormal assays, and substitute the value thus obtained for the abnormal one, and again average. Some definite method, such as the above, of dealing with abnormally high assays might well be adopted at every mine. The practice of rejecting a high

assay in order to insert a haphazard low one is not satisfactory. In every case the method followed should be stated.

In the case of missing sections, such as a section where it is impracticable to sample the reef, but where the reef is known to exist, we suggest that the missing section should be taken (having regard to the known presence or absence of ore-shoots or local enrichment and allowing accordingly) to be the mean of sections of equal length on either side, such length, unless the special circumstances of the case demand otherwise, being at least equal to the length of the gap. Supposing that it was impossible to sample a drive for 20 ft., the value of that 20-ft. length would be taken to be the mean value of the two 20-ft. lengths bounding it on either side, provided always that the reef is shown to exist in the section.

When one of the adjacent sections is an exceptionally rich ore-shoot, it is obviously impossible to apply any hard and fast rule.

Ore-Valuation

In the valuation of the ground developed, the ore should be divided into blocks of “ payable ” and “ unpayable ” value.

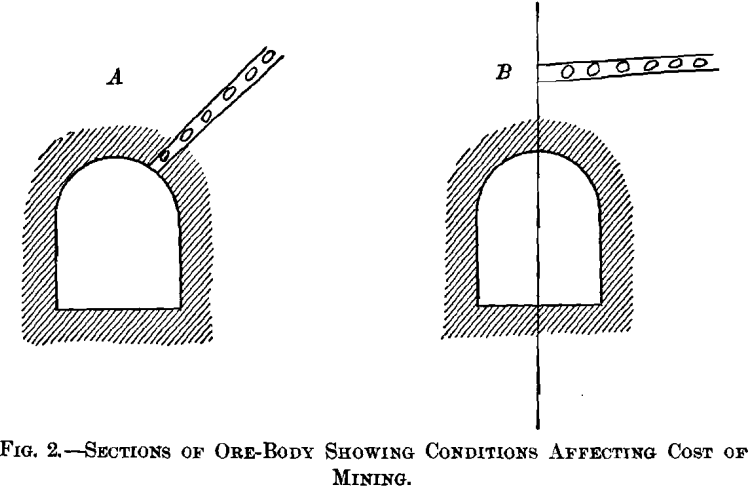

The actual grade which is to be classed as payable depends upon the circumstances existing in the mine itself and the working-conditions of the district. Local conditions in the mine will sometimes vary materially. For instance, in a district in which working-costs average about 17s. 6d. a ton, a 3.75-oz. 2-in. reef may be payable in one case and not in another, as is shown in Fig. 2, A and B. In the former, A, a comparatively narrow (say 30-in.) stope could be carried and the ore would gravitate readily into the level; in the latter, B, owing to the flatness of the pitch, a large amount of waste would probably have to be mined with the reef, and much labor be expended in transporting the broken ore. The above example emphasizes the fact that it is often desirable to use different factors for different blocks, instead of taking a constant factor of payability for the whole mine. It is not always easy to draw a sharp line of demarcation and to divide all the developed ground into payable and unpayable blocks. Sometimes several high assays occur together in poor tracts of ground, and sometimes bunches of poor ores are found in rich blocks.

In dividing the payable ground into blocks consideration should be given to the placing of future stopes, so that the management will know readily how to attack the ground from the various working-faces in order to maintain a certain grade of ore. In estimating the grade likely to be obtained from a block of ground which is traversed by dislocations, it must be remembered that in carrying a stope through normal faults much waste may be mined, which will lower the grade. This fact is not always borne in mind, since many computators deduct a percentage from the tonnage for faults, without altering the grade, In practice the tonnage is usually increased in such a case owing to the waste that is mined along the break, and the grade is thereby impoverished. On the other hand, it may sometimes be possible to improve the grade (and lower the tonnage) by arranging pillars in the poorest ground.

One of the most important questions in ore-valuation on narrow deposits is that of the probable average stoping-width. On the Rand assumptions of width have almost invariably been too narrow. In one case, a stoping-width of 30 in. was assumed where 2-ft. of the hanging-wall a little above the reef was so loose that it would obviously have to be broken with the latter. It is hard to understand why a desire to minimize the stoping-width should so often be found. Owing to this practice, a mine which has been rated by development-sampling as, say, a 12-dwt. proposition, too often turns out 9-dwt. rock. Moreover, in the case of certain mines the mining-costs are burdened at the outset with a higher charge per ton for development-redemption than necessary, owing to the lower tonnage estimated on the basis of an impractically narrow stope-width.

It is perhaps only just to add that in some cases the estimated width was probably sufficient, but the stopes were subsequently carried unnecessarily wide owing to careless mining. In assuming a stoping-width, not only the minimum to which the ground can be made to break must be considered, but also the amount that may subsequently come away as the face advances. This latter amount is frequently considerable, and unless it is used for filling it generally finds its way to the mill sooner or later. Mr. Way estimated the amount of this waste material at 12 in., but it is inadvisable to assume any arbitrary figure for all cases, since the scaling will be negligible in some cases and considerable in others; and it will also differ in hand- and machine-stopes, being naturally greater in the latter.

Concerning the amount of ore likely to be sorted out, this question should be considered in the case of each block when assuming its milling-width. The too common practice of assuming one uniform stoping-width and a constant sorting-factor for the whole mine, regardless of the variations of dip, nature of the country-rock, or reef thickness, is to be deplored.

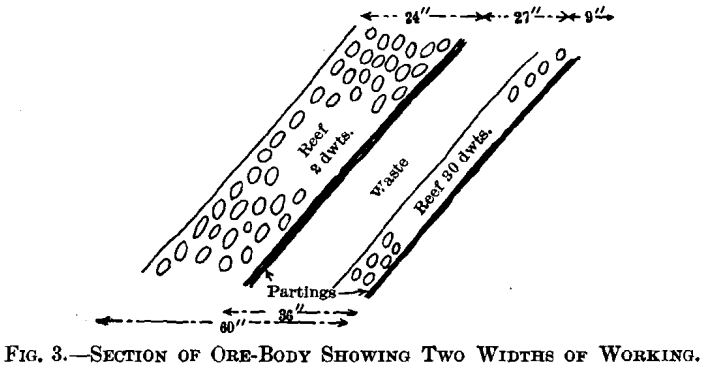

In the case of very wide reefs it is necessary to decide whether it will not be more profitable to work only a portion instead of stoping out the whole width. Fig. 3 illustrates a case in which a choice is offered between mining 36 in. of 7.5-dwt. ore or 60 in. of 5.3-dwt. ore.

Problems like those referred to in this paper have to be considered before ore-reserves are calculated, and they demand for their solution a thorough knowledge of mining conditions acquired by sound technical training coupled with wide practical experience.

In conclusion, no hard and fast rules are advisable for ore valuation, except in one or two cases, and in the main these rules are inappropriate for trained mining engineers. However, it is desirable that in formulating hypotheses reason and method should be observed, and that assumptions, when made, should always be stated, so that opinions may be formed of their value.