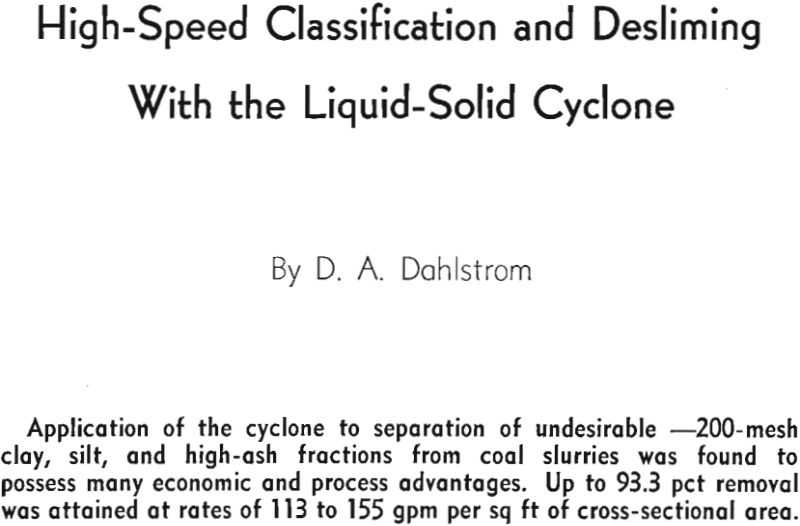

Table of Contents

- Hydraulic Water Cyclone Theory

- Test Results

- Industrial Correlations

- High Speed Classification and Desliming with the Liquid-Solid Cyclone

- Cyclone Possibilities in Desliming

- Test Procedure and Equipment

- Judging Desliming Efficiency

- Test Results

- Hydraulic Water Additions

- Desliming Efficiency

- Industrial Correlations

- Desliming Capacities

Ordinarily slimes have been classified as ranging from 75 microns, or 200 mesh, down to colloidal dimensions of less than one micron. At the same time there is general agreement that the most troublesome slimes are primarily clays, silts and extreme fines, so that the actual top size may be placed at approximately 30 to 40 microns. This immediately restricts any Desliming Cyclone operation to classification, as screening or other methods would be both uneconomical and grossly inefficient at such dimensions.

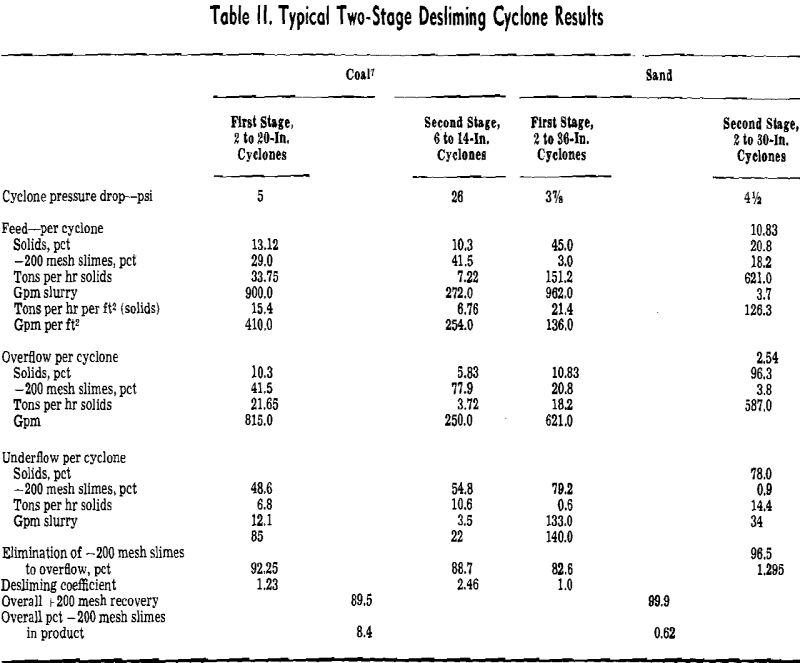

In cases where feed solid loading is high or pressure available is low, it may be more expedient to utilize a two-stage process. In this instance the overflow from the primary cyclones is fed directly or through a pump to secondary units where the remaining desirable solids are deslimed.

In many desliming processes on fine solids, slime removals of 80 to 90 pct are unsatisfactory. Two predominant reasons can be cited for the higher restrictions. 1—In today’s market, there is an ever-increasing demand for higher purity in fine solids, necessitating slime removals of higher than 95 pct. 2—Because of water shortages, waste water disposal restrictions, or high clay percentages in the run-of-mine solids, circulating water slime contents must be held at a relatively high level in many preparation plants. Thus it is not uncommon for the slurry fed to a desliming operation to have a slime content in the total solids of greater than 30 or 40 pct.

Hydraulic Water Cyclone Theory

From experimental evidence and a mathematical study he proposed that radial flow into the cyclone core between overflow and underflow ports is uniform at any radius within the cyclone. Thus radial velocity at a radius ri, lying between the overflow and underflow nozzles is independent of elevation. Furthermore, he hypothesized that after a fluid particle reached a certain plane near the apex of the cyclone, it could then no longer return in a path towards the overflow but must be discharged in the underflow. The location of this plane is directly proportional to the percent of feed volume reporting to the underflow.

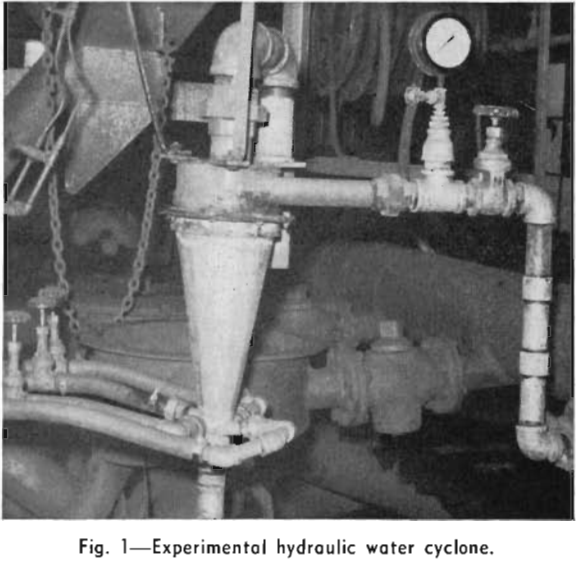

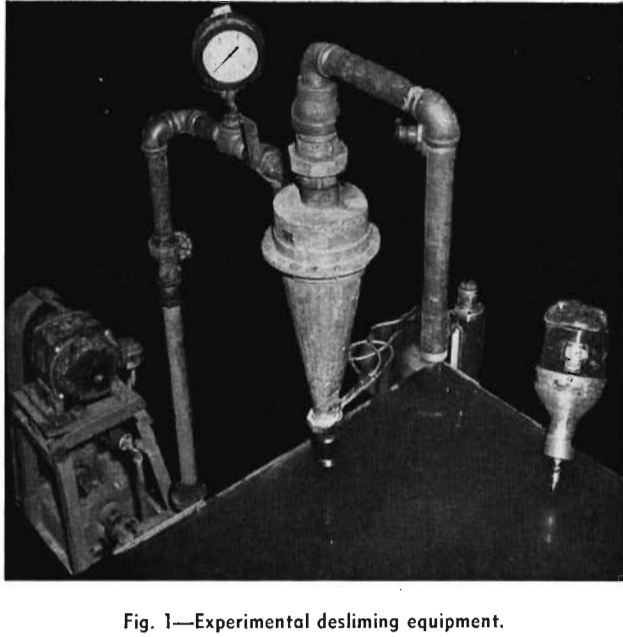

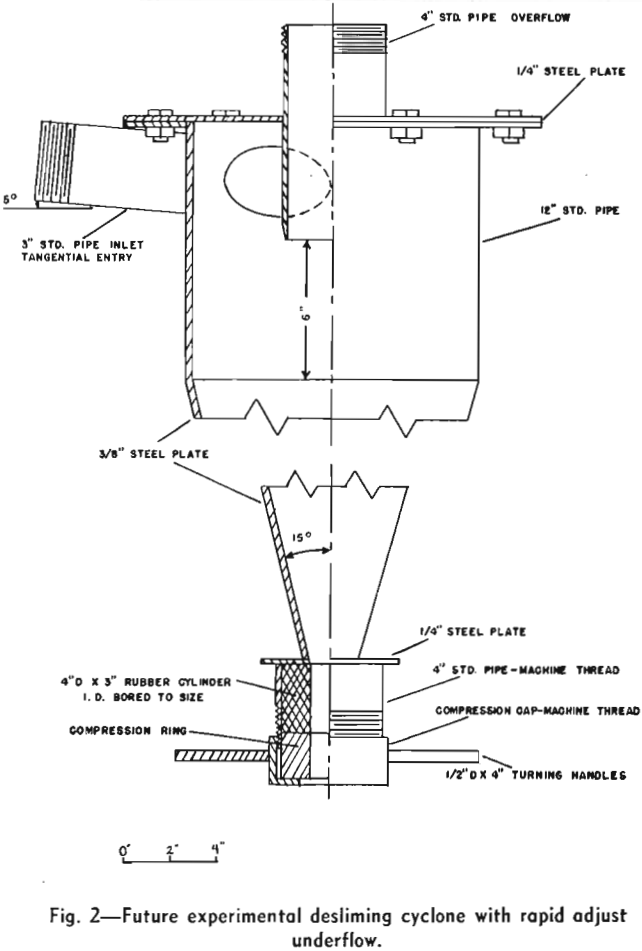

To test the proposal, a 9-in. cyclone of galvanized sheet metal was constructed with a 2-in. standard pipe feed entry and a 2½-in. I.D. copper tubing overflow. The included angle was 20°, and interchangeable underflow cones were made of different lengths so that any underflow diameter could be obtained. Four standard 1-in. pipes were brazed to the unit at 90° around a circle normal to the cyclone centerline near the apex.

At the Fiatt Plant the —200 mesh fraction could not be considered as containing only slimes. There are small quantities of pyrite, calcite, sand, and high-ash coal which are of near 200 mesh size. Thus to eliminate these by classification would entail severe losses of coal up to 30 or 40 mesh in size. Naturally this cannot be tolerated, and such particles must be removed by other cleaning methods.

Test Results

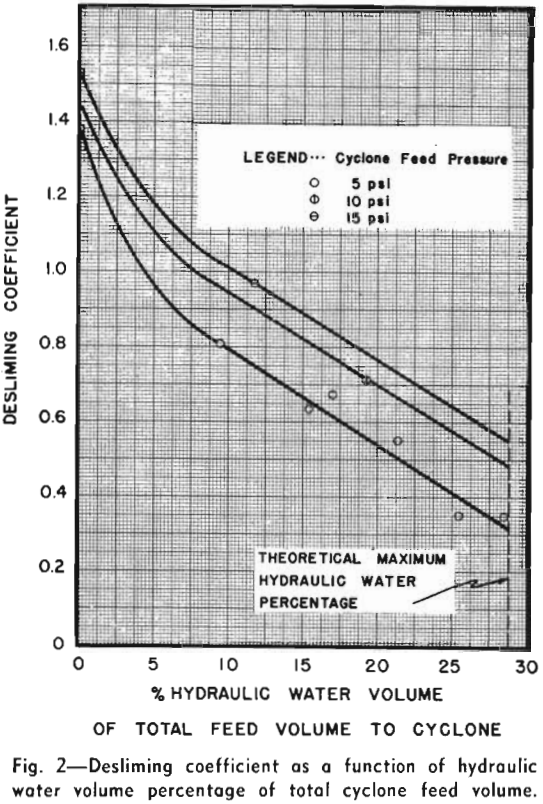

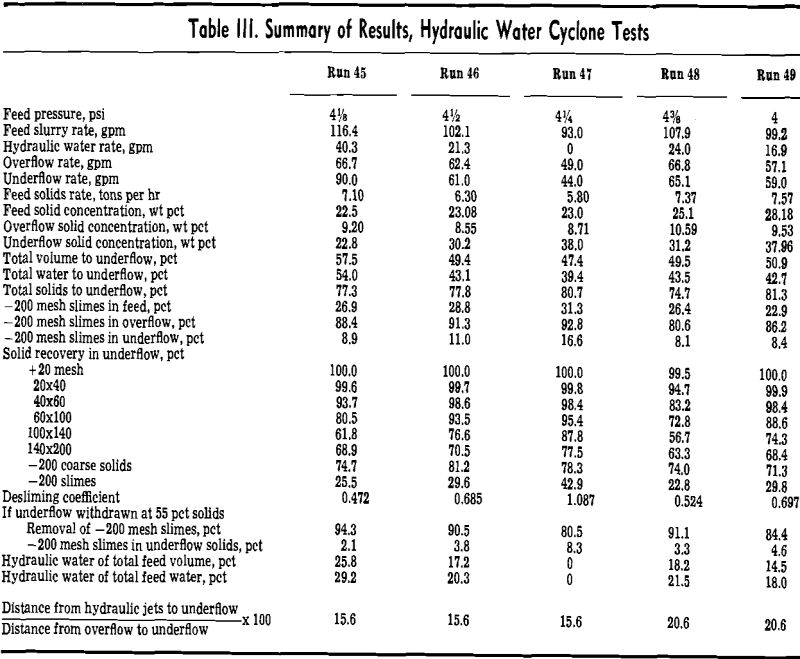

The unit was first installed on the circulating water line of the plant where cyclone feed pressures up to 15 psi could be obtained by use of a throttling valve. Several preliminary runs were first made to determine the feasibility of the hydraulic water design. Results indicated desliming coefficients could be lowered to less than 0.35 with only about 25 pct of the total feed water, that is, slurry water plus hydraulic water, being fresh water additions. Such operation would permit elimination of 93 pct or better of all slimes fed to a cyclone.

This result apparently substantiated the original hypothesis that the hydraulic water additions were largely replacing rather than diluting the slime- bearing water. To add weight to this conclusion a series of tests were made at constant cyclone nozzle dimensions and a feed pressure of 5 psi with varying amounts of hydraulic water rates.

To establish the significance of the above results, some important background material must first be discussed. The distance between overflow and underflow nozzles in this series of tests was 24¼ in. with the top of the hydraulic water nozzles located on a plane 7 3/8 in. above the underflow. According to the cyclone radial flow theory previously mentioned, (7 1/8 ÷ 24¼)100 30.4 pct of the total feed volume, which is slurry plus hydraulic water, will pass this plane.

The hydraulic water cyclone was next installed on the underflow line from the fine coal settling cone to obtain additional data. Unfortunately the solid concentration in this feed slurry ranged from 22.5 to 28.18 pct by weight, necessitating volume splits in excess of 31 pct to the underflow with no hydraulic water additions to the cyclone. As larger underflow nozzles had to be used to accommodate the greater volume rate at this port, the hydraulic water jets were only 15.6 or 20.6 pct, depending on which of the two possible insert cones were used, of the overflow-underflow distance away from the underflow.

Industrial Correlations

A commercial installation of the hydraulic water principle has just been made to deslime a high-quality chemical sand. Contamination must be less than 0.5 pct slimes to meet purity restrictions. A two-stage cyclone process was necessary because of heavy feed solid loading and available pressure drop. Two primary 36-in. diam cyclones were designed to handle 1000 gpm of slurry containing 45 pet solids at 37/8 lb per sq in. pressure drop.

Hydraulic water jets were added to the primary cyclones to lower the slime content. Because of fabrication difficulties, the jets could not be added on a plane normal to the cyclone cross-section but rather were placed at calculated points along the slant height of the conical section to achieve a displacement action.

High Speed Classification and Desliming with the Liquid-Solid Cyclone

Within the past decade, certain economic, legal, and technological changes have intensified the necessity for an efficient classifier or deslimer of particles at and below the 200-mesh point. First, mechanization of mining has increased the percentage of clays, silts, refuse, and high-ash material in the run-of-mine coal. Second, many washing plants must rely on smaller percentages of fresh make-up water because of shortages, economic factors, or legal restrictions on waste water disposal. Finally, the crushing of middlings and coarse refuse plus the trends toward the finer sizes in sales has further increased the amount of fines produced per ton of mine-run coal.

Cyclone Possibilities in Desliming

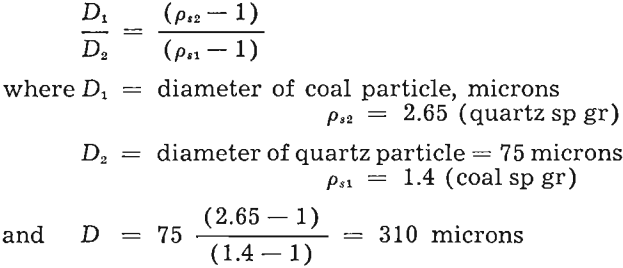

To overcome the disadvantages of present desliming methods, it is necessary to use a device that exhibits a very stable and uniform flow pattern while greatly increasing the settling velocity of

the 200-mesh particle. Fortunately, the inexpensive cyclone containing no moving parts possesses both of these qualities. Basic operation and design principles have been well formulated by several authors. The desired symmetry and uniformity of velocity gradients within the cyclone have already been established by Criner. For one specific gravity material each diameter particle will have a definite radius within the cyclone where concentration occurs. At this point the centrifugal force acting on the particle caused by the tangential velocity, radius of curvature, and particle mass is exactly balanced by the opposite frictional resistance forces due to the radial flow of the fluid past the particles toward the cyclone core. Both forces increase with a decrease in radius of curvature, but the former at a higher rate. Thus, particles coarser than the mesh of separation for the classification will tend to congregate at radii equal to, or less than, the cyclone radius, while finer particles are concentrated primarily at radii approximating the magnitude of the cyclone overflow.

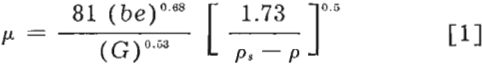

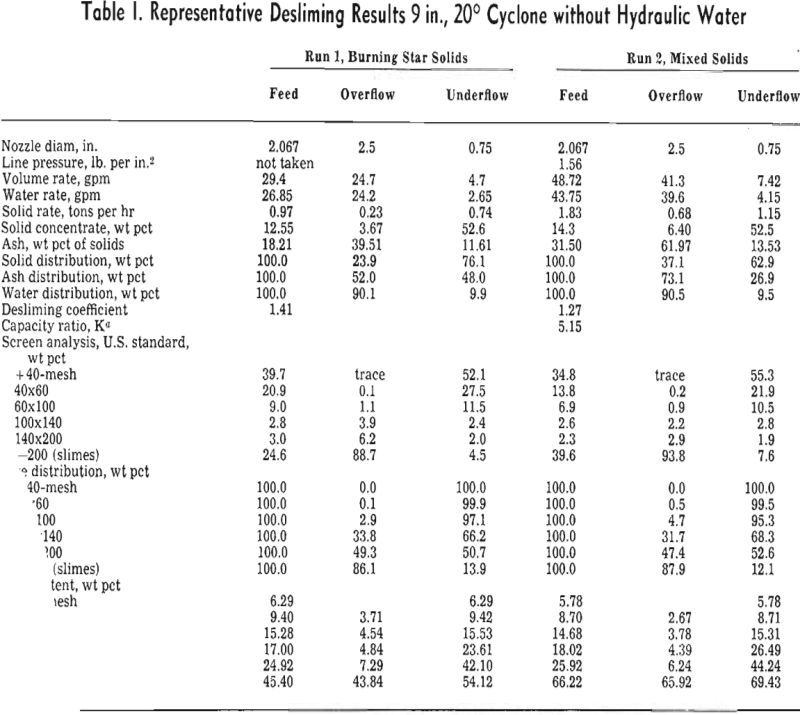

Some method must be found to estimate cyclone design, nozzle dimensions, and feed rates for a desliming operation. An equation for the prediction of the 50 pct point (the particle size that reports in equal weights to underflow and overflow streams), which is another name for the critical separation size or mesh of separation used in classifier terminology, had been previously obtained as

for a 20° cyclone with a vortex discharge. The expression is applicable to cyclone design but is so far only valid for high efficiency cyclones with 50 pct points from 8 to 30 microns. These particles appear to act according to Stokes’ law under the conditions of operation, while those near the 200-mesh size will definitely deviate from this law under the increased gravitational force. Until experimental work now in progress is completed, which should develop an equation which will predict separation values accurately for desliming purposes, eq 1 must serve as a good first approximation in estimating cyclone dimensions and rates for desliming design.

Test Procedure and Equipment

To test desliming possibilities, a 9-in. cyclone was selected which had been utilized in a previous study. The unit possessed interchangeable inlet, underflow, and overflow nozzles, and included angle, permitting investigation of all previously mentioned variables. It was decided to use the largest overflow and inlet nozzles (2.5 and 2.067 in., respectively) for the base comparison tests since this would give maximum aid in raising the 50 pct point predicted by eq 1. Furthermore, a better idea of capacity per unit area would be available. Also in eq 1, from experience, specific gravities of the —200-mesh fraction containing slimes and high-ash coals will run 1.7 to 2.0, so that an average value of 1.85 was selected. A fluid density of 1.0 was assumed, although this would have to be altered if high-solid-concentration feeds were used.

Probably slightly higher feed rates can be used as any deviation from Stokes’ law would tend to increase the 0.5 exponent of eq 1. Accordingly, most test work for maximum elimination of —200-mesh material was conducted at input volumes of 45 to 60 gpm.

Judging Desliming Efficiency

Some basis or standard must be designated in order to judge efficiencies properly. When no fresh or hydraulic water is introduced to any deslimer,

maximum elimination of a particle size to the overflow will occur when no concentration of that size takes place within the unit. The particle size then will report to the overflow and underflow stream in the same weight ratio as the water split. In this study, it is desirable to reject all the —200-mesh fraction possible, as it has been designated a slime. Thus, the first basis of desliming efficiency will be the comparison of water and —200-mesh split between overflow and underflow. Therefore, a term entitled “desliming coefficient” was used, which is merely the quotient of the percent of feed —200- mesh solids found in the underflow divided by the percent of total water reporting to the underflow. It would be desirable to make the coefficient approach zero for perfect desliming, but with no addition of hydraulic water, 1.0 will be the minimum value. While this coefficient accurately illustrates the efficiency of slime elimination under the condition of operation, it is by no means the only element to consider. Other factors, such as loss of desirable +200-mesh material to the overflow, moisture content of underflow solids, water split to underflow, feed solid concentration, cyclone capacity, and any other important operating conditions, must be given conjunctive treatment.

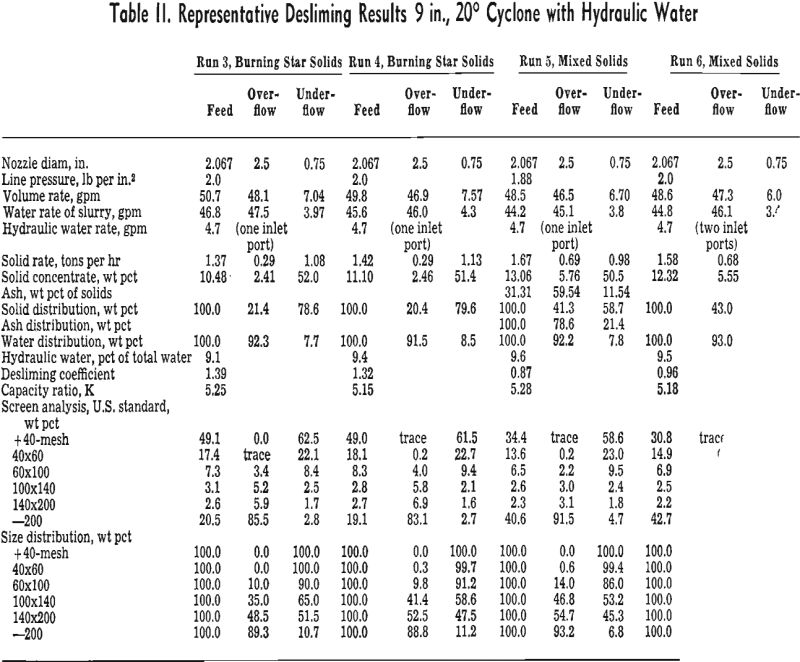

Test Results

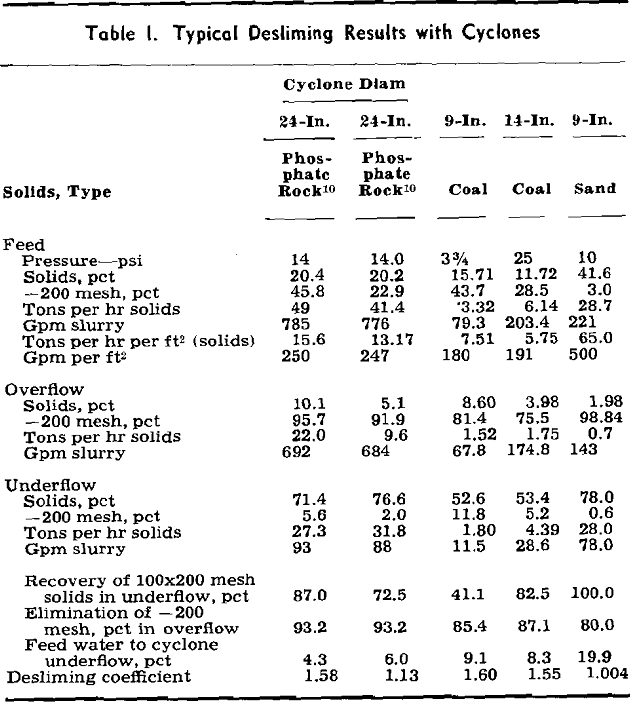

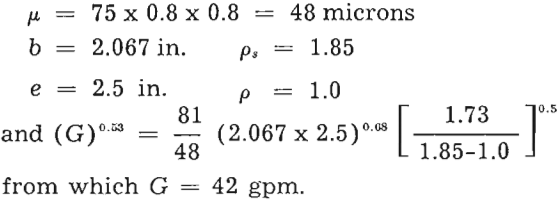

Relatively little concentration of the —200-mesh fraction in the underflow occurred as shown in Table I. Desliming coefficients of Runs 1 and 2 were 1.41 and 1.27 with the elimination of 86.1 and 87.9 pct of the slimes, respectively. Water splits were less than 10 pct to the underflow with moisture contents of both underflow solids at about the probable maximum. The higher desliming coefficient (thus the poorer desliming efficiency under operating conditions) of Run 1 was believed primarily due to the larger content of heavy quartz, calcite, and pyrite grains present near the 200-mesh size in the Burning Star solids.

Appreciable amounts of 100 x 200-mesh low-ash coal are lost to the overflow as indicated by size dis-

tribution between underflow and overflow streams and ash analysis tests. This is due to the classification ratio phenomenon previously discussed and must occur with even the best hydraulic classifier. As a rule, the —100-mesh coal fraction represents a relatively small weight percent of the total coal, and this loss is considerably more than offset by the advantage of large slime reduction at the high capacity of the cyclone.

Hydraulic Water Additions

It is impossible to lower the weight distribution to the underflow of a nonconcentrated particle to less than the water split to the same stream for the cyclone under present methods of operation. However, if fresh water could be added, it might be possible partially to replace underflow slime water with new water and thus further reduce slime content. According to the theoretical and experimental work performed by Criner, any fluid that reaches a certain vertical point with respect to cyclone underflow cannot reverse its path at the inner spiral but must be discharged through the underflow. The vertical distance of this point is furthermore hypothesized to be only the product of the linear distance between overflow and underflow times the fraction of total feed volume reporting to the underflow. Thus, it would seem logical to introduce fresh water slightly above this level.

Desliming Efficiency

In order to indicate qualitatively the effect of previously mentioned variables, several tests were performed, varying only one factor for each run. For the former variable, feed-solid concentration of the mixed solids was increased over Runs 2, 5, and 6 by approximately 100 pct without altering cyclone underflow diameter and other important design and operating factors. Run 7 was executed without addition of hydraulic water and should be compared for stability of performance with Run 2. It was indicated that heavy media and hindered settling effects were pronounced because of the high feed-solid content of 24.9 pct and an overloaded underflow discharge. The effect of the latter factor, which can be eliminated by an adjustable underflow nozzle, will be discussed under Run 9. Because of these phenomena, large percentages of 40×100-mesh material were lost in the overflow, but the desliming coefficient was reduced from 1.27 to 1.12. Only 11.9 pct of the —200- mesh fraction remained in the underflow with a solid concentration of 59.6 pct. However, it must be remembered that, while the desliming coefficient is improved by heavy solid loadings, higher percentages of water must accordingly be withdrawn in the underflow, resulting in approximately the same percentage removal of slimes as with the lower feed-solid concentrations.

Run 8 was similar to Run 7 with the exception of an addition of hydraulic water amounting to 9.4 pct of the total water entering the cyclone. Comparison of results with Run 5 indicates almost the same relationships as between Runs 7 and 2. The desliming coefficient was reduced to 0.74 with a retention of only 6.8 pct of total slimes in the underflow stream. When rejection of slimes was increased over Run 7, loss of the coarser sizes in the overflow was also slightly augmented.

Industrial Correlations

Correlation of the above work with industrial data is made very difficult by the lack of such information upon actual desliming processes at the 200-mesh point. There is only one coal operation of which the author is aware being conducted on cyclones with the specific intent of rejecting all —200-mesh mate¬rial possible to the overflow. Furthermore, literature data on other desliming methods on coal slurries are nonexistent.

The pilot plant operation at the Ceredo, W. Va., tipple of the Truax-Traer Coal Co. has been desliming a feed stream obtained from high levels within the raw coal cones by use of a 14-in. cyclone. A detailed discussion will be found in Sutherland’s paper, from which Table VII has been obtained, to illustrate cyclone performance. It will be observed that the desliming coefficients are relatively good (1.075-1.61) even though capacities are approximately three times that used on the 9-in. 20° cyclone, with comparable nozzle dimensions. The maintained desliming coefficient at the higher rates was caused by two important factors pointed out in the previous experimental work.

Desliming Capacities

An empirical equation based upon experimental work and industrial correlations for any cyclone operating with a vortex underflow has been advanced in a previous article.

Gpm/√F = K (be)0.9…………………………………………..[2]

The proportionality constant is a function only of included angle, separation between overflow and conical section, and minor design deviations. Values of 5.48 and 4.82 were found for the 20° and 30° cones, respectively, used in these tests. Assuming eq 2 as valid, K values were calculated for the various runs as indicated in the tables. For the 20° cyclone, the K’s were very consistent with the exception of Run 9. In this case, over 45 pct of the volume reported to the underflow, which undoubtedly resulted in a different flow pattern and also represents an industrially inoperable condition. Eliminating Run 9, average K for the 20° cone was 5.35, or only 2.4 pct below that for the higher pressure cyclone. Average value for the 30° cone on two runs was 4.31, or 10.6 pct deviation from the previous result. This small deviation is probably due to the increase in importance of wall friction when low centrifugal fields are used. If this latter force is high, practically all inlet energy is consumed in overcoming fluid friction to create a high rotational kinetic energy. It should be noted at this point that the K value of the 30° cone can be increased (and thus decrease energy requirements per gallon of slurry pumped) by separation of overflow and conical section. Previously it was demonstrated that by a separation of 6 in., K value of the 30° cone equaled or bettered the 20° cone value.