Table of Contents

When Hugh Lee Pattinson discovered, in 1829, that the crystals formed during the slow cooling of molten lead were poorer, and the remaining liquid richer in silver, than the original lead, an important step was made in the metallurgy of this metal. Being the first process applicable to the desilverization of low-grade lead bullion, it soon found its way into all European countries having such a product to treat, thereby effecting the saving of many ounces of silver annually which previously had been thrown away. The old hand process was expensive, as viewed from the standpoint of more modern methods; the labor was great and the tonnage was small, but on the other hand the results were fairly satisfactory.

This process flourished for some time after the introduction of the cheaper Parkes process in 1852 and it is still in use in a few European smelteries.

Only one notable improvement was made on the original process, that of Luce and Rozan at Marseilles, France. It consisted in the application of steam for stirring and the tapping of one-third of the liquid lead, through perforated plates covering the tap holes flush with the bottom of the kettle, thus leaving two-thirds in the form of crystals in the original kettle. This modification considerably lowered the operating costs as it permitted of much larger kettles, an increased tonnage and eliminated much of the slow, hard labor of the hand process. The Luce and Rozan process has persisted in its original form to the present day.

Stephen Tredinnick, English born, spent most of his years around the Luce and Rozan plants at Marseilles and elsewhere in Europe, coming later to Eureka, Nev., in 1878, to operate the Luce and Rozan plant at that point.

Mr. Tredinnick was a competent Luce and Rozan operator and being devoted to the process he firmly believed that with modifications the costs could be so lowered as eventually to supplant the Parkes process.

Out of many schemes he decided that this could be accomplished by placing the Luce and Rozan kettles upon hydraulic rams so that each kettle could be raised or lowered at will. He accordingly took out patents to cover this idea.

As Mr. Tredinnick’s age and infirmities incapacitated him for active service, the writer was commissioned by a large lead refinery to design, erect and place in operation a plant of the Tredinnick-Pattinson type.

Working on refined desilverized lead from the Parkes process, carrying variable percentages of bismuth, two objects inspired the installation: First, to produce a large tonnage of refined lead low enough in bismuth (0.05 of 1 per cent.) for corroding purposes; and, second, a small tonnage in which the major portion of the bismuth would be concentrated so that it might be recovered by further treatment in the Betts electrolytic process, all of which constituted a step in metallurgy hitherto untried.

After considerable experimental work, it became evident that in order to produce a large tonnage of corroding lead at one end of the plant and at the other end a small tonnage of anode lead carrying 1.0 per cent, of bismuth from a refined lead supply carrying 0.33 per cent, bismuth, an 11-kettle plant would be required with the charge-lead going into the eighth kettle from the corroding end.

As the operation of such a plant would resemble a train of gear wheels, inasmuch as the breaking down of one unit would stop the entire plant, it was necessary to make decided changes in the Luce and Rozan equipment so that all parts from the kettle down could be quickly replaced.

In the Luce and Rozan operations the crystallizing of the kettle required about 1 hr., and the melting of the 30 tons of crystals resulting from the operation required about 2 hr., thus 3 hr. were required to an operation.

It was evident that such speed would be fatal to our requirements and that it would be necessary to crystallize and tap in about 30 min. and melt 42 tons of crystals in about 45 min. This was eventually accomplished in the first instance by increasing the steam pressure from 45 to 110 lb., thus permitting the more copious use of water for cooling down, and in the second instance by an efficient application of fuel-oil heating. The increase in steam pressure necessitated a different and much stronger type of steam valve and a secure anchorage for the baffle plate at the bottom of the kettle.

As each kettle would be raised and lowered 7 ft. at frequent intervals, the air, water and oil connections would, of necessity, be flexible rubber and metallic hose and the steam, fume, and smoke connections of a telescoping type.

Thus it will be seen that this plant necessitated a considerable departure from the Luce and Rozan as regards equipment and methods of operation, as the liquid lead would be tapped directly to the next kettle to be operated, thus avoiding the use of auxiliary melting pans.

In this paper, I will omit mention of the mechanical difficulties encountered, although they were numerous, describing only the strong and simple final construction.

Equipment Used to Remove Silver

The completed 11-kettle plant contained the following:

- Eleven stands of Pattinsonizing kettles having a working capacity of 63 tons each and placed in a line at 12 ft. centers;

- One 180-ton storage furnace receiving refined lead direct from the Parkes process refining furnace;

- One 150-ton molding furnace for the corroding lead coming from No. 1 kettle in frequent taps of 21 tons each;

- One 42-ton anode molding kettle for the high-bismuth anode lead coming from No. 11 kettle in occasional taps of 21 tons each;

- One 150-ton dross-reducing furnace;

- One oblong spout kettle, filled with hot lead, for heating the tapping spouts, the spouts being kept therein until needed;

- One 18-ton ladle for charging molten lead from the holding furnace into the charge kettle, which is usually No. 8.

All of the above equipment was covered by a 25-ton traveling crane which was used primarily for charging molten lead to the process, and secondarily for the replacement of broken kettles and other heavy equipment. (A defective kettle can be removed and a new one installed in 20 min.)

Each stand consists of a 63-ton kettle and combustion chamber inclosed in a brick-lined steel casing having an I-beam base, all superimposed upon a hydraulic ram 26 in. in diameter with a 7-ft. stroke. These rams are connected with a pump and accumulator and operate under a pressure of 500 lb. per square inch. Thus any kettle can be raised and lowered at will, by means of a Critchlow valve, and its contents tapped to either adjacent kettle (Fig. 1).

Each kettle is supplied with a special steam valve which enters the side close to the bottom and terminates under the center of the heavy baffle plate which is 45 in. in diameter, being perforated so as to secure as equal distribution of the steam as possible throughout the lead mass (Fig. 2). This steam valve is so constructed that it can be replaced in a few minutes. The steam is carried to the valve through a telescope pipe connection at a pressure of 110 lb.

Each kettle is provided with a truncated cone cover having four working doors. Four inches above the top of the cover is placed a circular ¾-in. water pipe, 24 in. in diameter, having eight equally spaced 3/32-in. holes on the under side for introducing water into the kettle by means of funnel cups which pass through the cover. The water connection to the stand is a ¾-in. hose 9 ft. long. The water and steam are both controlled by the operator on the second, or kettle floor.

Each kettle cover has a 13-in. round opening and collar in the center connected by a telescope pipe to a sheet-metal flue. This flue is provided with an 8-ft. exhaust fan running at 300 r.p.m, whereby a strong draft is created to remove the waste steam and lead oxide dust from the top of the kettle,

Heat is applied by three fuel-oil atomizers equally spaced around the casing and operated on an oil pressure of 40 lb. per square inch and a blast pressure of 24 oz. The oil is connected to the stand by a ½-in. metallic hose 9 ft. long and the air by a flexible 2-in. suction hose.

The waste gases from the oil combustion are drawn off at three equally spaced openings by a horseshoe pipe around the top of the casing and provided with a telescope pipe connection to an underground smoke flue. This smoke flue is provided with a 48-in. fan running at 440 r.p.m. and serves to draw the flame well up around the sides of the kettle, thus providing equal heat to its entire surface.

Method of Operating

In the hand Pattinsonizing, it was possible, with very low-grade bullion, to dip out as much as seven-eighths of the contents of the kettle as crystals, leaving one-eighth remaining as liquid, although the more common practice was to remove two-thirds as crystals, leaving one-third liquid behind. In the Luce and Rozan process, as the crystals remain in the kettle and the liquid is tapped out through screens which hold the crystals back, it is not practicable to thicken to more than two-thirds crystals and effect a good separation. Therefore, there was no choice but to follow the custom of thirds and make 42 tons of crystals and 21 tons of liquid at each operation.

How to Operate a Desilverization Plany

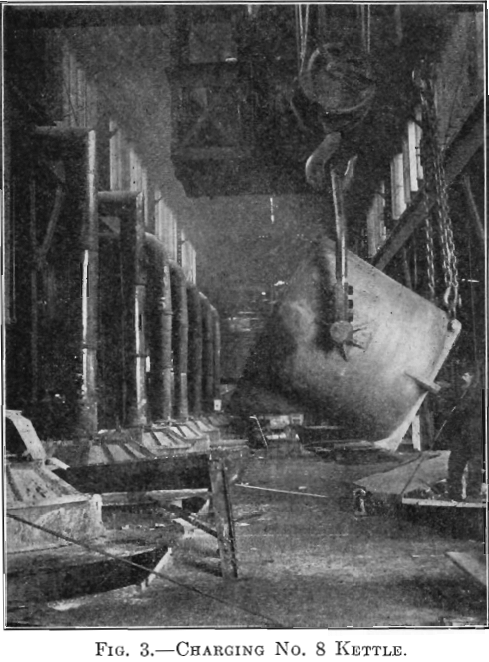

Assuming that the supply of lead is fairly constant as to its bismuth contents, the periodical charge of lead to the plant will always be made

in the same kettle. In the present instance this would be the eighth kettle from the corroding end of the plant (Fig. 3).

In order to place the plant in operation, each kettle must contain a certain tonnage of lead with a fixed percentage of bismuth depending upon the position of the kettle in the string. That the process may be continuous, the kettles must be crystallized according to some definite system, as otherwise the plant would soon be in a serious muddle which would require considerable time to straighten out. Two such systems are possible, each permitting of numerous variations, and have been designated the Tredinnick system and the Newnam system (see Fig. 4 and 5).

If the plant is correctly charged to begin operations, according to either system, it is evident that the first operation will change the distribution of the lead in the plant, as will each additional operation, and a

fixed number of operations must be performed before the plant will work back to its original state.

This period of operations is termed a cycle, and, charging in No. 8 kettle, two types of cycles are possible. The first, or single cycle, is that in which one tap of anode lead is made during the period, and the second, or double cycle, that in which two taps of anode lead are made before the plant returns to its original condition.

When the plant is in such a condition that the 9th, 10th and 11th kettles are not operated, the work on Nos. 1 to 8 is called the short string, whereas when these upper kettles come into play the long string is operated.

With the short string, 40 to 50 operations are possible in 24 hr., while, with the long string 70 to 80 operations can be made in that time.

As very few persons on this continent are acquainted with Pattinsonizing operations, a detailed description thereof will be necessary to make the accompanying cycle diagrams intelligible. I will first describe the Newnam system (Fig. 4) as that is the easiest to follow, using the following conventional figures to illustrate the process.

The following diagram will represent an 11-kettle plant as it stands at the beginning of a double cycle, operating on the Newnam system.

No. 1 kettle is full (63 tons) of melted crystals ready to crystallize. Kettles Nos. 2 to 10 inclusive are each two-thirds full (42 tons) of melted crystals, and No. 11 kettle is empty. The percentage of bismuth in each kettle is indicated below the kettles and represents the approximate grade at which they should be maintained. All charges to be placed in No. 8 kettle.

The plant stands as follows:

No. 1 kettle is now crystallized, the kettle elevated and 21 tons of liquid are tapped into No. 2 kettle, making it a full kettle. The 42 tons of crystals in No. 1 kettle are melted and 21 tons are tapped to the corroding lead-molding furnace, thus completing operation No. 1.

The plant stands as follows:

No. 2 kettle being full, it is now crystallized and 21 tons of liquid tapped into No. 3 kettle, filling it. As soon as the 42 tons of crystals in No. 2 are melted the kettle is again elevated and contents tapped to No. 1 kettle, filling the latter and completing operation No. 2.

The plant stands as follows:

Kettles Nos. 1 and 3 now being full, it is evident that these two kettles may be operated at the same time, requiring two crews. As the first crew progresses up the string, the second crew would follow behind and as close up as melting of the crystals would permit. In actual practice, usually two or three kettles intervene between the two crews. In order to avoid confusion in the cycle diagram, the work of the two crews is shown in alternating lines; thus, the first crew works out the string marked Series A after which the second crew works out the Series B although, as stated, in actual practice they follow as close behind one another as plant conditions will permit.

Returning to the last diagram, the first crew will successively crystallize the kettles 3 to 10 inclusive and the operation on No. 10 will place 21 tons of liquid into the empty kettle No. 11. In each case the melted crystals are tapped toward the corroding end.

The plant will stand as follows:

The first crew has thus made 10 operations on the long string, Series A. The second crew now begins on No. 1 kettle and, in like manner, successively operates the kettles Nos. 1 to 9 inclusive and the operation on No. 9 will place 21 tons of liquid into the empty kettle No. 10.

The plant will stand as follows:

The second crew has thus made nine operations on the long string Series B, and the first crew now returns to No. 1 kettle to work out its second string, or Series C. Owing to the necessity of correcting the grade of the kettles, as explained later on, a variation of the procedure now takes place in Series C. During this series none of the melted crystals are tapped toward the corroding end but are left in their original kettle, with the exception of the crystals in No. 1, 21 tons of which instead of being tapped to the corroding furnace are tapped into No. 2 kettle, and the plant stands as follows:

The second crew returning to the corroding end to work out its short string, Series D, is obliged to pass over kettle No. 1 and begin operations on the full kettle No. 2, thus proceeding straight up the line with the operation on No. 8 kettle placing a second tap of 21 tons of liquid in No. 9 kettle. As all crystals on this series are tapped back as usual, and as this will leave the charge kettle No. 8 empty, it is in order to give it a 42-ton charge.

The plant stands as follows:

No. 8 having been charged, the Series E will now be run out by the first crew, and it will be observed that the operation of No. 8 will fill kettle No. 9 which must then be worked, placing an additional 21 tons of liquid in No. 10, or 42 tons in all. Therefore, at the close of Series E by the first crew the plant will stand as follows:

The second crew now begins its 17th consecutive operation with kettle No. 1 of the Series F, at the conclusion of which the plant will stand as follows:

As No. 9 was not operated in Series F, there were no return crystals to No. 8; therefore, the second charge of 42 tons was introduced into that kettle.

On Series G the correction for grade is again made by omitting the corroding tap and running 21 tons of No. 1 crystals into No. 2 kettle.

The plant is steadily worked according to the above plan until the end of Series N, when the plant stands as follows:

As the 9th, 10th and 11th kettles now contain 42 tons each, it is evident that the operations on Series O will include all kettles from 1 to 11 inclusive and that 21 tons of anode lead will be tapped from No. 11 kettle into the anode molding kettle. As the correction of grade occurs at this time, none of the crystals produced on Series O will be tapped back, and at its termination the plant stands as follows:

The first crew will now run out the last string of the cycle, Series P, operating all the kettles from No. 2 to 11 inclusive and placing a second tap of 21 tons of anode lead into the anode kettle. All the crystals having been tapped down the line, at the termination of this series the plant returns to its original condition, as first shown, and a new cycle begins.

During this cycle the following operations were made:

As four corrections for grade were made during this period, 138/4 or 34½ represents the number of operations made for each correction in grade. On the cycle shown, corroding lead was made in sets of two consecutive taps between corrections; now should these taps be made in groups of one, three or four, an entirely different cycle would result, necessitating a separate diagram for each instance.

During the period, the ingoing and outgoing lead was as follows:

Dividing these tonnages by the total number of operations, 138, the tons of lead charged and produced may be expressed as follows:

In order to handle the same tonnage and obtain the same results by the Tredinnick system, an entirely different procedure is necessary. Whereas in the Newnam system each series is worked out by one crew,

in the Tredinnick system each series is split up between the two crews and in order to understand its workings the series must be shown in two parts. The condition of the kettles at the beginning of a double cycle is entirely different, and the plant, ready to operate, stands as follows:

Observe that there are four full kettles, Nos. 1, 3, 5 and 7, and that Nos. 8, 9 and 10 contain 42 tons each while Nos. 2, 4, 6 and 11 are empty.

The first crew operates in the following order: No. 7, No. 5, No. 3, No. 1. All resulting crystals are tapped down the line, 21 tons of No. 1 crystals being tapped to the corroding furnace. At the end of the first half of Series A, the plant stands as follows:

The second crew will now work successively Nos. 8, 9 and 10, placing 21 tons of liquid in No. 11. They will then operate in order Nos. 6, 4 and 2 and the plant stands as follows:

The first crew now returns to No. 7 and works successively Nos. 7, 5, 3 and 1, 21 tons of crystals being tapped to the corroding furnace from No. 1 kettle. At the end of the first half of Series B the plant stands

as follows:

The second crew will complete Series B by operating kettles 8 and 9, placing 21 tons of liquid in the empty kettle No. 10 and then operating in order Nos. 6, 4 and 2.

The plant stands as follows:

Series C is now run out by the first crew taking the kettles 7, 5, 3 and 1 and then the second crew the kettles 8, 6, 4 and 2. As a result of this series, 21 tons of liquid are placed in the empty No. 9. Since preparation for correction of grade begins at this point, the tap to the corroding furnace is omitted, and the crystals in 8, 6, 4 and 2 are not tapped back.

The plant stands as follows:

Now the 21 tons of liquid in Nos. 7, 5 and 3 are tapped respectively to Nos. 8, 6 and 4 and 21 tons of crystals in No. 1 are tapped back into No. 2, and the plant stands as follows:

The first crew now operates Nos. 8, 6, 4 and 2 and the resulting crystals being tapped back as usual, Series D is terminated and the plant stands as follows:

As No. 8 kettle is now empty it must receive a charge of 42 tons. With slight variations the foregoing procedure is repeated until the plant returns to its original condition, which will take place at the 64th operation of the second crew.

The above double cycle produces the following data:

A comparison of the two systems may be summed up as follows from the two cycles shown:

From an inspection of the above figures, it would seem that the Tredinnick system has decided advantages in every respect. But with the material on which we were experimenting we found it necessary periodically to make a correction for grade. We also found that the necessity of skimming kettles one-third full of lead was a laborious task, and if not properly done the bottom of the kettles soon took on a heavy coating of litharge most prejudicial to the heating and to the life of the kettles.

In overcoming these disadvantages, we worked out the Newnam system, and found that with our particular class of work its relative simplicity more than offset the advantage of the Tredinnick system. Other plants might have a different experience and might find the Tredinnick system superior.

Grade of Kettles

Each kettle in the string has its own particular grade, as determined by experience, and it must be maintained at that grade to insure the production of corroding lead from No. 1 kettle crystals.

https://www.911metallurgist.com/effect-zn3ag2-desilverization-lead/

The grade of a kettle is governed by the bismuth contents of the mixture of one-third liquid and two-thirds crystals going to fill that particular kettle. It is manifest that this should be the same at all times, but this is far from being the case, and thereby serious complications arise.

As the liquids all travel toward the anode end of the plant and all the crystals travel toward the corroding end, it is evident that if one kettle becomes overgrade it will communicate that effect to its neighbors and a correction of some kind will be necessary.

Owing to the natural percentage of enrichment of bismuth in the liquid lead by crystallizing, there is a decided tendency for the grades of all kettles between the corroding end and the charge kettle to increase steadily. This insidious tendency has been termed the “crawl.”

The following semi-mathematical exposition of this “crawl” will clearly show its cause and effect.

The average percentage of bismuth in the liquid from any operation is about 1.4 times the percentage of bismuth in the kettle charge before crystallizing. Although not strictly true, it has been the custom to call this 40 per cent, enrichment.

The average percentage of bismuth in the crystals is about 0.8 times the percentage of bismuth in the kettle charge before crystallizing. In like manner, this is spoken of as 20 per cent, impoverishment.

For the sake of simplicity, consider the effect of this 40 per cent, enrichment on one kettle only and it will be evident that this applies to any kettle between No. 1 and No. 11, except that the kettle considered, No. 8, has a partial correction made to it every time it receives a charge of new lead, hence the crawl is not so constantly accumulative in No. 8 as it is in any other kettle.

Assume that No. 8 is charged with lead containing 0.300 per cent. Bi.

Crystallize the kettle of 63 tons which will furnish:

No. 7 with 42 tons of crystals carrying 0.240 per cent. Bi.

No. 9 with 21 tons of liquid carrying 0.420 per cent. Bi.

It is legitimate to assume, at this point, in the next series of operations up the line that No. 6 will furnish:

No. 7 with 21 tons liquid carrying 0.240 per cent. Bi.

The kettles stand thus:

Now crystallize No. 7, which will furnish:

No. 8 with 21 tons liquid carrying 0.336 per cent. Bi.

No. 6 with 42 tons crystals carrying 0.192 per cent. Bi.

Charge No. 8 with 42 tons, of lead at 0.300 per cent. Bi; the average contents of No. 8 will then be 63 tons carrying 0.312 per cent. Bi.

Crystallize No. 8 which will furnish:

No. 9 with 21 tons liquid carrying 0.437 per cent. Bi.

No. 7 with 42 tons crystals carrying 0.250 per cent. Bi.

Observe that the liquid from No. 7 to No. 8 is 0.336 per cent. Bi, or 12 per cent, higher than it should be. This before it has been subjected to the influence of any of the higher kettles. It is therefore correct to say that the liquid from No. 6 to No. 7 will increase 12 per cent, every time the operations proceed up the line. Hence, as No. 7 is approached the next time, No. 6 will furnish:

No. 7 with 21 tons liquid carrying 0.268 per cent. Bi.

The kettles will stand thus:

Crystallize No. 7 which will furnish:

No. 8 with 21 tons liquid carrying 0.358 per cent. Bi.

Charging No. 8 kettle with 42 tons lead at 0.300 per cent. Bi; it will contain 63 tons of lead carrying 0.319 per cent. Bi.

Crystallize No. 8, which will furnish:

No. 9 with 21 tons liquid carrying 0.446 per cent. Bi.

No. 7 with 42 tons crystals carrying 0.225 per cent. Bi.

No. 9 now contains 63 tons of lead at 0.434 per cent. Bi, which crystallized will furnish:

No. 8 with 42 tons crystals carrying 0.347 per cent. Bi.

As No. 7 is approached the next time, No. 6 will furnish:

No. 7 with 21 tons liquid carrying 0.300 per cent. Bi.

The kettles will stand thus:

Crystallize No. 7 which will furnish:

No. 8 with 21 tons liquid at 0.378 per cent. Bi. It will now contain 63 tons carrying 0.357 per cent. Bi.

Crystallize No. 8 which will furnish:

No. 9 with 21 tons liquid carrying 0.500 per cent. Bi.

No. 7 with 42 tons crystal carrying 0.286 per cent. Bi.

As No. 7 is again approached, No. 6 will furnish:

No. 7 with 21 tons liquid carrying 0.336 per cent. Bi.

The kettles will stand thus:

Crystallize No. 7 which will furnish:

No. 8 with 21 tons liquid carrying 0.422 per cent. Bi.

Charge No. 8 with 42 tons of lead at 0.300 per cent. Bi, and it will contain 63 tons carrying 0.341 per cent. Bi.

Crystallize No. 8 which will furnish:

No. 9 with 21 tons liquid carrying 0.477 per cent. Bi.

No. 7 with 42 tons crystals carrying 0.273 per cent. Bi.

As No. 7 is again approached, No. 6 will furnish:

No. 7 with 21 tons liquid carrying 0.376 per cent. Bi.

The kettles will stand:

It can readily be seen that this is an accumulative “crawl” and while it is aggravated each time No. 9 is brought into play and in like manner more so when No. 10 and No. 11 are drawn upon, yet it would exist were there no kettles above No. 8. Furthermore, the percentage rate of “crawl” of No. 2 or any other kettle will be the same as that of No. 7.

It is evident that the percentage of enrichment does not fit the method of crystallizing in “thirds” as it does in the case of the enrichment of silver. Compare the kettle grades as they are maintained in the case of bismuth and silver.

It has been shown that with “40 per cent.” enrichment and consequent “20 per cent.” impoverishment, if the impoverished lead from any other kettle be crystallized it will yield a liquid 12 per cent, higher than the grade of the original kettle from which it came. This does not represent the rate of “crawl” proportional to it on account of the charges introduced into No. 8 of proper grade. For the sake of comparison, however, the following table will show what the relative per cent, of “crawl” is for the different percentages of enrichment.

Therefore, the only percentage of enrichment with which there would be no “crawl” would be 100 per cent., which is nearly the case in that of silver, thus in the old Pattinson operations for silver the “crawl” was insignificant.

Correction of Grade

In order to offset the “ crawl,” it is necessary to resort to some mechanical method of correction (at least up to our present knowledge), such as tapping a kettle overgrade to the kettle of next higher grade or to increase the number of crystallizations upon a given tonnage of lead.

This is accomplished by a so-called “jump” whereby a combination of these two schemes is effected but which results in greatly lowering the tonnage of the plant with a corresponding increase in the cost per ton charged.

The “jump” is made by periodically tapping 21 tons of melted crystals from No. 1 kettle onto the 42 tons of crystals in No. 2 kettle and then going straight up the line, without any of the crystals in advance being tapped back. Thus the crystals receive an extra operation and one-third liquid is pushed by successive stages up the line.

The method of “jumping” is shown by the cycle diagrams under “ Order of Operations.”

Table 1 gives the relative tonnages according to the frequency of the “jump” and the kettle receiving the charge.

Experience has shown the necessity of jumping:

In each of the above four cases, two consecutive taps of corroding lead are made between corrections for grade, the operations in each case being similar to those shown in the cycle diagrams.

The following analytical results shown in Table 2 were made on a 10-kettle plant, each determination being made on a sample taken from a full kettle just before crystallizing.

Description of an Operation and Process

A full kettle (63 tons) skimmed clean and ready to crystallize, should have a temperature not much above the melting point of lead, but the brickwork surrounding the kettle should be hot to prevent a crust freezing on the inside of the kettle. Correct temperature is an important factor, as lead too hot greatly prolongs the time of crystallizing and produces an excessive amount of dross. In practice, the lead is tested by thrusting a broom handle into the molten metal; if the lead freezes to the handle the temperature is low enough to proceed with the operation. If the lead does not freeze to the handle the kettle must be cooled down by freezing crusts with water and pushing these crusts under the surface with a pole until the proper temperature is secured. As this also consumes time, it is necessary to keep a sharp watch of the temperature.

https://www.youtube.com/watch?v=AhrwF-uwAE4

The kettle being in the proper condition, the operator opens the steam valve slowly until the surface of the lead is violently agitated. (In order to prevent slop the kettles are filled to within 15 in. of the top only.) Water is now cautiously introduced through the eight water cups on the cover, by a valve close to the steam gear wheel. The operator regulates the admission of steam and water so that a maximum amount of water is introduced without causing explosions, the formation of chunks or the slopping of lead through the cover doors.

The water cups occasionally become clogged with lead and have to be freed by a special punching rod in the hands of the barman.

Lead soon freezes in a crust on the upper ring of the kettle and to the cover. Periodically the water is turned off, the cover doors thrown back and the crusts barred down with a 6-ft. steel bar, 1 in. in diameter, having a chisel point. Considerable judgment must be exercised not to allow the crusts to become too thick, as in this case they are difficult to break up with the steam and tend to form chunks. Also, too frequent barring down consumes time, as the water is turned off during that period.

To facilitate barring down, the inside of the cover and the upper ring of the kettle should be as smooth as it is possible to make them.

Soon crystals of lead, from 1/16 to 1/8 in. in diameter, begin to appear in the bath, and from this point on they multiply with ever increasing rapidity, the violent agitation by the steam keeping the crystals from adhering to one another.

When the consistency of two-thirds crystals is reached, the surface of the lead appears as an exceedingly thick mass of boiling crystals. At this stage the water is shut off, the kettle barred down for the last time and the crusts broken up by steam. Steam is now turned off, the kettle elevated and two hot spouts, just out of the spout kettle, are placed on the double lead cocks. These cocks (which are kept hot with charcoal) are opened slowly and the one-third liquid tapped to the adjoining kettle through a screen in the bottom of the kettle covering the double taps. This screen has 96 holes 3/16 in. diameter, 2 in. centers.

As soon as the last crust is barred down, the burners are fired, and by the time the liquid has run out the temperature is rapidly rising.

It is surprising how accurately a good crystallizer can judge the proportion of liquid and crystals in the finished kettle. A good man will seldom be in error over 2 tons and this inequality may be eliminated on a subsequent operation by slightly over- or under-crystallizing as the case may require.

Under the proper conditions, a kettle can be crystallized in 15 min. An average operation, crystallizing and tapping, requires about 30 min.

It will be noted from the cycle diagrams that any delay on one kettle affects the whole plant. Quick crystallizing and quick melting are therefore necessary to speed and the more rapidly these are performed the fewer kettles need intervene between the kettles being operated, thus permitting of more kettles in operation at the same time.

On the short string, two crews are operating simultaneously, whereas on the long string as many as four crews may be operating.

As soon as the crystals are melted the lead is skimmed and tapped to the opposite adjacent kettle through the single lead cock without a screen. The average melting period is about 45 min. This completes an “operation.”

The kettles near the corroding end are much more difficult to operate than those near the anode end, also the finished kettle at the anode end appears much thicker. In both instances this is due to the crystals near the anode end being larger than those at the corroding end of the plant.

Dross

Dross has been one of the most objectionable features of a Pattinson plant, both hand and steam. In the early stages of the Tredinnick plant, 21 per cent, of the lead charged was skimmed out as dross. This was not only expensive to handle, reduce and recharge, but it also left the lower kettles short of lead and thereby reduced the tonnage materially.

It was found that by throwing small quantities of fuel oil into the kettle on top of the crystals during the melting period that the melting was greatly hastened and a large percentage of the dross formed during the crystallizing was reduced in the kettle.

Handled in this manner, the reducing furnace operates only 4 or 5 days a month, and the lead removed as dross is from 2 to 3 per cent, of the lead charged.

During the crystallizing, about 50 lb. of litharge, fine as flour, is formed, which is drawn off by the telescope fume pipe and caught in the flue. A very strong draft is necessary to keep this fume from blowing out through the cover doors and it is absolutely essential to the health of the men that none of it be allowed to get into the working atmosphere.

Fuel

The fuel requirements of the plant depend upon the number of operations. An average of 50 gal. of fuel oil is required per operation. Of this, 40 gal. pass through the burners and 10 gal. are thrown in the top of the kettle over the melting crystals.

Labor

The accompanying labor table is based on a crew sufficient to keep the operations up to the melting and capable of making from 50 to 70 operations each 24 hr., depending on the number of kettles in the operating line or “string.” Thus, whereas an 8-kettle plant would mean 50 operations per day, an 11-kettle plant would make 70 operations, the number of kettles in the string depending upon the condition of the kettles above the charge kettle. An inspection of the flow sheet will make this point clear.

As this plant was placed in operation at a time when the 10- and 12-hr.

day was in vogue, and as it was necessary to keep the plant working 24 hr. per day and not disturb the labor conditions in other parts of the works, a lap shift was introduced, four men coming on at 9 o’clock and working until 7 on each shift, thus keeping the plant moving between shifts and during the luncheon hour.

This arrangement was necessary, as temperature control is of the highest importance to secure tonnage. When the plant is moving at its maximum rate the temperatures take care of themselves to a great extent, as kettles ready to operate are not allowed to stand, but if for any reason the plant is held up for an hour or more it is very difficult to keep both the brickwork and the lead at the proper point.

Laboratory Experiments

The addition of a third substance or metal was tried in many experiments, in a vain endeavor to find a cheap addition agent that would increase the natural enrichment of bismuth in the liquid.

Out of the many substances tried, tellurium was the only one that had a beneficial influence, but on account of its cost and the difficulty of adding it to the lead it was not available.

Arsenic, tin, cadmium and zinc actually decreased the enrichment, the actions of arsenic being especially harmful.

The small quantity of gold and silver in the charge lead is practically all recovered in the anode metal.

The following shows the distribution of copper in the kettle samples taken after the plant had been in operation for a considerable period on refined lead.

Tredinnick – Pattinson Process as a Desilverizer

Under the heading of “Grades of Kettles,” it was shown that the enrichment in the case of silver is nearly 100 per cent, and that a correction of grade would only occasionally be necessary. It was this ideal natural enrichment that made the Pattinson process a success in its day, and although the Tredinnick-Pattinson process has never been used as a desilverizer, I believe that I am justified, with the figures at hand, in indulging in some speculation as to its possibilities.

As a basis of calculation, I assume that one Tredinnick-Pattinson operation costs $7.50, this including all overhead expense such as insurance, taxes, amortization, royalty, general expense, etc. The average Parkes cost per ton of bullion charged in a moderate-sized plant treating lead of 100 oz. silver, with zinc at a normal figure of 5 c. per pound, is about $4 per ton.

The Tredinnick-Pattinson plant would turn out a high percentage of the lead treated as common lead containing ¼ oz. of silver. This common lead would be suited to the ordinary purposes to which common lead is put but it could not be used as corroding lead in the manufacture of white lead as its copper contents would be prohibitive, as the analytical results given in Table 4 will show.

The small percentage of rich lead varying from 100 to 500 oz. of silver would be best treated by the Parkes process, therefore a combination of the two processes would be in order.

Disregarding the periodical correction of grade and avoiding fractions, Table 5 will show the approximate distribution of tonnage for varying amounts of silver, the kettle into which the charge is introduced and the number of kettles in the plant.

From Table 5 and the costs given above, it will be seen that 4-oz. bullion charged in No. 4 kettle in a 9-kettle plant will require 4.35 tons of charge for each operation in that plant, and the cost per ton would be $7.50/4.35 = $1.72. Again, 0.07 ton of rich lead would go to the Parkes process for treatment at a cost of $0.28 (0.07 x $4), which would bring the total cost of the combination treatment to $2 per ton of bullion charged.

Table 6 shows the probable outcome by applying the foregoing cost figures.

The figures in Table 6 indicate the possibilities for the combination process with bullions assaying between 4 and 60 oz. of silver per ton, but the price paid for fuel oil or gas and the labor rate would have a very vital bearing on the results.

A plant such as described should treat from 150 tons to 200 tons of bullion per 24 hr., and the construction cost of a completely equipped 12-kettle plant.