Table of Contents

Continuously separate mixture of non-magnetic materials (such as scrap, precious metals, or certain ores) at a reasonable cost.

Nonmagnetic materials of different densities are rapidly float/sink separated by an augmented lifting force produced in a magnetic fluid (liquid) by the effect of an external magnetic field. The magnetic fluid is a colloidal suspension of magnetite in kerosene, prepared by a low-cost process.

How Density Separation Works

Separation is accomplished in an open trough filled with magnetic fluid. A magnetic field is established in the fluid, by energizing an electro magnet having poles on each side of the trough. Due to the design of the magnet poles and air gaps, the magnetic field is strongest at the bottom, about 10,000 oersteds, and uniformly decreases in strength to about 2,000 oersteds at the top of the fluid. Therefore, the magnetic field gradient increases with depth.

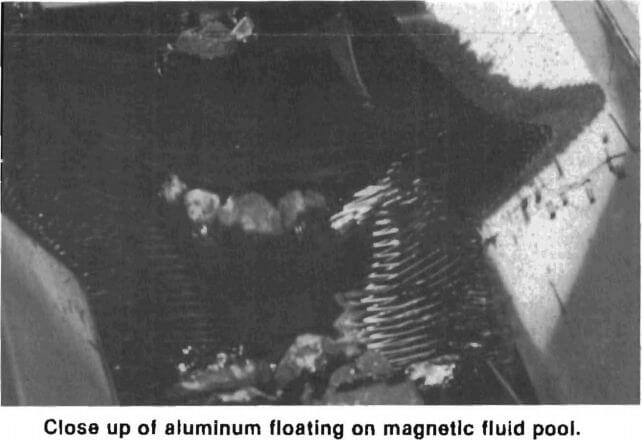

The magnetic force attracts the entire separation medium (magnetic fluid) creating a reaction force of equal magnitude and acting in the opposite direction. This reaction created within a magnetic fluid/magnetic field combination is called a magnetic levitation force. It increases with the field strength. In this case because the magnetic field is strongest at the bottom of the trough, the magnetic levitation force will quickly float lighter material while heavier material sinks.

The separated materials are removed from the trough by two conveyor belts. Sink materials are collected near the bottom while float materials are collected near the surface.

Changing the magnetic field strength, by changing the current through the electromagnet and/or the magnetic strength of the magnetic fluid, allows

matching the density effect to a wide range of applications. Densities from lighter than water to heavier than platinum have been simulated to separate materials over a wide range of density. Unlike conventional heavy liquids that are limited to a specific gravity range of 4.0 to 4.5 these liquids can be extended over a density range from below 1.0 up to 21 or more.

Test Results

After initial testing, a magnetic fluid-separator was built at the Bureau’s Twin Cities Research Center. The Installation was used to segregate shredded automobile scrap containing aluminum, copper, zinc, and lead. This scrap was segregated at rates of 1,000 to 1,500 pounds per hour by the Installation which draws 20kw of electric power. The magnet weighs 8,500 pounds.

The system has also been successfully used by small scrap dealers and secondary metal processors, some of whom have Installed Bureau-type separators. One company has Installed a similar separation facility that upgrades scrap containing titanium. Sorting of mixed scrap metals in magnetic fluid minimizes the need for costly and energy intensive processing and refining steps.

In the most recent Bureau test last year, diamonds were recovered from diamondiferous jig concentrates. Initially, 2,750 pounds of South American gravels were processed to float remove minerals lighter than diamonds. Next, using a higher setting of the magnetic field, 1,170 pounds of sink products were segregated by floating the diamonds from heavier minerals. All separated products were washed in trommels with hot water sprays to clean them, and recover the adhering magnetic fluid for recycling.

Development of both the low cost method for making magnetic fluids and the magnetic fluid separation equipment was done at the Bureau’s Twin Cities Research Center. Project Officers in charge of this research are Mr. George W. Reimers and Dr. Sanaa E. Khalafalla.

Patent Status

United States Patent No. 3,843,540 covering chemical dispersion methods to prepare magnetic fluids from magnetite in kerosene, has been assigned to the U.S. Department of the Interior. Also assigned to this Department is Patent 3,788,465 which covers a means of passing a mix of materials or minerals through a magnetic fluid between the poles of a magnet, and splitting the mix into different paths that are characteristic of their specific gravities.

In the past the Department of the Interior has granted free non-exclusive licenses for some patents to United States companies. For further Information write to the Department of the Interior, Office of the Solicitor, 18th and C Streets, N.W., Washington, D.C. 20240.