Table of Contents

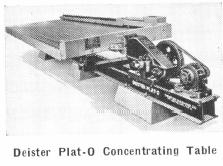

The Plat-O Deister Concentrating Shaker Table exemplifies simple, low cost, high quality equipment for the separation and recovery of the free mineral in ores containing gold, silver, platinum, copper, tin, lead, zinc, iron and other minerals having a similar range of specific gravities.

The metallurgical superiority claimed for this unit over others in the concentration and recovery of minerals is due to three important and exclusive features:

- patented plateau systems;

- patented riffling systems; and

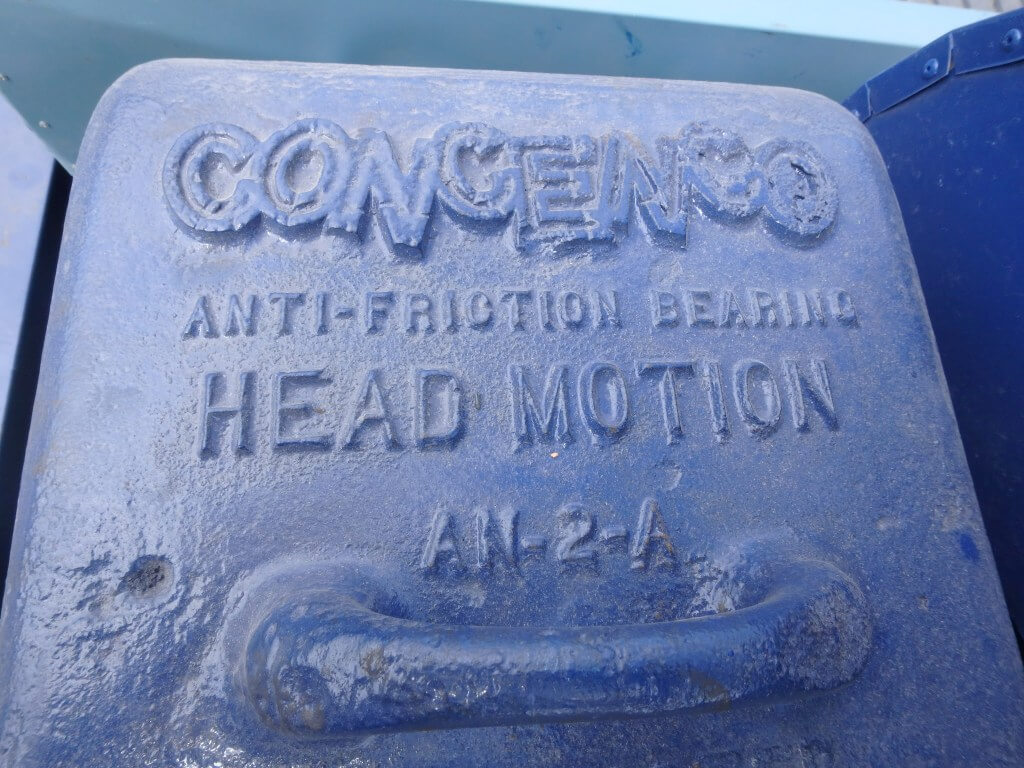

- patented self-oiling head motion for maximum efficiency and low power requirements.

The surface of this type table deck lies in two or more substantially parallel horizontal planes. The lowest plane, extending forward from the feed end, constitutes the greater portion of the deck surface and is known as the stratification and primary concentration zone. The highest plane, known as the plateau, or cleaning zone, extends back from the concentrate discharge end and is connected to the lower plane, along a diagonal line, by a bevelled strip known as the resistance plane. The upward slope of this resistance plane is just steep enough to allow the mineral strata to advance, but at the same time, holds back the upper and sand strata; thus forcing a constant, well defined line of separation between the two.

The standard riffling system on this type table consists of wide, flat riffles, longitudinal to the deck and covering all but the plateau or cleaning zone. These riffles are so spaced as to leave comparatively narrow channels for carrying heavy minerals only, with consequent displacement of the sand from between them; thus causing the pulp to spread out in a thin bed which permits more rapid and thorough stratification of the mineral and sand.

These tables are made in three types: triplex plateau sand table; single plateau fine sand table; and single plateau slime table. Each of these is in turn, by proper combination of riffling, height of plateau, internal arrangement of head motion, rate of reciprocation and length of stroke, assembled for the particular work it is to perform. In all other respects, insofar as general shape, foundation piers, under-construction, and overall dimensions are concerned, the three types are identical.

Standard Deister Plat-O Concentrating Tables are furnished in two different installation types; one for erection directly on concrete piers, and the other on steel longitudinal main channel frames. Further information will be gladly furnished upon request.

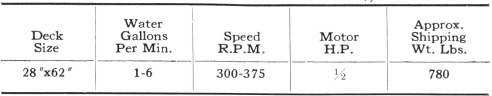

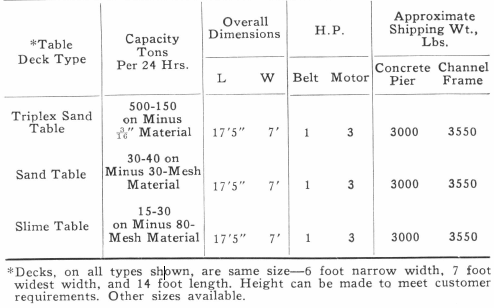

Gold Shaker Table Capacity

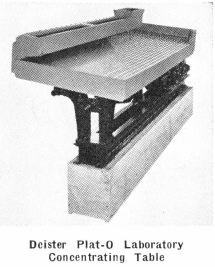

Laboratory Deister Concentrating Table

The Deister Plat-O Laboratory Concentrating Table is ideally suited for treating small quantities of ore in experimental plants and ore- testing laboratories, and for use as a pilot table in large plants. The 28″ wide x 62″ long deck, actuated by a half¬size Plat-O self-oiling head motion, will give results comparable to those that can be obtained with a full size table. This laboratory table is a simple, low cost, durably constructed unit incorporating the latest design features.