Table of Contents

It is generally accepted that no method of coal cleaning except froth flotation is effective in cleaning dust. In the majority of coals mined in the United States the dust sizes contain a high percentage of impurities, hence the removal of the dust from the coarse sizes lowers the impurity content of these sizes. Dedusted coal is desired as a means of providing a better feed to cleaning plants because of increased efficiency in both dry and wet plants.

Dedusting

The practice of dedusting, sometimes called aspirating, has presented a problem in disposing of the dust and intermediate small sizes recovered in the process. It has been found that no difficulty is experienced in disposing of the intermediate sizes, since they are free of fine dust and burn freely on grates built for small coal. They handle well, flowing freely from bins and hoppers and into conveyors, and pulverize easily. They have a low angle of repose. In tests made on this size as a feed to coke ovens, the results have been excellent, in that the natural breakdown of coal in handling and shooting in the mine gives this small-size coal good coking characteristics—producing a strong, fingery coke structure. Deduster dust from Illinois coal has been found to increase the tendency to form a block coke structure at domestic coke plants.

Dust may be used also as part feed to pulverizing equipment for steam production, with a resultant apparent increase in grinding capacity, since most of the dust passes through the pulverizer without grinding. It is necessary that only part of the feed be dust, since dust alone has a tendency to pack and does not handle well alone in bins and conveyors. When mixed with coarser coal it flows freely. Dust may be shipped in railroad cars designed to handle cement, provided facilities are available at destination for unloading and handling the dust.

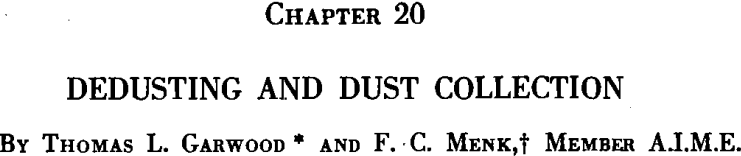

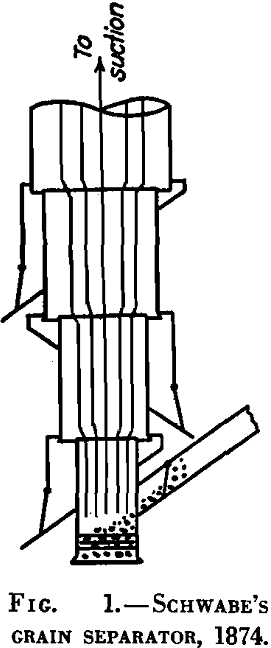

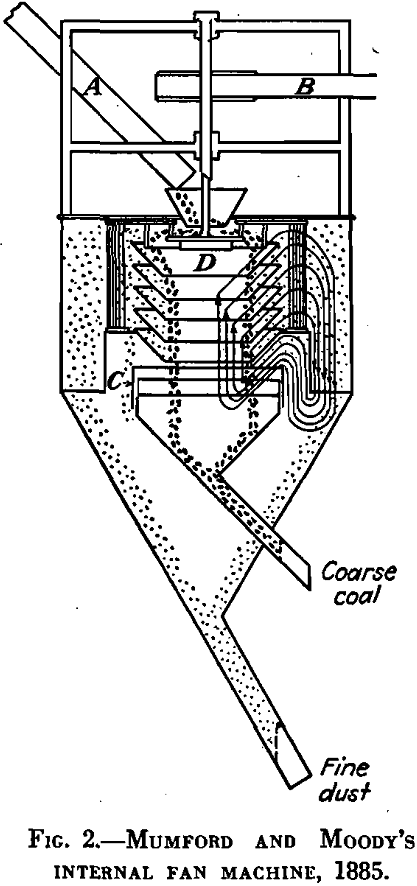

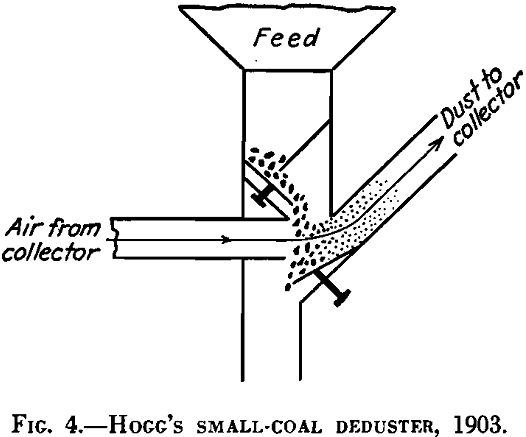

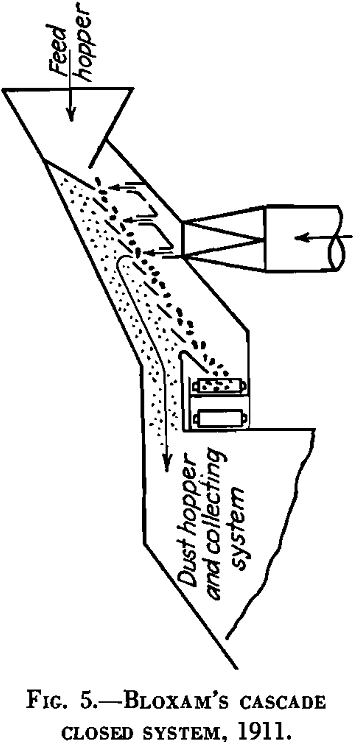

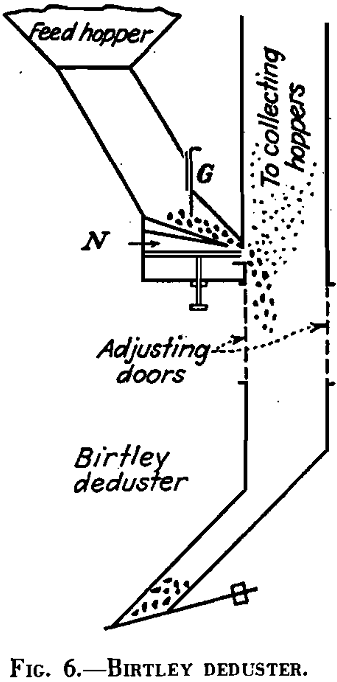

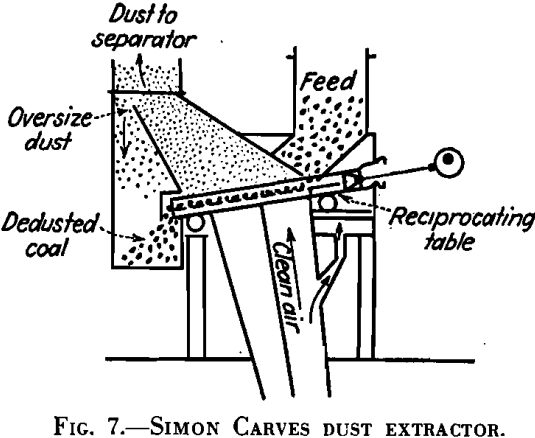

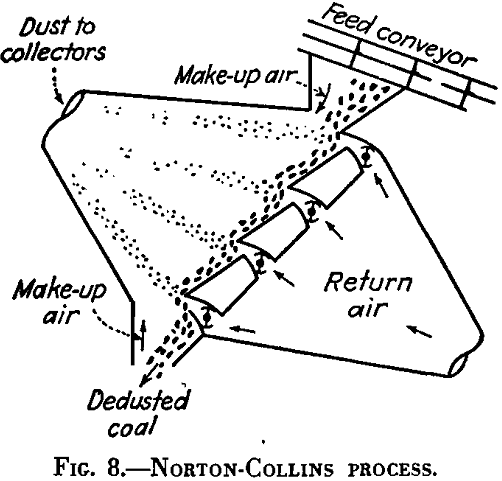

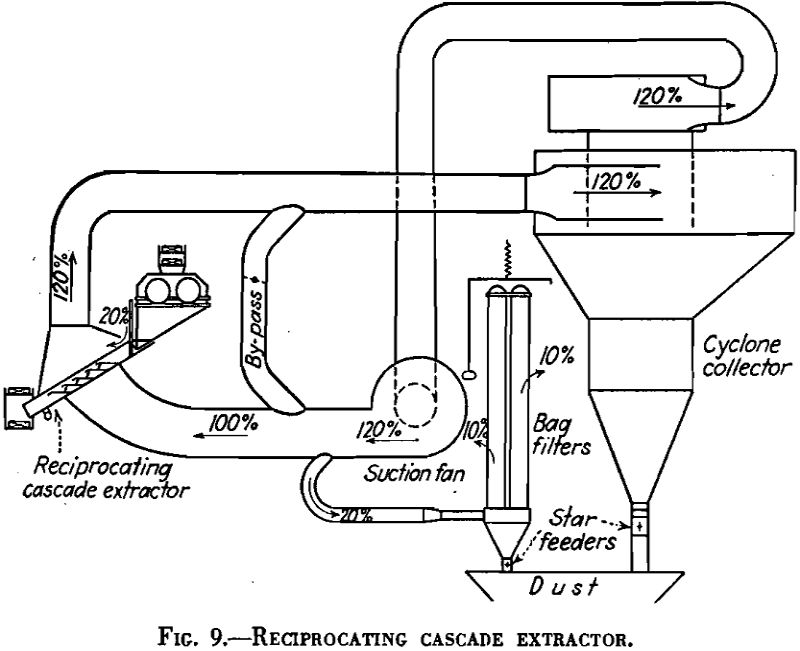

Modern dedusting equipment consists of machines using the principles described, applied singly, in combination, or with variations, in an effort to improve separating efficiency.

The Birtley, a modern system widely used in Great Britain. It is usually operated open circuit with the dedusting chamber under negative pressure. The controlled inlets allow air to pass through the nozzle N, aspirating the coal stream and forming a fluid mass, which flows off the adjustable plate and falls into the dedusting column. Air admitted through the adjustable doors for controlling the volume of air picks up the dust from the falling coal and carries it to dust collectors. The dedusted coal falls into a trap-type hopper at the bottom of the unit, from which it is periodically discharged through the weighted door that seals the outlet.

An alternative arrangement consists of a double-deck extractor, the upper deck being surfaced with screen plate or wire cloth of the desired opening and the bottom deck having the cascade arrangement. By means of this unit the dedusting may be combined with the sizing operation. Where mine-run or other coarse feed is to be dedusted, it is also desirable that the larger material be scalped off on the upper deck, permitting a more sensitive and accurate air removal of dust from the undersized product. This construction usually involves sufficient total weight to justify two balanced, tandem unit-sections, actuated in opposition to each other, in which the second deck only is used for dedusting. The entire machine is set up with the fans on the discharge side of the dust collectors and with the dedusting units under negative pressure, to ensure inward passage of air. Excess air is bled from the system through filters and the duct to the underside of the extraction unit is controlled by a damper, necessary to balance the losses in the filters and to control the flow of air to the dedusting unit.

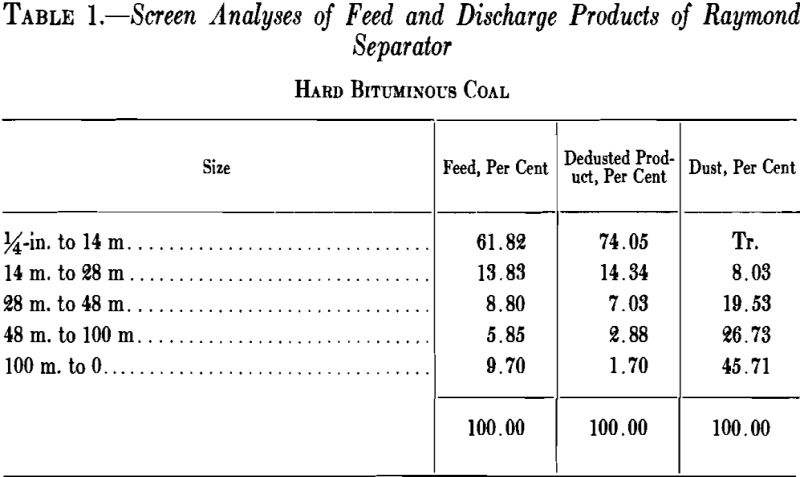

The Raymond mechanical air separator is a totally enclosed, conical unit into which the feed is admitted through an air lock and from which the dust and dedusted products discharge through their respective spouts. In the cycle of operation the coal enters a hollow-shaft, center feed pipe at the top of the separator and drops upon a rotating plate below. The distributor plate throws the material across an open space and the fan in the top chamber creates a large volume of circulating air that sweeps upward through the coal. The air current carries the fines upward and outward and deposits them in the outer chamber. The return air passes back to the inner cone through a series of deflector vanes, setting up a continuous circuit.

The coarse dedusted coal falls freely through the uprising air currents, to be collected in the inner cone for delivery through the coarse spout. Intermediate sized particles are thrown tangentially out of the air stream by radial arms or “whizzers” and travel down to join the coarse particles in the cone below. The deflector vanes aid in unloading the return air before it reverses to pick up additional load of dust. By adjustments that can be made in the separator, the size of the separated dust may be changed.

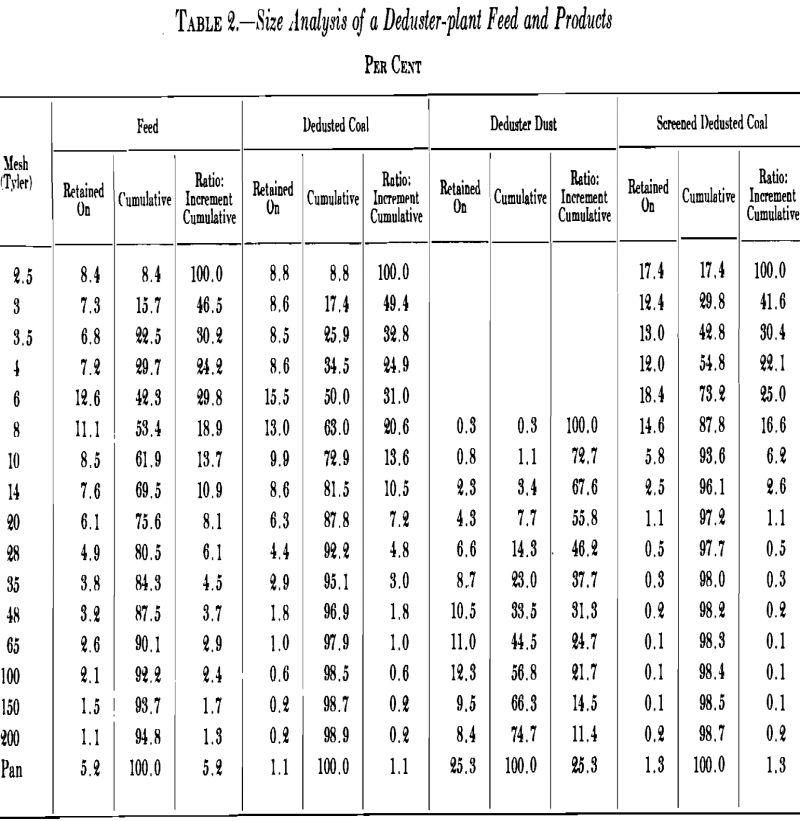

The curve for dedusted coal apparently is made up of two sections of different curvature, and gives an apparent intersection at the point of initial

disturbance. For screening this is found invariably at a point on the curve coinciding with the opening of the screen. Assuming that all the material coarser than that indicated by the point of apparent intersection is identical with the original feed coarser than this indicated size, the percentage of material in the feed that went into this product can be determined easily. The data given indicate that the change occurs just below 14 mesh. It can be assumed that the plus 10-mesh is identical with that of the feed. From the size analysis, 72.9 per cent of the dedusted coal is identical with 61.9 per cent of the feed, and from this relationship (72.9/61.9) calculations show that 118 tons of feed will be required to produce 100 tons of dedusted coal; 84.8 per cent of the feed will be recovered as dedusted coal and 15.2 per cent as dust.

In this plant (a screen-type deduster) the product obtained over the screen may be analyzed in the same manner and curves plotted. The apparent intersection of the curve in this case is at 0.104 in. and, utilizing the valves taken from the size analysis at a point just coarser (6-mesh) a percentage of 73.2 per cent cumulative is obtained. This was derived from the identical part of the feed, and is equal to 42.3 per cent. From the relationship 42.3/73.2, the percentage of recovery of this coal from the feed is 57.7 per cent; i.e., 57.7 per cent is the over-screen product and 27.1 per cent is the through-screen product, 57.7 per cent plus 27.1 per cent equals 84.8 per cent, the dedusted coal recovery, hence 15.2 per cent is the dust recovery.

Dust Collection

Dust usually is measured in microns. One micron is equal to 1/1000 millimeter. Dust particles larger in diameter than 10 microns are visible to the naked eye. For seeing smaller sizes, a microscope is required.

For practical use about American coal-preparation plants, Tyler Standard sieves are used for measuring the size of coal dust. The 200-mesh sieve is equivalent to 74 microns and usually is the smallest used in the industry. Generally coal particles minus 48-mesh (295 microns) are considered dust. A few plants dedust at 28 mesh and a few at 10 and 14 mesh.

Coal dust is formed by cutting, drilling, blasting, grinding, and abrasion in the mine and preparation plant. Coals rich in fusain and of soft structure are much dustier than coals of harder structure, such as anthracite and splint coal. Inherent and surface moisture influence the amount of dust released from coals from different localities or seams.

In the mine, coal dust has always been a source of trouble, danger, and expense. Much experimental work has been done to allay the dust at the source, so that it can be loaded with the coal and hauled out of the mines. These methods include the use of water sprays on cutting, drilling, and loading machines, on haulageways, and at dumping points. Wetting agents added to spray water have been found particularly effective.

Exhaust Hoods

Exhaust hoods installed over all coal-transferring and other producing machinery are desirable. A minimum exhaust-air velocity of 300 ft. per min. over the total opening is effective in preventing the escape of all objectionable dust. For best results, hoods must be very carefully designed to utilize the direction of the air currents produced by the flow of coal and movements of machinery. Since large air volumes are reflected in the rather expensive dust-collecting equipment, it is important to design hoods having minimum opening and strong air motion close to the dust source and yet with sufficient clearance for passage of coal. It cannot be overemphasized that air hoods, cover plates, and air ducts must be arranged for quick and convenient removal, for easy access to machinery and for cleaning purposes. In practice many covers or enclosures have been removed permanently to save the time required for removing and replacing them.

The desirability of this is apparent when one considers that the air quantities required for exhausing from hoods are considerable. For instance, an exhaust hood over a 48-in. run-of-mine belt-conveyor discharge to a screen requires two openings, each about 2 ft. high and 4 ft. 3 in. wide, which at a velocity of 300 ft. per min. require a minimum of 5000 cu. ft. of air per minute to be effective, even though canvas drop curtains are used over the openings.