Bauxite, dolomite, and magnesite are natural occurring minerals that are used extensively in the manufacture of refractory products. In addition, magnesia produced from seawater or brine finds its way into the production of refractories. All of these materials must be processed at high temperatures, 1500°C to 2200°C, to produce an intermediate raw material (refractory grain), which can then be used in the final manufacture of refractory bricks and shapes.

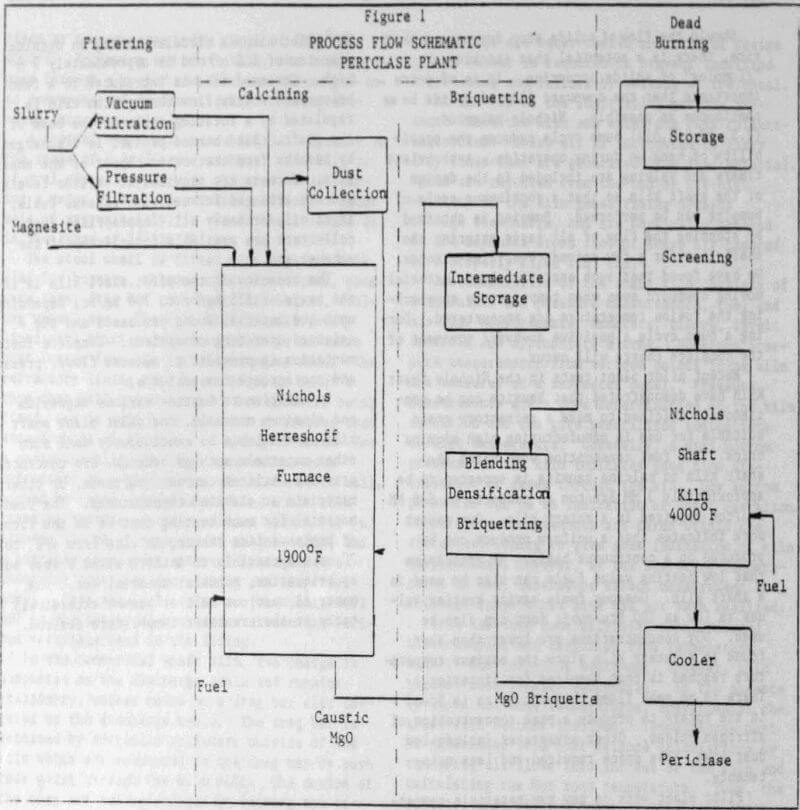

Magnesia production from seawater and brine is on the order of 2,200,000 tons per year, with the major producing countries being the U.S.A., Japan, the U.K., Ireland, Mexico, the U.S.S.R., Israel, Norway, and China. A large proportion of the magnesia from seawater and brine is calcined in Nichols Herreshoff Multiple Hearth Furnaces before deadburning in the Nichols Shaft Kiln.

Several of these installations were completed under turnkey contracts in which Nichols designed, supplied, and installed all of the facilities including: slurry handling, filtration, calcining, briquetting, the shaft kiln, buildings, and storage vessels, site preparation, structures, electrical, piping, and instrumentation, all on a complete turnkey basis.

With magnesite as feed, crushed feed is elevated to the top hearth in a bucket elevator and introduced into the furnace through a sealing type feeder. Most of the multiple-hearth furnaces used in these commercial installations are 21′-6″ x 12-hearth or larger with the largest installations being 25′ O.D. x 16-hearth. Herreshoff furnaces are equipped with dust collectors, such as electrostatic precipitators or baghouses, as well as all of the associated combustion equipment and burners, plus the conveyors and elevators to move the filter cake as well as the calcined products.

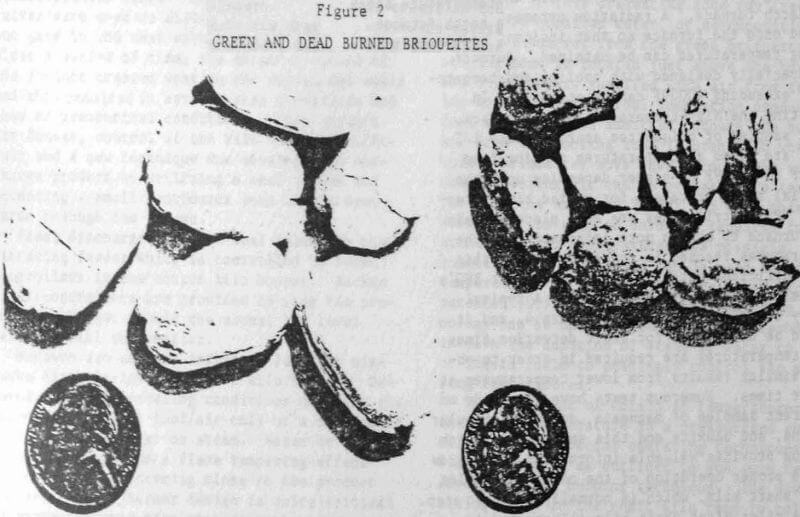

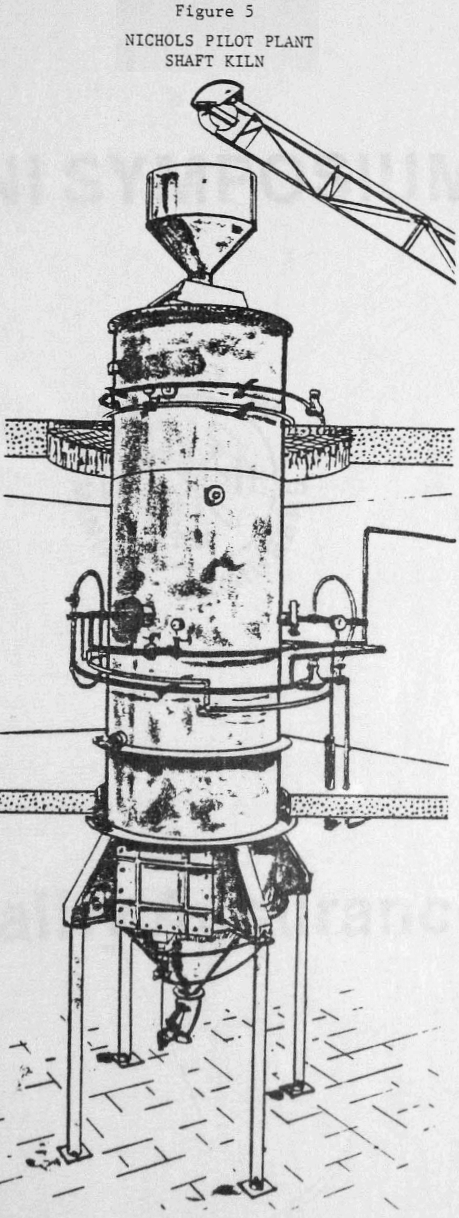

Green briquettes are elevated from the presses to hoppers and screens located above the high-temperature Shaft Kiln. Fines from the screening operation are returned to the briquette plant for rebriquetting, along with fresh caustic material. The proper sized green briquettes are fed into the top of the shaft kiln where they are fired at temperatures in the range of 3600° to 4000°F. Following the shaft kiln, the briquettes pass through a cooler and then are discharged into conveyors and crushers, prior to being elevated into storage silos.

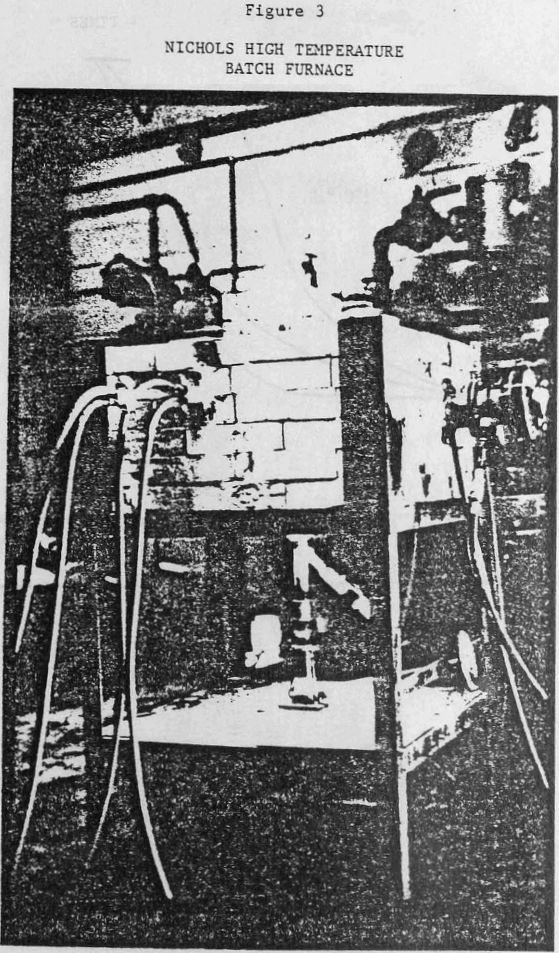

In the commercial shaft kiln, the charge is supported on the discharge table and remains stationary, unless moved by a drag bar also located on the discharge table. The drag bar is actuated by hydraulic cylinders outside of the kiln which are connected to the drag bar by push rods going through the kiln wall. The motion of the drag bar can be changed by varying the timers that control the hydraulic cylinders.

Final discharge from the seal column is via a vibrating feeder which is controlled by level controller’s in the bottom kiln hopper. Backup level controllers are provided to stop the product discharger should the normal low level detector fail to function.

In the top of the shaft kiln, descending briquettes are preheated by rising products of combustion. In this preheating zone any free water, chemically combined water, or decomposition products are removed from the green briquette. The soaking zone is located just above the burners and this zone is supplied with air from the cooling zone as well as fuel combustion products from fuel that has been admitted through the burners. Air from the cooling zone is preheated when the burned briquettes move down through the cooling zone.

Recent pilot plant tests in the Nichols Shaft Kiln have demonstrated that bauxite can be continuously calcined to make a refractory grain suitable for use in manufacturing high alumina brick. The fuel consumption when using the shaft kiln to calcine bauxite is expected to be approximately 3 MM Btu/ton as compared to 5-6 MM Btu/ton required in a rotary kiln.