Distillation Procedure

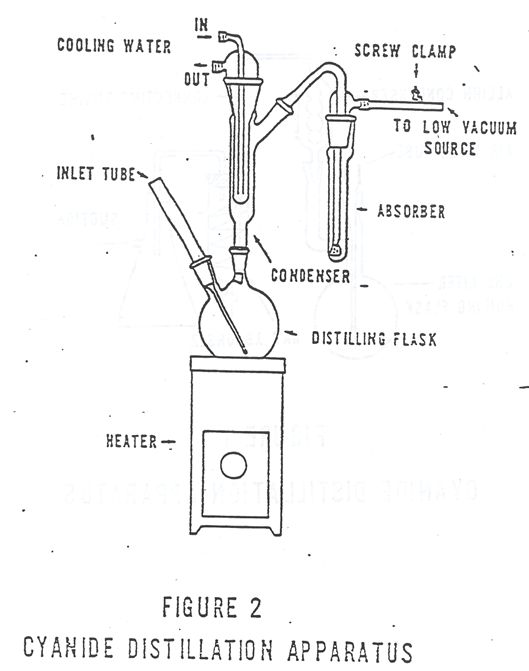

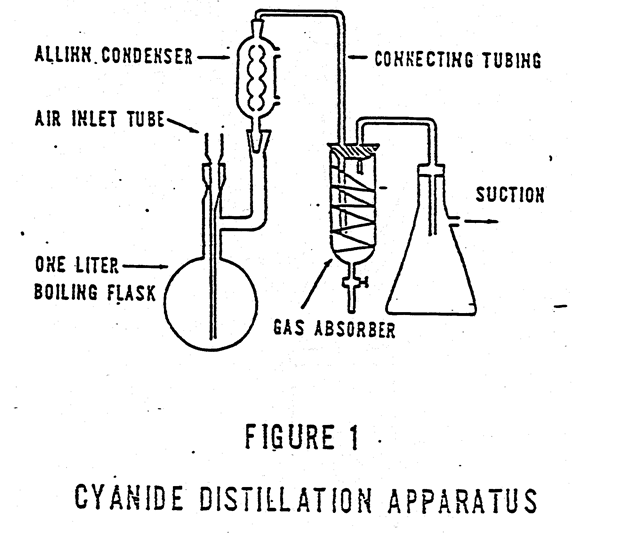

Samples without sulfide. Place 500 mL of the combined sample or an aliquot diluted to 500 mL in the 1 liter boiling flask. Pipet 50 mL of 1.25 N sodium hydroxide into the absorbing tube. If the apparatus in Figure 1 is used, add distilled water until the spiral is covered. Connect the boiling flask, condenser, absorber and trap as shown in Figure 1 or Figure 2.

Start a slow stream of air entering the boiling flask by adjusting the vacuum source. Adjust the vacuum so that approximately two bubbles of air per second enter the boiling flask through the inlet tube. Proceed to Section 5.

Samples that contain sulfide. Place 500 mL of the combined sample or an aliquot diluted to 500 mL in the 1-liter boiling flask. Pipet 50 mL of 1.25 N sodium hydroxide into the absorbing tube. Add 25 mL of lead acetate solution to the sulfide scrubber. Connect the boiling flask, condenser, scrubber and absorber as shown in Figure 3. The flow meter is connected to the outlet tube of the cyanide absorber.

Start a stream of air entering the boiling flask by adjusting the vacuum source. Adjust the vacuum so that approximately 1.5 liters per minute enter the boiling flask through the air inlet tube. The bubble rate may not remain constant while heat is being applied to the flask. It may be necessary to readjust the air rate occasionally. Proceed to Section 5.

If samples contain NO3- and/or NO2-, add 2 g of sulfamic acid after the air rate is set through the air inlet tube. Mix for 3 minutes prior to addition of H2SO4.

Section 5 Slowly add 50 mL 18 N sulfuric acid (5.3.4) through the air inlet tube. Rinse the tube with deionized distilled water and allow the airflow to mix the flask contents for 3 minutes. Pour 20 mL of magnesium chloride solution into the air inlet and wash down with a stream of water.

Heat the solution to boiling. Reflux for one hour. Turn off the heat and continue the airflow for at least 15 minutes. After cooling the boiling flask, disconnect the absorber and close off the vacuum source.

Drain the solution from the absorber into a 250 mL volumetric flask. Wash the absorber with deionized distilled water, and add the washings to the flask. Dilute to volume with deionized distilled water.