The suggested reserve capacity for quarry operations applies as well to open-pit mining operations employing power shovels for loading the ore. Usually the original crusher is expected to produce the required daily tonnage in such plants in one or two shifts, so a time-reserve does exist which can be utilized to make up for delays. But this can only be accomplished by overtime operation of pit, transportation, and primary crusher-house, which under existing labour conditions is costly. From the standpoint of economical operation, reserve capacity in the primary crusher is just as important here as it is in the commercial crushing plant.

Underground mining operations are, in many cases, provided with a substantial surge capacity between the mine and the primary crushing plant. Furthermore, in medium and large operations of this character, the primary crusher is almost invariably large enough (to meet the required output) so that the mined ore causes little or no trouble due to bridging or blocking. For such operations the reserve may safely be cut to a somewhat narrower margin than we have suggested for the preceding classes of operation. From 10 to 15% will usually be safe, if the crushing plant is designed for one-shift operation. Underground mining operations without surge capacity ahead of the primary should be figured for at least 25% reserve.

The average gravel plant usually has some surge capacity between the pit and the primary crusher; in many instances, however, this surge is so small that it cannot be counted on to smooth out protracted delays in the pit. On the other hand, primary gravel crushers are not, as a rule, subjected to bridging and blocking, because provisions are easily made to keep oversize boulders out of the system. For gravel operations having little, or no, surge capacity ahead of the primary, a reserve crusher capacity of about 25 percent will usually suffice.

Progressive gravel pit operators are awakening to the importance of providing a large surge pile at some point between the pit and the recrushing, screening, and washing section of the plant. It is not always practicable to place this surge pile ahead of the primary crusher; large boulders cannot be handled economically on field conveyors, nor can they be handled through storage unless large and expensive feeding apparatus is installed. Where the operation involves boulders larger than 12 to 15″ the primary crusher is almost always installed ahead of the surge pile. This of course calls for reserve crusher capacity, but this is usually taken care of automatically, because a crusher that is large enough to receive these large boulders will generally have plenty of excess capacity to handle the rock component of any gravel deposit. This excess should be not less than 25% for such operations. Where the large surge can be located ahead of the primary, a reserve of 10 to 15% is sufficient.

It is quite common practice, in some basic products plants, to design the original installation so that it may readily be expanded to take care of anticipated increases in product sales. Such expansion might involve doubling or tripling the initial output. A case in point is the Portland cement plant, which is frequently started as a one-kiln plant, but which is usually so arranged that additional kilns, grinding units, and auxiliary apparatus can be installed alongside the original machines. In a plant of this character the primary crusher, and its auxiliaries, are a minor part of the total investment, even as compared to the cost of the original single-unit installation. Furthermore, most cement plants are supplied from open-pit workings, utilizing power shovels for loading the raw materials; hence the primary crusher must usually be of medium-to-large proportions to provide sufficient receiving opening. These facts have led quite logically to the almost universal practice of installing primary crushing departments, in such plants, large enough to take care of ultimate anticipated requirements.

It is not always necessary nor advisable to install a single-unit primary crushing department. Occasionally the required plant capacity is so high that the load can be divided between two primary crushers of ample receiving opening to handle shovel-loaded, quarry-run, or mine-run rock. Some successful high-capacity crushing plants have been built in this manner. In general, the dual primary arrangement is not economically applicable to shovel-loading quarry operations unless the required capacity is in excess of 800 to 1000 TPH. For plants above this range the duplicate set-up has some definite advantages: the two crushers can be set to turn out a smaller product than the one huge machine which would be required for the single-unit installation; trains or trucks can be handled through the crusher house more rapidly because of the duplication of dumping points; and the arrangement has the inherent flexibility, which has long been recognized as being an important and desirable feature in the succeeding stages of the crushing and screening plant.

For plants handling a smaller size of primary feed, for example, gravel plants, and those connected with underground mining operations, the dual, or multiple, unit primary crushing arrangement is more widely applicable, and the advantages are much the same as we have outlined in the preceding paragraph. Probably the most important single advantage is the smaller product obtainable from the smaller primary crushers as opposed to the larger single unit. It is possible in some cases to eliminate multi-stage of reduction by utilizing such an arrangement.

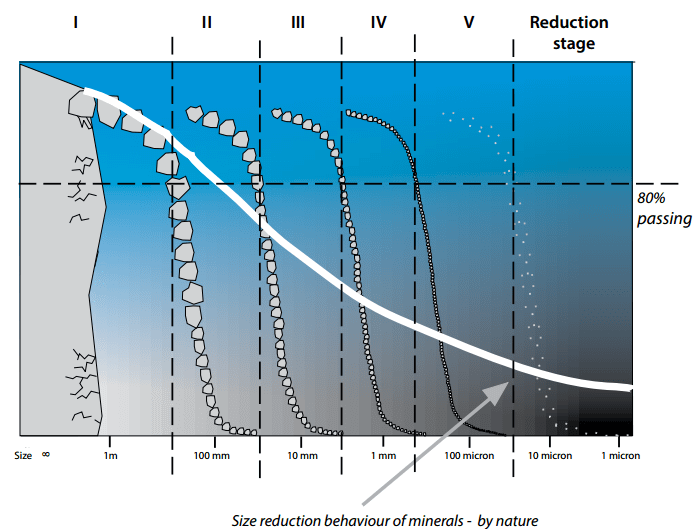

Crusher Discharge Product Size

This factor is intimately connected with that of capacity, and it has been discussed to some extent under that heading. Usually the operator wants to get as much reduction as is economically feasible out of his primary crushing stage; therefore, the primary crusher will, more often than not. be set at or near the minimum permissible setting. If his operation involves shovel-loading of quarry-run rock, he will generally want as much receiving opening as he can get for whatever expenditure he feels is justifiable for primary crushing equipment; in the case of the standard gyratory and jaw crushers this means that straight concaves or jaw plates will usually be chosen, and hence the minimum product size must be predicated upon minimum permissible settings with such liners.

There are cases, however, where the choice of a crusher fitted with straight concaves or jaw plates does not work out for the most economical over-all installation. Considering the standard gyratory line as an example, if we compare almost any two contiguous sizes, we find that the larger machine if fitted with non-choking concaves can be set to a closer discharge opening than can the smaller one when fitted with straight concaves. Also we find that, although there is some sacrifice in receiving opening because of the non-choking concaves, the larger machine will still exceed the smaller one in this respect. And we find that our larger machine, even at the reduced discharge setting, has a marked advantage in capacity over the smaller crusher with its straight concaves. In certain cases the reduction in size of product obtainable in this fashion may enable the plant designer to eliminate one stage of reduction. Where this can be done, the greater cost of the larger primary crusher will usually be more than offset by the saving in cost of recrushing equipment.

In choosing the setting for a primary crusher it should be borne in mind that it is difficult, if not impossible, to maintain a given setting over a long period of time. This is especially true when the rock is abrasive. Even though the crusher is provided with means for adjusting the discharge opening, it is the exception rather than the rule to find operations where the machine is maintained strictly at any one setting; certainly it cannot be so maintained when the only means of adjustment is to reset or change-out gyratory parts (concaves). Therefore, when limitations in succeeding units require a certain maximum one-way dimension in the product of the primary crusher, a suitable margin should be allowed when selecting this machine to permit a reasonable amount of wear to take place without exceeding the permissible limit. No fixed rules can be established for this margin. Small machines can be maintained more closely than larger sizes; jaw crushers are easier to adjust than arc standard gyratories; abrasive rock demands a greater margin than non-abrasive rock. The advisable margin may run anywhere from 0.5″ to 3″ or more, depending upon the size and type of crusher, and upon the character of the material. The succeeding instalment shall discuss the relation of the quarry equipment to the selection of the primary crusher.

https://www.metso.com/