It is difficult to define exactly the meaning of the terms crushing and grinding, or crushing and pulverization; the finer crushing stages may embody a certain amount of pulverizing or grinding, but in the main, crushing may be said to cover the reduction of stones or ores to a size of ½ inch, and in some cases slightly less.

It would not be possible, within the scope of this Paper, to describe all the forms of crusher at present in use; it is therefore proposed to select a few of the better-known types and to show how the improvements in materials and, in particular, the introduction of the alloy steels, have aided in their development.

Each type of crusher is considered from the following aspects:

(a) Its origin.

(b) Intermediate stages in its development.

(c) Modern examples.

(d) Its special use.

(e) Performance-diagrams.

DOUBLE-TOGGLE JAW CRUSHER

The double-toggle mechanism, patented in 1858 by Mr. E. W. Blake, remains unrivalled for all units of exceptional power and size.

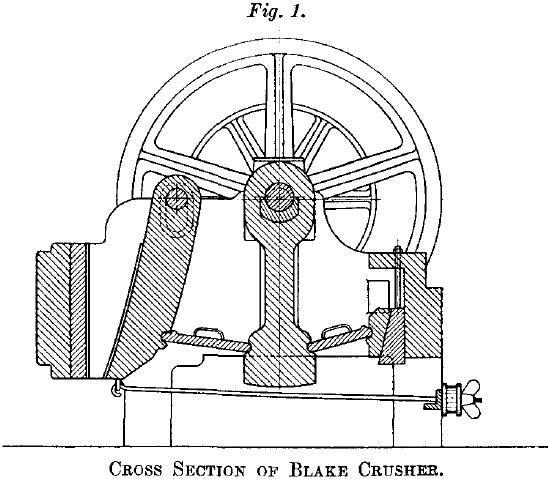

Fig. 1 is a cross section of an early Blake crusher. The power was applied to an eccentric shaft rotated in fixed bearings situated close to the centre of a heavy cast-iron frame. The eccentric oscillated a pitman or connecting-rod, which was made with grooved seatings near its lower end to receive the adjacent ends of two toggle-plates. The rearmost toggle-plate was pivoted at its back end in an adjustable toggle-block mounted to slide in the frame. The outermost end of the front toggle-plate rested in a groove at the back of the jawstock which included the moving jaw.

The jawstock was pivoted above the feed-mouth in bearings formed in the main frame, and the double-toggle system imparted a purely pendulum-like swing to the moving jaw, the crushing stroke decreasing from a maximum near the outlet to a minimum at the point of entry for the stone ; that is, the crushing stroke was greatest on the fine material and least on the big lumps, whilst the leverage was greatest on the large lumps and least close to the point of exit.

In the early machines there was no renewable jaw in the jawstock, and no removable seatings or toggle-grooves. The frame, jawstock, and pitman were made of cast iron, and the parts had to be very massive and heavy to withstand the severe strains imposed upon them.

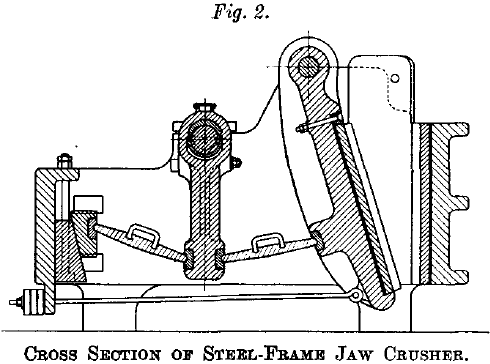

For a time the development of the jaw crushers closely followed the existing designs for Blake breakers. The heavy cast-iron frames were reinforced by strong longitudinal tie-bolts; in some instances they were made in sections to permit of easier handling, but the parts became so cumbersome that cast steel was used to reduce their weight.

A notable advance was made in about the year 1890, when steel castings were introduced for all the important parts of the double-toggle crushers. An early design for a steel-frame jaw crusher by Messrs. Hadfields is shown in Fig. 2.

Not only was the margin of strength to resist shock very considerably increased by this change, but the weight of the machine was also much reduced, a matter of great importance where transport charges were high. With the change-over to cast steel for the main components of these machines came the introduction of manganese steel for the crushing faces and other parts, in replacement of the original chilled iron.

The introduction of the mechanical shovel into quarries and mines created a demand for crushers with feed-openings of adequate size to take the largest pieces of stone or ore that could be handled by these appliances. Feed-openings have increased to 84 inches by 66 inches and, notwithstanding the use of steel wherever practicable, a machine of this size may weigh as much as 260 tons and require a motor of 300 or 350 HP. to drive it.

In these sledging-machines the jaws and cheek-plates are made of manganese steel, and in many cases the renewable toggle-seats are also of the same material. Jaws and cheeks are made in sections so that localized wear does not necessitate the replacement of the whole.

Springs fitted under the pitman and other means are adopted to overcome the constant downward thrust on the eccentric shaft, and permit of free passage of the lubricant; the bearings are water-cooled to absorb the excess heat, and automatic lubrication is now recognized as an essential feature.

Jaw crushers of the type shown in Figs. 1 and 2 are particularly suited for crushing harder rocks and ores, although they will break almost any kind of material that is free-breaking without packing, or that does not stick or ride in the jaws.

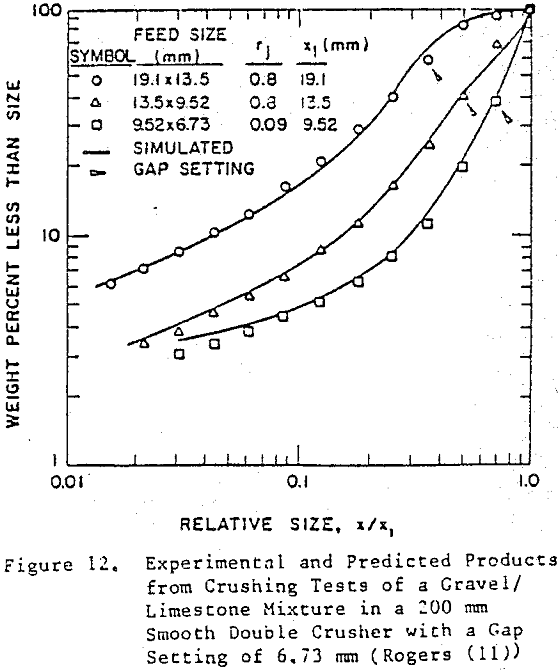

The gradation of the finished product from any crushing-machine is dependent on the average feed-size and the extent of the work done in the crushing process. Fig. 6, p. 45, shows a series of typical gradation-curves based on a feed of clean lump material at the standard reduction-ratio of 5 to 1.

THE SINGLE-TOGGLE JAW CRUSHERS

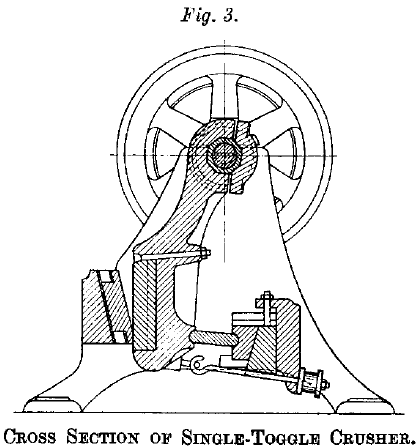

Fig. 3 is a cross section of the single-toggle crusher, as introduced by Mr. G. Dalton of H. R. Marsden & Company in about 1879. It is quite probable that this patent is not the real origin of this mechanism, but it is the earliest example known to the Authors that was developed in practical form.

In this machine the jawstock was carried on the eccentric shaft which was located above the feed-mouth of the crusher. The travel of the lower end of the swinging jaw was controlled by a single toggle- plate, and the movement, commencing as a true circle on the shaft centre, changed to an ellipse with a gradual reduction in the minor axis towards the outlet end of the jaw. By flattening the angle of the toggle-plate, the effective crushing stroke could be reduced to the minimum at the sizing point.

As originally constructed, all castings were of iron, and this material is in common use to-day for the parts not actually in contact with the stone. Manganese steel soon became standardized for the jaws and cheek-plates, as the rolling action of the swing-jaw is liable, on any abrasive material, to cause heavy wear on the jaw-plates.

With this mechanism the crushing action is more complex than in the Blake machines. There are two cycles of movement applied to the swinging jaw, which overlap to some extent, one half of the crushing stroke being due to the eccentric movement at the top of the jawstock, and the other half to the side-swing from the radial toggle- plate.

With this mechanism it is necessary, in order to avoid a neutral zone between two reflex crushing movements, that the centre-line of the toggle-plate should be level with, or fall below, the bottom of the moving jaw. It is also advisable that the shaft should turn in such a direction that the jawstock moves downwards as it nips the stone near the top of the feed-mouth, otherwise there is a tendency to lift the material and hinder its downward travel.

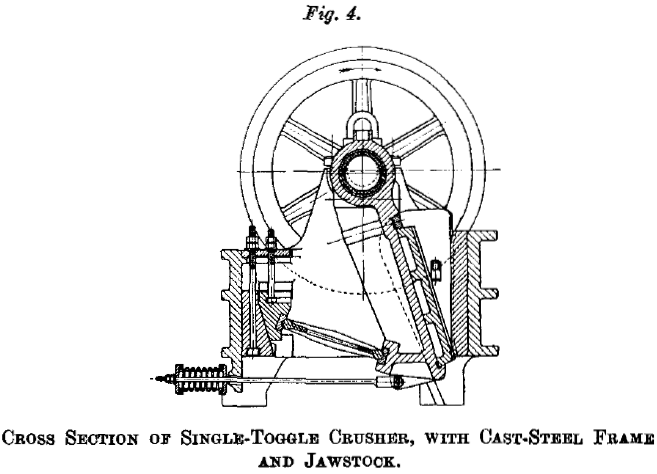

This machine developed as a coarse breaker as well as a fine crusher or granulator, and the frame and jawstock were also made by Messrs. Hadfields of cast steel instead of cast iron, as shown in Fig. 4. The Authors have not been able to trace a machine embodying this type of mechanism in the sledger class.

The latest improvement in the design of these machines is the incorporation of roller-bearings for the eccentric-shaft. Not only do these require much less attention and lubrication, but they enable the crushers to run at higher speeds, with less internal friction, and with consequent gain in output.

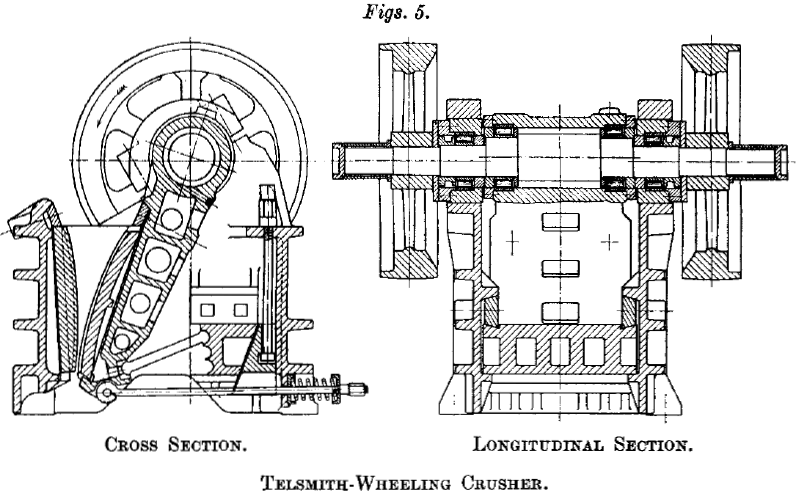

Figs. 5 show the Telsmith-Wheeling design for a series of single-toggle jaw crushers fitted with roller-bearings. These machines are made in this country by Messrs. Pegson, Limited, of Coalville. The frames and jawstocks are of cast steel, the eccentric-shaft of special alloy steel, and the jaws of manganese steel. Dust is excluded from the bearings by piston-ring seals, and the hardened rollers are held in position by bronze retaining-rings. The speed at which these crushers run is about 50 per cent, faster than that of machines fitted with ordinary bearings.

Jaw crushers of the single-toggle type are most useful for dealing with the softer rocks or materials having decomposed outer surfaces. The very lively crushing movement at the feed-mouth, combined with the force-feeding action from the rolling jaw, make it possible to penetrate quickly and shatter materials that would “ ride ” in the short stroke at the top of a pendulum-jaw. They are also entirely adequate as coarse crushers within the limits as normally manufactured, say up to a size of feed-mouth of 36 inches by 12 inches.

Wear and tear of the jaw-plates on any abrasive stone is always higher than in the Blake-type crushers.

The graphs in Fig. 6 may be taken as generally applicable to both types of jaw crushers.

LONG-SHAFT GYRATORY CRUSHERS

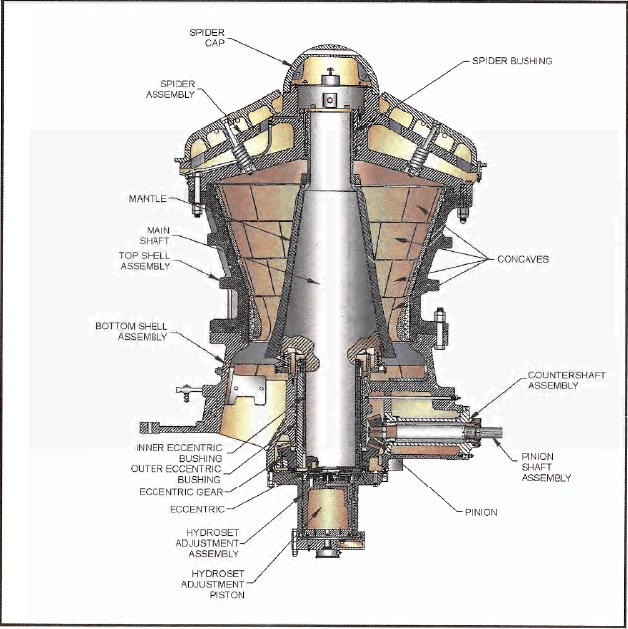

In the normal gyratory crusher the inclined shaft carrying the crushing head is semi-rigidly supported at its upper end in a spider which bridges over the feed-opening, whilst the lower end is inserted in the bore of an eccentric by which the force and movement are applied to the shaft and cone. The crushing-head is situated between the upper bearing and the eccentric, and the shaft becomes a lever with its fulcrum in the spider-bearing and with the source of power below the cone.

In 1877, Mr. Charles M. Brown, of Chicago, filed a patent in the United States for the breaker illustrated in Fig. 7, which was probably the prototype of the “ long-shaft ” gyratory crusher.

The crushing-basin or concave casing was fitted with removable liners ; the long lever-shaft carried a renewable cone ; a diaphragm- shoot for collecting the crushed material was incorporated in the lower part of the frame-casting, and the bearing for the eccentric was integral with the body. The spider had four arms, and there were consequently four feed-openings. The upper end of the spindle was of the ball-and-socket pattern. The upper bearing was free to move vertically in the bore of the spider, and a footstep-bearing with screw adjustment was provided at the lower end of the main shaft to allow of the head being raised or lowered as required.

These machines were developed in America by the Gates Iron Works, and for many years they were constructed to the design shown in Fig. 8.

Two changes worthy of mention were made from the Brown design ; the ball-and-socket bearing for the upper end of the main shaft was discarded, and the bottom plate supporting the eccentric bearing and bevel-wheel was made detachable from the body for convenience in dismantling. The ball-and-socket bearing apparently gave trouble due to wear, and proved difficult to adjust satisfactorily.

In service a full bearing is hardly ever obtained between the ball and the socket, and, with the reduction in diameter of the ball caused by wear and the simultaneous enlargement of the socket, the bearing deteriorates practically to a point contact, which causes intensified wear. This upper bearing was changed to a part-conical design, the spider-bush being made parallel in the bore, and the upper end of the main shaft coned to a taper coincident with the angle of gyration. By these means the shaft and bearing maintained line-contact on the side opposite to the crushing pressure notwithstanding increased clearance due to wear. Although apparently both crude and inefficient, the simplicity and durability of this form of bearing have proved to be among the outstanding features of merit in the gyratory crusher.

Gyratory crushers of the type shown in Fig. 8 held the field for a considerable time, during which certain improvements were made in the materials used for the wearing parts, as in the case of jaw crushers. The liners for the crushing-basin, known as concaves, were originally made of chilled iron, and the crushing-cone was a solid head in cast iron with a chilled crushing-face. These were replaced by fighter concaves of manganese steel and a cone made up of two parts, an outer shell or “ mantle ” of manganese steel and an inner core or centre either of cast steel or cast iron. Cast steel was also used for the gearing.

The demand for crushers with larger feed-openings, to take quarry-run stone as shot from the face and loaded by mechanical shovels, led to a steady growth in the size of gyratory crushers, equal to that of crushers of the jaw type. The feed-openings increased in width from 36 inches to 54 inches, and in some instances to 60 inches.

SHORT-SHAFT GYRATORY CRUSHERS

The excessive height of the long-shaft gyratory crusher, and more especially the great amount of head-room required for the removal of the main shaft, when repairs became necessary, favoured the development of the short-shaft type of crusher.

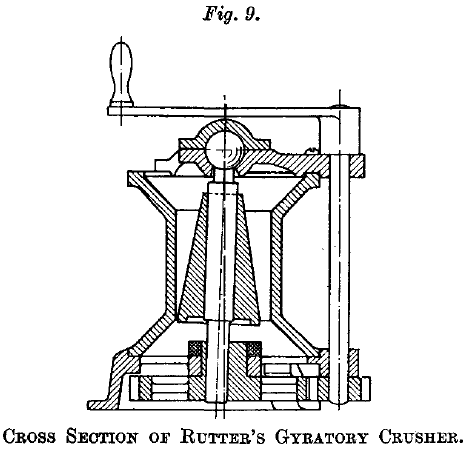

Mr. R. H. Richards mentions Mr. James W. Rutter, of St. Louis, Missouri, as the probable inventor of the first true gyratory crusher. Rutter’s ore-crusher (Fig. 9), patented in 1869, consisted of a cone attached to a square shaft working inside an open cylinder, with a ball-and-socket joint supporting the upper end of the shaft and an eccentric wheel rotating in the base-plate, which gyrated the spindle carrying the crushing-head in a conical orbit about the true axis of the machine. The crushed product in escaping had to fall through the spaces in the spider carrying the fixed bearing for the eccentric as well as through the arms of the gear-wheel, and these hindrances to free discharge must have proved very undesirable in a breaker of any size.

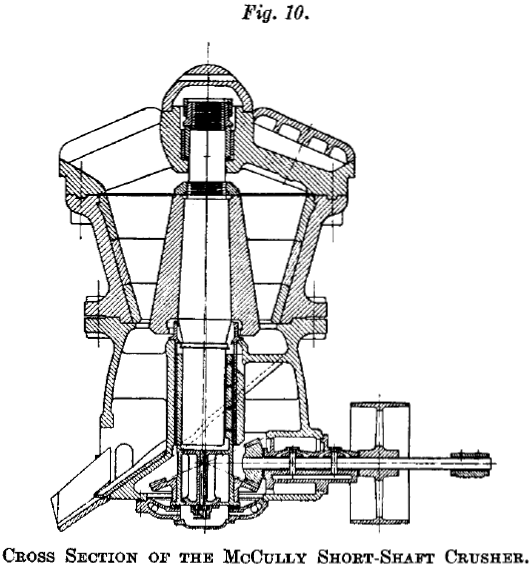

Fig. 10 shows the McCully short-shaft crusher, which was the first machine of this design to compete seriously with the then-existing types of gyratory crushers.

The body of the machine was reduced in height as far as possible with a free-running discharge-shoot, and the eccentric was made to revolve inside the chimney passing through the diaphragm- plate, which was strengthened to withstand the crushing pressure and further supported by bridge-pieces spanning the space above the outlet. By raising the eccentric in this manner, the spindle was considerably shortened, and the reduction in distance between the supports increased the rigidity of shafts of equal diameter by about 55 per cent.

About 1926, the Allis-Chalmers Company built two very powerful 60-inch gyratory crushers for the Chile Exploration Company. The ore to be handled was exceptionally hard, and the machines were made almost entirely of steel. The concave casing was in three parts, the lower section consisting of a solid cast-steel ring weighing 57 tons, whilst the upper section, also of cast steel, was made in halves, each half weighing 46 tons. The bottom shell was in two parts, and weighed 88 tons. The main shaft was nearly 22 feet long, and its weight, complete with oversize mantle, approximately 78 tons. The total weight of the machine was about 500 tons. A 500-HP. electric motor running at 200 revolutions per minute, was directly connected to the crusher countershaft through a flexible coupling.

The Chile Exploration Company, to whom the Authors are indebted for the following information, explain that the ore is first dumped over a grizzley, and the proportion removed before crushing varies from time to time. With both machines in operation they have passed 4,900 tons through the plant in 1 hour, of which, as an average, possibly one-third would not reach the crushers. The product may be taken as 9 inches and under.

High-arch spiders, frequently made in cast steel, heat-treated main shafts, cut steel gears, manganese-steel wearing parts, and improved methods of lubrication, have added greatly to the merits of the gyratory breaker as one of the most useful crushing-machines now in service.

Gyratory breakers may be used for crushing all kinds of material for which a jaw breaker is considered suitable, with one or two rare exceptions. So far as the gradation of the product is concerned, jaw and gyratory crushers are similar, particularly when corrugated mantles and concaves are fitted in the latter machines. Fig. 11 covers a fair range of tests, but for the coarser settings corrugated wearing parts were fitted.

GEAR-DRIVEN CRUSHING ROLLS

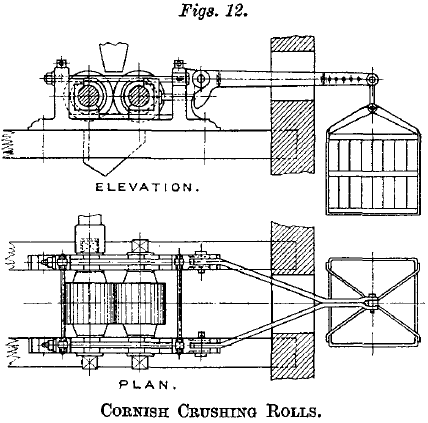

Records show that crushing rolls were introduced at the mines in Cornwall in about 1806 : the machines proved so successful that they became widely used, the designation “ Cornish rolls ” being used for many years to define this particular type. Figs. 12 illustrate an early machine of this type. The rolls were usually from 18 to 30 inches in diameter, and from 11 to 20 inches wide. They were driven at speeds varying from 5 to 15 r.p.m., the motive power being frequently obtained from a water-wheel, through a train of gears. The rolls were mounted on heavy shafts revolving in open bearings, which were contained within strong cast-iron side frames. The bearing-blocks were held down on their slides by square-section rods, which served also to reinforce the end columns of the frames. One of the rolls was positively driven through coupling-boxes, whilst the other was usually revolved by frictional contact with the positive roll. The primitive character of the arrangement for maintaining pressure between the rolls is shown.

When machinery was introduced into the road-stone quarries, in about 1895, for the preparation of macadam, the jaw breaker was used for coarse crushing and heavy slowly-moving rolls were adopted in some of the quarries for finishing the stone. A few of these machines are in service to-day.

A number of mills of this type were constructed by Messrs. Hadfields. For a granite quarry in the Channel Islands the rolls were 33 inches in diameter, and 36 inches long, both being positively driven through “ wobbler-boxes ” and short “ wobbler-shafts ” coupled to a train of powerful gears. The roll-frames and shafts were of cast steel, and the bearings were adjusted to alter the setting by removing or inserting packing-shims between the frame-pillars and the bearing- blocks. Manganese-steel roll-shells, having chequerboard-teeth, were fitted to these rolls with the intention of repeating by mechanical means the action of hand-hammers knapping the stone. Used in the preparation of granite macadam, these rolls, running at 16 r.p.m., were fed with slabby pieces averaging 5 inches by 4 inches by 3½ inches, reducing these to pass a 2½-inch mesh at the rate of from 40 to 50 tons per hour.

Rolls of a similar type to the foregoing, but of much larger size, are used on the Continent in the crushing of limestone for the blast-furnaces and lime-kilns.

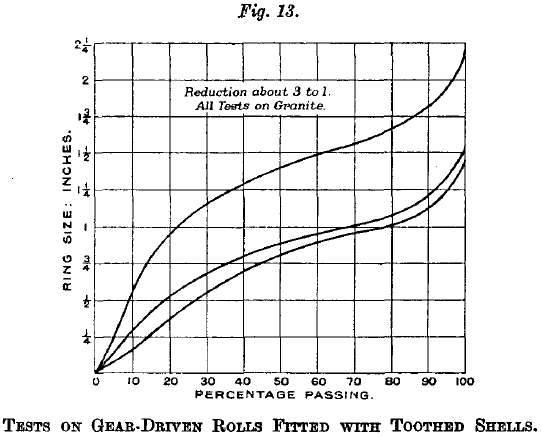

Geared rolls of suitable design will deal with a great variety of materials. They are used for crushing natural products such as green bones, oil shales, coal, and all kinds of rocks and ores. They will also handle many artificial products such as glue, glass, carborundum, mattes, and the ferro-alloys. It is probable that no other type of crushing machine is applicable to so wide a range of purposes as gear-driven rolls in their many forms. Fig. 13 shows that with properly designed toothed rolls the percentage of fines is reduced to the minimum, and the proportions of the intermediate grades are higher than those made by any other type of crusher.

BELT-DRIVEN CRUSHING ROLLS

Driving the rolls through gearing was at first almost universal, and this system is by no means obsolete. When toothed or corrugated shells are used the rolls are frequently connected by equal gears to ensure the correct meshing of the corrugations and spaces on opposing rolls, and in some rare instances, where a differential speed is required to give a tearing action on the material, the positive rotation by gears is preferred to independent belt-drives.

As rolls came into use for finer crushing, it was found necessary to run them faster to obtain any reasonable output. The greater velocity increased the kinetic energy in the rolls, which was augmented by fitting heavy belt-pulleys directly on to the roll-shafts, and the drive was simplified by the elimination of gearing with a consequent reduction in internal friction and wear. Mr. S. R. Krom was a pioneer in the United States of this system of direct belt-driving for crushing-rolls, and the machine illustrated in Fig. 14 was recommended by him, about 1874, for the work of medium-fine crushing.

The bearings for the fixed roll were bolted to a deep bed-plate, whilst those for the adjustable roll formed part of two rocking-lever arms hinged to the underframe and connected by strong tie-bolts to spring-batteries buttressed on extensions of the rigid bearings. One feature in these rolls, which was applied at a later date to a good many machines of the same type, requires some explanation, and that is the practice of fitting one roll with a large pulley and the other with a pulley of much smaller dimensions. The large pulley, capable of transmitting the whole of the power required by the rolls, is keyed on the fixed-roll shaft, whilst the pulley on the movable roll is made of sufficient size to keep the roll revolving positively in the intervals between crushing. The rolls are driven at nominally equal speeds, and, should any differential movement arise, the tractive effort of the larger pulley, transmitted by friction through the material to the movable roll, is sufficient to overcome all irregularities and to maintain equal velocities.

As rolls became more generally used for fine crushing, some of the operating difficulties were emphasized and the design of the machine was modified in certain details to overcome them. When the roll-faces were not matching properly, due to improper alignment, flanges were formed on the overlapping edges which were a serious impediment when the spacing had to be changed to compensate for wear. There was always a tendency for the outermost edges of the rolls to wear less than the body of the shells. Positive lateral displacement of one or both rolls, by means of adjustable thrust- collars, was introduced to minimize these flanging troubles.

Where rolls are fitted with springs to relieve overstrain, the passage of any material of unusual hardness causes the movable-roll shaft to swing out of parallel with the main shaft, and seriously disturbs the alignment of the bearings, creating one-sided strains dangerous to the machine. As the spring-pressures and journal-sizes were increased to meet more arduous working conditions, this tendency became more pronounced, and swivel bearings were introduced to allow freedom for irregular movement.

Continual advances in the size of the rolls and their operating speed necessitated great increases in spring-pressures to meet the shocks and impacts inseparable from high velocities and choke- crushing. In the early days of spring-rolls, for fine crushing 4,000 lbs. per inch width of face was considered perfectly satisfactory ; as time went on and the rolls increased in diameter, this figure grew to 12,000 lbs. per inch, and, in modern machines with rolls 5 or 6 feet in diameter, the pressure now reaches 30,000 lbs. per inch, and this limit has in some instances been exceeded.

With the increase in strength of the springs, the defects in the single tie-rod system for transmitting the pressure to the bearings for the movable roll became more pronounced, and led to the reintroduction of the double tie-bar type, notwithstanding the drawbacks inherent in this form of construction.

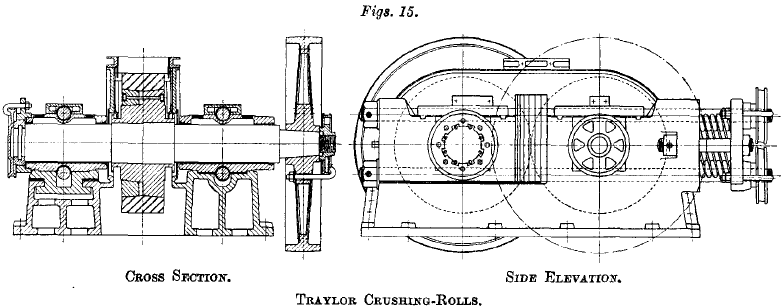

Among the later examples of high-speed crushing machines, the rolls illustrated in Figs. 15, built by the Traylor Engineering and Manufacturing Company, are among the largest of their class. These rolls measure 78 inches in diameter by 24 inches in width, and the shells are 9 inches thick weighing 13,250 lbs. each. The four tension- rods are 7½ inches in diameter, and the spring-pressure 15 tons per inch width of face. The pulleys are 10 feet in diameter and 21 inches wide, with flywheel-rims and steel-plate centres, the shafts being fitted with equal pulleys and driven by separate motors. In one plant, the motors are each of 225 HP. The bearings are of the solid self-aligning type and are fitted with dust-excluding devices, the shafts being 21½ inches in diameter at the journals and 22 inches in the body. When running at 110 r.p.m., these rolls are capable of reducing 1½-inch stone to a finished size of 5/8 inch and under at the rate of 400 to 500 tons per hour.

Belt-driven rolls usually, but not invariably, have smooth shells, and are more suitable for the work of fine crushing than geared rolls. With the exception of the Edison type mentioned below, they are specially suited for secondary-reduction processes, and may even, in extreme cases, be set to give a product passing 20 mesh. They will handle any hard or soft material from the artificial abrasives or natural emery to those with the consistency of burnt lime.

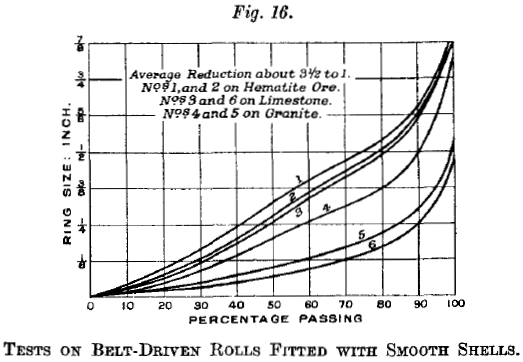

The gradation of the product from belt-driven rolls may be affected by several extraneous factors. If a proportion of the feed is too large to be gripped immediately by the rolls, excess fines are made by attrition. A high ratio of reduction can also cause an abnormal amount of fines by “ packing ” and high internal friction in the final crushing-stage. Given free crushing, well within the capacity of the rolls, the actual character of the material does not seem seriously to affect the results obtained so long as it is homogeneous. Fig. 16 gives a few test-records taken at random.

Reference to belt-driven rolls would be incomplete without mention of the series of coarse-crushing machines of this type introduced by Mr. Thomas A. Edison, about 1894, when large jaw and gyratory crushers were still in their infancy, and the steam-shovel was just entering into use for mine and quarry work.

Mr. Edison designed a primary crusher consisting of a pair of large rolls, the crushing surfaces being made in the form of a series of plates covered with knobs or projections to assist in breaking up the material. This set of rolls would crush larger pieces of stone than the jaw breakers then available, but when an extra large stone was dumped into the hopper it would ride about instead of being gripped. To overcome this, two rows of knobs, set diametrically opposite, were lengthened to project about 2 inches above the normal teeth on one of the rolls. These “ slugger ” teeth were placed in this way in order to strike a succession of heavy blows on the larger pieces of rock, so as to break them down to a size within the angle of nip of the normal roll-surfaces.

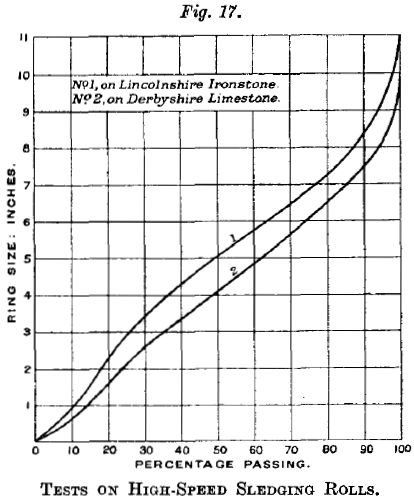

Rolls of this type, with certain improvements in the design of the bearings, and some modification in the construction of the rollers, have found a special field of service in this country in dealing with some of the ironstones that are particularly troublesome to handle in jaw or gyratory crushers. Messrs. Hadfields have built a series of machines for this particular duty, the largest including a pair of rolls 6 feet in diameter and 5 feet wide. Each roll comprises an outer shell in the form of a casting of high-grade steel, which is machined internally to fit on a heavy cast-iron centre made up of four sections, two of which are pressed on to the roll-shaft, while the other two rings are secured by through-bolts to wedge the outer shell in place. Each roll-shaft is supported by two bearing-blocks, the bearing proper consisting of a circular flanged bush made of cast iron and lined with babbitt metal. Thrust-rings are formed in one end of each shaft, and a babbitted thrust-collar, made in halves, is secured to two of the main bearings. The two blocks on each side-frame are tied together by through-bolts above and below the shafts. A packing-block partly fills the space between the bearings, and strips of wood are inserted to make up the distance to the required dimension. Force- pump lubrication circulates an ample flow of oil through all the bearings. The rolls revolve at speeds varying from 160 to 200 r.p.m., and each roll is driven by a separate motor of 200 HP. Crushing ironstone in blocks up to 4 feet 6 inches square by 3 feet thick, these rolls are capable of an output of 500 tons per hour with a product approximately of 8-inch size and downwards. Typical grading-tests are given in Fig. 17.

DISK CRUSHERS

The outstanding feature of the disk crushers is the utilization of centrifugal force as a means of spreading the material quickly and evenly over the crushing face.

The crushing faces, in one series of these machines, take the form of a pair of saucer-shaped disks revolving at equal speed in the same direction, one disk travelling in a fixed plane while the other advances and recedes under the influence of a series of crushing-waves or impulses.

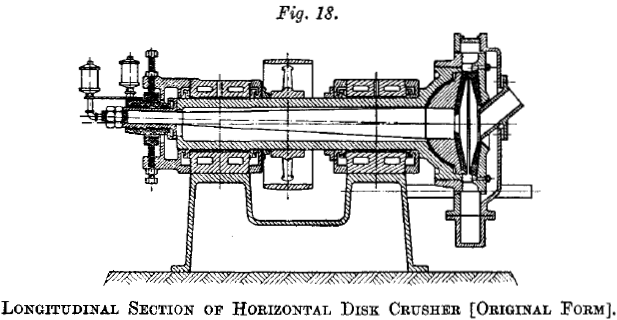

The machines are constructed of two distinct types, which may be classified under the headings of “ horizontal disk ” and “ vertical disk ” crushers, these terms having reference to the situation of the axis of the machine and not to the position of the disk. In the horizontal disk crusher the axis of the main shaft is horizontal whilst the disks are vertical, and in the vertical machine these conditions are reversed.

Fig. 18 shows the disk crusher in its original form, as introduced about 1908. A hollow shaft was supported in two bearings carried on a frame or bed-plate. One end of this main shaft was enlarged to form the cup-shaped seating for a semi-spherical bearing pressed on a taper-shaft free to move independently within the bore of the hollow shaft. The outer disk, with a central hole to permit of entry of the material to be crushed, was attached to a circular back-plate connected by distance pieces to an angle-ring with internal threads corresponding with the screw formed on the outside diameter

of the flange on the hollow shaft. The inner disk was secured by a large countersunk set-screw to the inner shaft and spherical bearing, and the inner shaft was lengthened to project through the hollow shaft at the opposite end to the disk. In this form of disk crusher the sleeve on the end of the inner shaft was supported in an adjustable bearing, in which it was free to rotate, and by means of which the inner shaft could be set at a variable angle to the axis of the hollow shaft. The hollow shaft was rotated by means of a central belt- pulley, causing the outer disk to revolve in a vertical plane, and the friction of the ball-and-socket bearing, supplemented by the wedging action of the material contained within the crushing cavity, caused the inner shaft and disk to revolve at the same speed and in the same direction. Due to the inclination of the inner shaft, the crushing face of the inner disk remained at a constant angle with the face of the outer disk, giving a variable aperture with the minimum opening in a fixed position in line with the eccentricity of the bearing for the sleeve.

Material entering the space between the disks was gripped at the point of maximum opening and carried round by and with the disks to the nipping point, being subjected to a crushing stroke for one half, and a freeing stroke for the other half, of each revolution. As the machine only gave one crushing stroke per revolution, it was necessary to run the hollow shaft at a relatively high speed, and the bearings for the main shaft were water-cooled and force-pump lubricated.

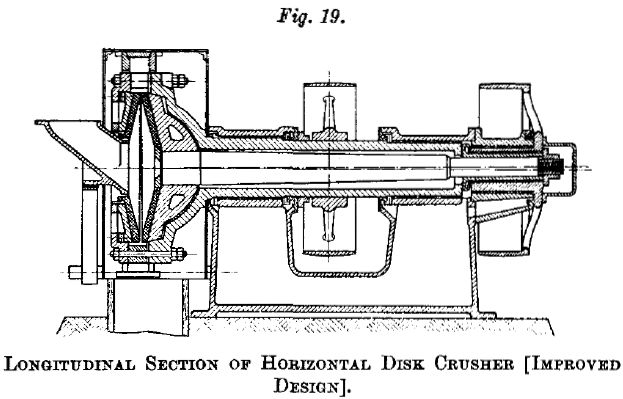

Fig. 19 illustrates the improved design of horizontal disk crusher in which an important change was made in the method of applying the crushing force to the inner disk. An extension piece was bolted to the end of the main frame, and a pulley with an eccentric boss was

fitted over the sleeve on the outer end of the inner shaft; the pulley- boss was supported by the bearing attached to the frame. The lock-nut at the end of the inner shaft was provided with a flange projecting beyond the end of the sleeve and partly covering the end of the pulley. This eccentric pulley was not attached to the inner shaft in any way, and any circular movement of the pulley caused the shaft to gyrate without rotation. When the eccentric pulley was made to revolve in the opposite direction to the main-shaft pulley the number of crushing strokes was equal to the revolutions of both pulleys added together. With this form of construction it was possible to reduce the speed of the main shaft, and with it the revolutions of the disks, to the limit imposed by the centrifugal force necessary to give perfect spreading of the material between the crushing-faces. Without impairing the crushing-efficiency, this reduction in speed made water-cooled bearings superfluous, and the machine was therefore simplified by their removal.

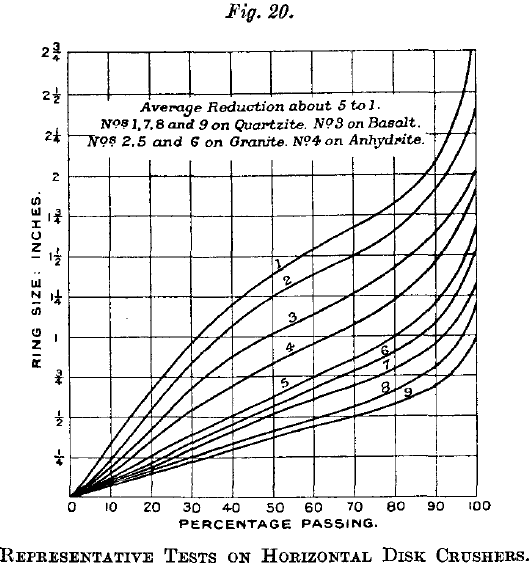

The horizontal disk crusher is essentially a secondary breaker, the largest machines of this type taking a feed of up to approximately 7-inch cubes and reducing this to 1¼ inches or more, whilst the smallest unit takes a feed of about 1¾ inch in size and gives a product as fine as ½ inch and under. They will crush the hardest grades of ore, and their centrifugal action is of value in dealing with moist or slippery substances that require something more positive than a gravity-flow to make them pass freely through the crushing-cavity. A comprehensive series of tests on various grades of rock is given in Fig. 20.

The vertical disk crusher was originally intended as a large- capacity unit for finer reduction than was possible with the lever- type machines.

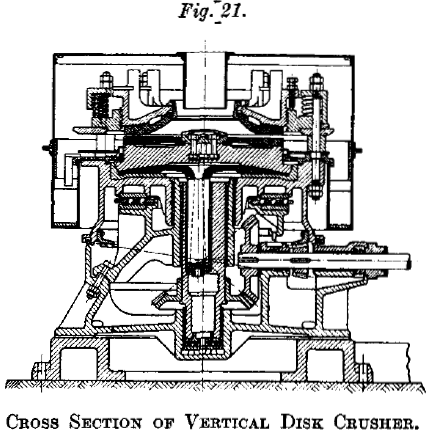

Fig. 21 shows this crusher in its latest form. The upper disk was dished to give the tapering cavity, while the lower or floating disk was made flat. The crushing-surface of the upper disk was also flattened at the periphery for a radial distance of about 4½ inches on an outside diameter of 48 inches. This construction made the exit-opening approximately parallel for the distance indicated so that a piece of ore, broken near the outer circumference of the tapering cavity, would have to travel outwards for a distance of at least 5 inches before it could escape from the disks, and, during that interval, the disks would have time to close again and subject the particle to another crushing stroke.

The maximum size of the finished product from the horizontal disk crusher is determined by the greatest outlet-opening between the disks at the end of the withdrawing stroke, but, in the vertical crusher, by reason of the special construction described above, the maximum size of the product was regulated by the minimum aperture between the disks, and it was therefore possible to obtain a finer product without setting the disks too close to each other.

The superstructure carrying the upper disk and spring-cushion was bolted to the outer flange of the rotating table supporting the ball-wedge and lower disk. This table was made with a tubular boss with a babbitted lining forming a bearing outside the centre stem rising from the base-plate of the crusher, and, in the very early machines, the entire weight of the revolving parts was taken on ball thrust-washers placed directly under this boss. This method of supporting the revolving mass did not prove adequate in practice, and the design was revised to include a roller-track, of a diameter practically equal to that of the disks, placed immediately below the revolving table. Among the latest changes shown in Fig. 21 this roller-cage is replaced by a multiple ball-race of special design.

In this machine there were two independent systems of gearing, both driven from the common countershaft. The smaller bevel- pinion, close to the outer bearing, engaged with a large gear-ring attached to the flange on the rotating table, and this imparted a turning movement to the disks to ensure sufficient centrifugal action to spread the material evenly between them. The second pair of bevels connected the countershaft with the eccentric, and caused this to rotate at a much higher rate, and in the opposite direction to the table. The sideways displacement of the spherical head of the wedge caused the anvil-plate containing the lower disk to lie at an angle to the horizontal, and the rotary eccentric motion imparted to the disk a series of circular undulatory movements that were free from any turning effort. The crushing movements were therefore identical with those in the horizontal disk crusher, the disks revolving together in the same direction and at the same speed.

These vertical disk crushers have been used in some of the largest plants dealing with copper ores, and practically all of them have been made of one size, namely, with disks 48 inches in diameter. A limited number of machines with 36-inch diameter disks have also been put into service.

Changes in design to meet extremely arduous conditions include the substitution of cast steel for cast iron for all the essential castings. Bronze has replaced most of the babbitt linings for the bearings, and the gears are machined from rolled- or forged-steel blanks. The disks and other wearing parts in actual contact with the stones are always made of manganese steel.

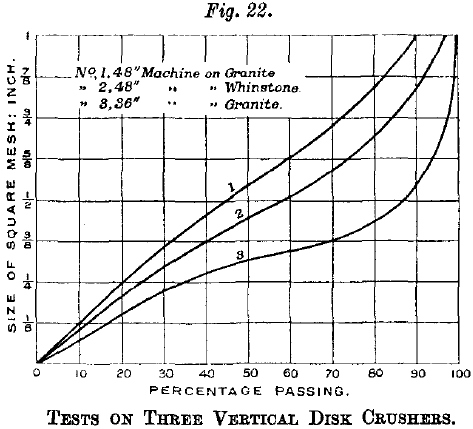

Fig. 22 shows the grading obtained in three typical tests on 48-inch and 36-inch vertical disk crushers.

Disk crushers are particularly serviceable for the intermediate processes in plants of moderate capacity ; the number of sizes in the horizontal machines is adequate to cover a wide range of outputs, and, within specified limits, the size of the finished product can be readily adjusted and maintained until the disks are completely worn out. The horizontal machines are made in this country by Messrs. Hadfields, Limited, and the vertical crushers by Messrs. Sandycroft, Limited.

SINGLE-ROLL BREAKERS

Roller-and-breast mills have been used for many years for reducing grains, beans, and similar friable materials, and attempts were made to apply the same principle to the crushing of stone, when, as far back as 1864, Mr. A. Thomas obtained a British patent for the machine illustrated in Fig. 23 for crushing stone.

The roller-and-breast mill, or single-roll crusher, became a very useful machine for the crushing of coal. For many years, double-roller mills with toothed rolls had been used for this duty, but it was found that, when the teeth were reduced in size to give a relatively fine product, the rolls would not properly grip the large lumps. The concave breaker-plate in the single-roll crusher acted in conjunction with the roll to make a wedge-shaped opening with a small included angle, so that this machine would grip much larger lumps than the two-roller mill.

Fig. 24 illustrates a single-roll coal-crusher, which consists of a crushing-roll and a breaker-plate mounted in a cast-iron frame.

The breaker-plate is hinged at its upper end, and is held in position by a pair of adjusting-rods threaded on a pin passing through its lower end. These tension-rods are carried through the end of the frame, and springs are fitted between the nuts and the bed-plate. Coal is frequently contaminated by pyrites and shale, and the working parts of the machine had to be strengthened to meet such conditions. In the larger crushers the breaker-plate is usually made of cast steel. The toothed segmental wearing-plates covering the roll are made of manganese steel, as is the renewable shoe at the bottom end of the breaker-plate. Steel gearing is also standard.

Concurrently with the development of the single-roll machine as a coal-crusher, it was being slowly adapted in America for the crushing of slippery or weathered materials, such as phosphate rock, gypsum, the friable iron-ores, and limestone rocks coated with clay.

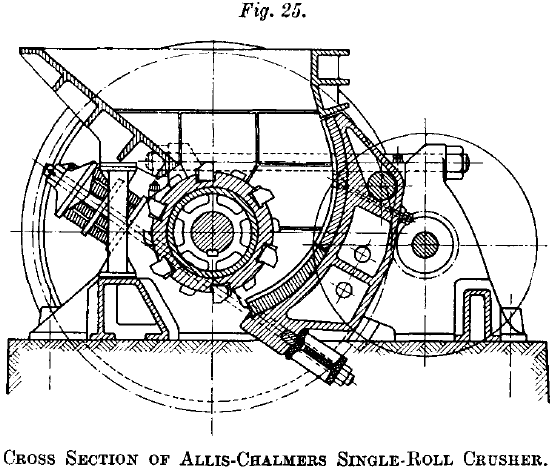

Fig. 25 shows the single-roll crusher in its most highly developed form, as made by the Allis-Chalmers Company for the crushing of limestone for fluxing purposes. The framework was made of two cast-iron side pieces of heavy box-section in which were incorporated the bearings for the roller and countershaft and the pivot-bearings for the hinged anvil-plate or jawstock. The tensile stresses imposed on the side-frames when crushing large pieces of rock were taken by two upper tension-bolts, which tied the pivot-bearings to the main bearings for the roll-shaft. The lower end of the breaker-plate was supported on a cross-bar secured by two pairs of diagonal tie-bolts, which passed through internal cavities in the frame-castings and were continued through double washer-plates enclosing nests of powerful springs, the latter being introduced as a measure of safety against accident due to a piece of steel or other uncrushable material passing between the roll and the anvil-plate. The roller was 60 inches in diameter by 84 inches long. The roll was built up of a cast-iron centre, to which was keyed a cast-steel shell with inserted teeth of manganese steel. The crusher weighed 225 tons and was belt- driven by a 250-B.HP. motor to give a speed of 23 r.p.m. to the crushing-roll. The feed-size reached a maximum of 4 feet by 7 feet and the crusher, when adjusted for a 7-inch product, gave an output of 700 tons per hour.

As previously stated, the single-roll crusher, as a stone-breaker, is suitable for dealing with rocks coated or mixed with clay, or for substances the outer surfaces of which decompose under the weather, and, so long as the material to be crushed is not harder than moderately hard limestone, and does not contain a high percentage of silica, it will handle effectively a number of earthy or shaley substances that cannot be crushed with certainty in any of the reciprocating breakers.

SWING-HAMMER CRUSHERS

There are many types of impact pulverizers, some with revolving cages, some with paddles, some with fixed beaters in circular rotors, and others with loose or pivoted hammers as the striking media.

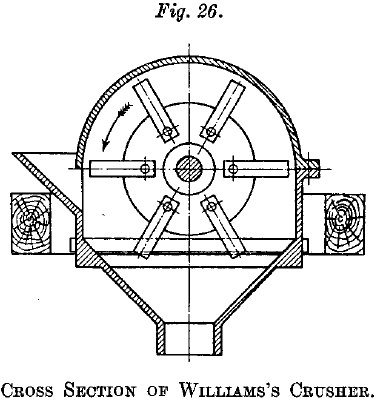

The name of Mr. Milton F. Williams is inseparably associated with the development of this machine, and one of his early patents is illustrated in Fig. 26. This design appeared in 1895, but it had many features in common with the swing-hammer crushers of to-day. The multiple hammers, made from narrow rectangular bars, were pivoted on pins passing through holes in a series of disks mounted on the main shaft, which was carried in bearings supported on a timber framework. A series of bars, passing through slots in the lower walls of the chamber, were arranged as a grating to span the opening in the base, the spaces coinciding with the paths of the hammers, whilst the bars were in line with the separating disks in the rotor. The material to be crushed entered the chamber through the feed-spout, lodged on or across the grate-bars, and was struck by the descending flail-like hammers until it was fine enough to pass the openings and escape to the outlet. As the screen-slots had to be of considerable length to leave clear tracks for the hammers, the bars could not be strengthened by cross bearers, and were liable to get bent by material wedging in the apertures.

Several methods of feeding were adopted for this type of crusher. Sometimes the material was made to slide under the descending hammers ; with others it fell directly on to the ascending hammers. In some instances the preliminary blows were struck by the descending hammers on a stream falling vertically, whilst in others the stone fell immediately on top of the rotating drum. There appears to be a definite relationship between the method of feeding, the internal shape of the chamber, and the system adopted for absorbing the energy of the hammers.

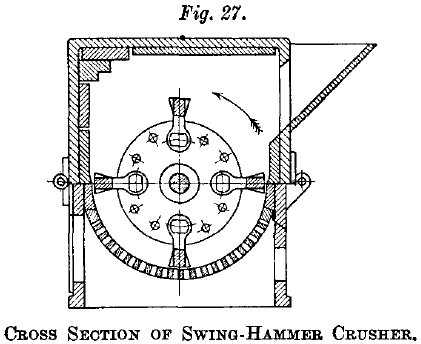

Fig. 27 illustrates a type of swing-hammer crusher introduced in France and England about 1904, and now made by the Patent Lightning Crusher Company. This machine was fitted with U-shaped or “ stirrup ” hammers instead of rows of multiple bars with narrow striking faces. The length of each hammer-head was approximately equal to the width inside the chamber. The rectangular shape of the upper half of the casing allowed ample clearance space above the path of the rotor, and the material was lifted by the hammers and dashed against the roof-plate, from which it rebounded to be driven again and again to the breaker-plates until it passed into the lower part of the chamber. By adjusting the speed it is also possible to work the machine without grid-bars, which gives a greater output with reduced maintenance charges.

Although the cage-bars are omitted in rare instances, they are usually retained when a fine product is required, to effect a secondary reduction of the material after the preliminary crushing on the

breaker-plate or in the upper part of the chamber. This second crushing process may be completed in the lower half of the chamber, or the oversize material may be driven round and re-broken by impact against the roof-plates, so that both large and small particles are subjected to the same shattering action.

As in the case of jaw and gyratory rock-breakers, swing-hammer crushers have gradually been adapted to take larger feed-sizes, and give greater outputs.

Fig. 28 shows the construction adopted by the Pennsylvania Crusher Company for their steel-frame hammer-mill suitable for taking large blocks of limestone and reducing them to a small product in a single operation. The frame is built of heavy steel plates strongly riveted together to withstand the severity of the shocks from the primary crushing. The framework for supporting the grid-bars and the backing-plates are made of cast steel. The rotor-shaft and disks are of alloy steels, and the hammers and grid-bars of manganese steel.

On many kinds of rocks the blows of the heavy hammers seem to cause the larger lumps to explode into a multitude of smaller fragments. Reduction, except on a relatively small portion of feed, is not a gradual process, but immediate and complete. The result of this explosive action is a material containing a high proportion of powder, making it difficult to estimate beforehand the character and gradation of the product.

Although the field of service of swing-hammer crushers is usually limited to the breaking down of the less abrasive materials such as limestone, shale, phosphates, gypsum, barytes, and asbestos rocks, they have been found to work well on some of the harder stones and ores.

SPECIAL GYRATORY MACHINES FOR SECONDARY CRUSHING

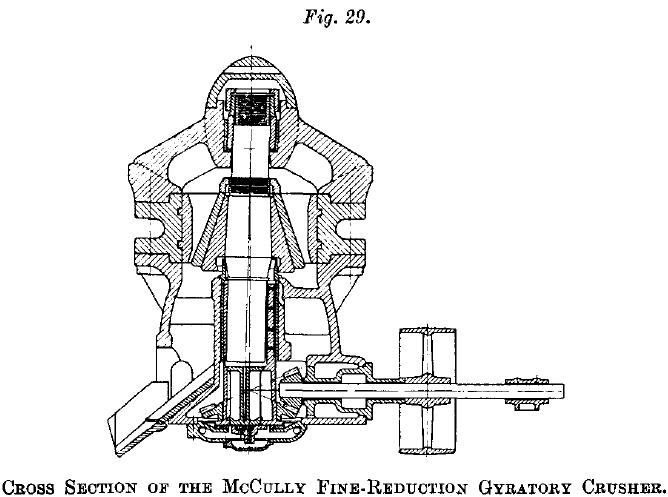

The outstanding feature of more recent developments in crushers has been the improvements made in gyratory machines for secondary crushing, including certain radical changes in constructional details, and the introduction of new principles of operation. The crusher- makers soon realized that a fine product necessitated a short stroke at the outlet-point. They also found that, when the movement at the bottom of the cone was restricted, the cone must be shorter than standard. A series of short-head gyratory crushers, based on the standard designs of coarse breakers, were only moderately successful, as they were very liable to choking and packing near the point of exit. They were ultimately replaced by machines mostly of the short-shaft type, as shown by the McCully design in Fig. 29. The concaves were vertical, and the head was made with a wide flare to give the greatest possible diameter at the bottom of the cone and so increase the area of the outlet. They were also speeded up to run faster than the coarse crushers in order to overcome, as far as practicable, the restriction in output brought about by the reduction in the width of aperture at the sizing-point.

It was known that, when the lower part of the crushing-zone was made practically parallel for a given length, and the number of crushing strokes increased beyond a certain limit, the time taken up by each crushing stroke was less than that occupied by the material in passing through the sizing-zone. Under these conditions it was possible to ensure that, instead of the size of product being limited by the width of aperture on the open side of the head, its thickness could be determined by the minimum aperture on the closed side at the completion of the crushing stroke. This principle of crushing was not entirely new; it had been applied to some of the roll-jaw crushers, and was used in vertical disk crushers, and it was thought, at one time, that it would enable reciprocating machines to replace rolls entirely.

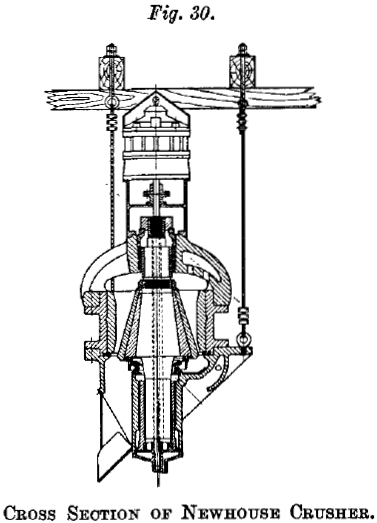

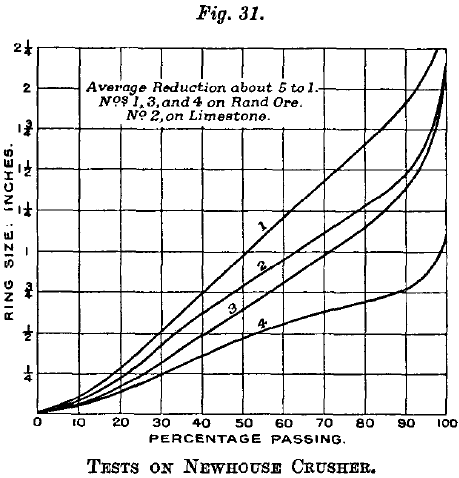

The Newhouse crusher (Fig. 30), built under licence in this country by Messrs. Edgar Allen & Company, Limited, of Sheffield, is a good example of the application of high-speed reduction with an approximately parallel sizing-zone. The eccentric in this machine is situated close under the head, and is direct-driven from the electric motor without the intervention of gearing. The number of crushing strokes per minute is about four times as great as in the ordinary coarse-crushing gyratory. The main shaft is suspended from the spider in the orthodox manner, but the shaft is bored hollow, which not only helps to relieve any internal strain, but also provides a passageway for the driving-shaft from the motor, situated directly above the spider, to the driver-plate on the eccentric. The concaves are reversible, and are so shaped that the crushing-angle changes in three progressive steps until, in the lowest stage, the lines of the head and concave are nearly parallel. This machine has a heat-treated main shaft, a high-carbon-steel coupling-shaft, and is usually fitted with mantle and concaves of manganese steel. Fig. 31 gives a few typical sizing tests.

In any breaker with rigid crushing members, there is always a danger that work may be impeded by stoppage due to the presence of unbreakable substances in the feed. Should nothing worse occur, a piece of metal may have to be cut or burnt away before the crusher can be restarted. This danger increases rapidly as the outlet setting is reduced to obtain the finer products, and, from the very earliest days of fine-crushing gyratories, efforts have been made to introduce springs or other yielding appliances to overcome this trouble.

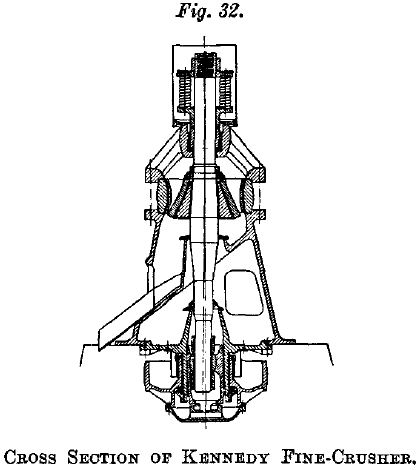

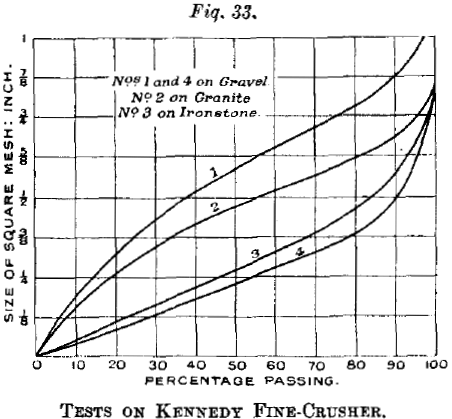

The Kennedy gearless fine-crusher (Fig. 32) shows how the necessary flexibility has been provided in one case, in the breaker made, in England, by the Sheepbridge Coal and Iron Company. This is a machine of the long-shaft type. It incorporates two special features peculiar to this range of crushers. The inner bushing has a ball-and- socket connection to the eccentric sleeve, and there are no bevel-gears, a pulley being coupled to the eccentric for direct drive by a twisted belt.

This breaker is also of interest because its designers were among the first of the gyratory-crusher builders to realize the advantage obtained by a progressive reduction in the crushing-angle as the material spreads out under the influence of the crushing strokes. The main shaft is extended for some distance above the spider- bushing, and a battery of spiral springs is inserted between the suspension-nut and the top of the sleeve, which bears on the ledge in the bore of the spider. When any piece of metal enters the space between the cone and the concaves the springs are further compressed, and the head and shaft move downwards to enlarge the gap sufficiently for the obstruction to pass with safety. Fig. 33 gives the proportions of the various screen-sizes as obtained from four selected tests made in one of the smaller crushers.

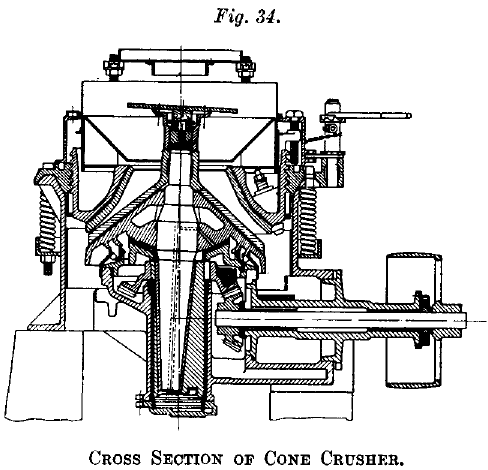

The cone crusher (Fig. 34) has proved to be very successful as a secondary breaker, and is remarkable for certain radical departures from the normal principles of gyratory-crusher operation.

In other gyratory machines the crushing process comprises reduction by pressure between two confining faces, and a subsequent freeing movement during which the material settles by gravity until it is caught and subjected to further pressure and again released. In the normal gyratory the crushing stroke or travel of the head has usually an important bearing on the size of the finished product.

The movement of the head in the cone crusher is similar to that in the ordinary gyratory with the exception that, towards the bottom of the cone, it travels through a much greater distance and gyrates faster. This long movement lower down the cone changes the crushing stroke from pressure to impact, and the increased clearance on the freeing stroke allows the stone to fall away vertically after each impact, the extent of the travel down the cone during the drawback stroke being controlled by the speed of gyration. The wide gap at the end of the opening movement permits the stone to move freely for the greater part of the time occupied in passing through the crushing-zone. The periods of confinement are therefore limited. The angle between the faces of the bowl-liner and the cone decreases gradually, and these faces are parallel near the outlet for a sufficient distance to ensure that the head must make one com-

plete gyration before the material can pass through this sizing-zone, which again means that it is the opening on the closed side of the crushing-head that regulates one dimension of the product. The length of the crushing stroke has therefore no direct bearing on the size of product.

The machine departs from the usual design in that there is no upper bearing for the gyratory shaft and no spider to bridge over the feed-opening. The head is supported in a part-spherical seating, and the tapering main shaft is actuated by an exceptionally long eccentric. The crushing-bowl, inverted over the cone and screw-threaded to permit of vertical adjustment inside a clamping ring, is held down to the body by a series of powerful springs that allow the bowl to rise the full movement of the head when tramp-iron or other uncrushable material enters the crushing-cavity.

With this machine the rate of feed should be carefully controlled, and the material should be evenly distributed round the circumference if regular and even wear is to be obtained : a feed-distributing and regulating plate is therefore mounted on top of the main shaft, with a vertically-adjustable spout above it.

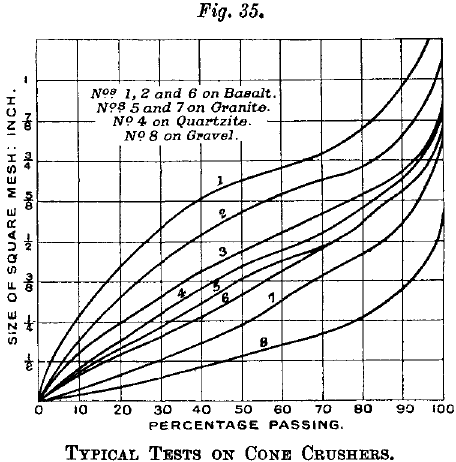

This machine was designed to obtain full advantage from constructional materials of the highest grade. Main frame, bowl, adjustment-ring, and ball-thrust-bearings are all of cast steel. The gears are also of steel with machine-cut teeth. The mantle and bowl-liner are of manganese steel. Fig. 35 gives a series of representative grading tests, for which the Authors are indebted to the Nordberg Manufacturing Company.

ALLOY & STEELS USED IN MAKING CRUSHERS

Manganese steel is mainly used for crushing-faces and other parts in actual contact with the stone. This alloy owes its pre-eminence to the property of work-hardening on its wearing face under the effects of pressure to a greater extent than any other metal; it also possesses exceptional tenacity and ductility. Although it can only be machined with difficulty, it is not essentially a hard material; in its treated condition it is very ductile and tends to spread or burr over under any excessive hammering or squeezing action.

Hardening of a manganese-steel working-face can only take place when crushing is accompanied by a certain intensity of hammering or pressure. When the material is abrasive but friable, the pressures developed may be insufficient to cause appreciable work-hardening, and rapid wear, under apparently easy conditions, should not always be taken as reflecting on the quality of the steel. Manganese-steel castings rarely exceed 5 inches in thickness, and, to obtain full value from the water-treatment, they are better kept within these limits.

Chromium steel is often used for large forged roll-shells as it is comparatively easily machined. To forestall the effects of the temperature rise that occurs under the severe working conditions, these shells have to be heated up when they are being fixed in position. In extreme cases the rings may be 9 inches thick and they should continue in service until they are worn down to approximately 1 inch in thickness. Unless the plant has special facilities for machining the parts, roll-shells should always be made of chromium or high- carbon steel where it is found necessary to machine their surfaces at frequent intervals to maintain their true alignment. Chromium steel is greatly improved by proper heat-treatment and its value is thereby greatly increased. These valuable properties may be destroyed by careless handling before being put into service.

Heat-treated steels are also of considerable advantage in those cases where crusher-shafts are liable to fatigue under constant reversals of stress. In some of the latest high-speed crushers the main shafts are of nickel steel suitably treated.

Crusher-frames and parts not subjected to direct abrasion are usually made from a good grade of carbon steel. Careful attention during the annealing process is of great value in enhancing shock- resisting properties.