Mining activities were typified by surface exploratory drilling identifying ore distribution and extension of underground workings to the lead and zinc deposits outlined. Exploration holes were either left unplugged or plugged at the surface with a section of a telephone pole. Low grade ore and waste rock were discarded in rained out portions of drifts. These waste piles containing pyrite and marcasite were left underground and oxidized during the many years of active mining.

Problem Definition

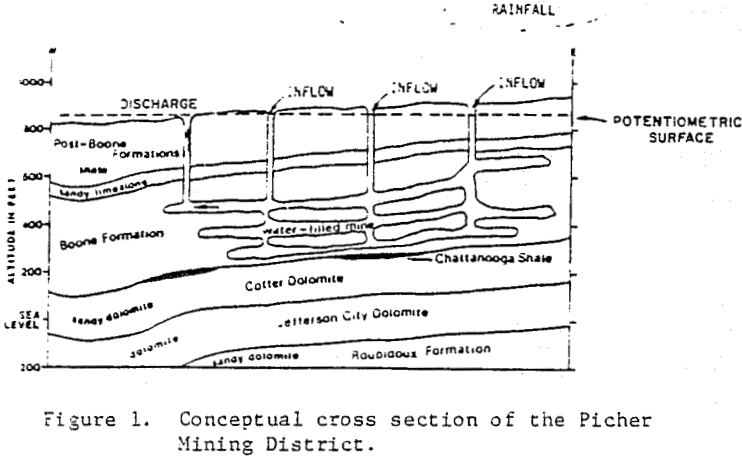

As with many underground mines, ground water inflows posed a problem during mining. To maintain unsaturated conditions in the workings large capacity sump pumps were used. Pumpage from the ore bearing Boone formation, a Mississippian cherty limestone, varied with time and depth of mining.

Filling of the cone of depression continued with time. Recharge to the cone was occurring radially and from direct surface water inflow to the workings through abandoned exploration holes, shafts and collapse features which penetrate the overlying shaley Krebs Group. Therefore, there was little potential for the highly mineralized water to move laterally, away from the mining district; but an opportunity existed for downward movement along the vertical hydraulic gradient toward the underlying Roubidoux formation, an Ordovician age sandy dolomite. The Roubidoux is the principal source of potable water for northeastern Oklahoma.

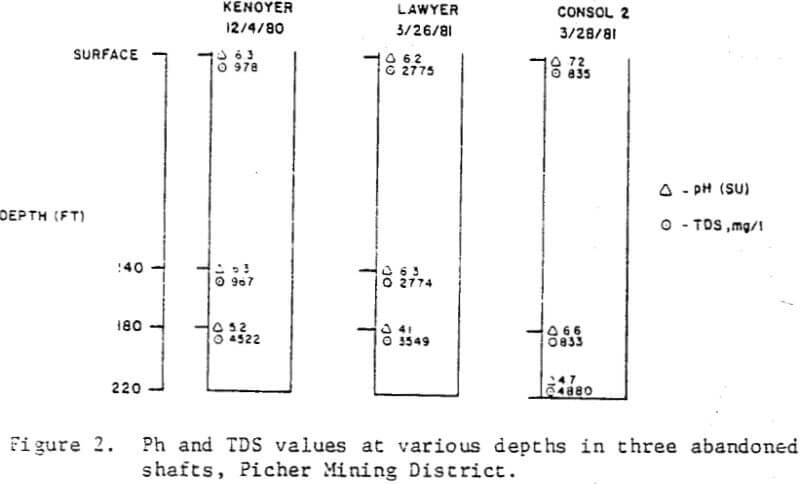

The quality of the acid mine water being discharged is significant in that toxic heavy metals such as lead and cadmium are present in average concentrations five times greater than drinking water standards. Iron and zinc are the predominant dissolved metals with average concentrations of approximately 150 mg/l each.

Mining Practices

Early exploration was accomplished by surface drilling to establish ore location and grade. In heavily mined areas, an excess of 1000 exploration holes per square mile (2.6 km²) can be identified on available mine maps. In actuality, the number of exploration holes is greater than indicated because the mine maps only show more recent exploration work conducted after consolidation of the workings by large operators. Typically, the exploration holes were abandoned or rudimentarily plugged. This was accomplished by either driving a 4 to 5 foot (1.2 to 1.5 meter) long section of a telephone pole in the hole or simply by shoveling surface material into the hole until it bridged off. Occasionally, a good show of ore would warrant casing the hole to provide access for air or power to the expanded workings.

The proposed solution to the acid mine water contamination in the Picher Field involves the collection of naturally occurring acid discharges, pumpage from wells in the lower portions of the drifts and treatment of the water collected. Natural spring discharges of acid mine water vary from about 0.25 mgd to 1.0 mgd (10.0 l/sec to 43.7 l/sec) depending upon the level of the potentiometric surface of the Boone as recharge and discharge oscillate. These natural discharges would be collected in lined spring boxes and transported to the treatment facility via a PVC pipeline.

Treatment

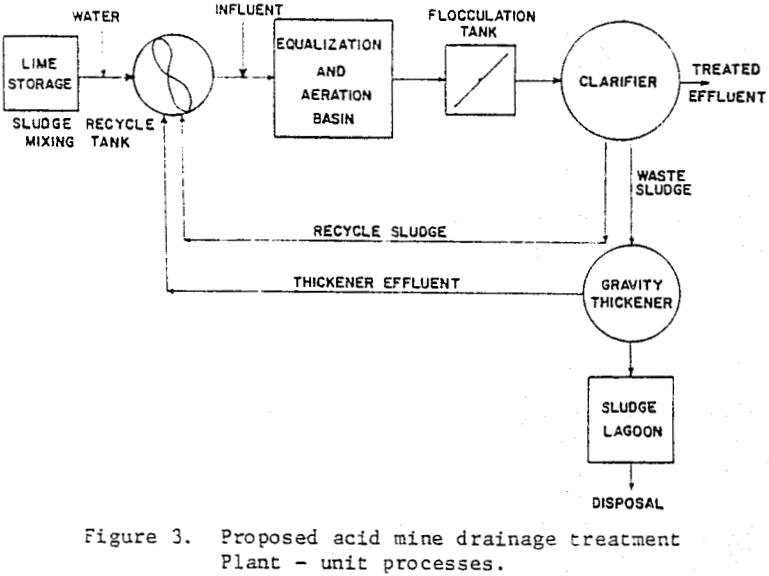

Lime neutralization and precipitation of acid mine water has been demonstrated to be the best available technology (BAT) and the most cost effective alternative for treating acid mine water. Various candidate treatment technologies were analyzed in detail with the technical feasibility of the candidate technologies based on criteria such as process fundamentals, control effectiveness, non-rater quality impacts, reliability, secondary waste streams, and preliminary cost and economic considerations.

A preliminary design and cost analysis was completed for a proposed 2 mgd (87.4 l/sec) treatment facility. Based on the water quality data from Tar Creek and various abandoned mine shafts, a level of treatment technology was selected. The proposed treatment plant is a mechanical system incorporating state-of-the-art unit processes used in acid mine water pollution abatement.