In a minerals-recovery context, the object of exercising control over milling operations must be threefold.

- To achieve maximum recovery at

- minimum operating costs and

- making maximum use of installed equipment.

Milling is one of a sequence of operations which have as their objective the economic recovery of minerals from mined ores. All operations in the sequence are inter-dependent and each is both influenced by and itself affects all other unit processes. The part which grinding plays in achieving each of the above objectives is indicated in the following analysis:

In South Africa, the most important mining operations are still the gold mines. A vast reservoir of knowledge and experience in treating the Witwatersrand and associated ores has been accumulated and recoveries are consistently high. However residue values do vary and frequently this is due to fluctuations in the degree of grind.

Mill Controls

The objects of any control procedures must be to obtain maximum operating efficiency at minimum cost and expenditure of labour. The tendency has been to concentrate on the efficiency of the grinding process itself when considering control methods and it would be worthwhile taking a look at the factors affecting cost and labour before considering the milling operation.

The major items affecting costs are:

- Power

- Stores

- Labour

- Maintenance

In a multiple-stage grinding system operating in closed circuit with classifiers, pumping accounts for about 10 per cent of the power consumed, and of all units the pumps are subject to the greatest fluctuations in power used.

Mills which run continuously under conditions of low efficiency waste power, but wastages of power equally, or even more serious can be caused by stopping and starting mills. If the stoppage is a voluntary one it is usual to cut off the new feed well in advance in order to run down the circuit and avoid the spillage and chokages which are almost invariably the result of involuntary stoppages.

Stores and particularly consumable items are a major contributor towards the cost of milling. The most important of these are the liners, rods and balls which effect grinding and may wear excessively as a result of unsatisfactory conditions in the mills, poor materials of manufacture, or the incorrect choice of grinding medium.

Automatic Control of the Milling Circuit

Steady production of ground ore at maximum rate, to desired size range and delivered at optimum per cent moisture, all at minimum cost.

In designing a mill control system certain basic assumptions are made, namely,

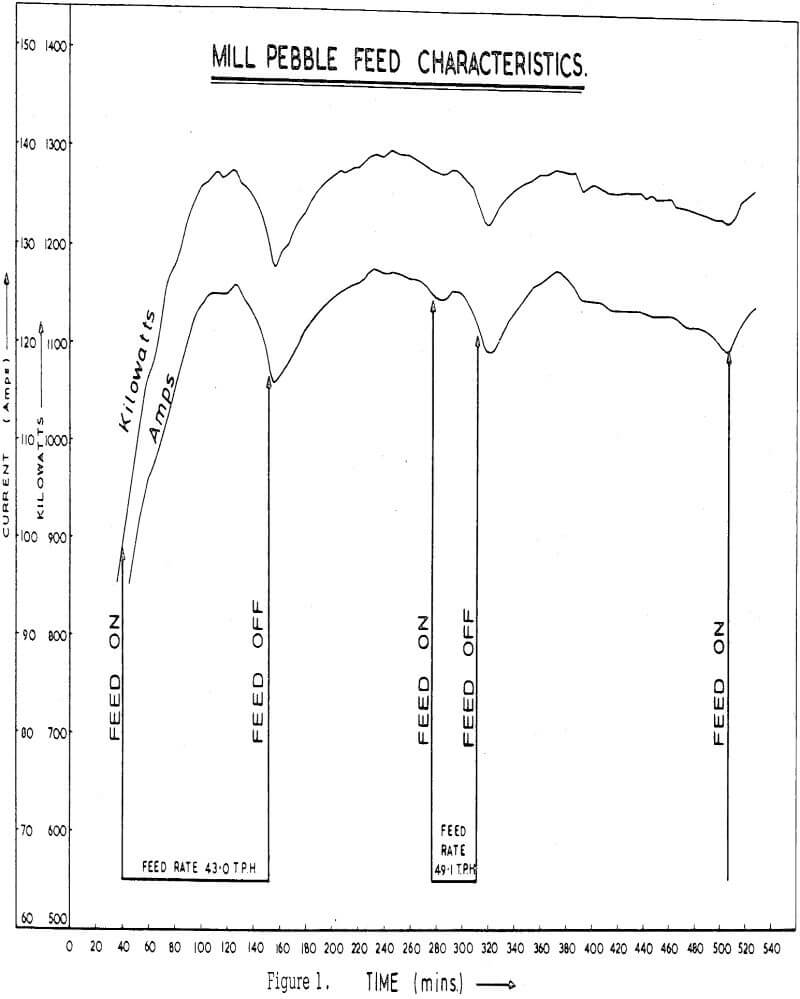

- That, other conditions being satisfactory, the power consumed by a mill is a measure of the work being done.

- That there is an optimum density for the pulp in a particular type of mill at which grinding efficiency is greatest.

- That the pulp should remain in a mill only sufficient long to achieve the desired degree of grind without overgrinding occurring.

- That a closed circuit allows a measure of selective grinding to take place,

A good control arrangement will therefore ensure that all mills in the circuit draw maximum power at all times; that the density in all mills is at the optimum figure for each mill that the material passes through each mill at the rate which will give the highest output of product of desired size; and that the classifiers in the circuit operate as efficiently as possible at all times to remove finished product and return oversize to the circuit for further grinding.

The influence which the consistency of the pulp in a mill exercises over grinding parameters has been discussed by the author in an earlier paper. The basic fact that emerges is that the pulp in a mill must be maintained, as consistently as possible at optimum density. This has been achieved by the Author and his colleagues in the Gold Fields mill control system.

The fundamental bases upon which this system has been built ares

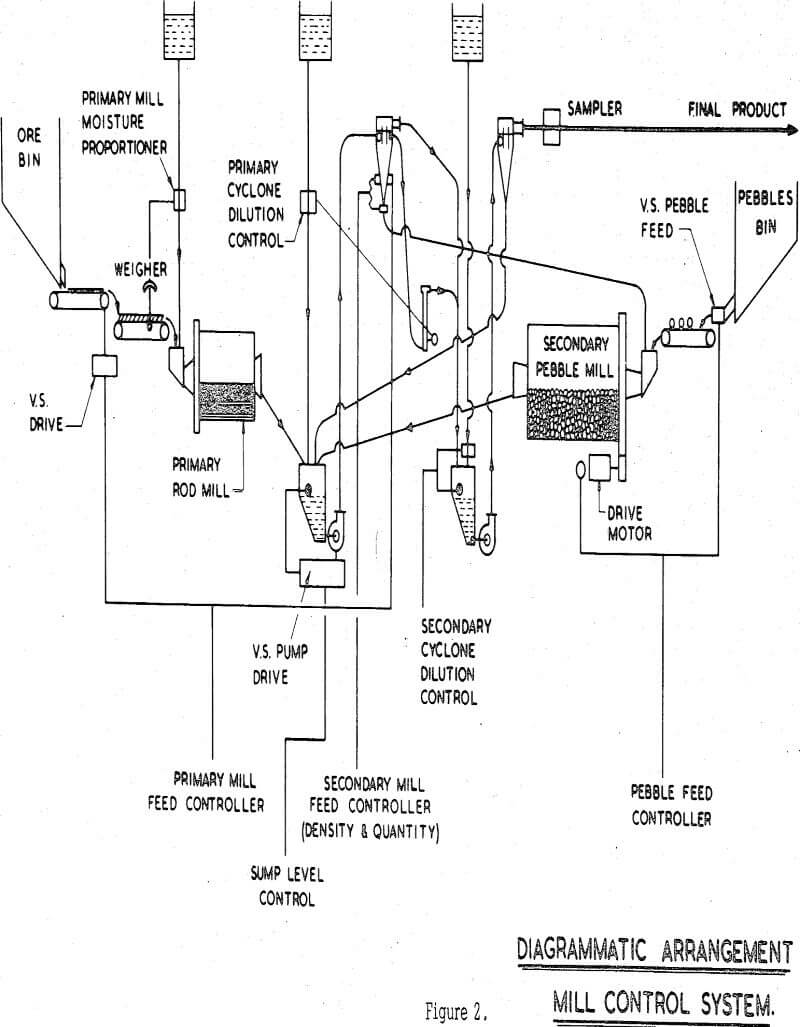

- That all recent grinding circuits with which the author is acquainted consist of a primary mill accepting new feed, followed by a second stage of milling in which the product from the primary mill receives further grinding.

- That the primary mill is usually a rod mill in open circuit while the secondary circuit employs ball or pebble mills in closed circuit with cyclone classifiers.

- That the cyclone classifier can be controlled to deliver an overflow product which can be maintained at a chosen specification, within narrow limits, and

- That the cyclone spigot product can be maintained at a constant density within limits sufficiently close for operating purposes.

Milling Control System

The density of the cyclone underflow product is measured by means of a nuclear gauge situated a short distance above the spigot valve. The type of gauge employed is a 300 millicurie caesium 137 isotope emitting gamma rays, which are detected by a Geiger-Muller pick-up unit. The signal from the G.M. unit is fed into a ratemeter where it is converted to a 0-10 mA current. The ratemeter is set so that the desired cyclone underflow density is represented by a 5 mA current. The signal from the ratemeter is fed into a spigot pressure control unit where a high and low limit is set above and below 5 mA. A deviation from 5 mA (representing a change in underflow density), beyond either of these limits, operates a motorized pneumatic valve allowing air into the cyclone spigot valve, causing it to close slightly, or allows air to escape, causing the spigot valve to open slightly. This will continue until the density is back to its desired value.

A signal, from the rod mill feed belt weigher is compared with a signal from a tachogenerator on the dilution pump. The signal from the weigher is proportional to the ore feed rate, and the signal from the tachogenerator is proportional to the rate of dilution water fed to the rod mill.

The cyclone overflow product is continuously sampled. The sample flows through a constant head cylinder fitted with a differential pressure transmitter which emits an electrical current signal. The signal is fed into a cyclone overflow density controller.