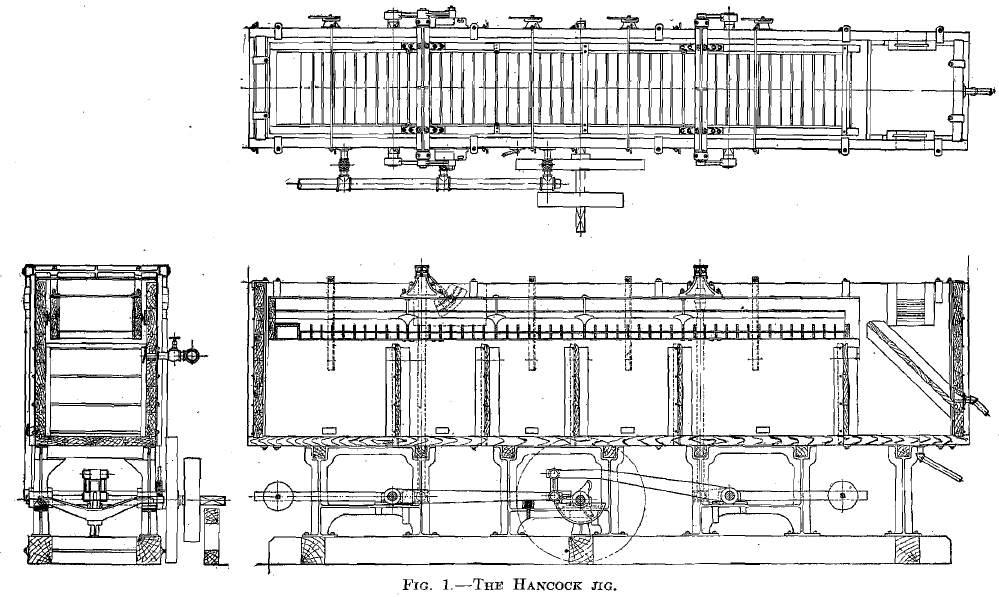

The following notes are taken from results obtained on a standard 25-ft. Hancock jig tested during regular operation. The object of the tests was to determine the conditions for most effective work, and the nature of products that could be made.

The material treated was sized between 9-mm. and 2-mm. round- hole screens, and was constant throughout the experiments. Three products were made, concentrates from the first three hutches, middlings from the fourth and fifth, and tailing from the sixth. The middlings were crushed in one pair of Allis-Chalmers Style B, 30 by 14-in. rolls, and elevated with the original ore to the 2-mm. screens, oversize of which formed the jig feed.

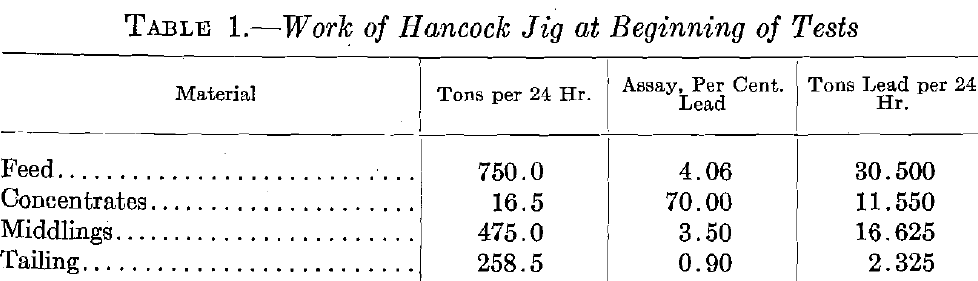

While this arrangement was very simple, it gave rise to undesirable crowding of the circuit. Table 1 shows tonnage and assay values of the jig feed and products at the beginning of the experiments, and brings out the excessively large amount of middlings, comprising 63.3 per cent, of the total material fed to the jig. The rolls, being heavily overloaded, did very little crushing, a screen crushed fine enough to pass to the tables. The remaining 347 tons returned to the jig with 400 tons of original ore. At times, this overcrowding became much worse, and the tonnage in circuit grew to enormous proportions. It became imperative either to decrease the amount of middlings, or to provide more crushing capacity, and series of experiments were begun along both lines. This paper deals only with the attempt to improve the work of the jig as then equipped.

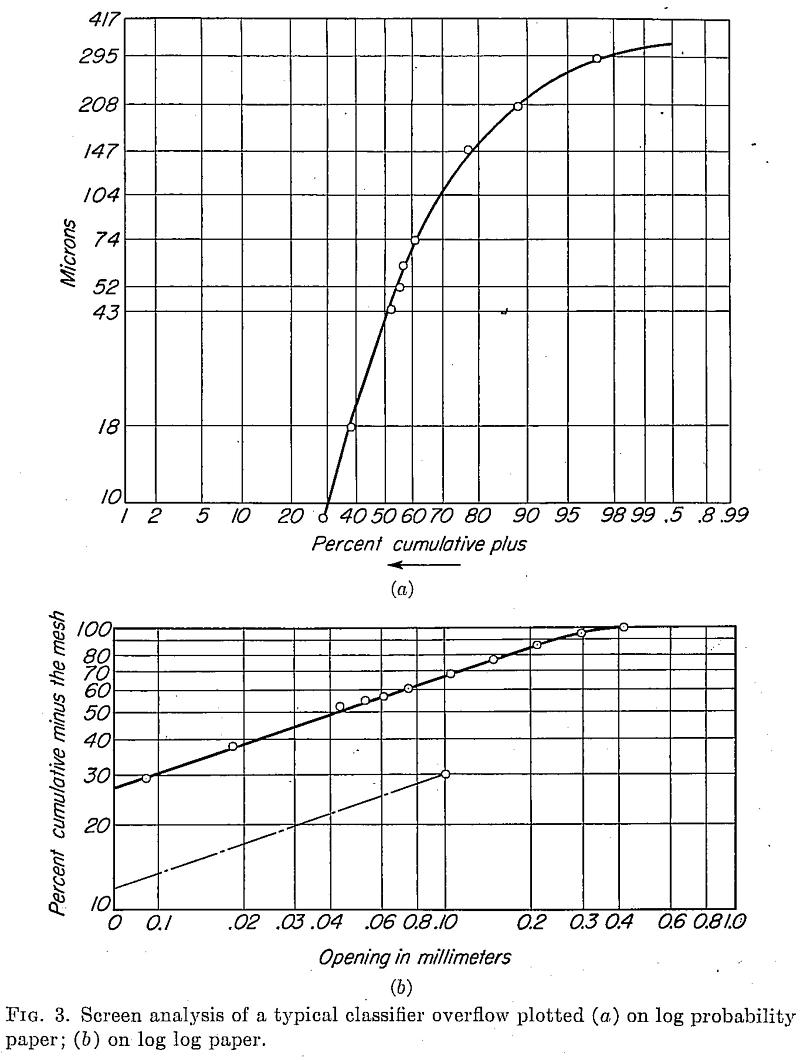

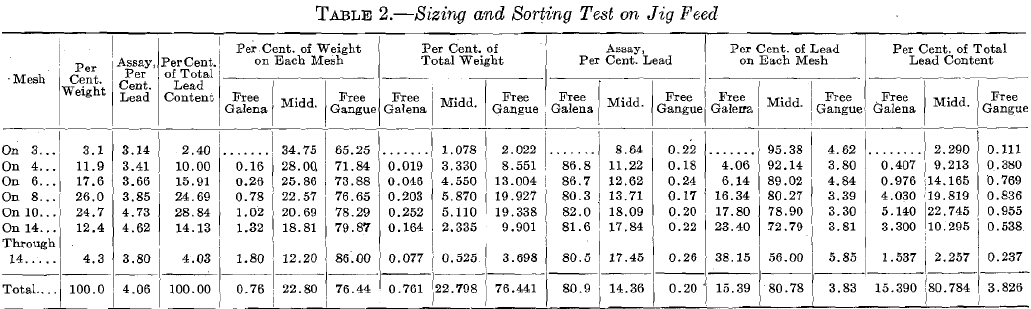

Before commencing the experiments, a combined sizing and sorting test was made on an average sample of the jig feed. Tyler standard screens were used for the sizing test and all sorting was done by hand. Table 2 shows the result of this test, and Fig. 2 and 3 represent the same thing graphically. The horizontal divisions in the diagrams represent the percentages of material on each size, and the vertical divisions the percentages of free galena, middling, and free gangue as obtained by

sorting. Areas, therefore, represent percentages of the total weight of sample. For instance, in Fig. 2 the length AB is 26 per cent, of the total length of the diagram, and represents the amount of material between 6 and 8-mesh. The length AD is 76.65 per cent, of the total height of the diagram and represents the percentage of the 6 to 8-mesh material, which occurs as free gangue. The area ABCD, therefore, shows the percentage of the total sample occurring as free gangue between 6 and 8-mesh and is equal to 19.927 per cent, of the total area of the diagram, while the area EFGH shows the total amount of free gangue in the sample, or 76.44 per cent.

The results obtained by this test led to the belief that it was possible greatly to reduce the tonnage of hutched product without affecting the

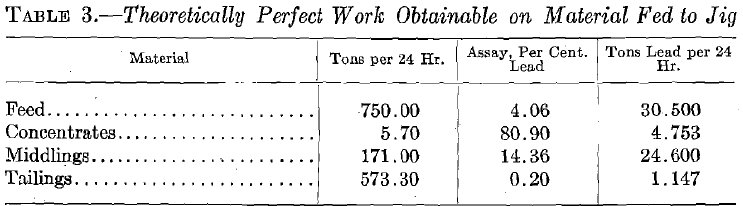

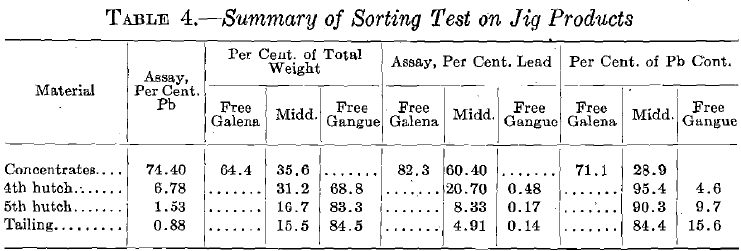

grade of tailings. Table 3, worked out from the results of the sorting, shows the work that might be expected from a theoretically perfect concentrating machine, and differs considerably from the record of the actual work obtained (Table 1). An unnecessarily large amount of free gangue seemed to be passing through the jig screens, and a sorting test on the jig products (Table 4) confirmed this, the fifth hutch especially containing almost as much free gangue as the tailing.

In the investigations following the above work, special attention was given to the possibility of decreasing the amount of gangue being hutched with the middlings, and a summary of results obtained and conclusions arrived at, is given here.

Operation of the Jig:

The following factors may be taken as having most effect on the work of the Hancock jig:

- The speed of the jig.

- Length of vertical stroke.

- Length of horizontal stroke.

- Depth of bed.

- The size of the grains forming the bed.

- The specific gravity of the grains forming the bed.

1. The speed of the jig was varied between wide limits—from 170 to 210 strokes per minute. The high speeds gave increased tonnage of hutch product, and were objectionable from a mechanical standpoint. At the slow speed of 170, difficulty was experienced in keeping the bed moving freely, it having a tendency to pack, and lose its quicksand effect. A speed of 190 to 195 strokes per minute was finally decided on as being the most desirable.

2. The length of vertical stroke, by affecting the pulsion and suction velocities affects the tonnage of hutched product, increased length causing more material to be hutched, and vice versa. It varies between 3/8 and 3/4 in., the adjustment being made by the operator according to the lead content of the material treated.

3. The horizontal stroke should be as long as possible, in order to have, above the bedding, a thin layer of ore. In treating large tonnages, the long stroke is particularly desirable, the improved separation in a thin layer more than compensating for the shorter time the material is under treatment. A minimum horizontal stroke of 3/4 in. is used, and it is probable that greater capacity could be had by making the stroke much longer.

4. The depth of bed on the Hancock jig is determined by the height of the slats above the screen. No experiments were made with variations of this distance, all jigs being operated with 3 in. of bed depth.

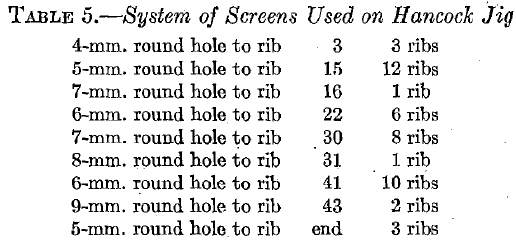

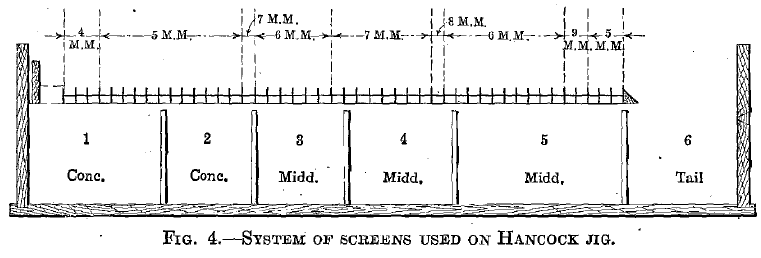

5 and 6. The size and specific gravity of the grains forming the bed are determined entirely by the size of the jig screens. No artificial bedding has been supplied at any time, as experiments have shown that with a carefully designed system of screens any desired bed can be produced and held, relying on the ore to supply all the material necessary. The nature of the bed being the most important factor influencing the work of the jig, the main part of the investigation was taken up by the effort to work out a system of screens that would give satisfactory work under average conditions, and would be flexible enough to take care of extreme variations in the grade and nature of the material treated.

The system that was finally evolved is given in Table 5, and while it would probably only be applicable to the Bonne Terre ore, the principles of its evolution may be found useful in the solution of similar problems elsewhere.

Close examination of the jigs brings out the following points:

1. Stratification of the material into layers of varying richness takes place almost immediately after it reaches the tray. This is helped by the strong pulsion effect on the first hutch, where suction is minimized by the fineness of the bed of free galena, which lies in a heavy mass on the screen.

2. In order to remove all the material containing lead, both as free galena and middling, a bed is required that gradually decreases in specific gravity, with increasing size of grains. This was found to be most effectively obtained by arranging the tray with an occasional row of large holes, to take out the bedding in steps.

3. The bed may be likened to a screen of varying size holes, this size depending on the size of grains. Any section should be just long enough to give a good “screening efficiency” on such material as will pass through it. For instance, a bed composed of grains of specific gravity 4.0 will hutch a product assaying about 40 per cent. lead. If it be found that all the 40 per cent, material present will pass through in a length of 2 ft., there is a loss of efficiency by extending this particular bed any farther

than 2 ft. A row of large holes at this point will allow the heavier particles to pass through, leaving a bed of lighter specific gravity for the next section of tray. A bed which changes rapidly in character will therefore allow all parts of the jig to do equal work, and give maximum efficiency.

4. There are two distinct operations to be considered. First, the making of clean concentrates, and second, the making of clean tailing. These are justly considered apart, and of the two the latter is by far the more difficult. The specific gravity of galena is 7.40 and of gangue 2.80, and while the separation of these two minerals is easy, the material received on the jig is made up of grains ranging from one extreme to the other. By sorting the products of the jig (Table 4) it is found that concentrates are made up of grains of free galena of grade 82.3 per cent, lead, and middlings of 60.4 per cent. lead. Specific gravities are 7.00 and 5.20 respectively; a difference of 1.80 tailings are made up of middlings of grade 4.91 per cent, or specific gravity 2.95, and gangue of grade 0.14 per cent., or specific gravity 2.82, a difference of 0.13. These figures illustrate the wider range of specific gravity permissible in concentrates, and therefore the relative ease of separation of the high-grade material.

5. The small amount of free galena present, as shown in Table 2, also helps to simplify its separation, and it would appear to be good practice to hutch the free galena in as short a distance as possible, reserving the greater length of the tray for the more difficult work of separating‘middling from tailing. An attempt to do this was very successful, and concentrates are now made on only two hutches, occupying 80 in. of screen length. The larger part is caught in the first hutch, the second acting as a safeguard to prevent free galena being carried over into the middling hutches. As a general rule, the tonnage of product from the second hutch is very small.

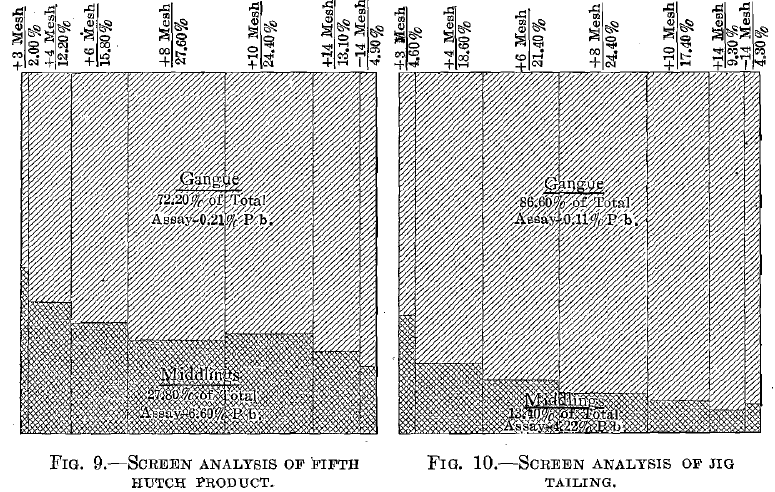

6. The separation on the final section of the tray, or the part over the fifth hutch, must necessarily be rough, owing to the low grade of the middling remaining, and the small difference in specific gravity between it and the free gangue. The bed consists of large-size grains of low-grade middling, and the heaviest tonnage of hutched product is made here. At the end of the fifth hutch, two ribs of holes, large enough to take out all the remaining bedding, are used.

7. Variations in grade of the feed introduce complications that must be allowed for in the screen layout. An excess of bedding material, due to higher-grade ore than usual, causes an accumulation of heavy grains that cannot pass through the screens, while low-grade ore will allow the bed to become too light, and the hutched product will contain too much gangue. By arranging the screen to take out the bedding in steps, as mentioned before, such an accumulation cannot extend very far, but extreme varia-

tions are best taken care of by the operator, who shovels off excess bed, and plugs the large holes in the screen when bedding material is scarce.

8. Wire cloth and punched plate were both tried for the jig screens,

with a final decision in favor of the latter. While it is sometimes claimed that wire cloth gives less trouble by blinding, it was found in these tests that there was very little difference in this respect, while punched plate had the advantage of being more easily cleaned.

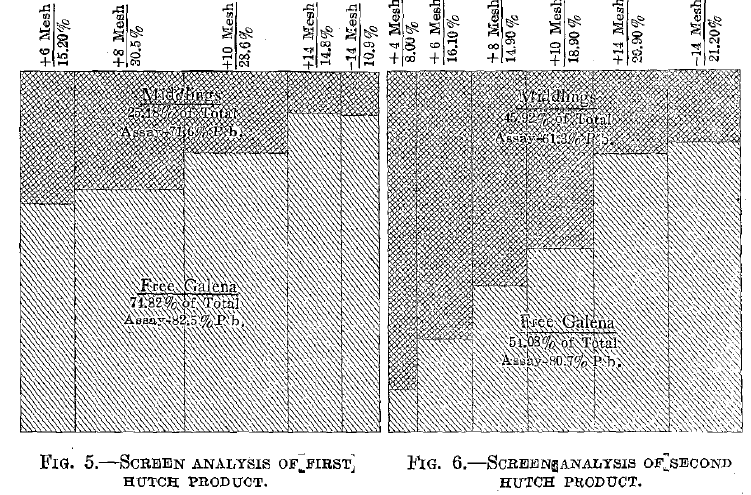

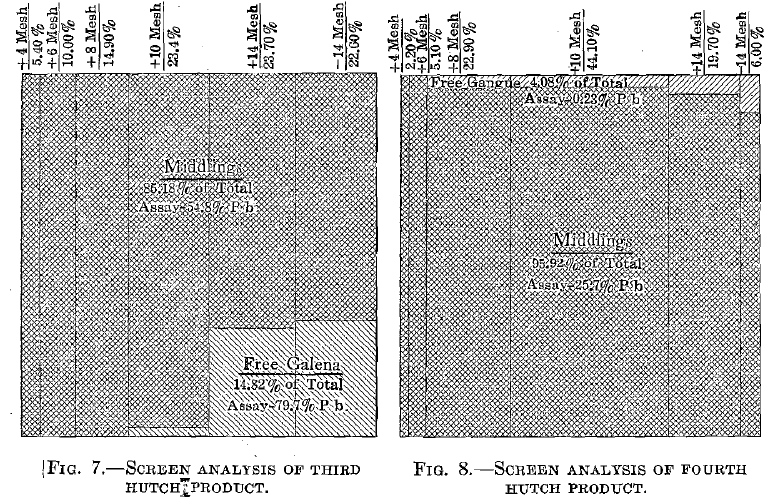

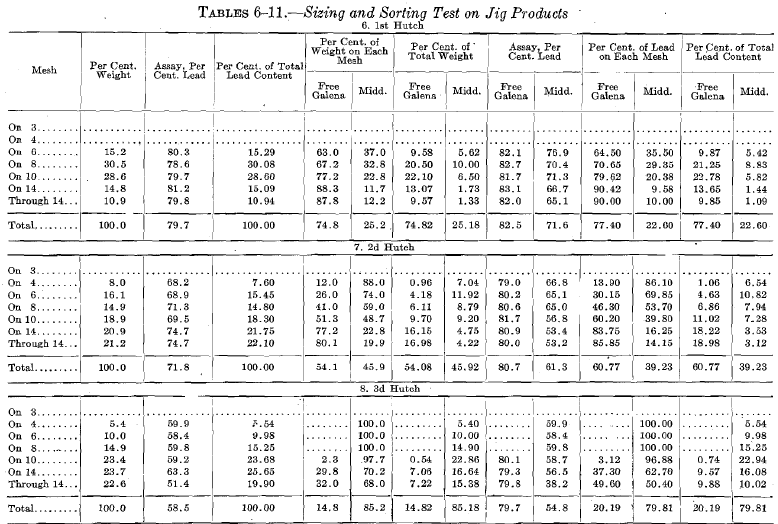

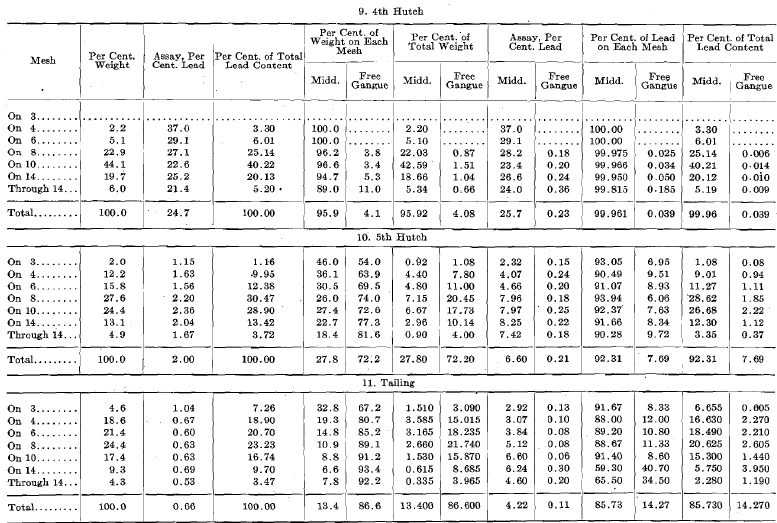

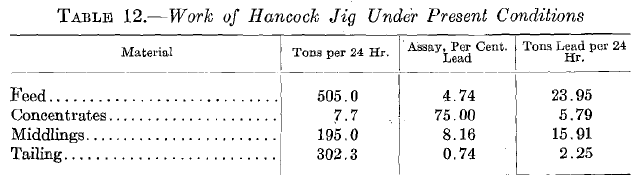

The nature of the products obtained with the screen system given in Table 5, are shown in detail in Tables 6 to 11 and Fig. 5 to 10. The first two hutches produce good concentrate, the third and fourth a rich middling, and the fifth a low-grade middling containing a large proportion of free gangue. Analysis of the tailing shows some middling escaping. The lead in this occurs as very small pieces sticking to the large pieces of gangue, or included in them, and owing to its low specific gravity it is doubtful whether this low-grade middling could be saved without recrushing the whole tailing. Table 12 shows results of a tonnage test on the jig, equipped with the screen system given in Table 5.

The rolls have a feed of 195 tons per 24 hr., of which 58 per cent., or 113 tons, is crushed fine enough to pass through 2-mm. screens. The remaining 82 tons returns to the jig with 423 tons of original ore. The lighter load on the jig enables it to do better separation, and a cleaner concentrate and lower tailing are possible.

Subsequently the tonnage of ore treated in the mill was raised from 1,800 to 2,200 tons per day without extra jig equipment, and with lower tailings than previously, the gain being almost entirely due to the more efficient work done by the jigs.

DISCUSSION:

A. P. WATT, Mine La Motte, Mo.—The information in Mr. Rabling’s paper is of great value to users of the Hancock jig. In the Lead Belt, these jigs treat a larger tonnage than any other type of concentrating machine, and produce tailing of a larger size. This indicates the necessity for logical operation of the Hancock jig. The jigs receive at least 75 per cent, of the total original feed, the other 25 per cent, going to tables and flotation machines. Jig operation is therefore of paramount importance on account of the large tonnage treated, and the great volume of coarse tailing, which ranges from 10 to 2 mm.

The tonnage of tailing made by jigs will vary with the efficiency of the crushing machinery used for re-crushing the jig middling. The use of ball-mills will diminish the tonnage of jig tailing. The ratio of jig tailing to jig feed may vary from 50 to 80, depending on the means used for crushing the middling. The loss of mineral by jigs, theoretically 4 per cent, but sometimes actually 16 per cent., is three to four times the combined loss of tables and flotation plants. This again shows the importance of proper jig operation.

Mr. Rabling’s figures are of special interest to the operators in the Lead Belt, because the tonnage of jig middling that may get into circulation with poor supervision sometimes reaches enormous proportions. At times, under poor operating conditions, the returned feed may equal the tonnage of original feed.

Furthermore, if the jig bed does not receive proper attention, the fifth hutch product may assay lower than the tailing. When this occurs, the jig is not acting as a jig but simply as a screen, the fine material being sifted through, while the larger sizes are tailed over; owing to their size and the presence of included grains, they assay higher in lead than the fifth hutch product. Under poor operating conditions, the fifth hutch may contain 90 per cent, clean gangue.

The Hancock Jig in the Concentration of Lead Ores, by Harold Rabling