Table of Contents

- Bumping Tables

- Development of Differential-Motion Tables

- Principles Of The Tabling Process

- Importance of Correct Operating Conditions

- Efficiency of Concentrating Table as Coal-Cleaning Device

- Evaluating Table Performance by Consideration of Washability Curves

- Concentrating Tables vs. Other Cleaning Systems

Wet-Process coal-washing tables as we know them today have been in use in this country for approximately 25 years. The literature records only a few table installations worthy of note prior to adoption of the present-day differential-motion table. According to Phillips, six Campbell bumping tables were being operated by the St. Bernard Coal Co., Earlington, Ky.

Bumping Tables

Bumping tables, as the name implies, utilized a bumping action for conveying the refuse and discharging it over the refuse end. The tables were hung from rods attached to overhead supporting beams. A shaft and cam arrangement at one end of the table served as the actuating mechanism and imparted to the table an endwise, back-and-forth, swinging motion. A bumping block was fixed in the proper position at the shaft end, so that the table would strike against it at the end of each backward swing. The hanger rods or stirrups were so adjusted as to give the table a slight uphill slope toward the refuse end; that is, the end next to the driving mechanism. The feed box was near the upper end of the table and designed to spread the mixture of coal and water over the width of the table. Wash water was added a short distance below the feed box. With the table in motion and coal mixed with water being fed to it through the feed box, a certain amount of stratification took place, depositing heavy refuse at the bottom of the bed in contact with the surface of the table. Constant bumping and a certain amount of friction between the refuse and table carried the refuse up the slope and discharged it over the upper end. The top layer of the bed, which was light and consisted mainly of coal, was carried along in the opposite direction by the wash water and was discharged at the lower end of the table as washed coal.

Development of Differential-Motion Tables

By means of radical changes in design the more serious faults of the original bumping tables have been virtually eliminated from modern tables. The concentrating table is now one of the most dependable and efficient devices obtainable for the cleaning of certain sizes of coal. There are two principal differences of design between the modern table and the original bumping table; namely, (1) the differential-motion feature has been substituted for the camshaft and bumping-block combination for actuating the table, and (2) the riffled deck with cross-flowing water now replaces the former boxlike deck with its longitudinal flow of water and end discharge of the washed coal.

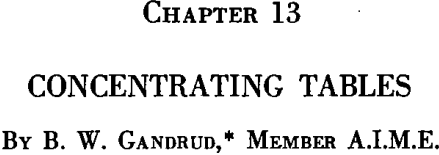

The differential motion imparts to the table a conveying action without resort to bumping. The fundamental effect of this motion is to make the table deck approach its reversing point and recede from it with greater speed at one end of its travel than at the other. It must be remembered that the table deck in its back-and-forth motion comes to a stop at each end of its travel before its direction of movement is reversed. This means that if it approaches one end of its travel with greater speed than the other its rate of retardation must be relatively greater at that end. Hence both the retardation and acceleration are greater at one end than at the other. This imparts to the table a conveying action fully as effective as that obtained by bumping, and with much greater smoothness of mechanical action.

The relation between the movement of the end of the pitman and the outer end of the toggle D is analogous to the relations in the familiar calculus problem involving a ladder that rests on the ground with one end and leans against the vertical wall of a building with the other. If it is assumed that the ground is level and that the lower end of the ladder is being pulled out along the ground, the downward speed of the upper end of the ladder with relation to the horizontal speed of the lower end is ex-

pressed by the derivative of the function based on the right-angle triangle formed by the ladder, the wall, and the ground, as follows:

dy/dx = – x/√a² — x²

Where a = the length of the ladder,

x = the distance of the bottom of the ladder from the wall,

y = the height of the upper end of the ladder above the ground.

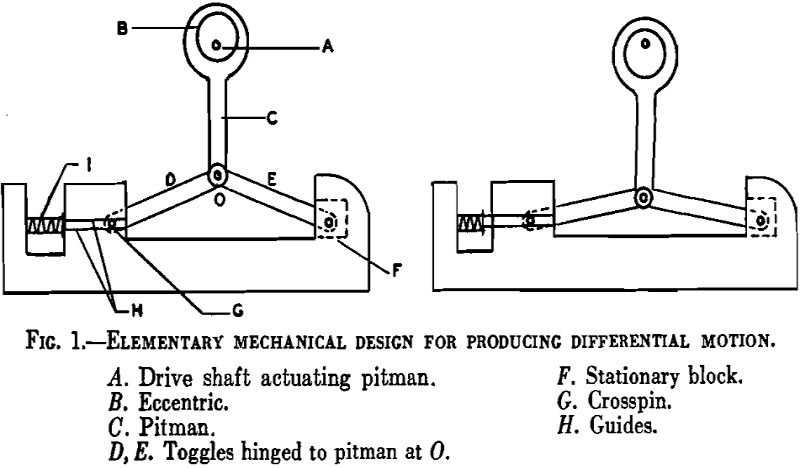

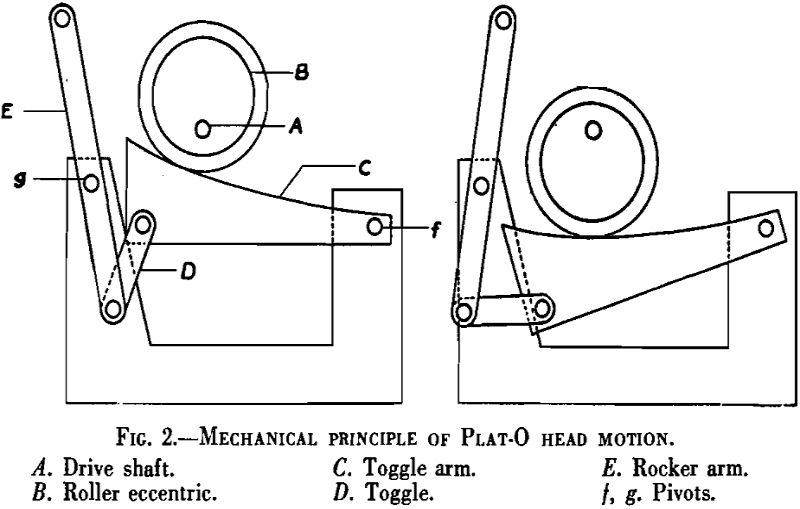

It has been pointed out that there are some variations in the mechanical – designs used for obtaining differential motion. Each table manufacturer uses a design slightly different from those of his competitors. There is no need to describe all these variations in design. The head motions of only the two tables commonly used for coal washing in this country, the Deister-Overstrom and the Plat-O tables, will be discussed here. Reference to the Deister-Overstrom and Plat-O tables is sometimes confusing owing to the fact that they are made by two companies having very similar names, the Deister-Overstrom table being made by the Deister Concentrator Co. and the Plat-O table by the Deister Machine Company.

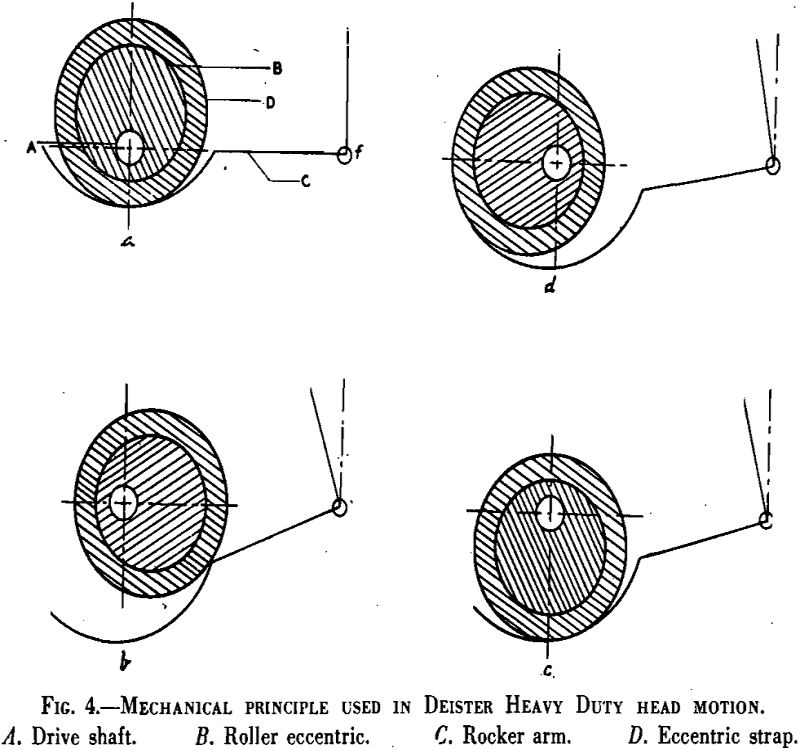

The older Deister-Overstrom table can be operated with either a Deister Heavy Duty or Overstrom head motion. The SuperDuty diagonal deck table is equipped with the Concenco head motion. The two latter use the simple modification of the pitman and toggle design shown in Fig. 3. A is a drive

The Deister Heavy Duty head motion is no longer used extensively on coal-washing tables. It is one of the few head motions that give differential motion without the use of a pitman-toggle combination. The rocker arm is pivoted at f by a bearing pin held rigidly in the frame. A coiled spring under the refuse end of the table deck keeps the left end of the rocker arm in tension against the face of the eccentric roller.

Although the differential action obtained with this mechanism in the Deister Heavy Duty head motion is extremely vigorous, it can be increased further if desired by another device, which is a part of the head-motion assembly. This device operates on the principle that by means of a sliding crank arrangement for transmitting the motion of the drive pulley to the main drive shaft the drive shaft can be given a differential angular velocity.

Principles Of The Tabling Process

The most generally accepted explanation of the action of a concentrating table is that as the material to be treated is fanned out over the table deck by the differential motion and gravitational flow, the particles become stratified in layers behind the riffles. This stratificaton is followed by the removal of successive layers from the top downward by cross-flowing water as the stratified bed travels toward the outer end of the table. The cross-flowing water is made up partly of water introduced with the feed and partly of wash water fed separately through troughs along the upper side of the table. The progressive removal of material from the top toward the bottom of the bed is the result of the taper of the table riffles toward their outer end, which allows successively deeper layer of material to be carried away by the cross-flowing water as the outer end of the table is approached. By the time the end of the table is reached only a thin layer, probably not thicker than one or two particles, remains on the surface of the deck, this being finally discharged over the end of the table.

The physical and mechanical principles involved in the concentrating action of a table are somewhat more complicated than this explanation implies. Mathematical calculations and experimental data are extremely useful in studying these principles, but they tell only a part of the story and do not explain the highly efficient separations that tables are known to be capable of making.

As far as is known, no exhaustive studies have ever been made of the principles involved in table concentration by either ore-dressing or coal-preparation engineers. Bird and Davis probably have given more attention to the subject than any one else, but their experimental work was of a preliminary nature. It was done on minus 4-mesh raw coal and on synthetic mixtures of various products derived from this raw coal by screen sizing and sink-and-float fractionations. They used an apparatus which they called a stratifier.

The theory of Bird and Davis as to the selective action of the crossflowing water is that only a part of the water flows over the top of the bed between riffles; the remainder flows through interstices in the bed. These interstices are comparatively large near the top of the bed but become progressively smaller toward the bottom, thus forming in effect V-shaped troughs. In this way the water currents would be relatively swift near the top of the bed and become progressively slower toward the bottom. According to Bird and Davis, “With paths for the water such that the top strata are subjected to relatively swift currents and the lower strata are subjected to progressively slower currents, the separation actually occurring on the table can be explained. As the coarse particles at the top receive swift currents and each successively finer size at the lower levels receives slower currents, the velocity of the water matches the size of materials comprising the different strata. Under these conditions a separation occurs in the lower strata similar to that in the top strata, only it takes place more slowly. The slow currents of water within the bed carry the fine coal particles along from riffle to riffle, at a more rapid rate than they do the fine bone and shale particles.”

To explain how a certain degree of hindered settling might occur on a table, we must assume, as Bird and Davis did, that although a part of the water flows across the top of the bed the remainder of it flows through interstices in the bed itself between adjacent riffles. This seems to be a reasonable assumption and it is one that is also made by Taggart in his discussion of the theory of table concentration.

Size and Shape of Particles

In this discussion of table principles shape of particle has been disregarded because it is believed that, as a rule, this is not an important factor in the coal-tabling process. Almost invariably the coal particles are somewhat more cubicle and less platy or flaky than refuse particles, but there is little evidence to show that refuse particles of one particular shape are more difficult to separate on a table than those of some other shape. As for the coal, the shape of particles in sizes suitable for tabling are pretty much alike in all coals. Yancey made a study of the effect of shape of particle. He decided that, for the coal he used in his study, “shape of particle is a factor of minor importance in tabling this unsized coal, in so far as the over-all efficiency of the process is concerned. Size and, of course, specific-gravity difference are the major factors.”

Importance of Correct Operating Conditions

In the use of tables in coal preparation, the importance of correct operating conditions can hardly be overemphasized. It is a peculiarity of tables that they give excellent results when correct operating conditions are maintained, but with conditions upset and unbalanced the results are likely to be as far on the bad side as they were on the good side under favorable conditions.

Table Foundations

It is a comparatively simple matter to build foundations substantial enough so that they will not have a tendency to shake or vibrate as a result of the motion of the tables. A reinforced-concrete slab need not be more than 6 or 7 in. thick to provide a perfectly rigid foundation, even at a considerable height above the ground, if properly supported on reinforced concrete pillars. It is important to provide tables with substantial, rigid foundations that will not deteriorate after a few years of service. Even a slight shaking or vibrating motion in the foundations is likely to interfere with the action of the tables and lead to serious loss of table efficiency.

With further reference to optimum separating conditions within the bed itself, it is important to maintain always the right kind of distribution—the term distribution in this connection referring to the table distribution of the material with which the constantly moving bed on the table is maintained.

Changes in the size distribution of a feed are sometimes caused by difficulties in the dry screening of run-of-mine coal. If dry screening is used and the amount of surface moisture in the run-of-mine coal varies, a finer table feed will be produced when the coal is excessively moist than when it is dry. Naturally, particles near the upper size limit will go through the screen readily if the coal is dry whereas if the coal is wet these particles are likely to go into the oversize. The resultant variation in the size character of the feed can interfere with table efficiency as readily as segregation in the bin. Wet screening eliminates this difficulty.

In summarizing, the principal adjustments and factors to be considered in putting a table into operation on a certain feed are: feed rate, as to volume of both coal and water; slope of the table (longitudinal and cross slope) ; riffling system, table speed, and length of stroke. A table installation should be so designed that any or all of these adjustments and factors can be changed easily to meet requirements during the procedure of placing the tables in operation. In starting a table plant, the main objective should be to find the combination of table adjustments and operating factors that will give the correct table distribution described previously in the discussion of feed uniformity.

The tonnage a table will handle effectively depends to a great extent on the washability and size of the coal. In treating an ordinary 5/16-in. to 0 raw-coal feed, high efficiency with respect to both cleaning and recovery usually can be obtained with a feed of as much as 10 tons per hour. High efficiency in this case means an efficiency that could not be improved appreciably by lowering the tonnage. If the coal is extremely easy to wash, higher tonnages can be cleaned with equally good efficiency. The claim sometimes is made by table manufacturers that their tables will handle efficiently as much as 15 to 20 tons per hour of 5/16-in. to 0 coal. On an average feed of this size, however, feed tonnages of more than 10 tons per hour are likely to cause a decrease in efficiency. With feeds as coarse as ½-in. or 1-in. to 0, it is not unusual to treat from 12 to 15 tons an hour per table. Modern tables will handle minus 1/8-in. feed at the rate of 7.5 tons per hour.

Efficiency of Concentrating Table as Coal-Cleaning Device

The discussion of this subject will be confined to a consideration of the tabling of fine sizes of bituminous coal.

Although there is no unanimity of opinion among coal-preparation engineers as to which sizes are too coarse for tabling and which are too fine for treatment by other methods, there is ample evidence that tables are advantageous mainly in the treatment of sizes from approximately ¼-in. down, and that sizes coarser than this can be cleaned about as efficiently in other types of equipment as on tables. This statement is made notwithstanding the fact that it is not at all unusual to wash sizes as coarse as 1-in. to 0 on tables. Although tables seldom are used for sizes coarser than 1 or 1½ in., the writer was informed recently by officials of the Deister Concentrator Co. that they are installing Super Duty Diagonal Deck tables in the plant of the Paris Coal Washery Co., Paris, Ark., for the washing of 3-in. to 0 coal. The plan is to screen this coal into 3 to 2-in., 2 to 1-in. and 1-in. to 0 sizes and treat each size on a separate group of tables.

Evaluating Table Performance by Consideration of Washability Curves

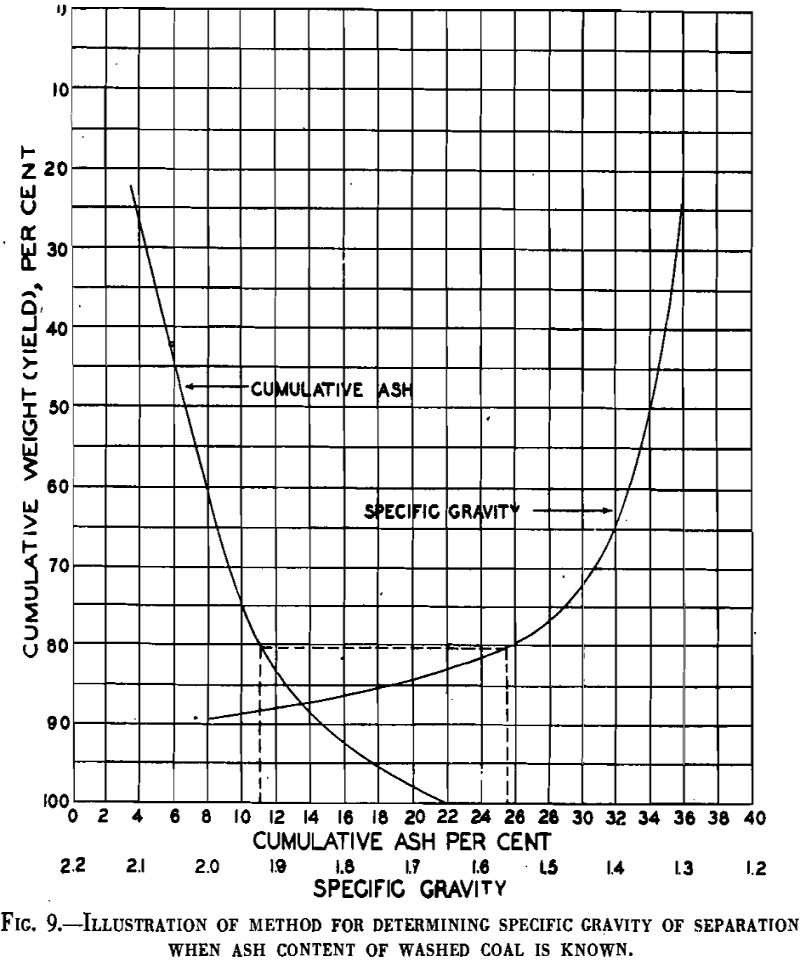

Although direct comparison of table performance with jig performance gives only a general idea as to the efficiency of tables, a better understanding of the subject can be obtained from a consideration of table efficiencies in relation to the washing difficulties reflected in the washability curves of various coals. Numerous methods of interpreting washability curves have been suggested by coal-washing engineers from time to time, and one method, which has become fairly well known in the last 8 or 10 years, is capable of giving a rather definite measure of the difficulty of washing any given coal to any desired ash content. Credit for developing this method should be given B. M. Bird, Chief Concentration Engineer, Battelle Memorial Institute, Columbus, Ohio, and those associated with him in his work at the Northwest and Southern Experiment Stations of the Bureau of Mines in 1928 and 1929. The method was first described by Bird in 1928. A more detailed explanation of the curves on which this method of interpretation is based has been presented by Coe. The method is based on the simple principle that production of a washed coal of a certain ash content depends almost entirely on how the various constituents in the feed to a washer are distributed with respect to specific gravity.

The first requisite for the application of this principle is to have a specific-gravity curve and cumulative-ash curve of the feed and to base the specific gravity of separation on the ash percentage in the washed coal and the corresponding values on the cumulative-ash and specific-gravity curves of the feed coal.

An important detail of this system of coal-washability analysis must be noted at this point; namely, that the values read from the specific-gravity curve should be divided by a correction factor, this factor being 100 per cent minus the percentage of the total feed that is sink material at 2.00 sp. gr. What this means can be illustrated very simply. Assume that in a given case a table has to make a separation at 1.50 sp. gr. to obtain the desired grade of washed coal, and that 5 per cent of the feed is in the range between 1.40 and 1.60 sp. gr.

There may be some difference of opinion as to what should be considered an efficient separation. In this discussion the expression will be taken to mean any separation in which the recovery of coal is at least 95 per cent of what is shown to be theoretically possible by the cumulative-ash curve. For instance, if this curve and the specific-gravity curve show that 85 per cent of a coal floated in a solution of 1.50 sp. gr. and analyzed 8 per cent ash, to make an efficient separation at 1.50 sp. gr. a table would have to recover 95 per cent of this 85 per cent; in other words, not less than 80.75 per cent by weight of the total feed, as washed coal analyzing 8 per cent ash. Only table feeds that have been given no preliminary treatment such as classification or special screen sizing will be considered in this discussion.

It is a well-known fact that on a feed that has been subjected to hydraulic classification or one from which all of the extremely fine material has been removed, a table will give better results both as to ash reduction and recovery efficiency than it will on feeds without such preliminary treatments, but there is not yet enough information available to show just how much the results can be improved by a classification or screening treatment of the feed. Furthermore, it is not customary in this country to resort to any such classification or screening. To the writer’s knowledge, classification of the table feed has not been practiced at more than two or three plants in this country, and in each of these instances only small tonnages of classified feed were treated. Some indications of the advantages to be gained by preliminary classifications may be obtained from reports published by the Bureau of Mines and the A.I.M.E.

What has been said about jig middlings should be applicable to middlings from almost any other type of washer except tables. The character of middlings from a table would be different from that of middlings from machines that operate mainly on the hindered-settling principle. Middlings from a table should be true bone products containing too small a percentage of coal to justify further treatment unless additional coal can be set free by crushing.

Concentrating Tables vs. Other Cleaning Systems

Among the various coal-cleaning processes that are based on the principles of gravity concentration, the tabling process is unique in that it is especially adapted to the treatment of the fine rather than the coarse sizes of coal. Neither jigs, upward-current classifiers, launders, nor heavy-media devices can claim any especial fitness for the cleaning of fine coal, although classifiers and launder washers have been developed rather recently that are claimed by their advocates to be about equal to tables. It has not been definitely proved, however, that these are capable of the same efficiency as tables with respect to both ash reduction and recovery of washed coal. As for heavy-media processes, usually they require that the fines be screened out of the coal before it is washed. When high-density suspensions are employed, fine coal in the feed would contaminate the suspension media; and when high-density solutions are used as heavy media there would be an excessive loss of solutions owing to the high rate at which they would be absorbed by the fines and the impracticability of recovering any solution thus absorbed.