Table of Contents

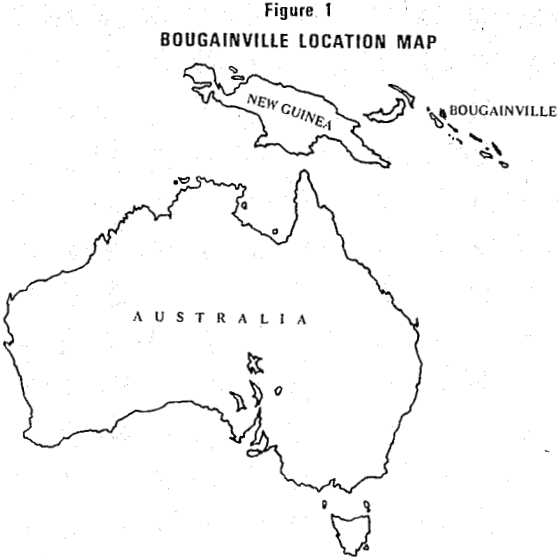

Exploration on Bougainville for copper by Conzinc Riotinto of Australia (CRA) began in 1963 and by 1968, through geophysical, geochemical and diamond drilling methods, an orehody containing nearly one billion tons of ore grading approximately 0.48% Cu. and some gold had been outlined. Bougainville Copper Ltd., the company operating the mine, is 53.6% owned by CRA, 20% owned by the government of Papua New Guinea with the public holding the remainder of the shares.

General Slurry Pipeline Background

Before discussing the Bougainville slurry pipeline, some background on slurry pipelines in general is in order. Behavior of solid-liquid systems can be very complex and in many cases designing a non-Newtonian pipeline system is as much an art as a science. Although the concepts of slurry pipelining were known basically before the turn of the century (a patent was issued in 1891 for a method of pumping coal and water), it was only in the late 1950’s that these principles were applied to the construction of major cross-country pipelines. The first major break-through was the Consolidation Coal Pipeline, a 108-mile, 10-inch coal slurry pipeline in Ohio. In the last decade and a half the technology has advanced further, both as a result of work in the academic and commercial fields and also, in the government sector as a result of slurry pumping applications to breeder reactors. Slurry pipelines are now in operation carrying materials with solids whose specific gravities range from 1.3 to 5.

The reasons for the interest in slurry pipelines, both for the Bougainville operation and in general, may be classified as follows:

- Reliability

- Economics

- Inflation Resistance

- Environment

Pipeline Development

Extensive bench-scale testing was conducted on numerous slurry samples obtained from the 100 ton per day pilot plant installed at the property. These samples were representative of the extremes expected to be found in the commercial concentrator output. Tests conducted included the standard battery of tests used for slurry pipeline design and may be generally summarized as follows:

- Rheological Tests

- Corrosion/Erosion Tests

- Operability Tests

- Characterization Tests

- Abrasivity Tests

It was found that at concentrations above 70 percent solids by weight a small increase in concentration resulted in a large increase in coefficient rigidity and yield stress. Therefore, the maximum concentration was limited to 70 percent with feasible operating concentrations from 55 percent up to 70 percent.

The velocity in the pipeline was designed for maximum of just under 2.1 meters per second (7.0 feet per second) which is fully adequate to maintain turbulence. Minimum velocities down to 1.2 meters per second (4.0 feet per second) were found to be feasible.

Another of the predesign tests conducted was to determine the expected corrosion/erosion rates. These tests were done on a laboratory scale using samples of the pilot plant copper concentrate. The method used is described in Ref. 3. From the results of this test, a corrosion/erosion allowance was included in the thickness of the pipe wall selected. In other words, with the expected life of the mine of thirty-three years and the anticipated corrosion rate, the 0.344″ pipe wall would still have adequate thickness after thirty-three years of operation to withstand the hoop stress created by the slurry pressure.

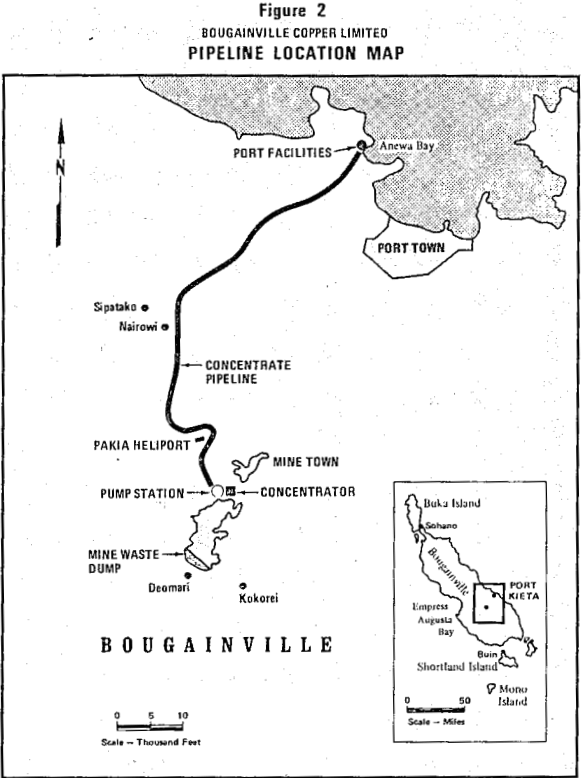

The 27.4 kilometer (17 mile) pipeline requires only one pump station to move the concentrate slurry from the mine site to the filter plant at the port. Selection of pumps was based on pressure requirements, throughput capacity and abrasiveness of the material. Due to the discharge pressure requirements, which were between 6,900 and 13,800 kPa (1,000 and 2,000 psig) depending upon throughput and concentration, positive displacement pumps were selected.

System Description

The final copper concentrate from the recleaner cells in the concentrator is first pumped to cyclones, which form part of the equipment used to remove the plus 65 mesh oversize. The cyclone overflow is pumped to a 64 meter diameter concentrate thickener, while the underflow containing the coarse material, is screened on two 0.7 meter by 1.2 meter inclined vibrating screens. The screen oversize is returned to the regrind mills while the undersize goes to the thickener.

The thickened copper concentrate is pumped to one of two storage or surge tanks about 9.1 meters diameter by 9.8 meters high, in which the concentrate is agitated using ship’s type propellors. A number of operations can be performed in these tanks. The density of the slurry can be adjusted should pumping it through the test loop indicate problems. The pH can be adjusted. During periods of low concentrate production slurry can be stored, and then pumped at a higher rate down to the coast.

The pipeline from the mine-concentrator area to the port consists of 26.5 kilometers (16.5 miles) of 6-inch diameter, 0.344 inch wall pipe. This pipe was manufactured in Japan in accordance with API 5LX52 Specification. Internal pressures up to 20,700 kPa (3,000 psig.) after full corrosion and abrasion (thirty-three years) are tolerable. To minimize internal corrosion, lime is added at the pump station to keep the pH of the slurry above 9.5. To prevent external corrosion, the pipe was coated at the mill with extruded polyethylene. Field joints were made using heat shrinkable sleeves compatible with the extruded polyethylene. Fig. 9 shows the pipeline during construction..

During the design of the system an effort was made to keep it as simple and trouble-free as possible. This was especially important as the operation is located in a remote area and would be manned by relatively unsophisticated and poorly educated personnel. The communication system between the two terminals was made as reliable as possible by providing:

- a radio link

- a “hot”line telephone

- a station on the internal telephone system

Operating Performance

The concentrate pipeline was designed to transport 136 tonnes per hour of concentrates at 64 percent solids. Tonnages down to 82 tonnes per hour can be pumped continuously at this solids concentration level. The minimum acceptable density is 55 percent and the maximum is 70 percent.

Concentrate pumping scheduling is based on the availability of a sufficient quantity of suitable slurry, the capability of the port site to receive slurry, and mechanical considerations. Thickener underflow of the proper density (ideally 53 – 65 percent solids) is pumped to either of the holding tanks. When one tank is full or being pumped, the other tank is used.

A major mainline pump failure occurred when the cooling water to the lubricating oil heat exchanger failed causing a main bearing to collapse. No other major breakdowns have been experienced and with the aforementioned changes these pumps have proved to be extremely reliable. Availability has exceeded 99.5 percent for both pumps since start-up.