When are steel liners better than rubber/poly-met liners in a SAG mill or Ball Mill? Let’s compare! Rubber Liners are better for abrasion grinding ie: cascade action but not for cataract mills.

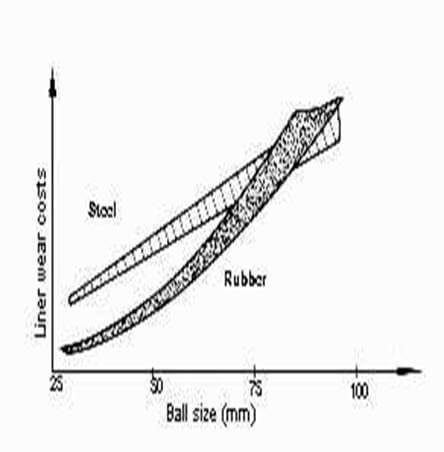

The graph below shows the increased operating cost of rubber and steel liners as the grinding ball size increases. Larger mill, larger ball… increases the cost benefit of using steel only mill liners.

|

|

|

Looking at this chart, any time a mill uses a ball larger than 3 1/2″ diameter say… the mill should be lined with high chrome steel liners.

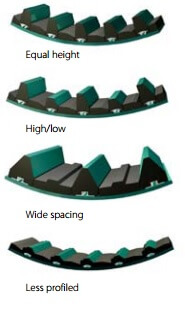

In using steel or rubber liners, you must carefully choose the best configuration for your application. Insure you have the correct liner spacing and lift for your SAG or Ball Mill.

A mill liner arrangement (steel or rubber) with lifter bars to tall or too close to each other will cause reduced tonnage for lost of cascading action due to material packing between liners.

Rubber liners do not perform that good under “impact” but good for abrasion.

|

|

|

|