Table of Contents

The foregoing descriptions and discussion of the different stoping methods and practices and the accompanying tabulated data indicate the conditions under which they may be applied and serve as a basis for comparing them. Stoping costs will be presented later.

Direct comparisons of the different methods are difficult because these methods and variations thereof are applied to different conditions. Thus, for example, while it is generally true that the cost per ton by shrinkage stoping is less than by cut-and-fill stoping and that timber consumption per ton of ore mined is generally less with cut-and-fill stoping than with square-set stoping, it does not necessarily follow that shrinkage is preferable to cut-and-fill in the first instance or that cut-and-fill is preferable to square-setting in the second, because conditions might be such that shrinkage or cut-and-fill could not be used. In a given instance any supported-stope method by which support will fail before the ore can be removed is immediately out of consideration. Likewise, caving methods cannot be considered if the ore will not cave and in doing so break small enough so that it can be taken out, or if, in top slicing, the capping will not cave and follow down as the ore is removed from below.

Stoping methods may be compared broadly on the bases of applicability, flexibility, amount of preparatory development required, percentage recovery of the total ore in the deposit, dilution of the ore with waste, rate of extraction, cost of stoping, and effect upon recovery in the ore-dressing plant. Applicability of the different methods or the conditions to which each is suited have been discussed briefly in describing them.

Flexibility

Open stopes are flexible in that irregularities in the ore body usually can be followed and the ore can be mined, lean ore and waste inclusions within the ore body can be left in place as pillars and if desired, waste usually can be sorted and thrown to one side in flat stopes or piled on stulls covered with lagging in steep stopes, except those worked by underhand benching. The ore can be removed from the stopes as broken, and usually is; but often, especially in sublevel stoping, considerable broken ore can be accumulated in the stopes to form a reserve.

Shrinkage stoping lacks the flexibility of other open-stope methods. Waste cannot be sorted from the broken ore in the stopes, although some sorting may be done at the level or in grizzly chambers protected by overhead pillars. Narrow tongues or offshoots of ore cannot be followed into the walls without breaking considerable waste with the ore, and irregular walls, rolls, or sharp offsets in the vein usually entail leaving ore behind, or considerable dilution, or both. More than half (usually about 60 percent) of the broken ore remains in the stopes until they have been mined to the top and, when finally drawn, must be taken as it comes without any control over its grade; control for grading purposes can then be secured only by drawing from several stopes of different average grade to maintain a normal mine average.

Cut-and-fill stoping is a flexible method; irregular walls can be followed and stringers or offshoots of ore can be followed and mined into the walls. Waste broken in mining these stringers can be sorted out and left in the fill. Waste inclusions within the ore body can be shot down into the fill if they are small or left in place if large. Waste broken with the ore in normal stoping operations can be sorted and left as fill in horizontal cut-and-fill stopes, though only a limited amount of sorting is possible in rill stopes. Veins of less than stoping width can be mined by stripping or resuing with minimum loss of ore and dilution of the ore with waste. Cribs or stulls can be erected on top of the fill to support local patches of loose back or wall rock, and change from cut-and-fill to square-set stoping can be made quickly after the stope has been started, should ground conditions require it. The method does not have flexibility from the standpoint of being able to force production, as breaking is interrupted periodically for removal of the broken ore and introduction of filling.

Square-set stoping is a flexible method; it can be accommodated to very irregular ore bodies, large or small, and permits following and mining offshoots of ore with minimum dilution and loss of ore. Waste can be sorted out and left in the gob. The method can be adapted where sudden changes in dip of the deposit occur and to following sinuosities or abrupt offsets along the strike or the dip. It usually is done from the bottom upward, or “overhand,” but can also be employed for mining downward from the level (underhand square setting). It is used frequently as an auxiliary to other methods, as for mining pillars between filled or caved stopes, crown pillars over completed stopes that have been filled, or sections of cut-and-fill stopes where the ground is too heavy to be mined by cut-and-fill. As with cut-and- fill stoping, it does not lend itself to forcing of production.

Block caving is limited in its applicability to large deposits that cave readily and break up well as the caved mass moves downward. It is applicable only to nonselective mining, and waste inclusions within the ore body together with tongues of waste projecting into the ore body are necessarily broken and drawn with the ore. Thus, the grade of ore can be controlled only to the extent possible by regulation of the amount of capping and marginal-grade wall rock that is drawn with the ore.

Sublevel caving lacks the flexibility of supported-stope methods but is more flexible than block caving. The sublevel development serves to explore the ore body at each caving horizon before mining begins, and irregular boundaries can be followed more easily than with block caving and with less dilution from the walls. Large inclusions of waste within the ore body often can be left and caved into the gob.

Top slicing is a limited selective method in that irregular ore boundaries may be followed and the ore mined from embayments or lobes of ore extending from the main ore mass into the country rock if these lobes are large enough so that the capping over them will cave tight after a slice of ore has been removed from below it. Some sorting of waste can be done in the stopes, and waste or lean ore inclusions too large to break up readily with the caving overburden and too small to stand permanently as pillars must be broken down with the ore. Such inclusions, if left, often will cause the gob or mat to hang up for some time, and later they may let go suddenly and endanger the workmen in active slices below. If a good mat is maintained little dilution of the ore by caved capping will result. If it becomes necessary to curtail or stop production for a time the stopes can be kept in good condition for quick resumption of work by completing active slices, so that no small pillars or stubs of ore are left between them, and by boarding them up and blasting the gob down onto the floors.

Open-stope methods are adaptable only to deposits having strong ore and wall rock; hence, open-stope mines usually can be left to stand idle for considerable periods without much preparation and work resumed quickly on short notice. Shrinkage stopes and cut-and-fill stopes may require some preparation for temporary shut-downs, depending on conditions. It may be necessary to stull the backs from the top of the broken ore or of the fill. Square-set stopes, which usually are employed only in heavy ground, may require considerable work to leave them in shape for quick resumption of operations; all sets not required to be left open usually should be filled, and considerable diagonal bracing, liner sets, and blocking may be necessary. In block caving, drawing of a block should be continuous after it has once started, to avoid packing of the broken ore and thus obtain best results. Some ores tend to pack more than others, and therefore the results of a prolonged shut-down are more serious in some mines than in others. Continued drawing may also be necessary to avoid development of excessive pressure on the grizzly level and pillars.

Preparatory Development

The subject of preparatory development has been discussed in a previous section under the caption “Stope Development” (p. 150), and tables 19 to 22, inclusive, presented data on the amount of stope development required per ton of ore developed for a number of mines representative of the various stoping methods.

With open stopes in ore bodies of the Tri-State and Southeast Missouri districts, virtually no development is required once the ore body has been cut, and the ore is stoped as developed.

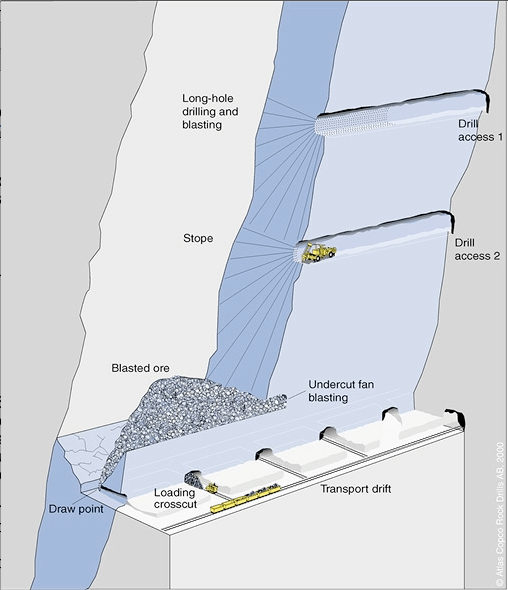

Sublevel stoping requires considerable preparatory work in the form of entrance raises, starting raises or stopes, sublevel drifts, and in some instances the cutting or bulldozing chambers and installation of grizzlies. The sublevel development, however, serves thoroughly to explore and block out the ore body and to define its boundaries. By using wide shrinkage stopes instead of raises for starting each stope, production of ore need not be delayed unduly by the preparatory work. Other open-stope methods require but little preliminary work, and stoping can be started soon after a small amount of drifting has been done unless a retreat system of mining is employed.

With shrinkage stoping in narrow ore bodies, the development is usually simple and only a small amount of preparatory work is required preliminary to beginning stoping operations. Where the stopes can be supported on stulls over the drift, stope development consists of taking down drift backs and installing stull timbers and chutes; raises to the level above may be required for ventilation, but these generally can be started from the stope after it has been mined up several slices and connected through while the stope is being worked. Where the stopes are supported on drift pillars, chute raises must be driven at frequent intervals (10 to 20 feet, usually) and connected over the tops to form the stope sill. In this instance it may be desirable to funnel the tops of the chute raises before regular stoping is begun. In some mines bulldozing chambers are cut and grizzlies installed over the chute raises and raises are run up from the chamber and connected over a pillar left above the chamber, which further increases the time and work required to prepare the stope for production. On the whole, however, shrinkage stoping as usually practiced permits the starting of stopes soon after the drifts have entered the ore. As only about 35 to 40 percent of the ore broken is available until completion of a stope, more stopes are required to produce a given tonnage at the beginning of operations than otherwise would be needed. Once the mine has reached its production stride, the deficiency in productive capacity of operating stopes can be made up by drawing from completed stopes.

With cut-and-fill stoping, preparatory work is similar to that for shrinkage stoping, except that raises must be put through to the level above before stoping can progress far, if filling material has to be supplied from sources outside the stope. Partly offsetting this, however, is the smaller number of chutes and chute raises required; and they may be 25, 50, or even 100 feet apart, depending largely on the method of handling the ore in the stopes, whereas chutes for shrinkage stopes must be closely spaced and seldom are more than 20 feet apart. In flat veins it may be necessary to drive drifts in the hanging wall for introduction of fill in addition to the regular ore- extraction drifts in or along the footwall.

Development in preparing for square-set stoping is simple, but usually at least one through raise to the level above is required for each stope section to provide for introduction of fill, improve ventilation, and afford a means for lowering timbers into the stope. As soon as a raise connection is completed, however, stoping may be begun.

Block caving requires a large amount of preparatory work, and before actual extraction of caved ore begins, considerable capital must be expended for this purpose. Thus, the estimated cost of preparatory work for a block containing 120,000 tons of ore at the Morenci Branch, Phelps Dodge Corporation, was $36,420. Similar costs for preparing a block of ore containing 560,000 tons at Ray were given as $81,939. Comprising the preparatory work were 325 feet of supply drifts, 1,456 feet of grizzly drifts, 700 feet of haulage drifts, 1,848 feet of haulage raises, the installation of 56 grizzlies, 560 feet of excavation for pony sets and chutes, and the removal of 27,476 tons of ore from shrinkage and undercutting stopes. It is obvious that considerable time is required to complete this amount of work and that the beginning of ore production is retarded accordingly.

Percent Recovery of Ore and Dilution

Cost of Stoping