In the 1950s, the opinion was often expressed that the mechanically-agitated machine forms the best rougher and a pneumatic machine the best cleaner, the reason being that the former type has come to be regarded as one that yields a heavily-mineralized froth, which, though giving a good recovery of the minerals, is likely to be of low grade because of the presence of gangue particles mechanically trapped between the closely packed bubbles, whilst in the pneumatic cell the froth is generally deeper and more open with less heavily mineralized bubbles, a condition which provides more opportunity for the gangue to drop out. Such a statement, however, is scarcely true of modern practice, since the design of flotation machines has been improved so much in recent years that any one of them, in conjunction with efficient conditioning, can be run to give almost any required type of froth.

Machines of the mechanically-agitated type are generally chosen for the flotation of ores which cannot be readily conditioned by chemical reagents and need prolonged agitation, sometimes with the addition of heavy collecting oils, in order to render them floatable. On account of their wide range of adjustment they are also often preferred for multi- stage selective flotation, since the admission of air to each cell can be regulated separately and reagents can be added at any point in the circuit.

When agitation is not of prime importance, air-lift and pneumatic machines are usually as effective as the others and require less power in operation. They have the disadvantage, however, that the pulp must be conditioned ahead of flotation ; no high-speed conditioning effect, such as is possible with an impeller or rotor, can be obtained in a pneumatic cell, and it is not very pronounced in an air-lift machine. With the reagents in use at the present day, such as xanthates and aeroflots, it is generally possible, however, to condition the pulp ahead of flotation, and under such conditions these machines will give as good results as those of the mechanically-agitated class with a lower consumption of power.

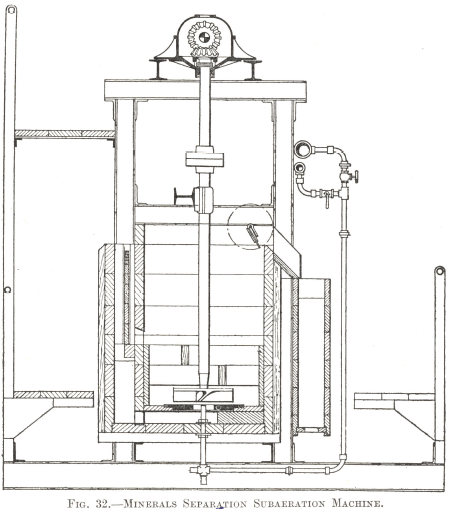

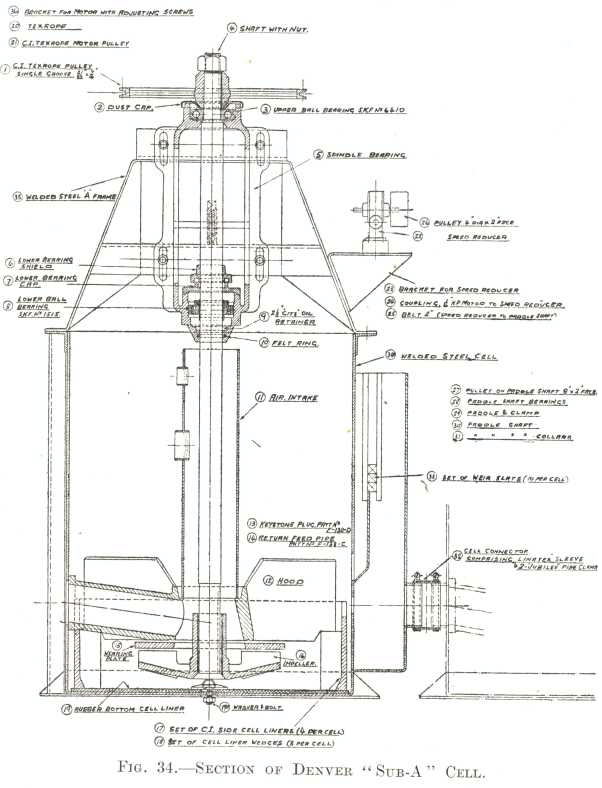

Denver “ Sub-A” and M.S. Sub-aeration Machines are more frequently employed than any other types. Of the two, the former has the advantage of conferring greater flexibility to the plant in which it is installed on account of its unit construction and of the provision of middling return pipes, which enable the circuit to be changed when desired without a lengthy stoppage for alterations. This is of great value in experimental and “ pilot plant” work.

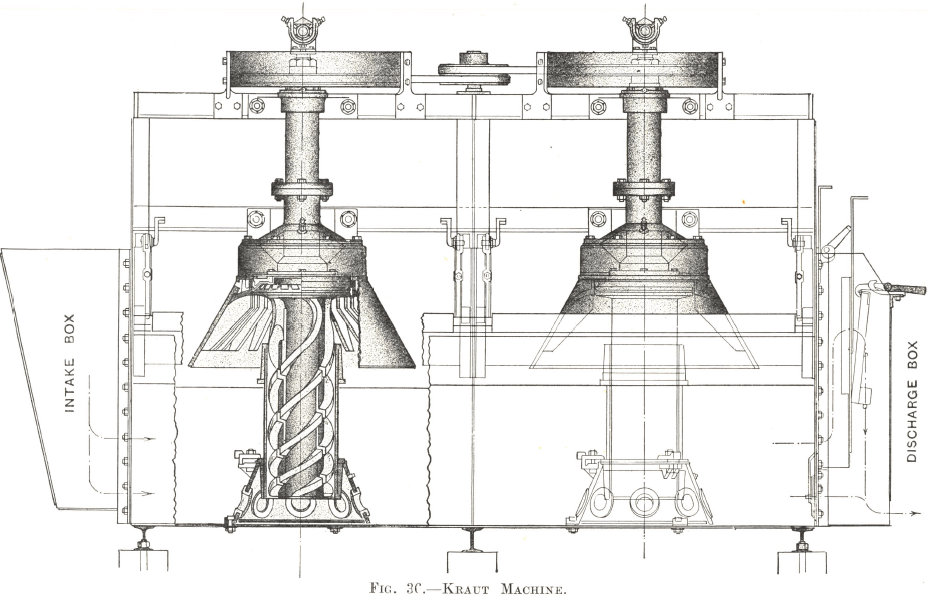

The Kraut Machine is not used as widely as the two just mentioned. Its particular advantage is the intensity of the agitation produced between the rotor and the stationary cylinder, which is probably greater than that obtainable in any other flotation machine. On this account it is especially suitable for the flotation of gold ores. The design of the rotor also enables a very large volume of air to be drawn into and disseminated through the pulp. In fact, the froth produced approaches the volume and texture of that of a pneumatic cell. The same is true of the Fagergren Machine, though the intensity of the agitation between rotor and stator is not quite so great. It has only been recently introduced into the flotation field, but it is operating successfully in the treatment of gold and copper ores. Both these machines possess the additional advantage that no surging can take place at the surface of the pulp, due, in the case of the Kraut Machine, to the provision of a hood over the rotor, and in the case of the Fagergren Machine to the horizontal outward direction of the stream of pulp issuing from the stator.

The reliability of mechanically agitated machines has been much improved in recent years, but they must of necessity possess moving parts, which need regular attention, and wearing parts, which have to be periodically renewed. The particular advantages of the Southwestern Air-Lift Machine are that, having no moving parts, it requires practically no maintenance, and it never wears out. Moreover, the blower supplying the air can be installed in a separate room free from dust or splashes of pulp and is easy to look after, needing little attention. The power consumption of the Southwestern Machine is also somewhat lower than that of mechanically agitated machines. For these reasons it has replaced the latter class in many installations treating ores that offer no particular difficulty in flotation.

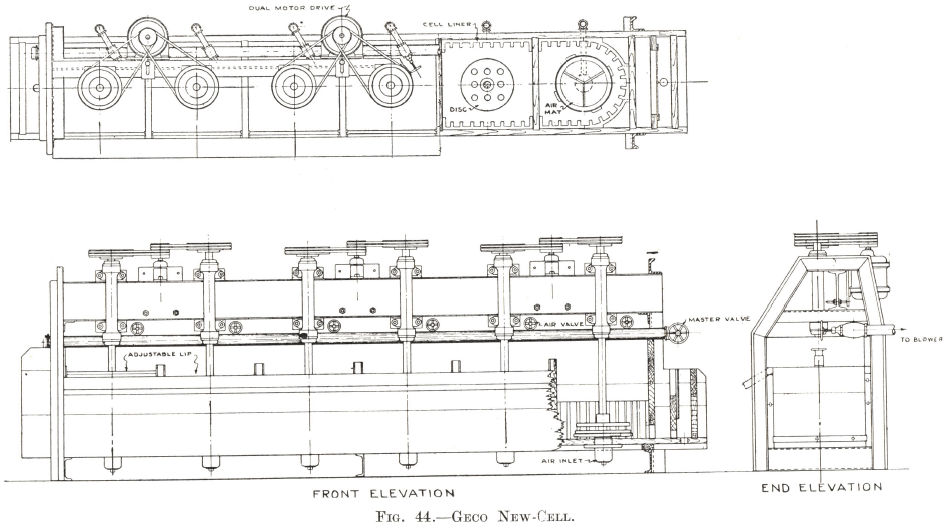

The Callow-Maclntosh Machine is not quite so simple mechanically as the Southwestern Machine, but it is often used in preference because of its lower power consumption and greater operating efficiency, both of which are due in a large measure to the fineness of the air bubbles produced and their even distribution throughout the pulp. The maintenance of the slow-moving rotor is a comparatively small item and the wear of its cover and of the motor and bearings is almost negligible if they are given regular attention. Although Denver “ Sub-A” and M.S. Sub-aeration Machines are usually preferred for multi-stage selective flotation, a Callow-Macintosh installation will give results that are quite as good provided that the pulp can be completely conditioned beforehand. The same thing applies to single-stage flotation. It also applies to the Geco New-Cell Machine, which possesses the additional advantage that a certain amount of agitation is produced by the rotating disc. There is not the same necessity, therefore, for the pulp to be so completely conditioned ahead of flotation, as a certain amount of action will take place in the cells. This machine, however, is of comparatively recent introduction and has not yet established its position in the flotation field.

No accurate comparison is possible between the power consumption of the three types of flotation machines, because it depends so much on the character of the ore treated. In the absence of definite test data, it is best to assume, if an approximate figure is needed, that the single- stage flotation of a simple ore will require 1.0 kilowatt-hour per ton for a Callow-Maclntosh or Geco New-Cell installation, and 1.5 kilowatt-hours per ton for air-lift machines. The power requirements of mechanically agitated machines are more difficult to predict. Although improvements in impeller design have made them more economical than was formerly the case, it is doubtful if it is safe to allow for a lower figure than 2.0 kilowatt-hours per ton; many installations show a considerably higher consumption. For multi-stage flotation the power must be increased in proportion to the number of stages.