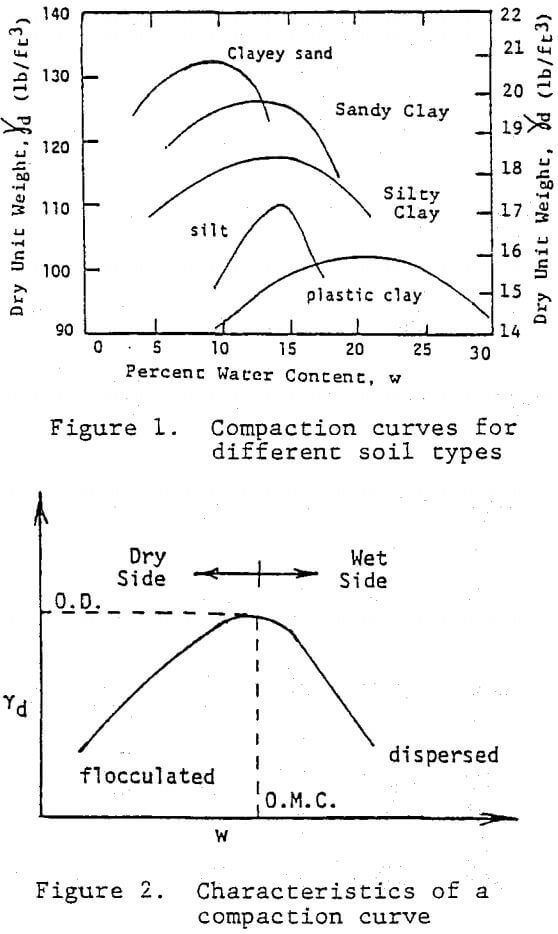

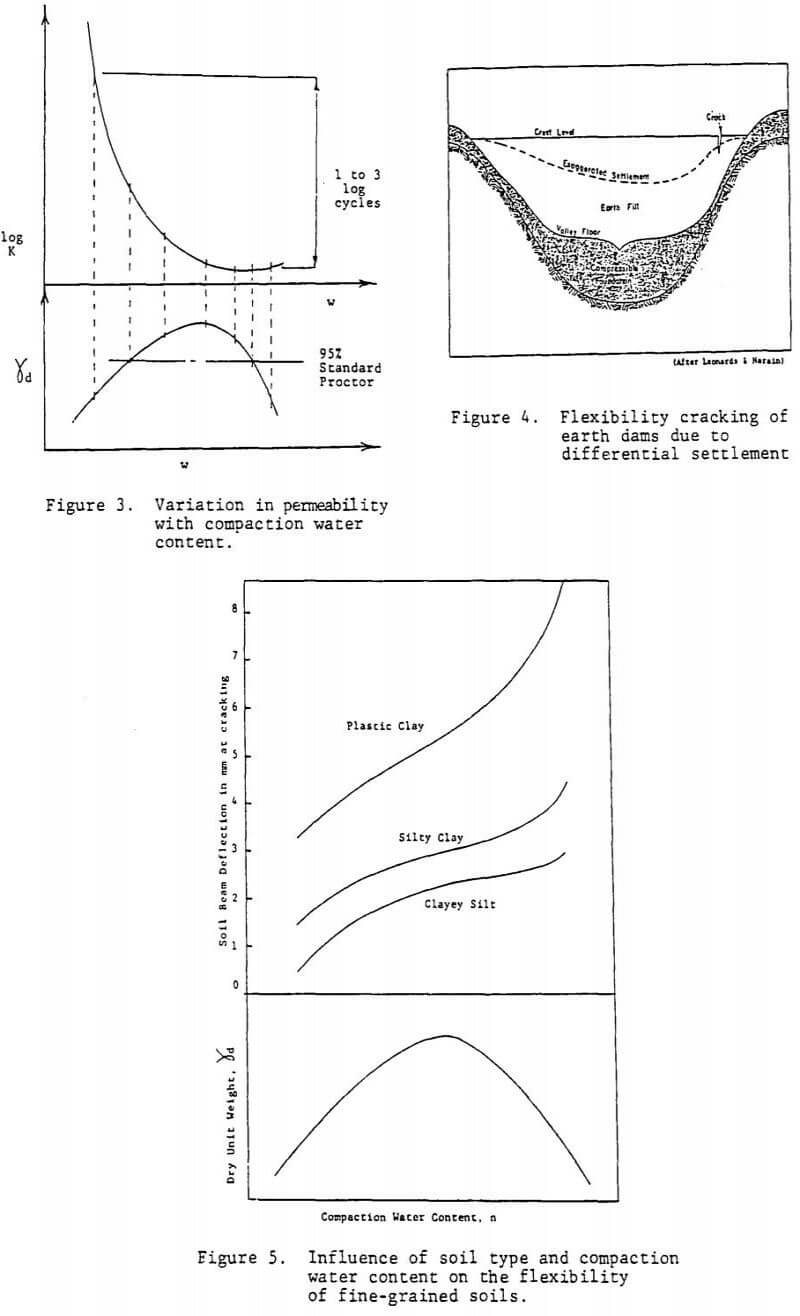

Soils used to construct compacted permeability barriers such as liners for solid and liquid waste landfills and lagoons must be carefully evaluated and designed to maintain their integrity in preventing seepage of pollutants off site. The practice of using any on-site soil without testing its hydraulic and flexural properties is dangerous. Silts and fine sandy silts, although they may be abundant on-site, are not acceptable because they cannot satisfactorily meet the minimum criteria for hydraulic conductivity and flexural strength. Clayey silts and other clay-silt-sand, admixtures with liquid limits less than 30 are marginal at best. Even though these soils may have acceptable compacted hydraulic conductivities in the laboratory, they can have field permeabilities that are as much as 1000 times greater than the laboratory results. In addition, they are extremely brittle and will crack with the slightest amount of flexure. Clay soils with medium plasticity (Liquid Liquids of 30 to 50 and Plasticity Indices of 10 to 25) can meet the hydraulic conductivity criteria if they are not compacted on the dry side of optimum. These silty and sandy clays can tolerate only a moderate amount of differential strain without cracking. The ideal soils for compacted clay liners are clays of high plasticity. These clays will have liquid limits above 50 and plasticity indices exceeding 20.

Soils used to construct compacted permeability barriers such as liners for solid and liquid waste landfills and lagoons must be carefully evaluated and designed to maintain their integrity in preventing seepage of pollutants off site. The practice of using any on-site soil without testing its hydraulic and flexural properties is dangerous. Silts and fine sandy silts, although they may be abundant on-site, are not acceptable because they cannot satisfactorily meet the minimum criteria for hydraulic conductivity and flexural strength. Clayey silts and other clay-silt-sand, admixtures with liquid limits less than 30 are marginal at best. Even though these soils may have acceptable compacted hydraulic conductivities in the laboratory, they can have field permeabilities that are as much as 1000 times greater than the laboratory results. In addition, they are extremely brittle and will crack with the slightest amount of flexure. Clay soils with medium plasticity (Liquid Liquids of 30 to 50 and Plasticity Indices of 10 to 25) can meet the hydraulic conductivity criteria if they are not compacted on the dry side of optimum. These silty and sandy clays can tolerate only a moderate amount of differential strain without cracking. The ideal soils for compacted clay liners are clays of high plasticity. These clays will have liquid limits above 50 and plasticity indices exceeding 20.

It is extremely important to specify to the contractor that the liner material must be compacted at or above optimum water content. Compaction at water contents below optimum results in a much more permeable fabric and a rapid decrease in flexibility.

The flexibility of a compacted clay soil has been overlooked when assessing the feasibility of a soil for a permeability barrier. Yet it is a most important property because any fracture transverse across the compacted layer will provide a channel way for a pollutant to rapidly escape from the containment site.

Both clays and silts and various admixtures of them with sand have been used in the compacted state as artificial permeability liners in waste disposal. In addition, shales and other argillaceous rocks have been broken up and used separately or as admixtures with soils as liner material. Not all of the above mentioned materials are a satisfactory source material. Their compacted properties can vary dramatically with grain size variations (amount of sand, silt and clay), the amount and type of clay mineral, and the compaction water content. To use just any soil available at a site for a compacted permeability liner does not insure the leachate or other fluids will not escape. In fact, indiscriminate use of on-site materials without evaluating their basic and compacted properties will almost guarantee the liner will fail in a very short period of time.

Permeability or how easily a fluid flows through a material is the primary property of compacted soil liners. It is evaluated as the rate of flow over a unit distance. The coeficient, K, that defines the rate of flow is known by numerous names but most often is called the hydraulic conductivity (preferred) or the coeficient of permeability in soil and rock mechanics. Also just the term permeability frequently is used in lieu of the above terms. The flow rate or velocity generally is given in centimeters per sec (cm/sec).

The relative permeability of a material is dependent upon the void spaces or pores that will allow a fluid to flow through them. Known as effective porosity, the percent of pore space available to transmit a fluid under gravity flow is governed by the amount of total voids in a material, their size and shape, their interconnection, the fluid chemistry, the character of the solid matrix, and the presence of clogging agents such as gases and other fluids that are immiscible with the water, leachate or the primary fluid being monitored. The total porosity and effective porosity are about the same for coarse sands and gravels, whereas, they are significantly different for clays. Clays or shales may have total porosities of 20 to 30 percent but will have effective porosities of less than one percent. This makes them ideal materials for containment liners. In their undisturbed state, homogenous clays (no joints or fractures) can have hydraulic conductivities of 10 -7 to 10 -10 cm/sec. This translates to a particle of water traveling about 30 centimeters (1 foot) at 10 -7 cm/sec to approximately 3 millimeters (0.1 inch) at 10 10 cm/sec in 100 years. When excavated and recompacted, laboratory permeabilities of 10 -8 and 10 -9 cm/sec are not uncommon.

Using the laboratory data, an engineer can calculate the thickness required to prevent the containment fluid from migrating a certain distance over a specified period of time. For example, if 500 years is the minimum time allowed for the fluid to escape from the site, a compacted liner with a mass hydraulic conductivity of 10 -8 cm/sec would have to be at least 5 feet thick.

Laboratory analysis of soil permeabilities is based upon compacting the soil to a designated unit weight or density and then conducting a permeability test on the compacted sample. Typically these test data and relationships are transferred to the liner construction in the field by specifying the compacted material must have the same density within limits as the laboratory test. It is assumed the field permeability of the material will be the same as the laboratory tests.