Table of Contents

Bubble Size

The most important physical aspect of flotation is bubble size. While most people agree that small bubbles are needed for good flotation, what is meant by “small bubbles?”

We have always maintained that the bubbler is the heart of the column and have spent many years developing our bubbler to its present state. Obtaining high grade concentrates is never a problem with the column. The difficulty is obtaining both grade and recovery at the same time.

Many types of bubbling systems were tried in the early days of developing the column. They included porous media and filter cloth. While some types of porous media will give the small bubbles, they are impossible to use from a practical standpoint as they rapidly plug due to calcium carbonate and the evaporation taking place at the surface of the pores. The filter cloth was rejected because of the relatively large bubbles produced.

The homemade columns use filter cloth bubblers.

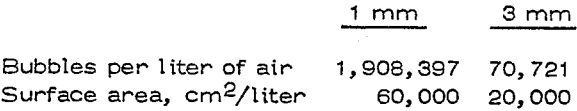

Gibralter Mines of British Columbia were the first to make a homemade column. At the 1985 annual meeting of the Canadian Mineral Processors it was stated that the bubble size in the Gibralter columns was approximately 3 mm in diameter. The same people tested our Gaspe columns and found our bubbles to be less than one mm.

Bubble Size vs Loading & Recovery

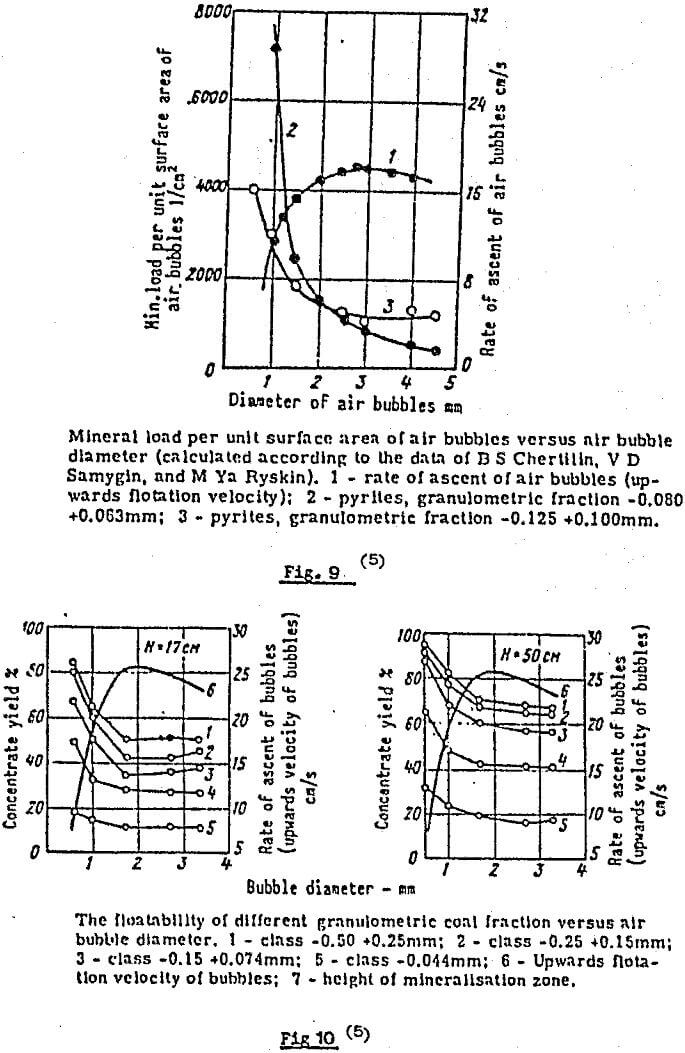

As flotation is based on the probability of collision between particle and bubble plus the carrying capacity of the bubble, 1, 908, 000 vs 71,000 bubbles and triple surface area are impressive numbers. However, it goes beyond this. Fig. 9 shows mineral loading to be seven times greater for 1 .0 mm diameter bubbles than for 3.0 mm ones in the size range —0.080 +0.063 mm, and to be 1.5 times greater for particles in the -0.125 +0.100 size range.

While the 1.0 mm bubbles have triple the surface area, the effect of bubble loading compounds this.

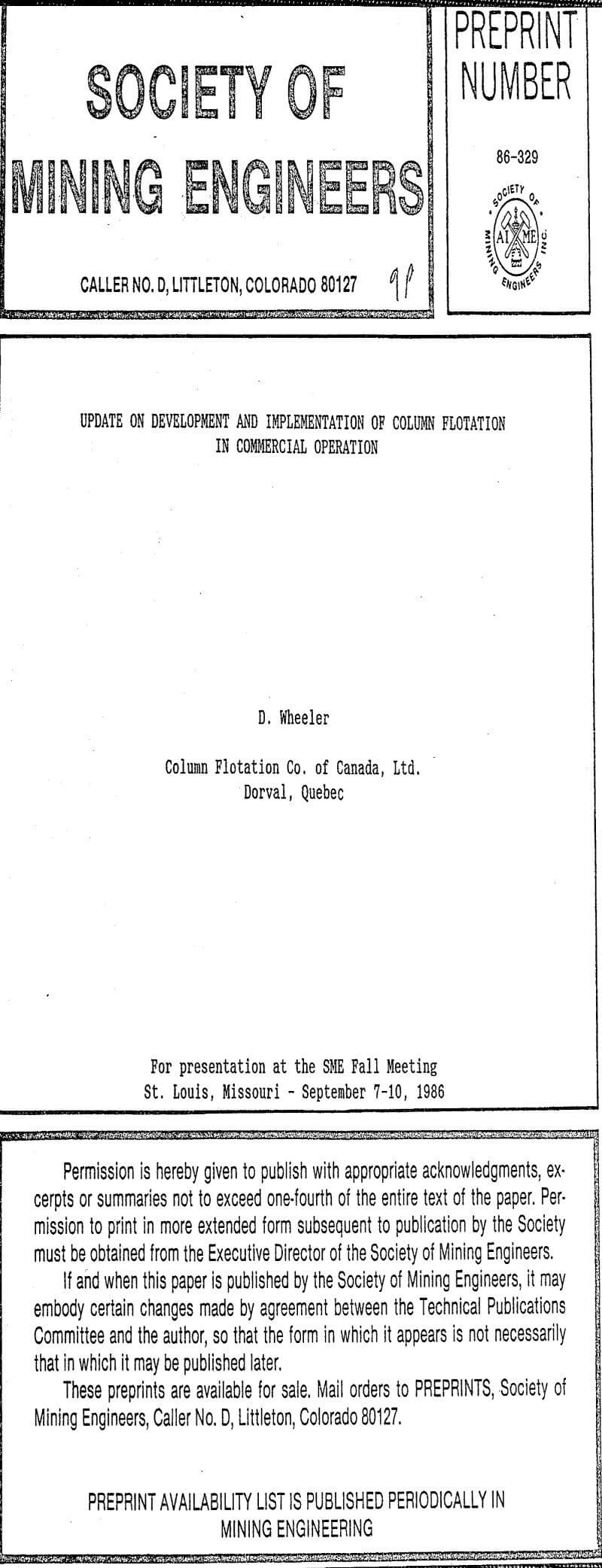

Fig. 10 shows recoveries of various size fractions as a function of bubble size. Again, the smaller bubbles are better. This is mainly attributed to the relative velocity between the solid particles and the rising bubbles.

Effects of Large Bubbles

Large bubbles mean fewer bubbles, less surface area and higher bubble velocity. All these hinder recovery.

There is another aspect of larger bubbles – they are physically weak and tend to collapse.

This effect has been noted at Lornex Mines in British Columbia when attempting to use their homemade columns as roughers. It was particularly evident when they attempted to use it as a copper rougher. When used as a cleaner on heavily reagentized slurries, some of the effects of large bubbles can be masked. On attempting to use the column as a copper rougher, the overflow continually collapsed, Even eliminating the wash water in an attempt to overcome this did little to improve the operation.

Lornex have more recently stated that their column is not suited for roughing work.

They attributed this failure to the fact that their ore contains only 0.35% Cu.

As mentioned earlier, our column was developed as a Rougher-Scavenger on heads as low as 0.40% Cu and produced excellent results.

The effect of small bubbles can also be seen when comparing the metallurgical results of Gibralter and Gaspe. Before columns, both had overall recoveries of 40% in their moly circuits. After columns, Gibralter still had 40% recovery while Gaspe increased to +70% moly recovery.