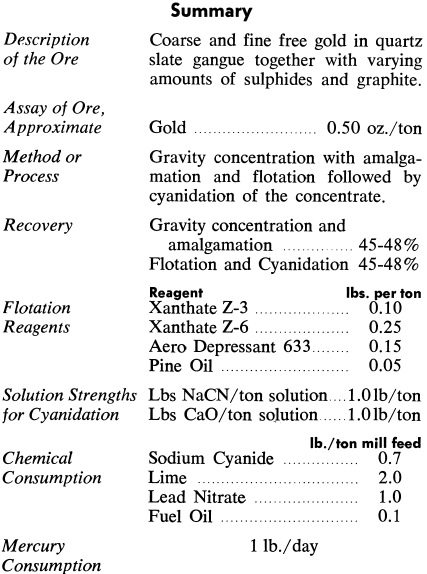

This study deals with an ore containing coarse and fine free gold associated with arsenopyrite, pyrrhotite, pyrite and graphite in a quartz and slate gangue. The sulphides and graphite constitute 10 to 12% of the ore.

Treatment required utmost economy. The flowsheet was developed from batch and pilot tests with the required flexibility to permit initial operation as a 50 ton gravity mill with later expansion to 150 ton gravity-flotation-cyanidation operation. Tests indicated a recovery of 60-65 % using gravity and amalgamation whereas 90-95% extraction could be obtained by combined gravity, amalgamation and flotation followed by cyanidation of the flotation concentrates. During initial operation the small ball mill is used. This ball mill is then used as the regrind mill when the tonnage is increased and the 6′ x 6′ mill is installed.

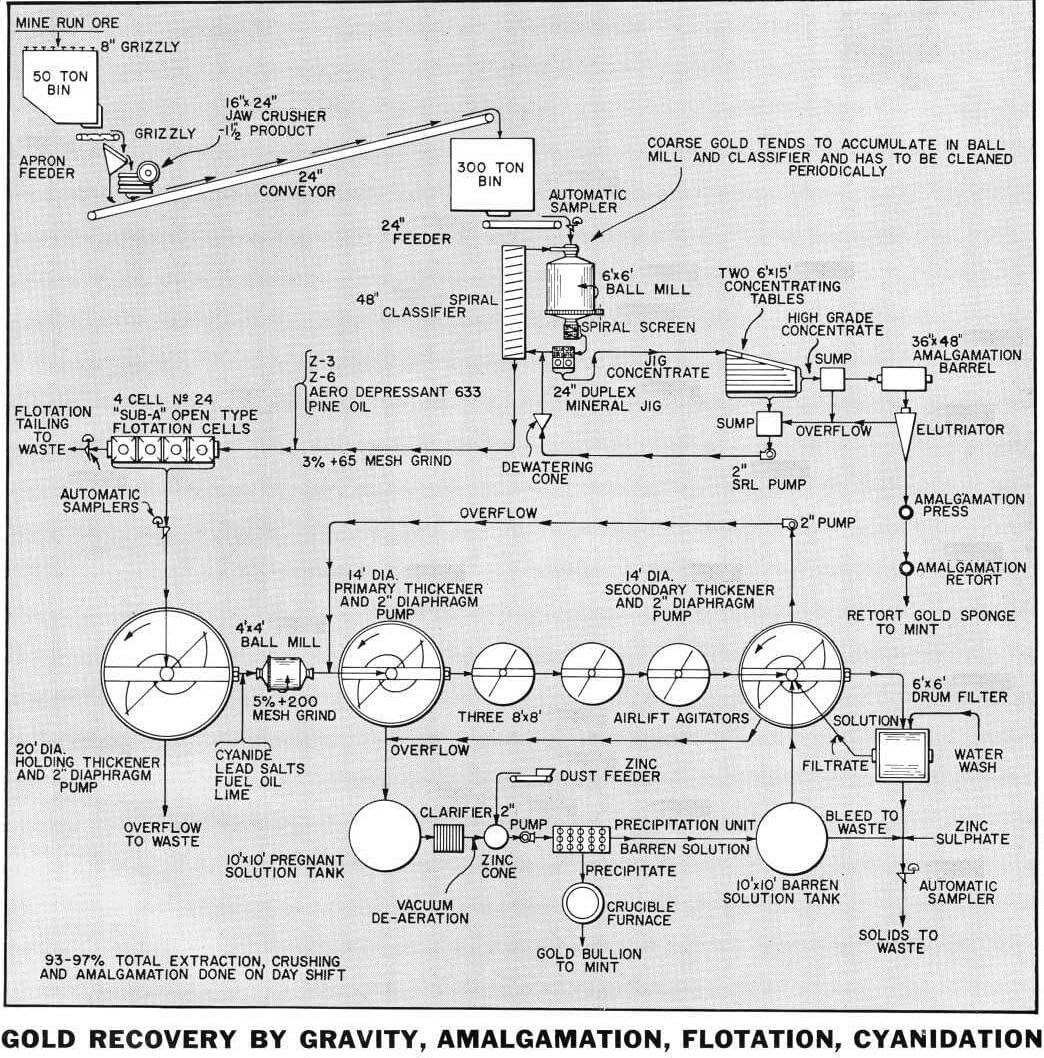

The Flowsheet

Coarse gold is recovered by gravity concentration and amalgamation. Fine gold is recovered by flotation as a concentrate along with the sulphides and graphite and then subjected to regrinding and cyanidation. Special attention is given to over-all costs. Total grinding costs are low as fine grinding is limited to only 15% of the mill feed since flotation produces an acceptable tailing at a relatively coarse grind of 65 mesh.

CRUSHING—The mill in this study is of hill-side design in steep mountain country. Gravity flow is used wherever possible. Single stage crushing is used, and was initially installed as an oversize unit so that it would be adequate for contemplated plant expansion.

GRINDING—Primary single stage grinding for gravity concentration and flotation is used. A Steel Head Ball Mill is in closed circuit with the Mineral Jig and Spiral Classifier. Final Classifier overflow at 3% plus 65 mesh grind goes to flotation.

GRAVITY CONCENTRATION—The Selective Jig in the grinding circuit is adjusted to produce a moderate ratio of concentration. The jig concentrate is sent to two 6′ x 15′ Concentrating Tables where the free gold is cut out and sent to the Amalgamation Section. Tailings from the tables and amalgamation are pumped to the Spiral Classifier. Partial dewatering of this product in a cone may be necessary to avoid excessive dilution of the classifier.

AMALGAMATION—Concentrates from the Concentrating Tables are processed on day shift by batch treatment. The concentrates are subjected to grinding in a Amalgamation Barrel to liberate and polish the gold before mercury is added. Amalgamation Barrel discharge is then washed through a Elutriator, overflow from the elutriator goes to the table tailing pump sump. Amalgam and mercury are separated, the mercury returns to reuse and the amalgam goes to a retort. Amalgam retort sponge is sold directly to mint. Over 50% of recoverable values are saved by the Selective Mineral Jig, Tables and Amalgamation Unit in this simple recovery process.

FLOTATION—Conditioning is not necessary in this study as the gold, sulphides and graphite are floated easily. Flotation recovers most of the remaining gold in a concentrate representing 15% of the mill feed. Flotation tailings are sent to waste. Concentrates flow by gravity to a 20′ diameter Spiral Rake Thickener located on a lower level of the mill.

CYANIDATION — Concentrates are pumped by 2″ Diaphragm Pump at 65 to 70% solids from the 20′ Thickener to 4′ x 4′ Steel Head Regrind Ball Mill in open circuit where cyanide, fuel oil, lime and lead nitrate are added. (Fuel oil is used to coat the graphite thus preventing adsorption of soluble gold; cyanide dissolves the gold; and the lead nitrate protects the cyanide from pyrite, pyrrhotite and other cyanicides.) The Ball Mill discharges to a 14′ diameter Primary Thickener where a high grade gold-bearing solution is decanted, clarified and sent to Bag Precipitation Unit, where gold is precipitated by zinc dust. The precipitate is mixed with flux and melted in a graphite crucible furnace and the bullion is sold to the mint.

Underflow from the primary thickener is pumped by the Diaphragm Pump to three 8′ x 8′ Air-Lift Agitators in series, where more lead nitrate is added. Total contact time in the agitators is 72 hours at 35% solids. Discharge from No. 3 agitator flows to the 14′ Secondary Thickener, overflow from secondary Thickener goes to reuse or to the primary thickener and to the pregnant solution tank. Thickener underflow is pumped to a 6′ x 6′ Drum Filter where the cake is washed with barren solution with the precipitation circuit or water and the filter cake is then discarded as waste. A portion of the barren cyanide solution has to be continually bled to waste because pyrrhotite and arsenopyrite decompose and if allowed to build up in the circuit will interfere with the dissolution and precipitation of the gold.

Dowsett’s colormetric test is used to determine presence of gold values in barren solutions from the zinc bag precipitator. When tests show values are present in the barren solution, and no free air is present in the zinc precipitation unit, and bubbles are seen rising in the zinc bag precipitator, more barren solution must be bled from the system to insure proper precipitation.

Appropriate reagents can be added to tailings to neutralize cyanide.