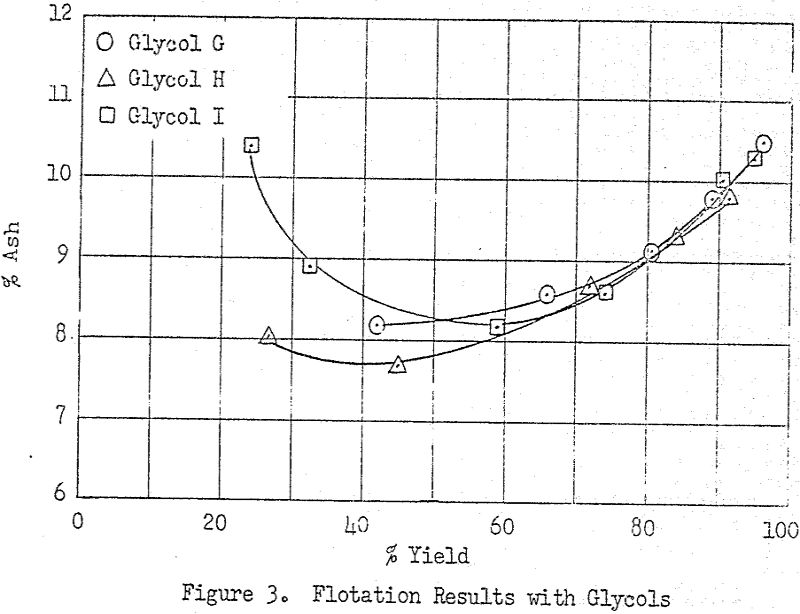

This paper presents the results of a study in which commercially available forms of various reagents were used as flotation frothers. Flotation procedures which would conform in general to those employed in a large number of commercial coal flotation plants were utilized.

The reagents employed have been grouped into the following chemical classes;

- aliphatic alcohols

- terpines

- glycols (synthetic water-soluble alcohol type frother)

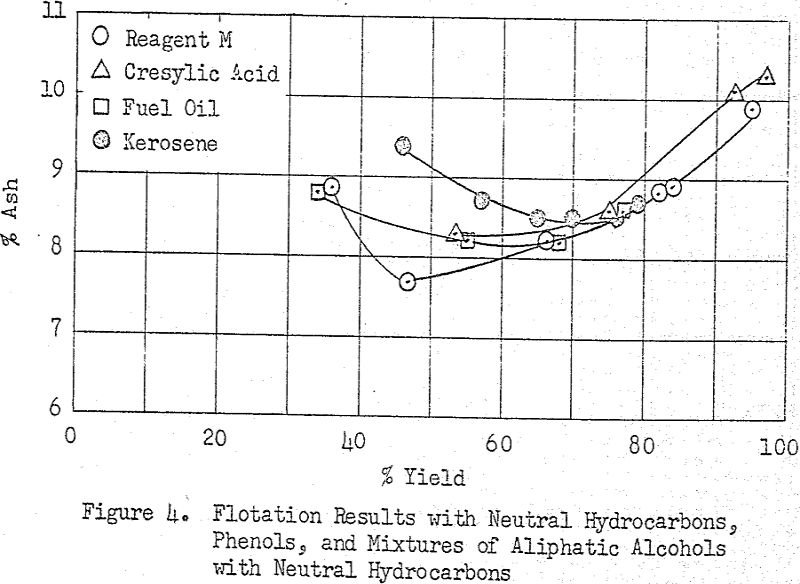

- neutral hydrocarbons

- phenols

- mixture of aliphatic alcohols with neutral hydrocarbons

Following grinding, the coal was transferred to a Fagergren laboratory flotation cell and diluted to the flotation pulp density, which was normally 9.7% solids. Impeller speed was 1520 rpm and the temperature of the pulp was maintained between 24 – 26°C for all tests. The pH was maintained between 7.2 – 7.4.

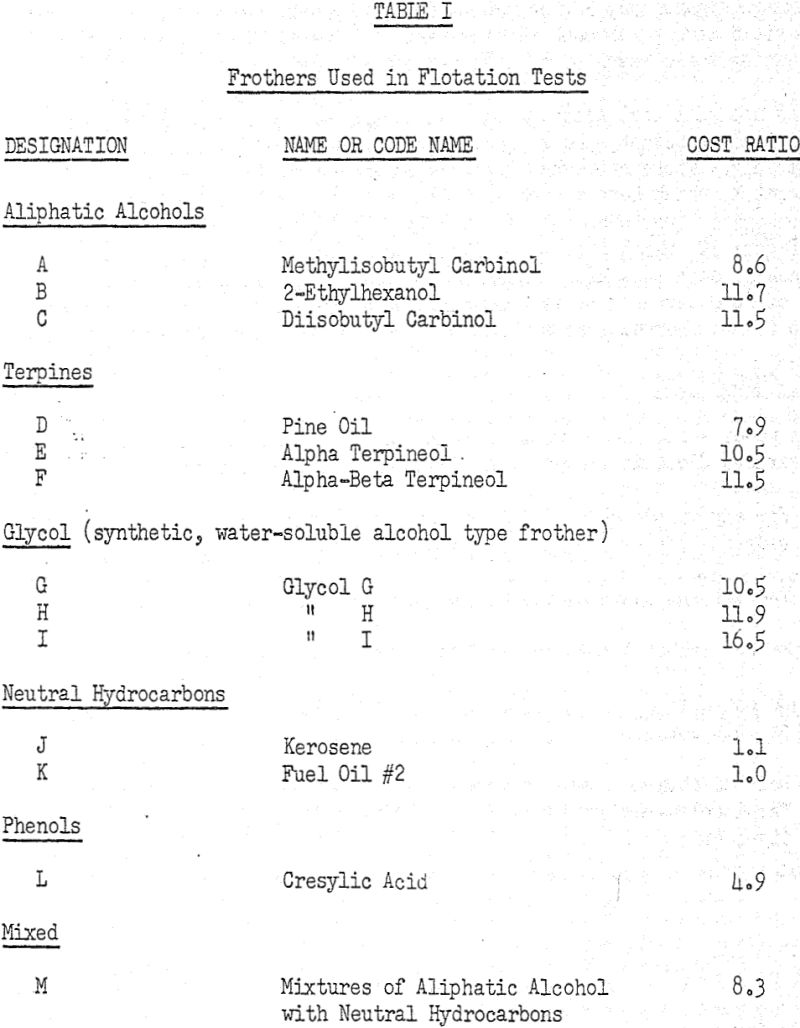

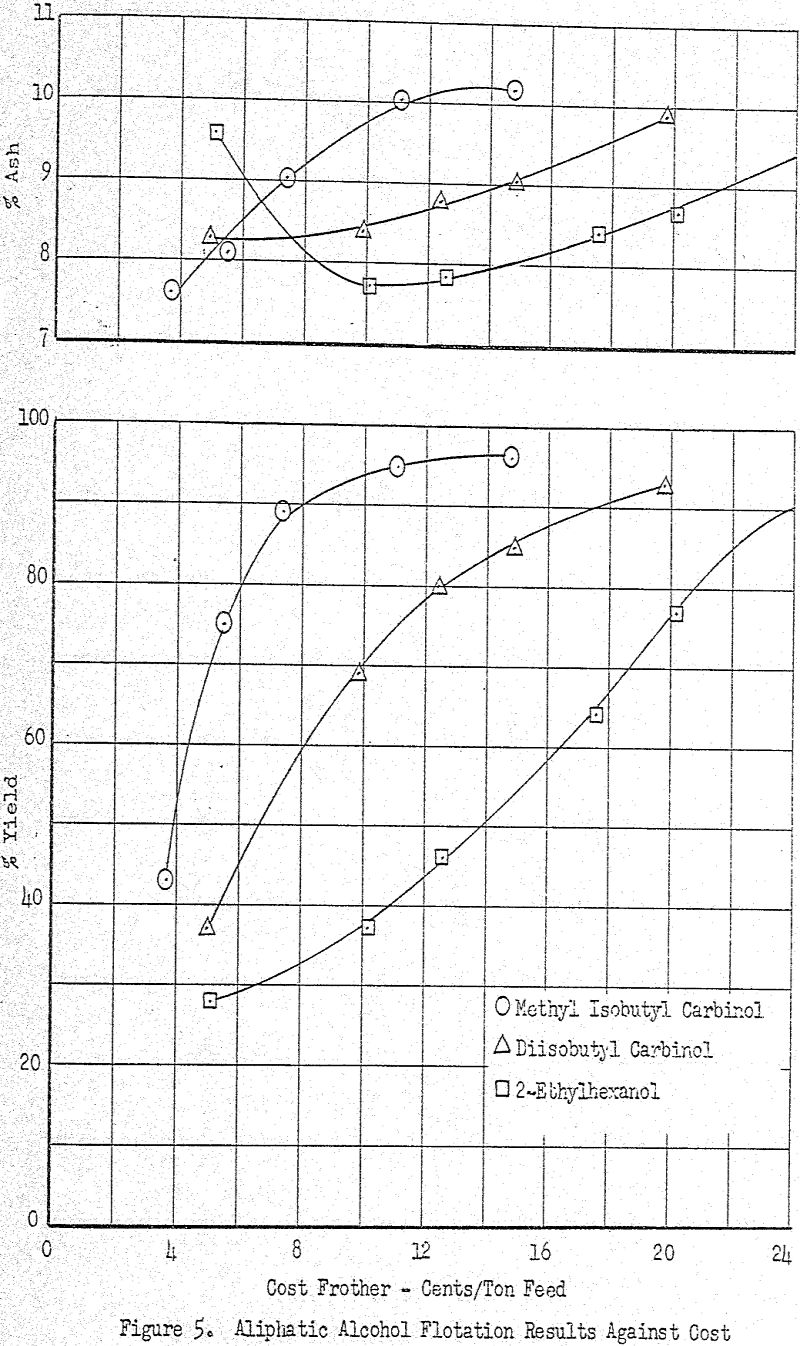

Close examination of the data does show that methyl isobutyl carbinol (MIBC) is superior to the other reagents tested on an ash-yield basis. However, the data also show a number of other reagents which closely approach the results obtained with MIBC.

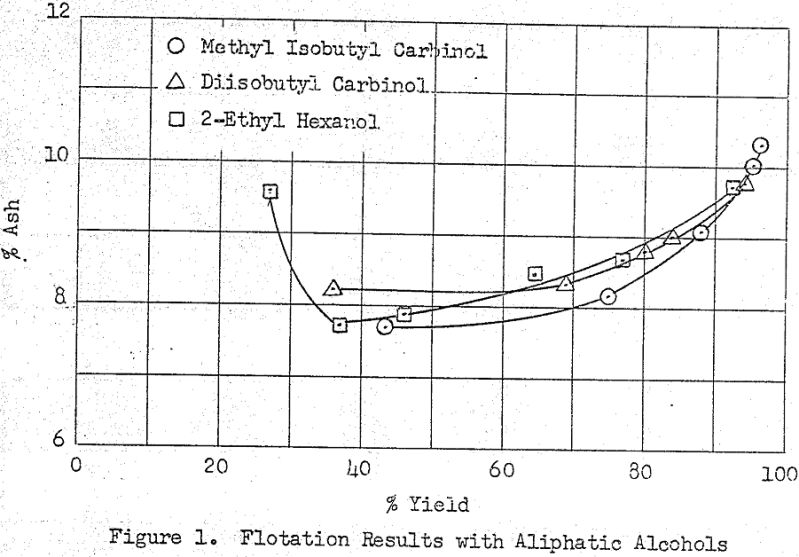

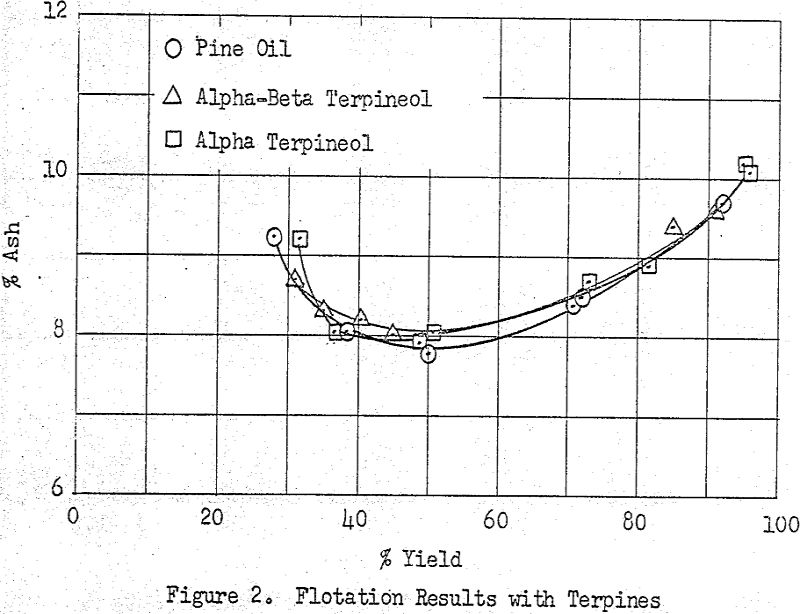

The data were replotted in graphs showing yield and ash against frother dosage and from these graphs, the dosages required for yields of 70, 80, and 90% were read. It is apparent from the data that, although the reagent dosage varied considerably for those reagents tested, the ash level at any given yield level remained relatively constant. Therefore, with the exception of MIBC, there is little to justify the substitution of one reagent for another except for the possibility of cost.