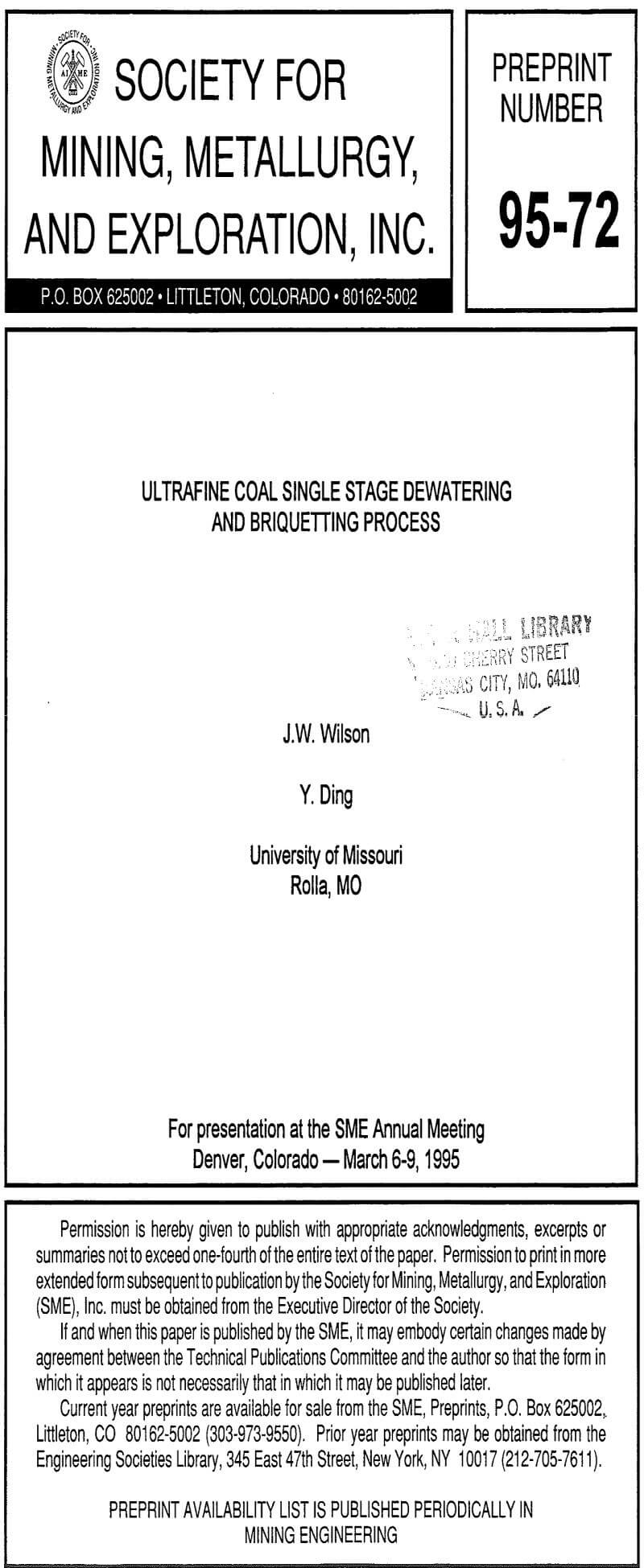

When the bitumen emulsion is mixed with the ultrafine coal filter cake, the bitumen droplets are evenly dispersed throughout the coal sample, due to its water based characteristics. The moisture content of the coal-bitumen mixtures can be as high as 55% for this briquetting process. Because of the hydrophobic nature of the bitumen material and its chemical affinity for coal particle surfaces, the dispersed bitumen droplets can easily be adsorbed onto the coal particles and cause the water from the coal particle surface to be expelled during the mixing process. After thorough mixing, the bitumen coated coal mixtures are ready to be fed into a compaction device and be reconstituted into coal pellets (see sketch below, Figure 1).

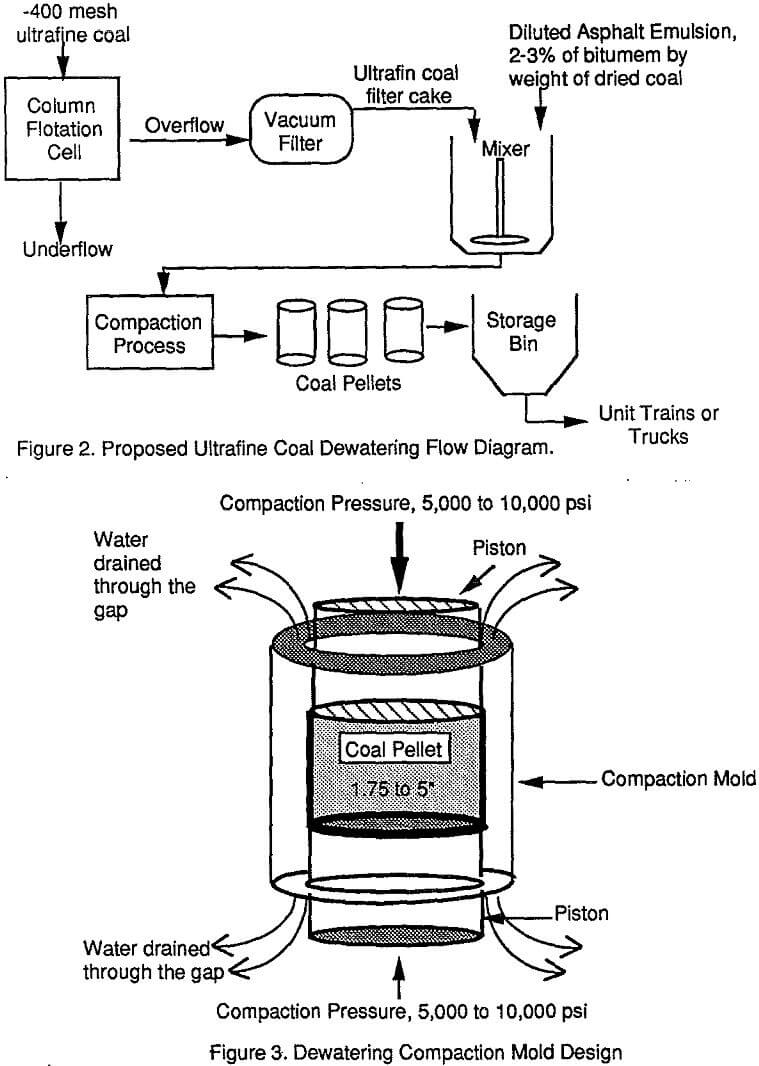

Because the coal particles are coated with hydrophobic bitumen material, the water existing between the coal particles is squeezed out of the compaction device during the briquetting process at compaction pressures of less then 10,000 psi. During the compaction operation, the moisture of the coal is reduced, and, at the same time, the coal particles coagulate to become strong and robust coal pellets which are ideal for transportation. The amount of moisture reduction and the strength of the coal pellets produced are dependent upon the type of coal and emulsion used, concentration of the emulsion, particle size and compaction pressure. Generally, a 25 to 30% moisture reduction can be achieved at a compaction pressure of 5,000 psi and 2% emulsion concentration by weight of coal.

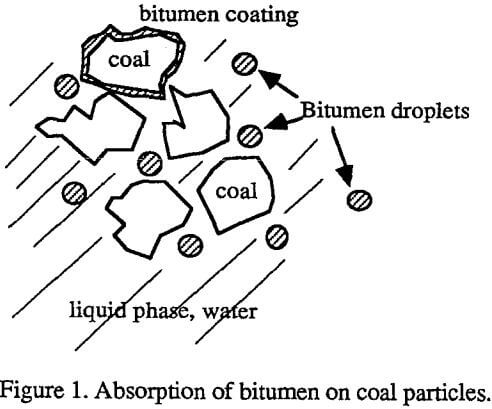

A sketch of the flow diagram for the proposed dewatering and briquetting process is shown in Figure 2. The simple design process requires only a mixing device and a briquetting facility (see Figure. 3) to be added into an existing coal preparation plant process flow chart The use of a mixer is to accelerate the coating of the bitumen binder onto the surface of the coal particles, and the briquetting device is to compact the bitumen coated ultrafine coal into robust coal pellets with a low moisture content

Two -400 mesh coal samples were used in this study, namely, IBC-108 (blend of Herrin and Springfield coal) and Springfield 5 coal. The samples were provided by ISGS and Turris Coal Mine, Elkhart, IL. The test results are summarized as follows;

The preliminary test results described in this paper shows that the single stage ultrafine coal dewatering and briquetting process is an effective method to solve the ultrafine coal storage and handling problems encountered at coal preparation and utility plants.

Because of the water based nature of the bitumen emulsion, a thorough mixing of ultrafine coal filter cake with emulsion can readily be achieved using a simple mixer at room temperature. The moisture content of ultrafine coal filter cake can be as high as 50% for the dewatering and briquetting process, i.e., no other drying stage will be needed before this proposed process.

Since the ultrafine coal particles are coated with hydrophobic bitumen material, the water existing between the coal particles is driven out during the briquetting process at compaction pressures less than 10,000 psi. Generally, 25 to 30% of moisture reduction can be achieved by using this process. Moreover, the coal pellets produced possess hydrophobic characteristics which will prevent water (rain or snow water) from re-entering the coal pellets during their transportation and storage period.

Because of the high efficiency and low cost of this process, it is believed that this research can benefit the commercial applicability and feasibility of the overall deep-clean ultrafine coal process.