Table of Contents

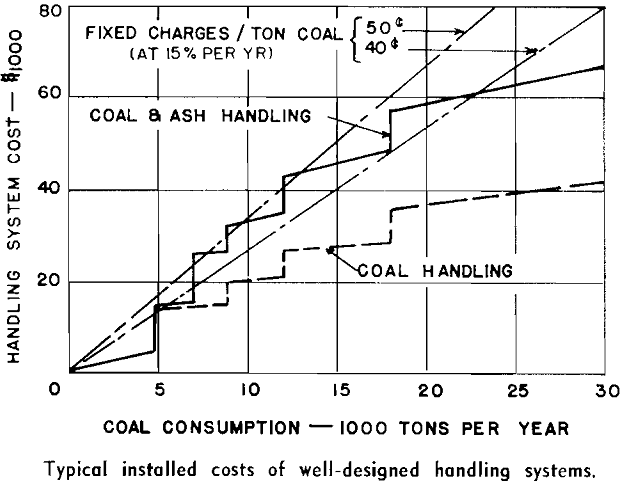

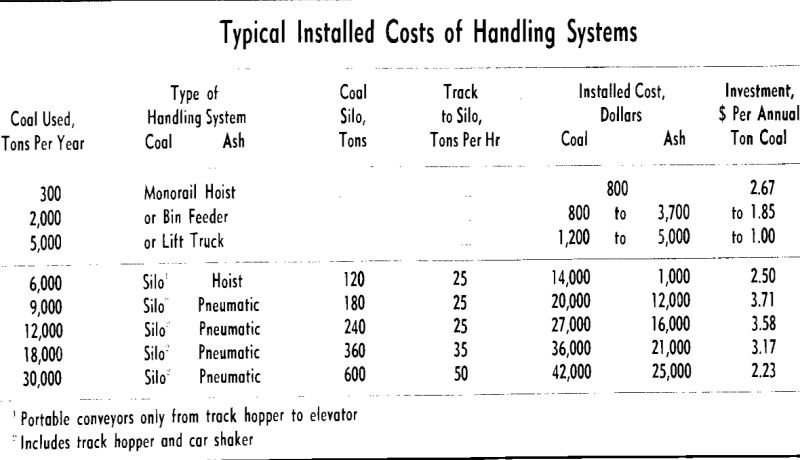

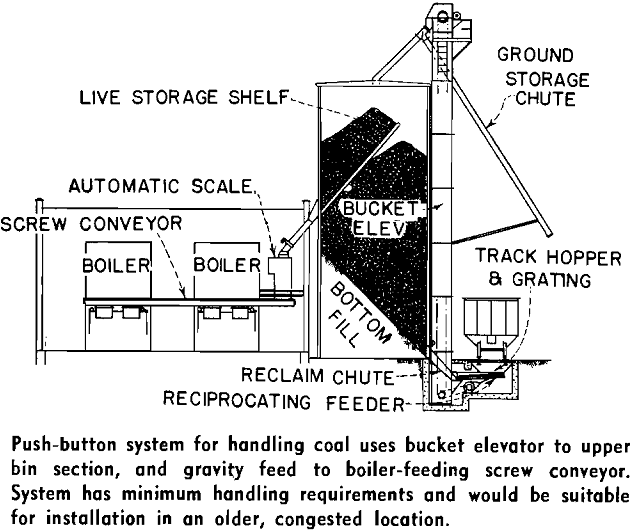

How much can the mine operator afford to spend on his coal burning boiler plant? The usual answer is as little as possible and still get the job done. Thus, attention must be focused on the spot where excessive costs are most likely to arise —the materials handling end of the job.

Silo System for 15,000 Ton-Per-Year Plant

A plant with a maximum steam load of 85,000 lb per hr and a 40 pct load factor will consume about 15,000 tons per year, or an average of 300 tons per week. A concrete-stave silo with 300 ton capacity, of which 20 pct is on a live shelf, would cost $7500 to build. Unloading conveyors sized for 35 tons per hr would permit one-shift handling of more than four times the average daily consumption.

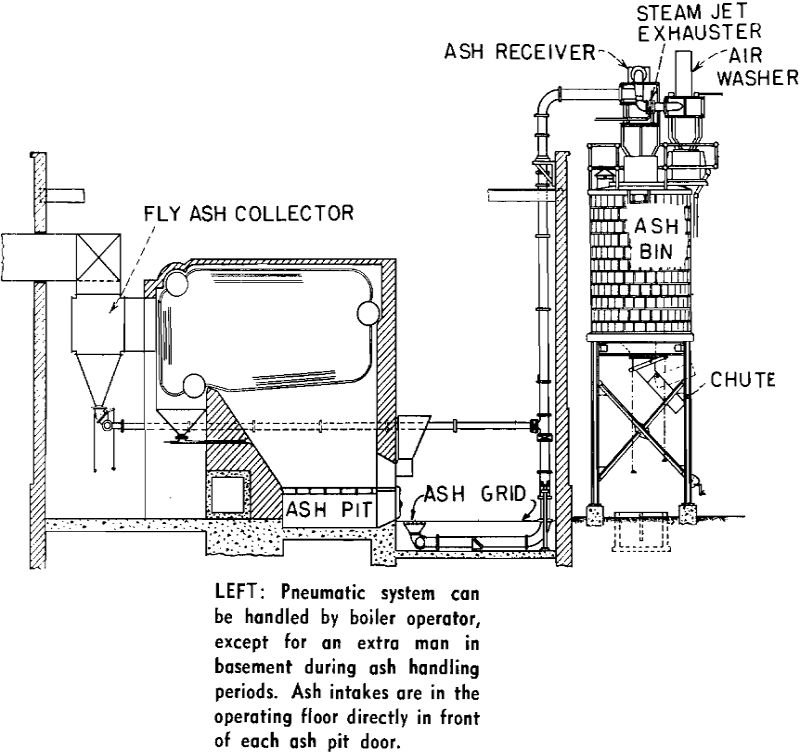

Ash Handling

Coal handling convenience should take preference over ash handling. Hoist buckets and other portable

systems are ideal for small plants. Where ash cannot be sluiced to a fill area, decanting tanks are required, making sluicing systems excessive in cost for the plants considered here.

Disposal system air flow is produced by a steam-jet ejector arranged to prevent steam mixing with the ash and causing storage bin freezing. An ash receiver is placed ahead of the steam jet to discharge the ash to the storage bin. Exhaust from the steam jet is then piped either to an air washer or to the rack, minimizing the amount of ash discharged to the atmosphere.

Lift Speeds Timber Handling

Hard pressed by rising costs and competition from other fuels, coal mine operators are coming up with plenty of cost-slashing ideas. Many methods used in coal mines provide more than the germ of an idea for noncoal miners—some devices would work even better in hard-rock mining. Timberlift, displayed at the recent Coal Show, is one of these devices that may see wider usage.

Designed to provide each timber crew with inexpensive mechanization, independent of power sources, the lift picks timbers up from tunnel floor or flat car, raises, and holds them in place. Low headroom requirements lift capacity greater than 8 ft., and hand-powered hydraulic lift cylinder permit flexible use. Cradles built for timber 6-in. size and larger are vital part of the operation, enabling the arm to first pick timber up with a chain, rest it on a cradle, then push it into place.

Hardening for Increased Bit Life

Special interest attaches to any means of increasing resistance to wear and abrasion, for in addition to mechanical wear common to all industries, mining has additional problems of bit and tool wear in handling its basic material: rock. One new method being tested is bit hardening with a product sold under the name of Hard-N-Tuff. Claimed to offer major improvement in wear resistance, it is a steel hardening compound in powder form.

Three hardening actions, carburizing, nitriding, and chromizing are stated to be accomplished in one operation. Photograph shows treated and untreated detachable bits after test. Churn drill bits operating in taconite were reported to show 25 to 80 pct increase in bit life for hardened bits over standard ones.

Crushing Plant Dust Control at The Ray Mines Division, Kennecott Copper Corp.

In 1947 an Industrial Hygiene Department was organized to represent and assist the four western mining divisions in industrial hygiene problems. Department headquarters are located at the Utah Copper Division, Magna Plant, Magna, Utah, with a branch office at the Chino Mines Division, Hurley, N. M. The headquarters staff includes a director, a department secretary, an industrial hygienist, a supervising ventilation engineer, and two ventilation designers. To be in closer association with work at the Southwest properties, a field engineer at the branch office conducts field studies which include ventilation problems at the New Mexico and Arizona properties, i.e., the Chino and Ray mines divisions.

Until Kennecott’s new Utah refinery came into the picture the major products of Kennecott Copper Corp. Western Mining Properties were copper concentrates and smelted copper; the principal concern of the Industrial Hygiene Department, therefore, was to control dusts in the mines and crushing plants. This was accomplished by dilution or by exhaust ventilation. In the crushing plants at Ray, exhaust ventilation was employed exclusively.

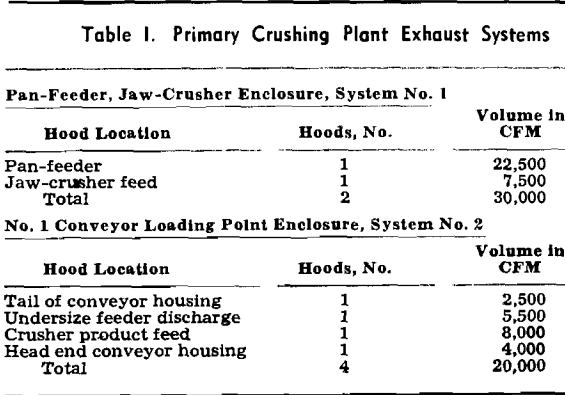

The ore from the open pit mine is transported to the crusher by 22-cu yd Euclid trucks. A two-gate horizontal slide portal admits the ore to the receiving hopper wherein grizzly bars separate the fines from the oversize product. The oversize material is carried by pan-feeder to the large jaw-crusher with the undersize, minus approximately 7-in. material passing to the undersize bin where it is fed to the No. 1 conveyor by a variable speed pan-feeder.

Transfer Station

The transfer station is furnished with exhaust ventilation both for protection of equipment and workmen, although men are not steadily employed at this location. The transfer point is completely housed; a type W Rotoclone, with exhaust hoods at the tail and head of the ore fall, exhausts 4000 cfm from the head and 1000 cfm from the tail of the enclosure.

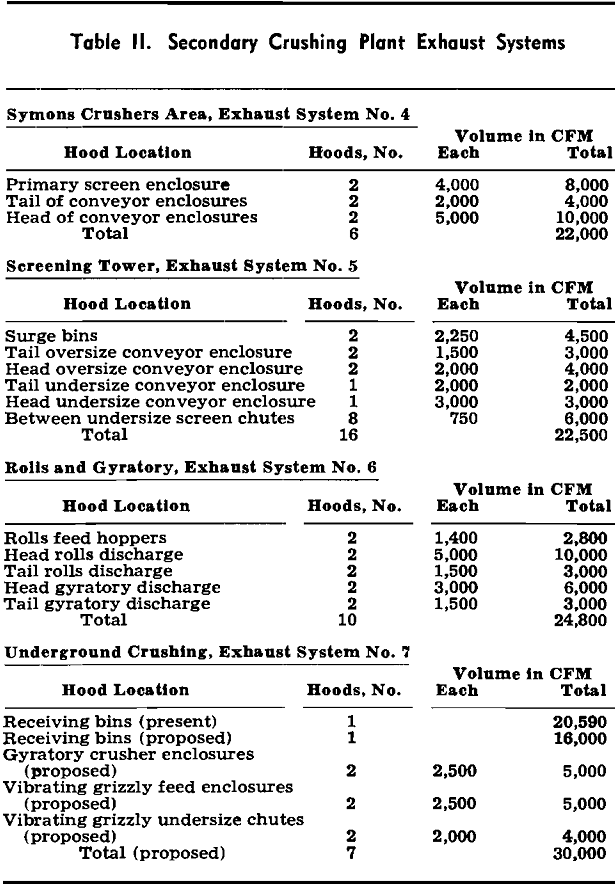

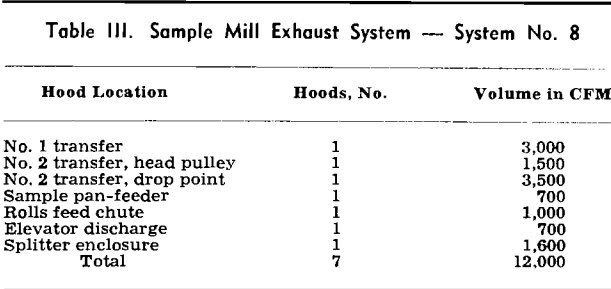

As shown in the flowsheet, there are four exhaust systems in operation in the secondary crushing plant, with additions planned for the system exhausting the underground ore-receiving bins. When the system is completed, a volume of 99,300 cfm will be exhausted from the crushing and screening operations in the secondary crushing plant.

No air is exhausted from the enclosure over the head pulley because the ejector effect of the falling ore creates sufficient indraft around the pulley to abate escaping dust. The hopper above each 7-ft cone crusher which receives the screen oversize as well as the area surrounding the cone is housed, but no exhaust is provided.

Housekeeping

A central vacuum cleaning system has been ordered to facilitate clean-up work in the secondary crushing plant. The unit is designed to handle two —2-in. or four 1½-in. hoses continuously. The network of piping extends to every nook and corner

in the secondary as well as the conveyor way leading to the storage bins. Long radius drainage fittings with self-closing valves will be used exclusively. Material collected by the primary and secondary separators will be emptied on the final products conveyor. At least for the present, no vacuum cleaning system has been planned for the primary crushing plant. Clean-up chutes with self-closing doors have been provided at the tail of all conveyors, eliminating air losses through the doors often left open after the clean-up work is done.