During this period of evolution, man struggled with the only fuel he knew – charcoal. Some 5600 years passed before any attempt was made to use coal as a fuel for the blast furnace.

Blast Furnace Practice

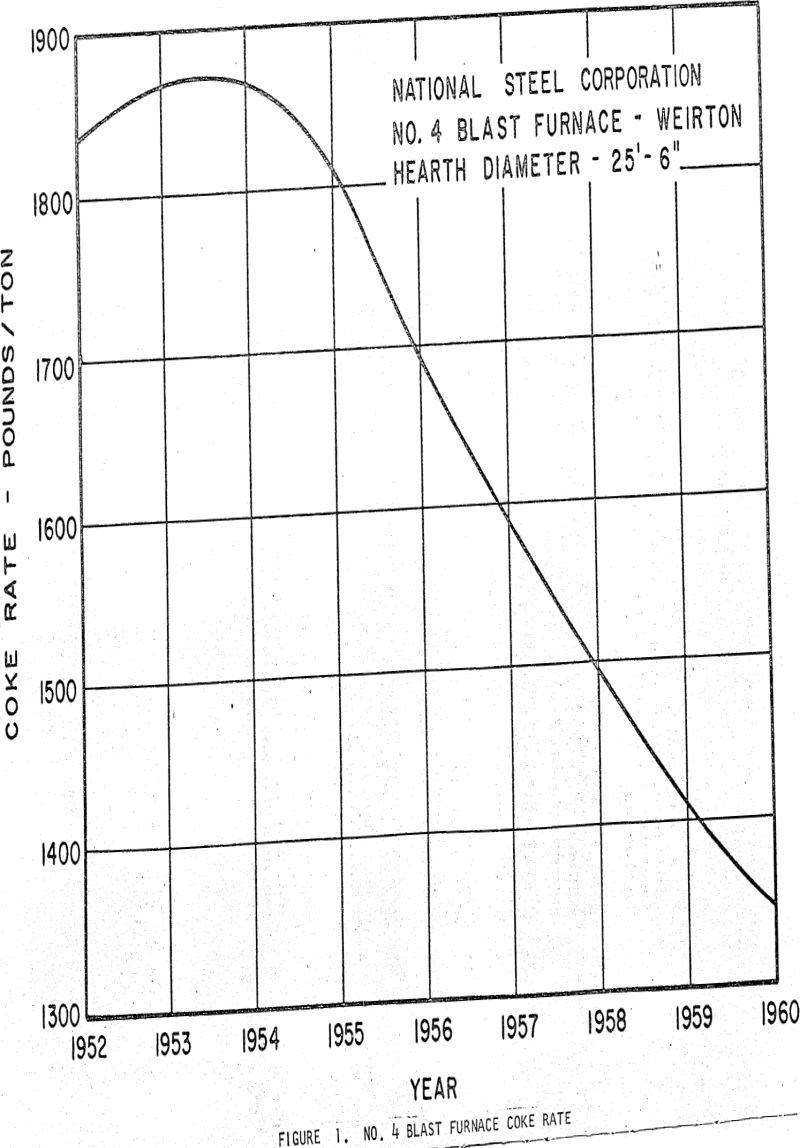

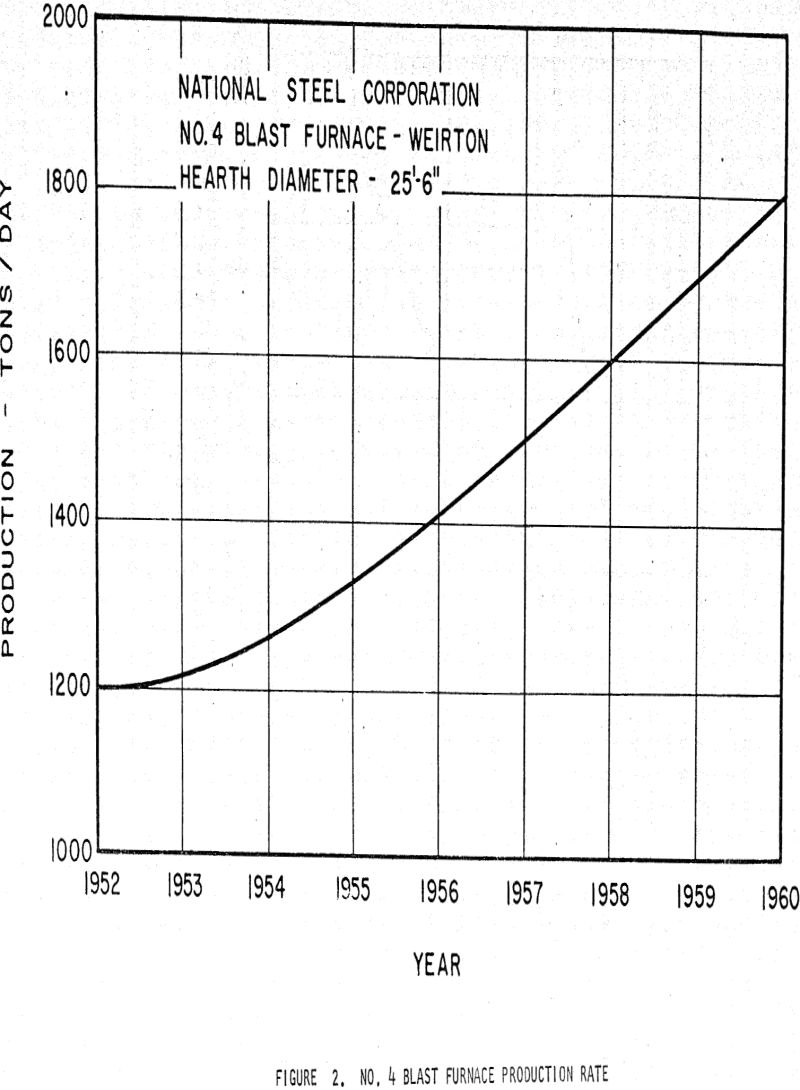

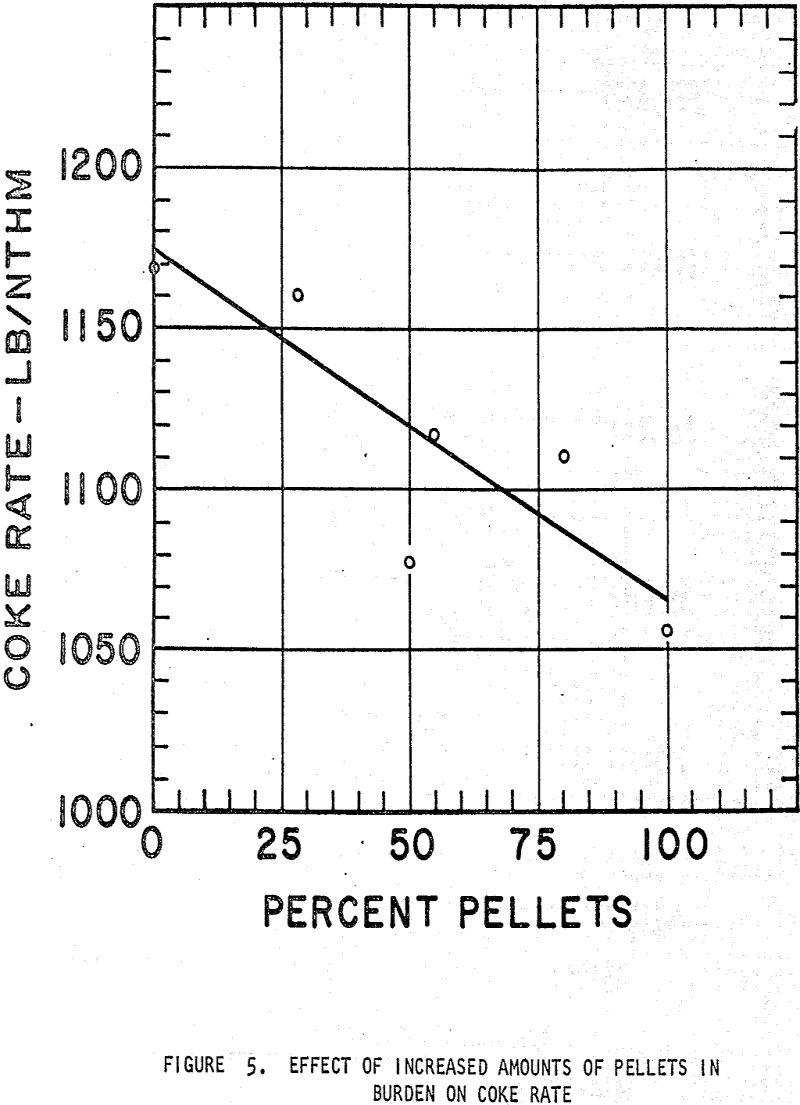

No one factor can be pointed to as the prime cause of reduced coke rates and increasing production. Constant changes in blast furnace technology have brought about varying degrees of improvements in this industry. Among the more prominent factors that have influenced the productive capacities and coke consumption per unit of iron produced are the following:

- The use of better burdens

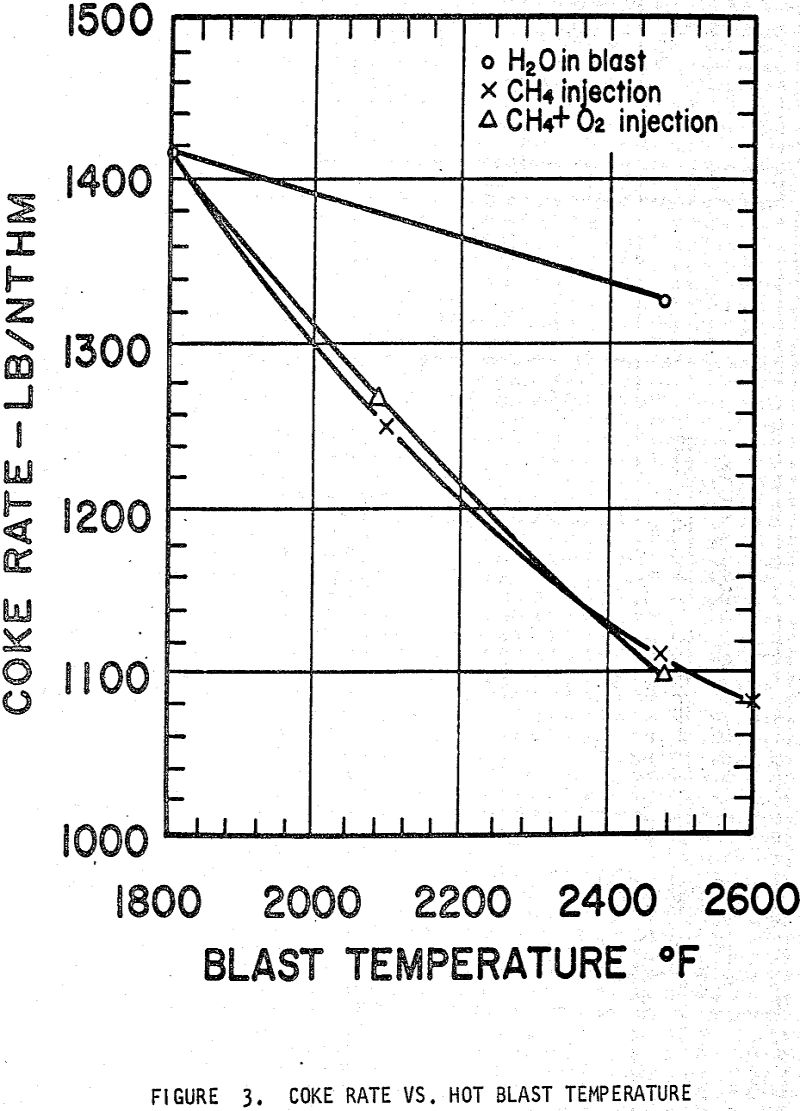

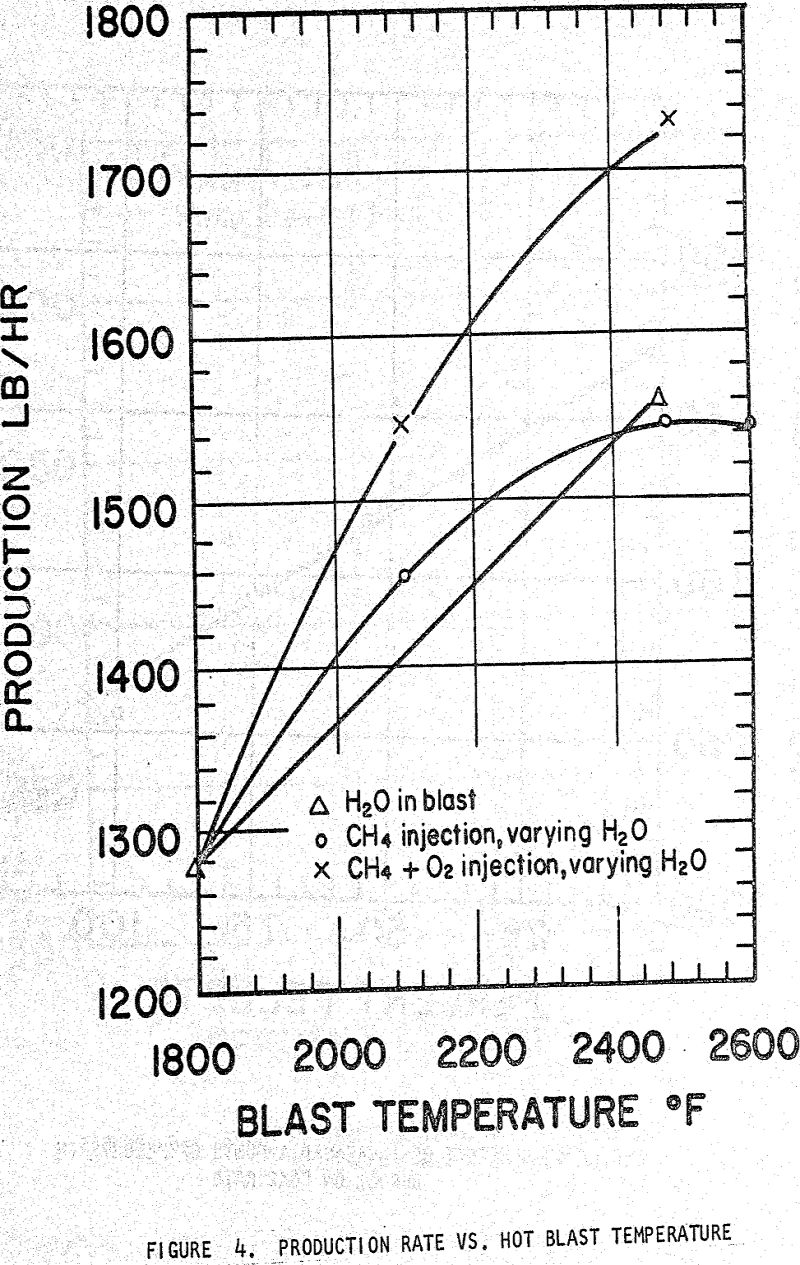

- The control of blast humidity

- The use of oxygen enrichment of the blast

- The use of high blast temperatures

- The use of increased furnace top pressure

- The use of substitute fuels injected into the blast furnace through the tuyeres

Solid Fuel Injection

The first commercial blast furnace to be equipped for solid fuel injection was the No. 2 blast furnace at the Hanna Furnace Corporation in Buffalo, New York. In December of 1960, the installation of the equipment was completed. The first coal was injected in December of 1960. This initial coal injection work was primarily concerned with calibrating the injection unit and putting the system through a trial run. Due to business conditions, the furnace was banked in January, 1961, and it was blown in again in

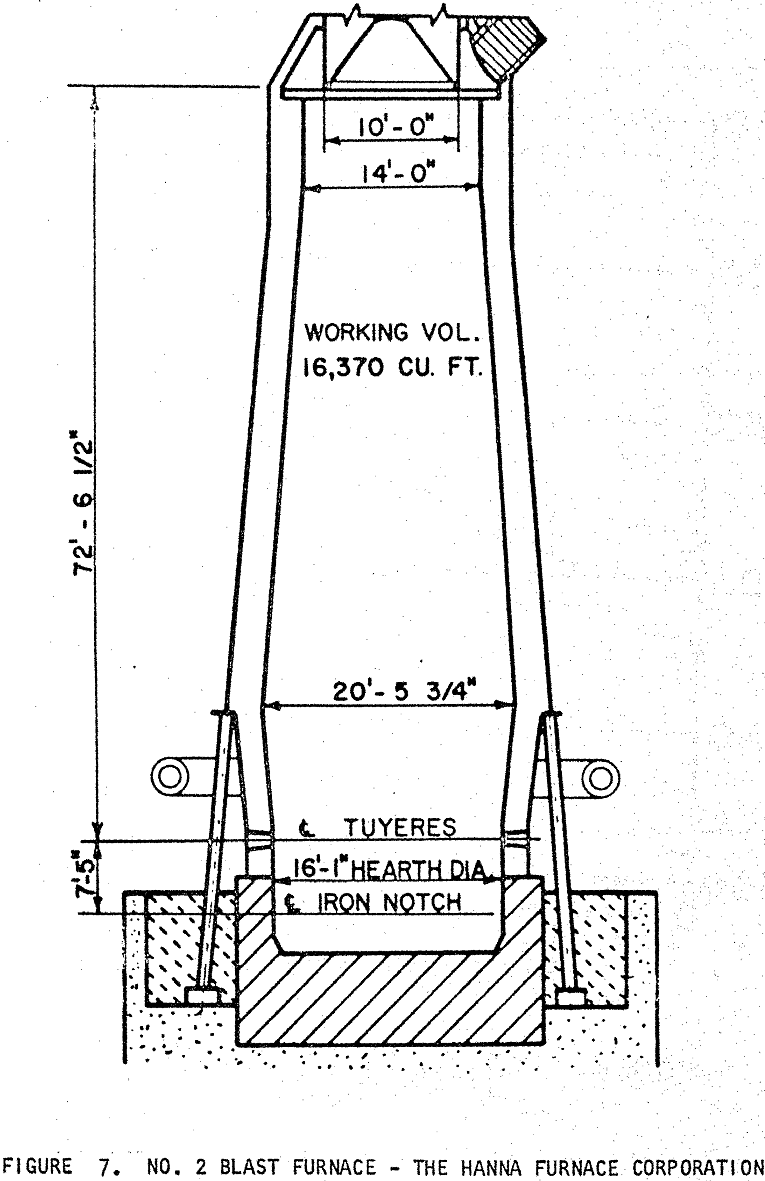

The first full-scale study of solid fuel injection on a commercial blast furnace was made on the Hanna Furnace Corporation’s No. 2 blast furnace. This furnace has a hearth diameter of 16 ft, 1 in., and has eight tuyeres all active. Figure 7 shows a section of the furnace with its principal dimensions.

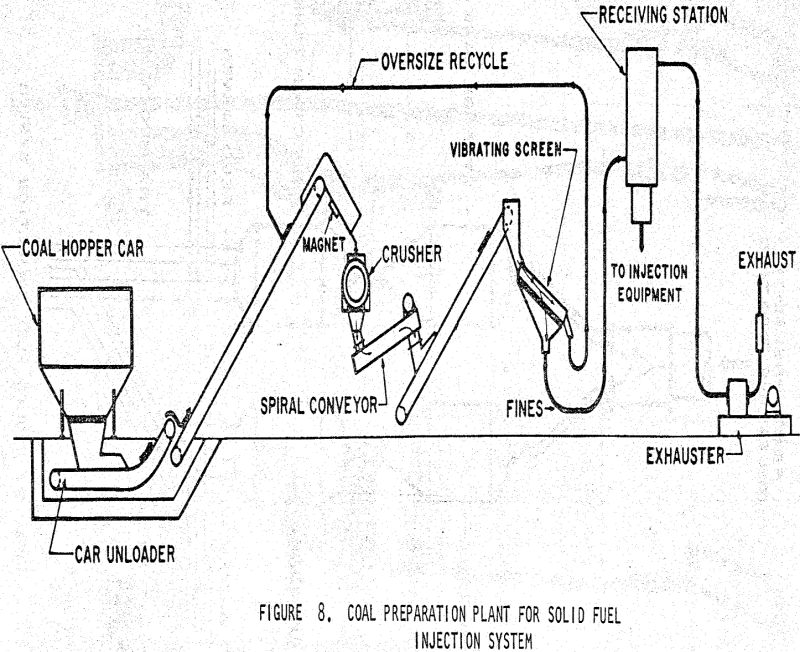

A temporary coal preparation plant was installed to prepare the coal properly for injection into the blast furnace. Because the injection system would only function on dry coals, shipments were made in covered hopper railroad cars. The coal was moved from the railroad cars to the crusher by a track unloading conveyor and an inclined conveyor.

Before the coal dropped into the crusher, it passed under a magnet which removed tramp iron materials. An impact-type of crusher was used to crush the coal to the desired size. From the crusher, the coal passed over a single deck screen where it was screened at either minus 1/8 inch or minus 3/16 inch.

Safety features built into the system which will close the motorized ball valves at the tank outlets include:

- Plant air failure

- Instrument air failure

- Electrical failure

- Low blast pressures

- Injection tank pressure drops to within 2 psi of the blast pressure

The lines used to carry the coal from the injection tank into the blast furnace were originally ½ inch I.D. black steel pipe. All connections were made with socket welding couplings. Line lengths ranged from 41 feet to 101 feet. Due to this variation in line length, the pressure drops within the lines varied; and, consequently, there was a need for varying the amount of carrier air to overcome this difference. During the period in which modifications were made to the system, these lines were changed so as to give nearly the same pressure drop by varying the inside diameter. The shorter lines were changed to 5/8 inch I. D. Buna N hose and the longer line to ¾ inch I.D. neoprene hose.

Calibration

Needless to say, metering of coal flow is very difficult. To add to this problem, it is very important that not only the rate be known at all times when injecting the coal into the blast furnace, but also that the distribution to each tuyere be very nearly the same. For this particular injection system the amount of coal being injected into the blast furnace was a function of the quantity of air used to convey the coal and the difference in pressure between the injection tank and the blast furnace. In order to establish the relationship between coal injection rate, carrier air flow and differential tank pressure, the system was calibrated over a wide range of injection rates. The method employed in calibrating the system was as follows:

- Fix the pressure in the injection tank

- Set the carrier air rate at different levels depending on line length

- Convey coal to collecting drums for a specified length of time

- Weigh the coal collected in the drum

Properties of Coal

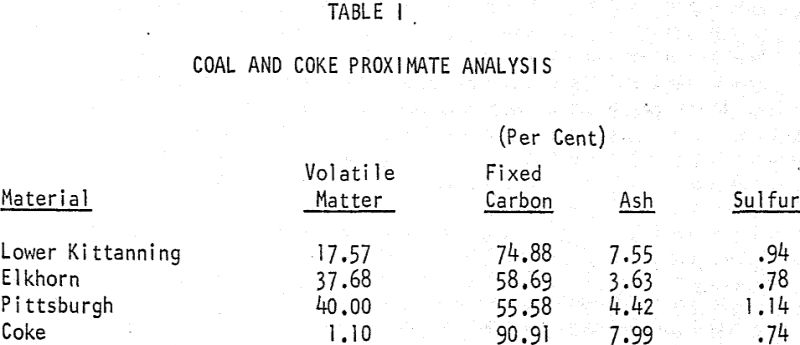

Four different coals were used during the solid fuel injection test work. These were low-volatile Kittanning seam coal, high-volatile Elkhorn seam coal, high-volatile Pittsburgh seam coal, and a few cars of anthracite coal. Table I shows the proximate analysis of the coals and the coke used.

Discussion

From the test work carried out on solid fuel injection at the Hanna Furnace Corporation, there is now sufficient evidence to uphold the belief that coal injection into the blast furnace can replace more of the coke in the burden than can other injected fuels. Reported results on natural gas injection and also on fuel oil injection have shown that the replacement of coke has been much less than that achieved with coal injection. The test work on solid fuels has shown that with only minor changes in blast temperature and blast moisture, 17.8 per cent of the total fuel was replaced with nearly a one for one replacement of coal for coke. It is conceivable that 25 per cent or more of the coke can be replaced by coal injection while maintaining a respectable replacement ratio.

The optimum size of coal to be injected was not determined during the test work; however, the use of minus 1/8 inch coal and minus 3/16 inch coal did not indicate that there existed a difference in the behavior of these two sizes of coal. Combustion appeared to be rapid in both instances. At no time was there any coal visible at either the slag or iron notches. It is highly improbable that coal of this size would not be thoroughly and rapidly combusted.

z