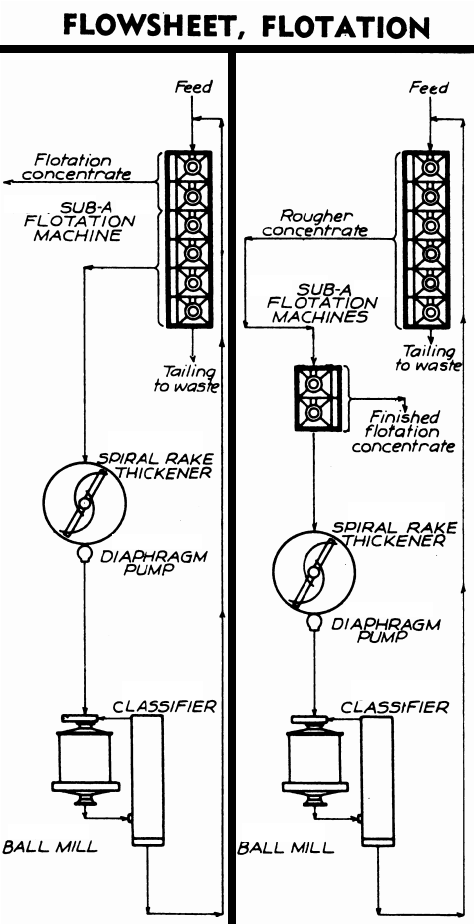

DESCRIPTION: Regrinding of scavenger flotation concentrate middling OR flotation cleaner tailing and refloating the ground product in closed circuit cleaning.

ORE TREATED: Flotation middling containing valuable mineral particles attached to the gangue particles and which can be freed by finer grinding.

ADVANTAGES: Middling is designated as such because it contains material which lowers the grade of the desired mineral concentrate to such an extent that it cannot be considered as a finished concentrate.

This middling contains valuable mineral particles attached to gangue particles, which, when returned for retreatment in the flotation machine without regrinding, again find their way to the middling product or are lost in the tailing. But with these flowsheets by regrinding and liberating the valuable mineral, it can then be removed with tne flotation concentrate and the gangue content then becomes tailing.

The result is a higher grade concentrate with better recovery. These flowsheets show regrinding the middling, preventing the retention of middling in the flotation circuit or its loss into the tailing. After regrinding, the freed mineral floats rapidly and is recovered successfully in the finished clean concentrate.

PROCESSING COMMENTS: This procedure makes possible the production of the maximum amount of finished high-grade concentrate and improves recovery. It also permits coarser grinding in the primary circuit, increasing mill capacity, and confines fine grinding to only the fractional part of the ore on which this is actually required. See our coarse flotation Flowsheet.