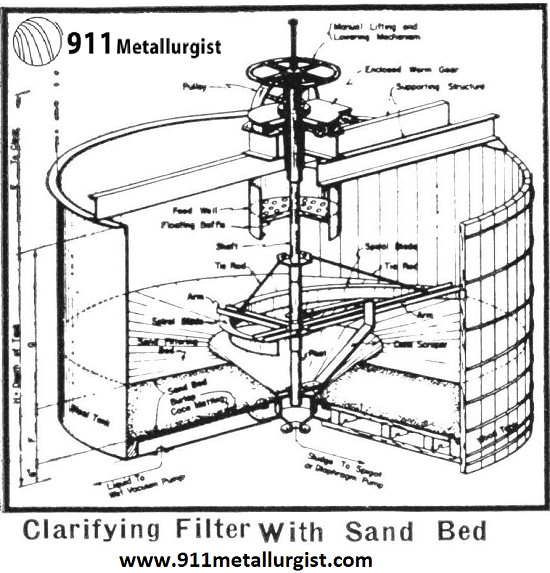

The Clarifying Filter is used to remove turbidity from practically any liquid. It can be used to remove either suspended solids or colloidal and dissolved solids, with the aid of an adsorbing agent. In certain cases a filter bed of porous material is used having decolorizing properties.

In the majority of cases in metallurgical plants the filter bed is composed of a sand which is one of the intermediate milling products, i.e., classifier return sands in the grinding circuit.

The clarifying filter is of simple construction, consisting of a tank of suitable material of relatively shallow depth equipped with suitable superstructure supporting a central shaft and spiral scraper to scrape the film of removed solids from the surface of the filter bed. This scraper can be lowered a fraction of an inch at a time by an adjustable handwheel lifting device. The liquid is removed by a wet vacuum pump connected to the area below the filter bed.

In special cases a supporting crushed rock bottom may be used to carry the filter medium where acid solutions are being handled and the entire mechanism is made acid proof.

The mechanism and superstructure can be adapted to any suitable sized tank. In certain instances tanks have been employed using static head instead of a vacuum pump.

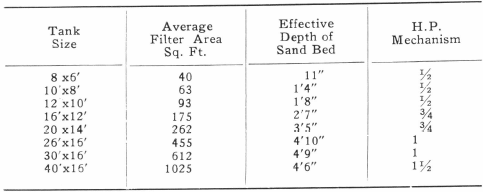

Clarifying Filter Capacity