Table of Contents

The Problem with Chromite Processing

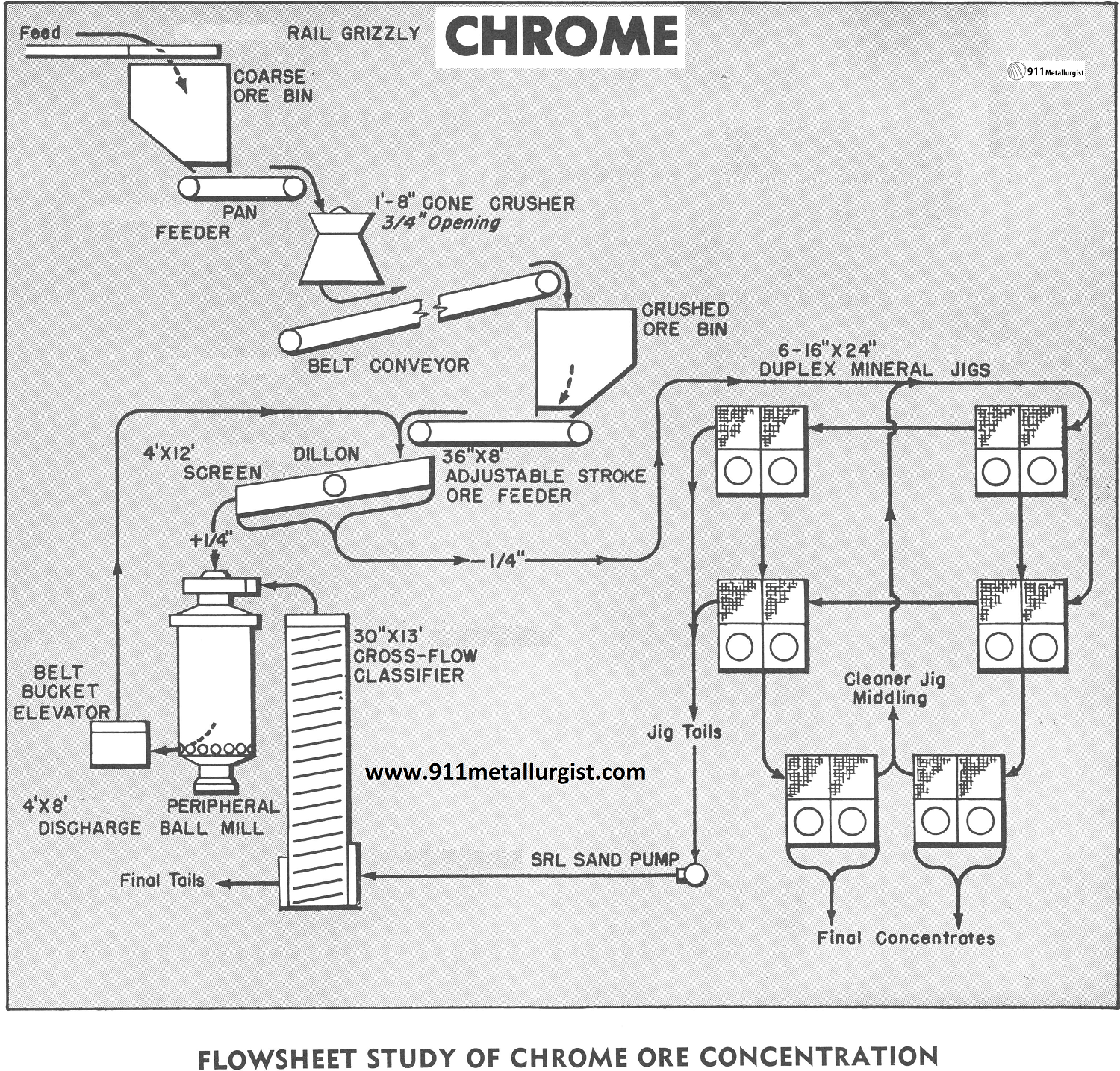

Experience indicates that chrome ores are concentrated to best advantage by gravity methods. Since recoveries are generally very poor in the fine sizes, the gravity flowsheet must be designed to remove the chrome as soon as liberated by crushing and grinding. For example, if the chrome is not entirely freed until the ore is minus 16 mesh, it is obvious that the plus 16 mesh particles should be removed after stage crushing and grinding to prevent further reduction of the chrome and consequent loss in the fine sizes.

The Chromite Extraction Flowsheet

Chromite Ore Crushing

The crushing section for this 250 ton per day chrome mill consists of a coarse ore grizzly, a coarse ore bin with pan feeder to a 1’8″ reduction crusher and a crusher discharge conveyor to a crushed ore bin. On this particular ore, we find that there is no chrome liberated in sizes larger than ¼”.

Accordingly the crusher discharge opening is ¾” and the minus ¼” material is removed for concentration before further reduction.

Chromite Grinding

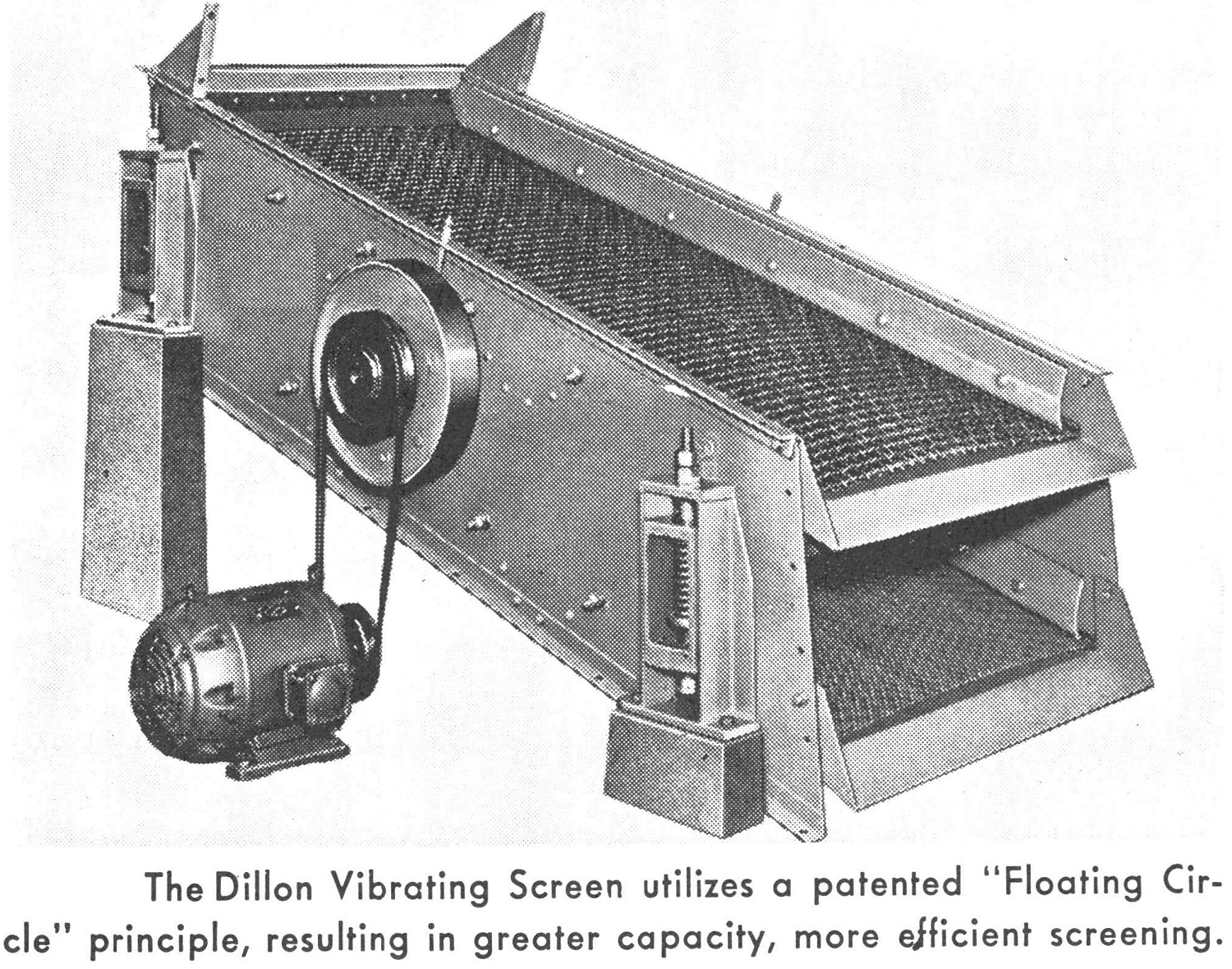

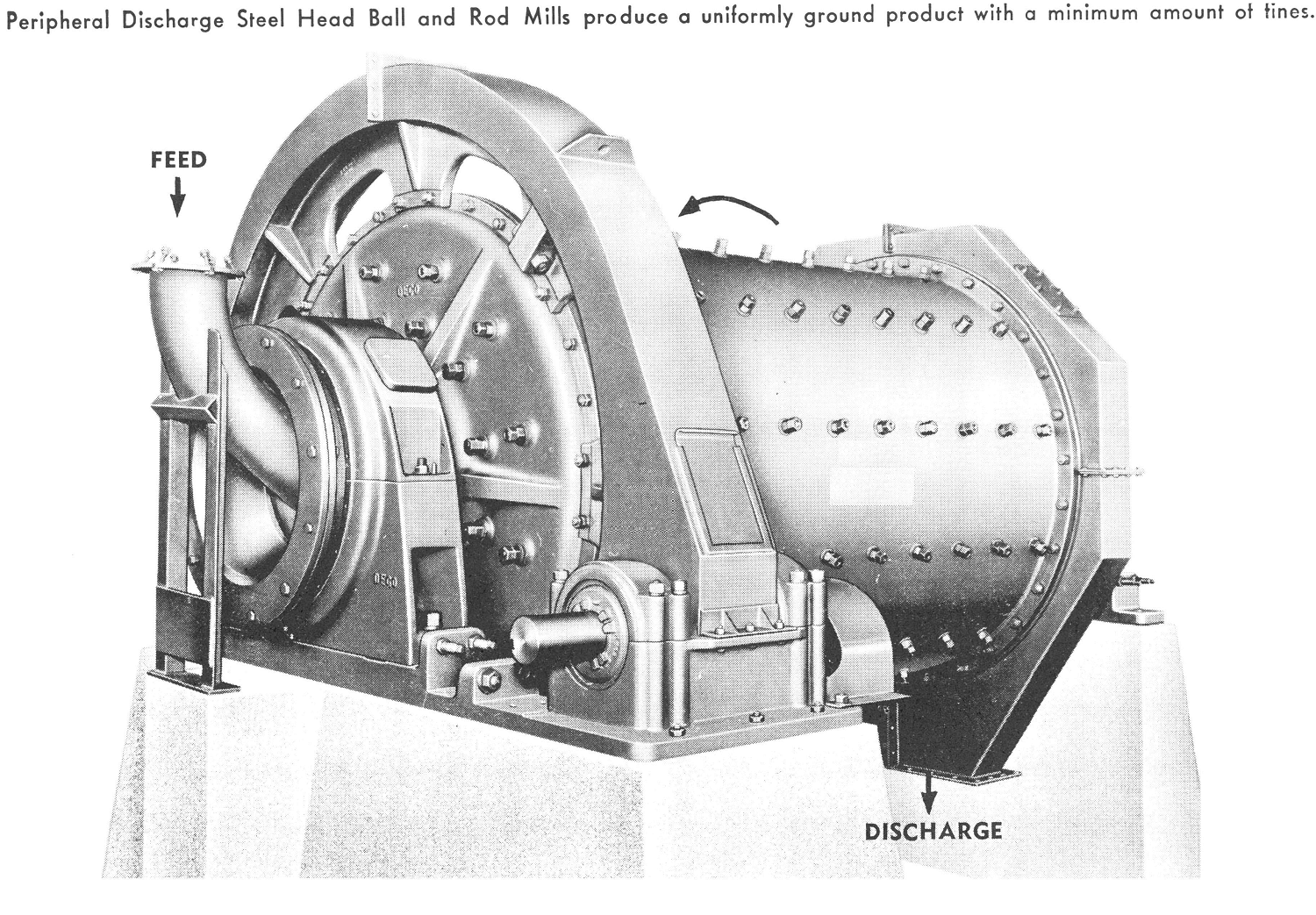

The 36″x 8′ Adjustable Stroke Ore Feeder is used to accurately control feed of crushed ore to the grinding section. Before it is fed to the 4’x 8′ Peripheral Discharge Rod Mill, the minus ¼” chrome ore is removed from the grinding circuit by means of a 4’x 12′ Dillon Vibrating Screen. This minus ¼” product is then ready for concentration in the Mineral Jigs.

The Vibrating Screen oversize is ground in the Steel Head Rod Mill. A rod mill with the peripheral discharge feature is preferred for this application because the ‘”rapid-pass” design produces a minimum of the undesirable fines. The discharge from the rod mill returns to the Dillon Vibrating Screen by means of a Belt Bucket Elevator, so that a closed circuit grinding arrangement is obtained.

Gravity Recovery Section

The minus ¼” undersize from the Vibrating Screen is divided to feed two identical, parallel jigging circuits, each consisting of l6″x 24″ Duplex Mineral Jig used for roughing and a I6″x 24″ Duplex Mineral Jig used as a scavenger. Automatic Density Discharge Control Valves on the hutches of the scavenger Mineral Jig provide a controlled, continuous, high-density feed to a l6″x 24″ Duplex Mineral Jig used for final cleaning.

A final, cleaned concentrate is produced by the two cleaner Mineral Jigs and also a middling product which is re-circulated back to the scavenger jigs. This procedure is preferable to the immediate regrinding of the middlings as it avoids the further reduction of relatively pure chrome particles which are bound to be present.

The tailing from the scavenger Mineral Jig is directed to a 30″x 13′ Simplex Cross-Flow Classifier which discards a waste product as a final tailing at minus 65 mesh and the sand product is returned to the rod mill for further grinding. A SRL Sand Pump is used to pump the Mineral Jig Tailings to the Cross-Flow Classifier.

Chromite Process Summary

This flowsheet is very effective due to the ability to remove the high grade chrome with very little grinding on each pass through the mill. In this way, grinding takes place with a large number of small reductions followed by immediate removal of the liberated chrome into a high grade concentrate.

In the concentration of certain chrome ores, high grade chrome particles are sometimes liberated at sizes larger than ¼”, For the concentration of these large size chrome particles, the Improved Harz Type Jig is indicated.

In the flowsheet described here, there is a minimum amount of valuable chrome in the classifier overflow and accordingly this product is sent to waste. However, conditions may justify the installation of slime concentrating tables and Tilting Concentrators.

- Melting Point: 3,465 F (1,907 C)

- Boiling Point: 4,840 F (2,671 C)

- Atomic Number: 24

- Atomic Symbol: Cr

- Atomic Weight: 51.9961

- Word origin: The word chromium comes from the Greek word chroma(color).

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.