Table of Contents

Location

Cerro Colorado lies on the eastern edge of the Atacama desert in the foothills of the Andean Cordillera of northern Chile. One hundred and twenty kilometers east of the port city of Iquique, the mine site is accessed by 30 km of paved highway and 70 km of upgraded road.

The mine site is located at an altitude of 2600 meters (8531 feet) on a gently west-sloping plateau adjacent to a deep canyon (Quebrada de Parca) on the north. Temperatures are moderate, ranging from 5° to 30° Celsius (41° to 86° Fahrenheit) with an average annual rainfall of 20 mm. The plateau is generally covered with 20 to 30 meters of Quaternary sand and gravel overlaying bedrock. In the immediate vicinity of the Cerro Colorado deposit, a semi-circular embayment has been eroded into a steep canyon wall that cuts through the surface gravels to expose a considerable section of the underlying bedrock.

Exploration History

Mineralization has been known at Cerro Colorado for many years as evidenced by old workings into copper oxide outcroppings in the embayment of Quebrada de Parca. Recent exploration of the deposit area began in 1963 by Normina (an American Chilean Group) which tested for a “blind” porphyry copper deposit beneath the younger cover rocks adjacent to copper oxide showings. This system identified a porphyry system and intersected some supergene copper sulfides.

Geology

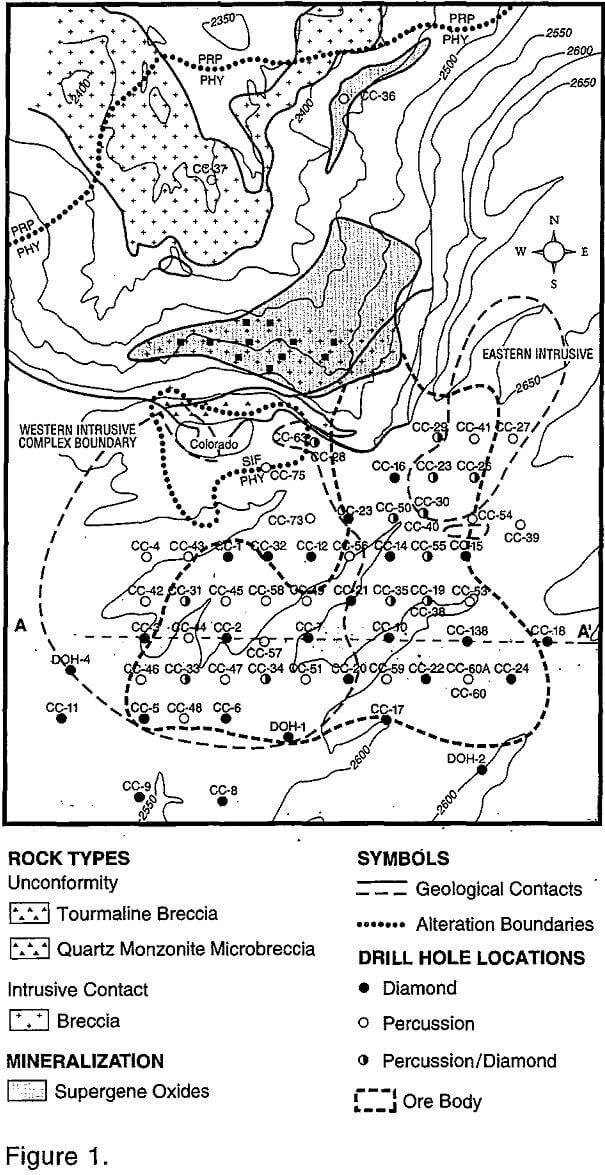

The Cerro Colorado deposit lies within a sequence of Cretaceous-age, andesitic volcanic rocks between two small closely spaced Tertiary-aged porphyritic intrusive stocks informally termed the western and eastern intrusives.

The andesitic volcanics (Cerro Empexa Fm.) are sub-horizontal to shallow southwest dipping, and consistent of a gently folded and faulted suite of porphyritic andesitic flows, breccias, agglomerates and lapilli tuffs.

Mining

The ore body is mined as a traditional open pit operation with a 10-meter bench height. There are six phases of expansion during the projected 23-year life of the mine. The stripping ratio is 2.6 to 1, excluding an initial pre-strip of 40 million tonnes. State-of- the-art mining methods are used with primary mining equipment consisting of two (2) Ingersoll Rand DMM2 drills, drilling 9 7/8 inch bore holes, three (3) D-MAG 185 shovels with 13-cubic-meter bucket capacity and a fleet of twelve (12) Cat 777 85-ton ore-haulage trucks. Design ore production is 11,140 metric tons per day with an average grade of 1.39%.

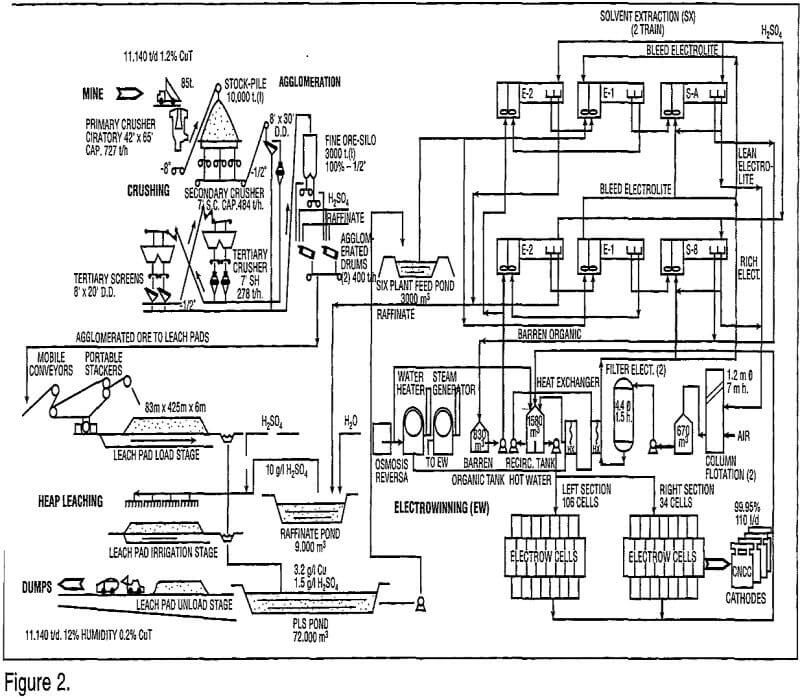

Crushing

The Cerro Colorado crushing plant design capacity is 560 tph with a final product size of 13 mm (.5-in.) for use on the leach pad. The plant is designed with considerable flexibility so that downtime on individual pieces of equipment produces minimum impact on production. For example, if a crusher goes off line, the crushing plant still has full use of all screening units, and vice versa. This is accomplished by using multiple equipment units, separation of crushing and screening operations, and intermediate ore storage. To reach the final ore size, three stages of crushing are required.

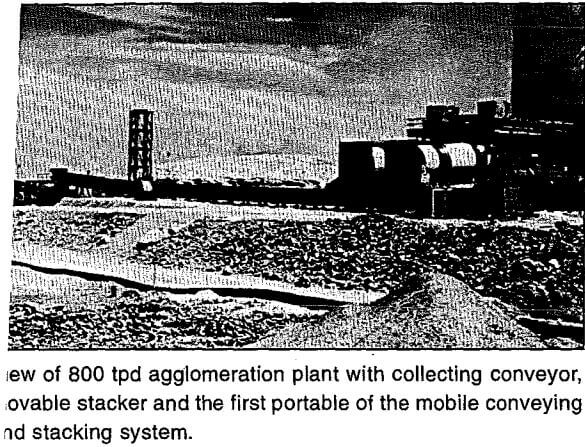

Agglomeration

The agglomeration system consists of two 2.5 m (diameter) x 7.5 m (long), variable-speed (5 to 10 M) variable inclination (4 to 12°) agglomeration ums with a total capacity of 800 tph. The addition sulfuric acid and water are strictly controlled at the glomerators so the ore leaves the agglomeration ums with a precise moisture content of 9 to 10%.

Heap Leach Pad

The heap leach pad is located at the north-eastern section of the mine site, on a 3.09° down-hill slope to the west. The leach pad was designed to capitalize on the bioleach oxidation of sulfide ores. To accomplish this, the cell design incorporates a narrow configuration and separation of the cells with ditches for the solution distribution and collection systems. The pad has a single lift of 9 cells, 83 m wide and 400 m long with a stack height of 6 m. Stack height is critical to the proper circulation of air through the heap for maximum efficiency of the bioleaching process. Stack heights can be varied to optimize the leach process for particular combinations of ore.

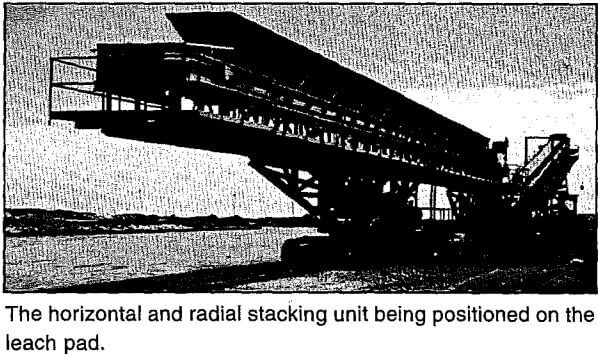

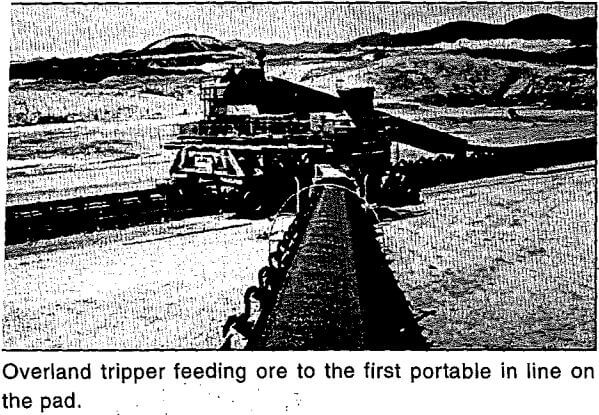

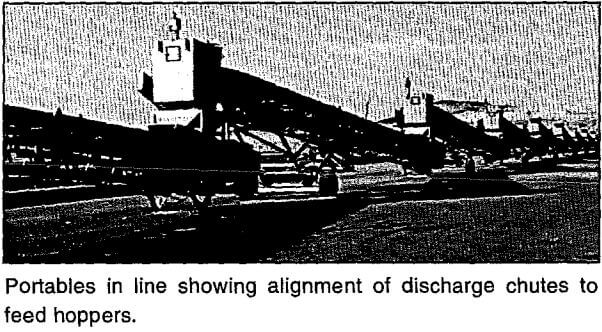

Conveying and Stacking System

To meet the scheduled construction time frame, all portable conveyors were assembled at a manufacturing facility in Antofagasta, Chile, test run and towed to site ready for service. This greatly reduced the man hours required for on site assembly of the conveying and stacking system.

The entire system is a 42-in. system and has a capacity of 1200 tph. Starting at the agglomerators, ore is collected from both drums by a collecting conveyor and delivered to a fixed-height, movable stacker conveyor. The stacker conveyor then feeds the agglomerated ore directly onto the mobile conveying and stacking system for stacking of the first two cells on the pad. When the first two cells are completed, the stacker conveyor is then aligned to feed the overland tripper conveyor system for distribution of ore to the remaining seven cells. This flexibility enabled copper production to begin 2½ months ahead of the completion of the total pad project.

.

Solvent Extraction/Electrowinning (SX/EW)

As soon as the ore has been placed on the leach pad, a solution distribution and spray system are installed and the ore is leached by acid solution for 210 days. Design Raffinate solution flow to the heaps is 1850 m³/hr with 0.3 gpl Cu++ and 10 gpl H2SO4. The pregnant solution coming off the leach pads to the pregnant pond contains a grade of 3.2 gpl Cu and 1.5 gpl H2SO4. The solution is then pumped to the SX-EW plant feed pond at a rate of 1,800 m³/hr.

The solvent-extraction (SX) plant at Cerro Colorado (Figure 2) is a conventional two-train (A & B) 2 x 1 circuit with a design feed rate of 799 m³/h. The electrowinning (EW) plant is made up of two sections totaling 140 cells. One section (right) has 34 cells and the other (left) section has 106. The EW plant design cathode production is 110 tpd. The right section (34-cell) was completed first and placed on line for copper production in order to support the fast track start up schedule. This section of 34 cells produced the first cathode of copper 3 days after light off and only 135 days after the start up of the crushing plant.