In the previous topic, we considered methods of stope mining were the stopes were intended to stay open and collapse and collapse of the roof was not an intended outcome. In some situations however, it may be permissible or even desirable that the roof of the mine collapse to fill the stope as mining proceeds. These methods are called cave mining or caving techniques. Cave mining has the advantage of greater recovery since less of the ore has to be left behind to support the rock above and the resource is not consumed in trying in stabilize the roof. The disadvantages however are; the subsidence occurs in the ground surface above, that progressive collapse may be difficult to control may be unpredictable and hence dangerous and as the roof collapses before or during ore removal, the ore is contaminated with waste which must then be removed. As with stoping, caving is adaptable to both inclined and flat deposits. Let’s start by taking a look at caving in flat deposits through a technique known as long wall mining, commonly used in the mining of coal seams. In long wall mining, flat seams up the six meters thick are progressively extracted as a series of large panels or blocks which may be up to four hundred meters wide and several kilometers long. Prior to extraction, the development works are undertaken using road hitters to establish access draws and road ways around the bandwidth of the panel. These are necessary since as the roof collapses after extraction egress to the miners and equipment needs to be provided ahead of the mining. Mining is carried out using a device known as a shearer which runs back and forth along the face of the panel shaving off slices up to one meter thick. A shearer has a rotating head with digging picks much like a road hitter but it is designed to work in the confined space of the long wall face. Coal is pulled out along the foot of the face by a chain conveyor to the end of the panel where it is loaded unto a conveyor for transport. To prevent the roof coming down on the shearer as it operates it is supported by a row of movable hydraulic supports variously referred to as jacks or trucks.

In the previous topic, we considered methods of stope mining were the stopes were intended to stay open and collapse and collapse of the roof was not an intended outcome. In some situations however, it may be permissible or even desirable that the roof of the mine collapse to fill the stope as mining proceeds. These methods are called cave mining or caving techniques. Cave mining has the advantage of greater recovery since less of the ore has to be left behind to support the rock above and the resource is not consumed in trying in stabilize the roof. The disadvantages however are; the subsidence occurs in the ground surface above, that progressive collapse may be difficult to control may be unpredictable and hence dangerous and as the roof collapses before or during ore removal, the ore is contaminated with waste which must then be removed. As with stoping, caving is adaptable to both inclined and flat deposits. Let’s start by taking a look at caving in flat deposits through a technique known as long wall mining, commonly used in the mining of coal seams. In long wall mining, flat seams up the six meters thick are progressively extracted as a series of large panels or blocks which may be up to four hundred meters wide and several kilometers long. Prior to extraction, the development works are undertaken using road hitters to establish access draws and road ways around the bandwidth of the panel. These are necessary since as the roof collapses after extraction egress to the miners and equipment needs to be provided ahead of the mining. Mining is carried out using a device known as a shearer which runs back and forth along the face of the panel shaving off slices up to one meter thick. A shearer has a rotating head with digging picks much like a road hitter but it is designed to work in the confined space of the long wall face. Coal is pulled out along the foot of the face by a chain conveyor to the end of the panel where it is loaded unto a conveyor for transport. To prevent the roof coming down on the shearer as it operates it is supported by a row of movable hydraulic supports variously referred to as jacks or trucks.

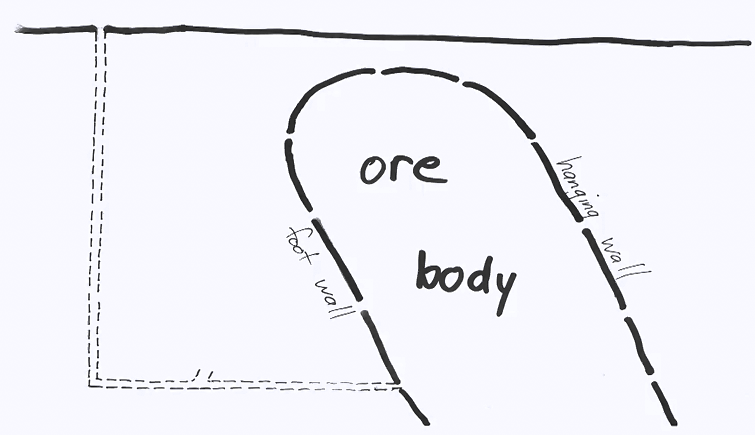

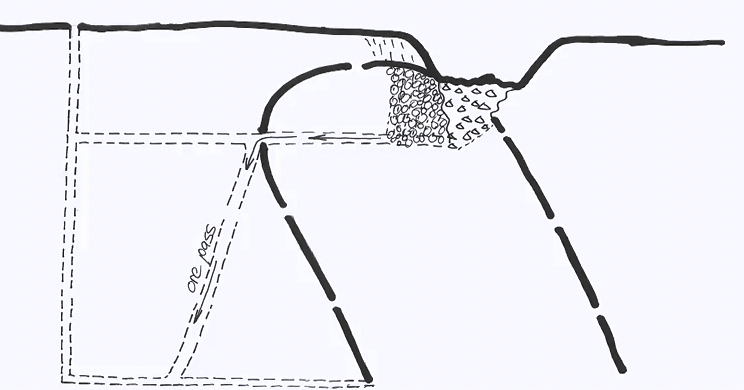

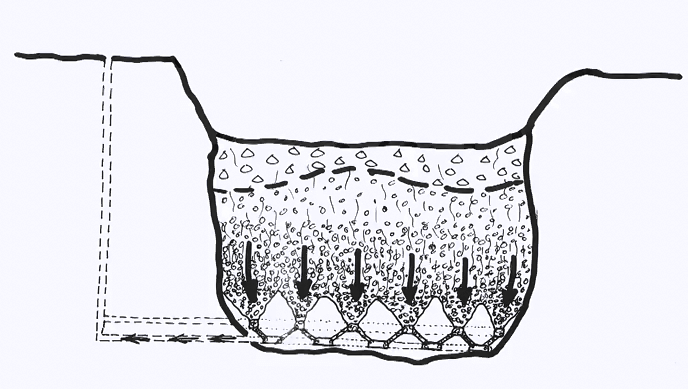

These are moved forward in the direction of mining one by one after each pass of the shearer. In this way the shearer works in a narrow moving tunnel where the roof above spins between the jacks on one side and the panel face on the other. As the jacks advance the roof behind them is left unsupported and it collapses. In favorable operations this happens slowly and progressively. In less favorable operations the roof hangs up and it may fall suddenly or sporadically throwing rock and injuring support. Large panels are very efficient allowing the continuous mining of coal for periods of up to a year. However, change of the equipment from one panel to another is slow and difficult limiting the applicability of the technique to larger panels. For steeply inclined and sub-vertical the roof or the hanging wall may be a long way above the floor of the foot wall and it is undesirable to have it collapse and free fall through the void created by mining. The technique of sub-level caving avoids this by commencing extraction at the top of the ore body and using overhand techniques to progressively mine the ore body allowing the roof to move downwards as the ore is extracted. The process is illustrated by the following diagrams. First the ore body is accessed by shaft and drift on the foot wall side an upper drift is extended through the ore body until it reaches the hanging wall. At the end of the drift at the highest sub-level the overlying ore is drilled and blasted allowing each in the overlying hanging wall rock to collapse. The collapsed ore is mopped out from the end of the drift only until the hanging wall rock is left. The operation then with draws further back into the drift and the next section of ore is drilled and blasted bringing again another slice of ore and roof. Mopping again removes the broken ore.  This continues across the level until all of the ore in this level of the ore body has been removed. The operation is then repeated at successive depths which will define the sub-levels for ore extraction from drifts located at the bottom of the next sub-level down. Block caving is an alternative to sub-level caving, where instead of caving the deposit in sub-levels from the top down, it is caved as a block from the bottom up. This operation involves excavating parallel extraction drives across the base of the deposit linked by cross-cut tunnels which will serve as ore passes. Parallel under-cut drives have been excavated in a plain above these from which conical rings of holes drilled in the overlying rock and blasted to break it up across the for width of the ore body creating a funnel shaped door bells above each ore pass. This leaves a layer of broken rock across the base of the deposit which feeds in an array of conical or sheets that can be mopped out from drill points between the extraction drives. As the layer of broken rock is extracted from the base of the deposit the overlying intake door collapses into the void form and feeds the ore passes. This process continues until caving propagates to the surface which then rides downwards on top of the ore body as it is extracted.

This continues across the level until all of the ore in this level of the ore body has been removed. The operation is then repeated at successive depths which will define the sub-levels for ore extraction from drifts located at the bottom of the next sub-level down. Block caving is an alternative to sub-level caving, where instead of caving the deposit in sub-levels from the top down, it is caved as a block from the bottom up. This operation involves excavating parallel extraction drives across the base of the deposit linked by cross-cut tunnels which will serve as ore passes. Parallel under-cut drives have been excavated in a plain above these from which conical rings of holes drilled in the overlying rock and blasted to break it up across the for width of the ore body creating a funnel shaped door bells above each ore pass. This leaves a layer of broken rock across the base of the deposit which feeds in an array of conical or sheets that can be mopped out from drill points between the extraction drives. As the layer of broken rock is extracted from the base of the deposit the overlying intake door collapses into the void form and feeds the ore passes. This process continues until caving propagates to the surface which then rides downwards on top of the ore body as it is extracted.

https://youtu.be/_AE6Wdkm_fA