Grinding Circuit Control for Optimal Mineral Recovery

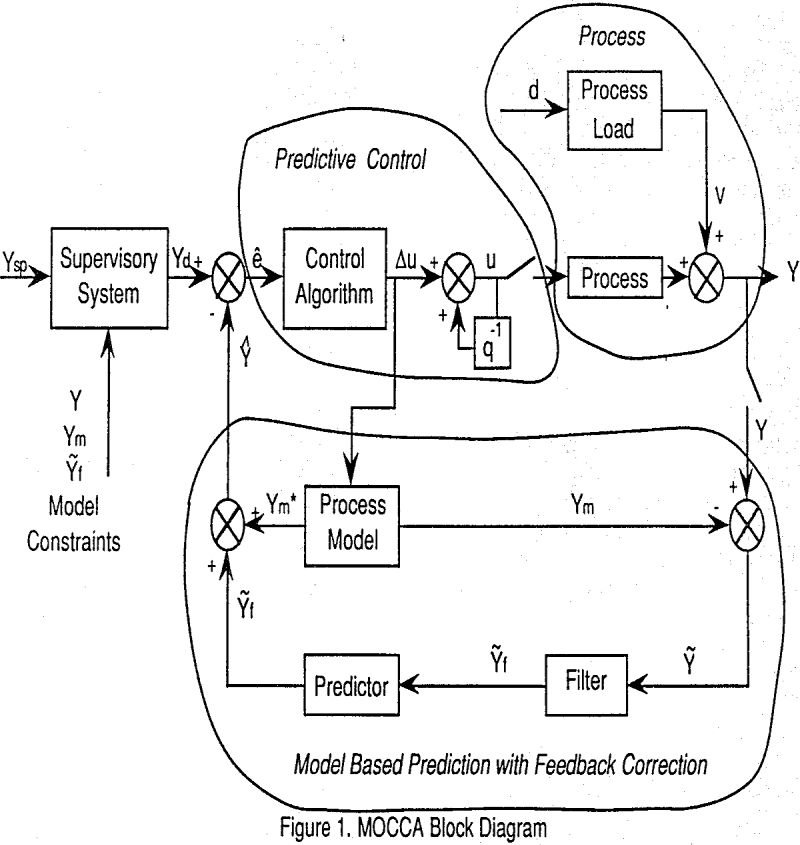

MOCCA is a Multivariate (Optimal Constrained Control Algorithm developed specifically for non-square industrial control applications with practical difficulties such as interactions, time delays, constraints, modelling development, etc. MOCCA consists of an off-line simulation/translation module, for tuning the control parameters, and an on-line module that implements the designed control law. An alternate means of constructing advanced […]

Variable Speed SAG Mill

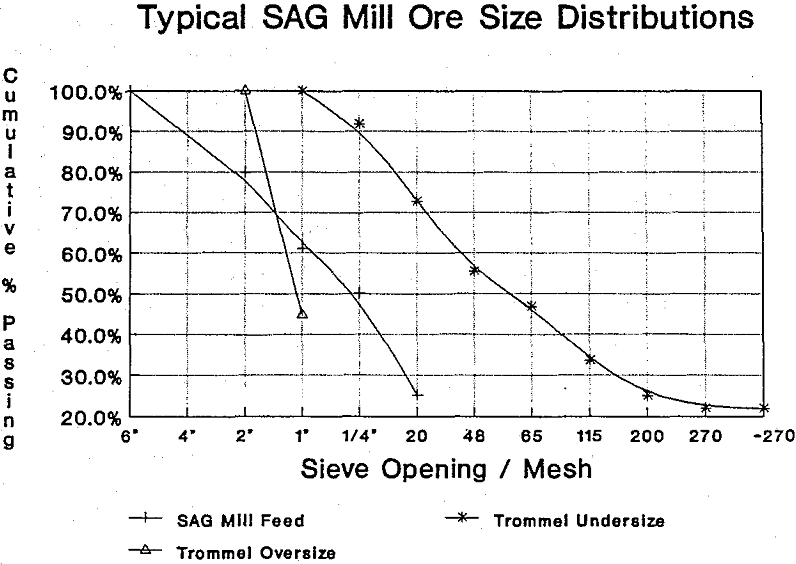

The single line grinding circuit at Bond Gold’s Colosseum mine consists of variable speed drive semi-autogenous (SAG) milling and secondary grinding with a fixed speed ball mill. There are several advantages and disadvantages of operating SAG mills with variable speed drives. Discussion in this paper will focus on the effects of variable speed SAG milling […]

Effect of Chromium on Wet Grinding Performance

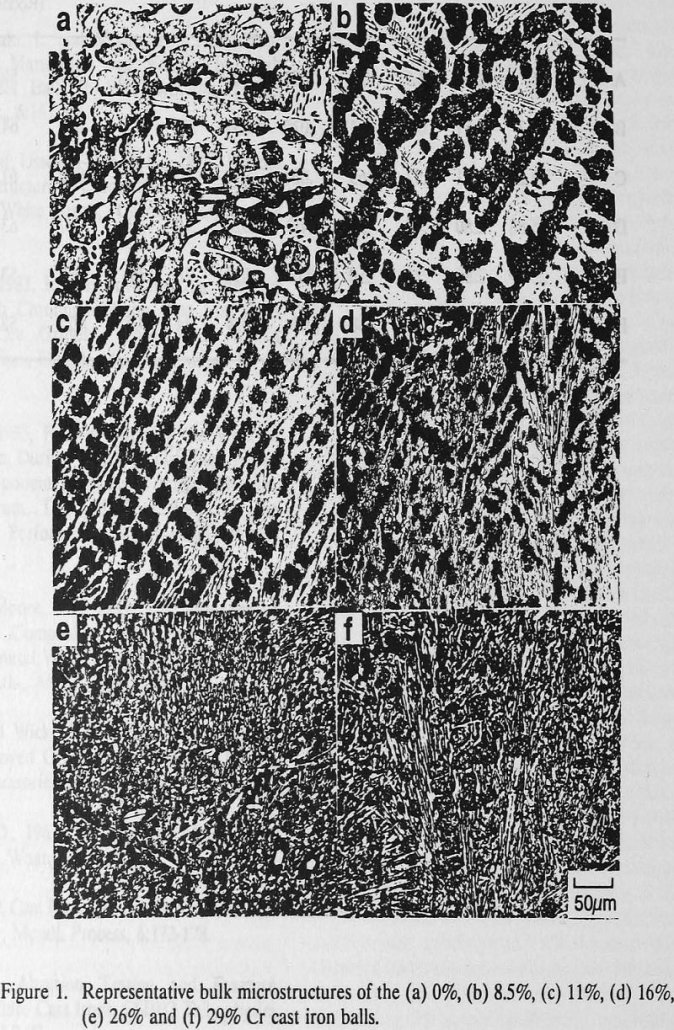

Because of higher efficiency, wet grinding is more widely used than dry grinding, but leads to an increased consumption of grinding media due to corrosion in some ores. In dry grinding, the wear rate of high chromium cast irons is frequently ten times lower than cast or forged steel with a cost ratio of 2-3 […]

Tower Mill Grinding of Molybdenite Concentrate

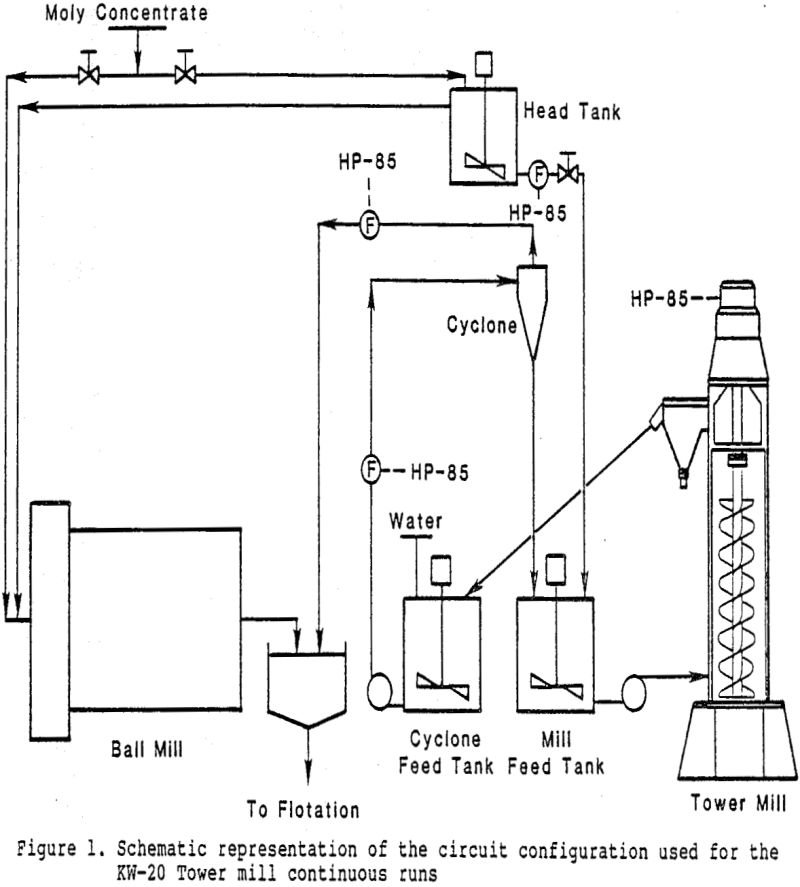

A Tower mill consists of a vertical grinding vessel provided with a central shaft screw-shaped impeller. The screw impeller rotates in such a way as to move the grinding media upward through the central portion of the grinding compartment and downward through the outer portion. Grinding media such as steel balls, ceramic pebbles, or natural […]

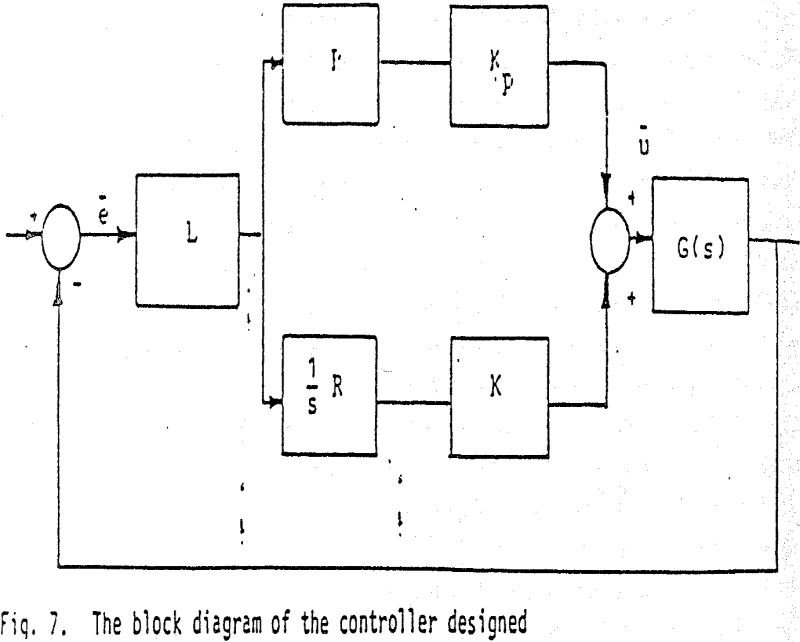

Design of a Grinding Circuit Control System

In this case, the primary grinding stage in a concentrator comprises a rod mill in open circuit and a semi-autogeneous mill in closed, circuit with a hydrocyclone classifier. All the measurements have computer interfaces and all the control circuits have been implemented by the process control computer. The crushed ore feed to the rod mill […]

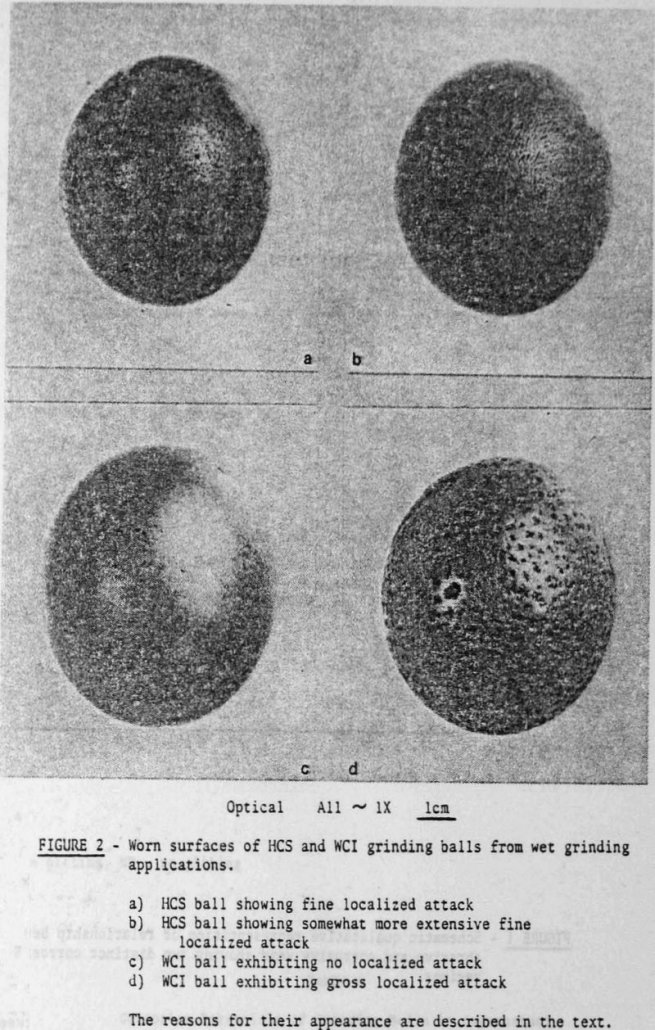

Grinding Ball Wear & Corrosion

Wear of grinding media represents a significant cost in the wet grinding of ores in commercial ball mills. The total wear process of grinding involves a number of mechanisms including abrasive and corrosive wear. More knowledge about the wear mechanisms and the relative importance of each wear component would enable one to better select grinding […]

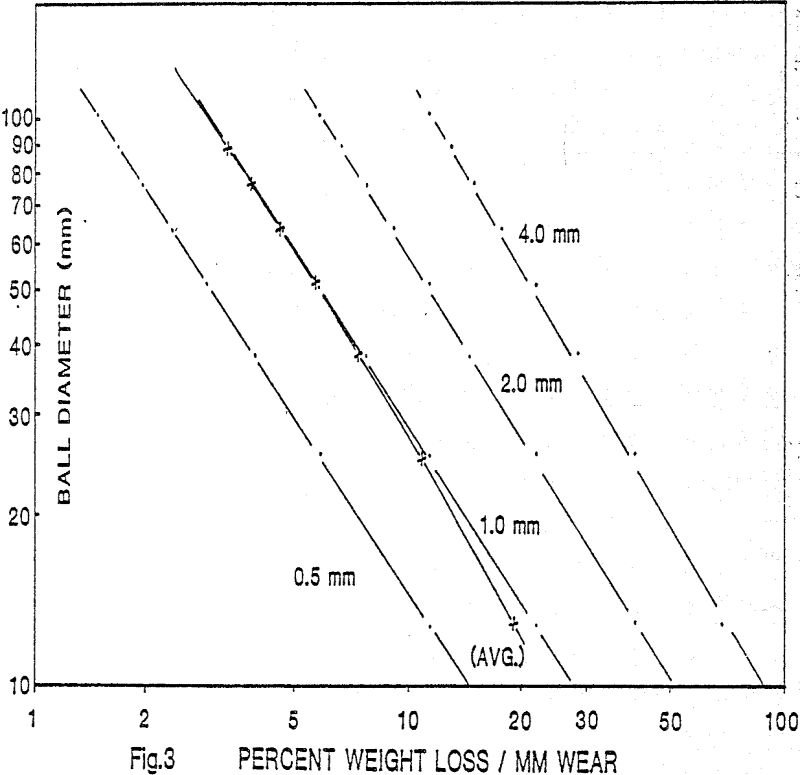

Ball Mill Media Maintenance

Improper size distribution of the grinding media in a multicompartment mill can be a source of many operation problems encountered. Inefficient use of the power expended for grinding, and an undesirable product size distribution are two frequent resultants. The objective then is to provide a method which would be practical to use and accurate enough […]

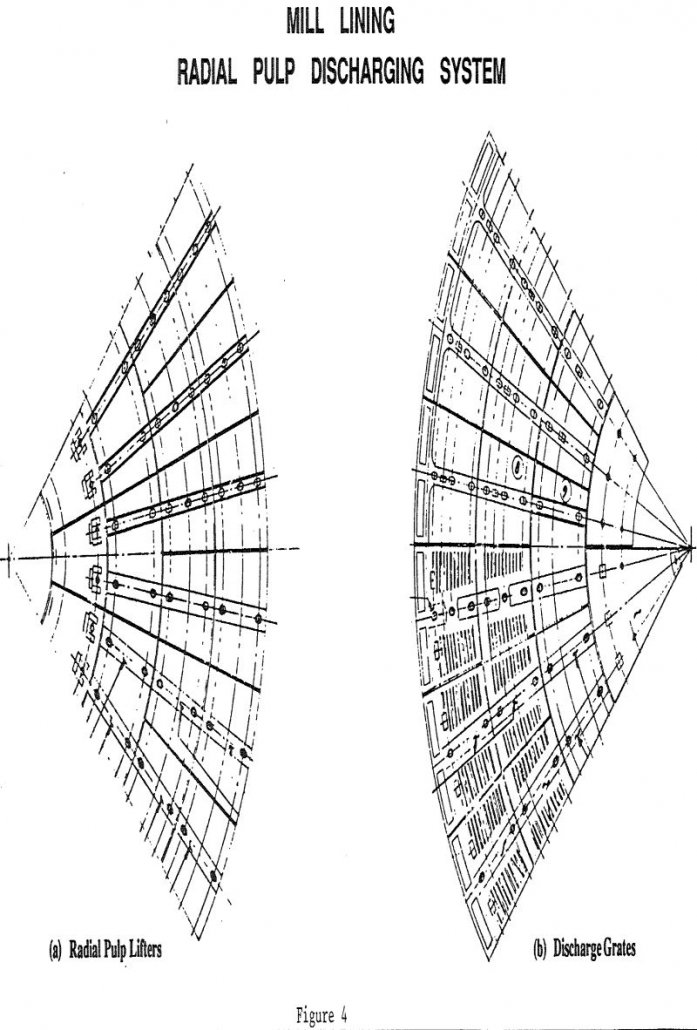

Pebble Crushing Circuit Design

The design of a pebble crushing circuit as an integral part of a North American style primary autogenous or semi- autogenous grinding circuit presents certain challenges to the process design engineer. Initially, the process requirement for pebble crushing has to be determined as part of: the design of a new plant the relief of a […]

Comminution Model Types

Many types of mathematical models are used in comminution and mineral processing. These models can generally be classified into one or more of the four categories shown above. Mill Power Draw Models The purpose of a mill power draw model is to predict what the mill power and/or torque draw will be for a mill […]

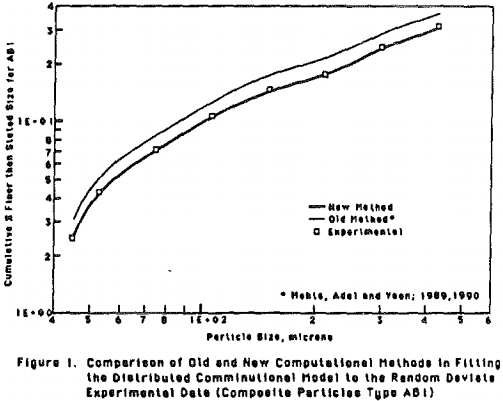

Mill Matrix of Distributed Comminution Models

Distributed Component Comminution Model The general form of the comprehensive distributed component comminution model has been described as follows d/dt(m(t)) = – [I – B]S m(t) = A m(t)…………………………………………..(1) Where A is the fundamental matrix/state companion matrix or the so-called mill matrix in comminution literature. The reason being that A as a general real matrix may […]