Conical Ball Mills Benefits & Advantages: Hardinge

The generally recognized fact that for economic reduction of any material, it is desirable to perform such reduction in steps or stages, removing that material which is sufficiently fine as soon as it is reduced and grinding it still finer in some device more adaptable to this finer reduction. It has been found that by […]

KK-8 Kiln Furnace Liner Maintenance

Three products are supplied with the KK-8 for optimizing and extending the life of the kiln liner: Liner Restore, Armor Coat and Spill Stop. All three products must be kept from freezing, or they will become unstable and unusable. Restored Kiln Sections Liner Restore is an alumina silicate based viscous material that is designed for […]

Rods-Balls

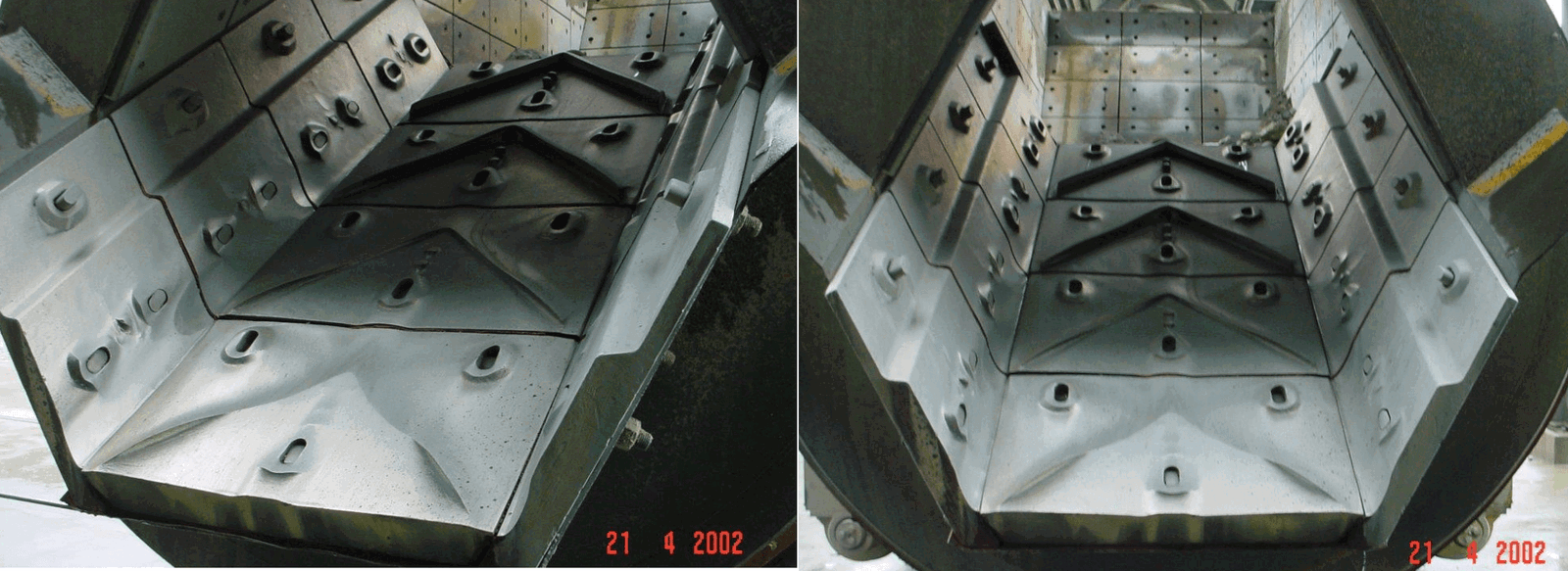

SAG Mill Feed Chute Design| Long Life | Wear Resistant

This design of SAG mill feed chute lasted 9 months seeing 90,000 TPD. It is 600 brinell chrome steel. With the big liners on the bottom of the chute you need to get a Chevron cast into the top to push the feed out to the sides for the first little while and then as […]

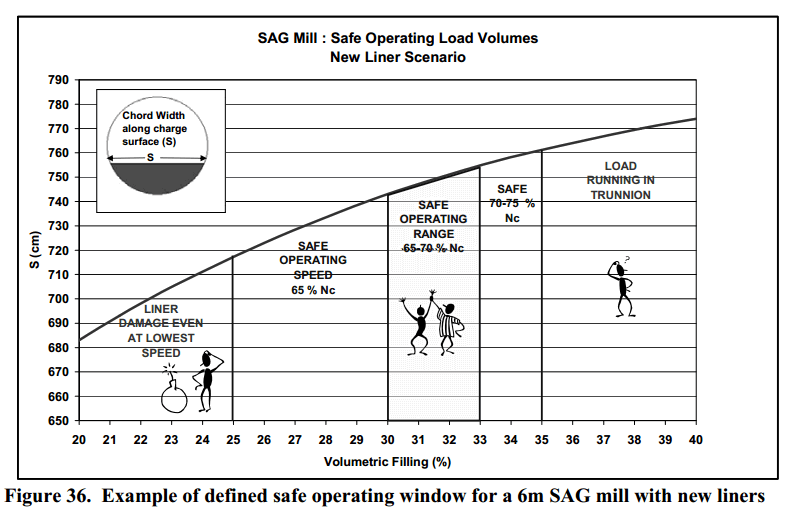

SAG Mill Operating Load : SAG Mill Volumes

How much rock and balls must you hold in your SAG mill for it to best operate?

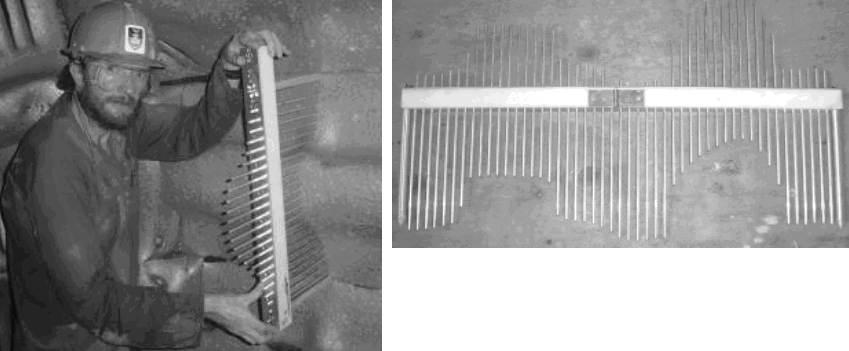

Mill Liner Profiler Tool -Track Liner Wear Pattern

Here is a home-made tool to measure or obtain a fingerprint of your SAG and Ball Mill Liner wear pattern/profile. Each time you shut down, get a profile and build a wear-life over time database to better predict your next reline job or monitor improvements to your liner design. Simple Tool to Track Liner Wear […]

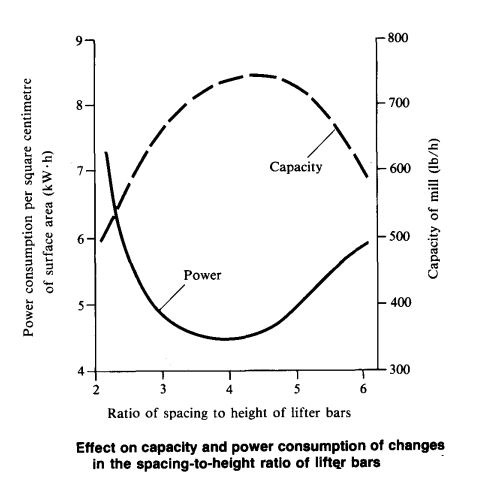

Optimum Mill Liner Spacing | Design Effectiveness SAG

The images (chart) below is industry standard when it comes to the relationship between a mill liner’s lifter bar height and the lifter to lifter spacing. What tonnage do you think this SAG mill liner design gets?

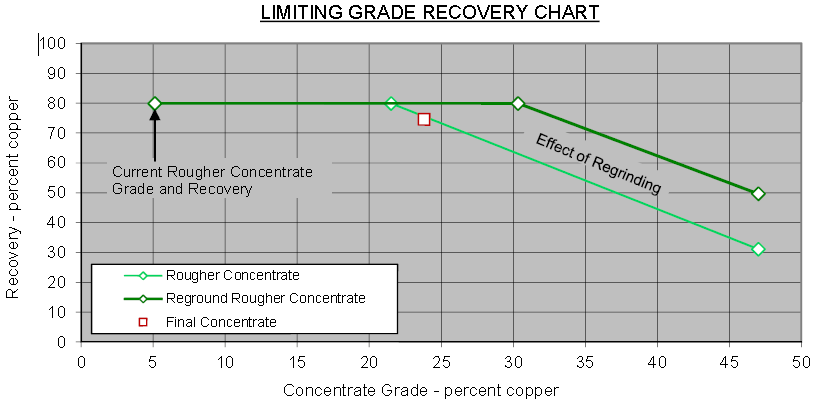

Effect of Regrind on Grade and Recovery

How do you know if or when regrinding and applying further liberation power can improve your metal’s recovery? Below here is data showing what is to be gained by correctly applying regrind to a copper stream. On the graph, the red/white dot points to where the plan currently is light green Grade-Recovery curve VS where is could be on […]

SAG Mill Ball Size Evaluator | Evaluation Factors | Calculate Diameter

Lets calculate/select/pick a new ball for your SAG mill. Now, lets suppose you have a SAG Mill and Ball Mill that are not drawing full kW Power. The SAG Mill has a “small” circulation load of oversize given be the 3/8″ trommel screen and the 1/2″ x 1 1/4″ discharge grates. The load of 4″ balls […]

Do I Need Bigger and Larger SAG Mill Balls

How do you know if a larger SAG ball will increase your tonnage and how to select it? When is it time to change to a larger Ball in your SAG Mill? It’s difficult to generalize on SAG mill ball size selection as it depends on a number of factors: Ore properties Level of impact […]