Drop Weight tests (DWT) using JKMRC Rotary Breakage Tester

The Drop Weight tests (DWT) by JK is now replaced by the JKMRC Rotary Breakage Tester. It is faster as confirmed by Tony and now used by many since its intro https://www.min-eng.com In an AG/SAG mill there are two main mechanisms of breakage, namely impact (high energy) and abrasion (low energy). The industry accepted JK impact breakage parameters, […]

Principle of Operation of Hydrocyclone

The Principle of Operation of Hydrocyclone is, in simple terms, the forces of gravity and centrifuge to separate large or heavy particles from smaller and lighter one. When sized correctly will “cut” like the ‘real cyclone’ below VS the imaginary ‘ideal’ one on the left. Hydrocyclones are preferred units for sizing or desliming large […]

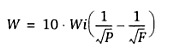

Ball Mill Critical Speed

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula […]

Rod Mill Work Index Table

Here is a list presented in table form of Rod Mill Work Index as tested/presented by SME handbook of mineral processing, N.L Weiss Editor, N.Y. 1985. Rapid Determination of Bond Rod-mill Work Index by Craig Taylor on Scribd

Table of Bond Work Index by Minerals

This Table of Ball Mill Bond Work Index of Minerals is a summary as tested on ‘around the world sample’. You can find the SG of each mineral samples on the other table. Source 1: Table of materials reported by Fred Bond Source 2: Outokumpu, The science of comminution Source 3: Equipment and pipelines Source 4: […]

Relative Bond Work Index BWi | Comparative Grindability Test Procedure

The test is designed to give a reasonable indication of the grinding work index of an ore material relative to one or more known standards. It is not applicable to mill tailings material. Basic Equipment Set of screens @ 75 to 2440 micron sizes. Ro-Tap Sieve Shaker Ball mill rolls CMS ball mill No.1 with approximately […]

Bond Grindability Test Procedure

The Bond Ball Mill Grindability test is designed to give a measure of the grinding characteristics of a material by finding the amount of size reduction resulting from a controlled energy input. Ball Mill Grindability of a material depends upon its hardness, structure, the manner in which it is fractured. The grindability is useful in evaluating power requirements […]

Bond Work Index Procedure and Method

This Grindability Test or Bond Ball Mill Work Index Procedure is used to determine the Bond Work Index of minus six mesh or finer feed ore samples. These equation application methods are used to process <1/2″ ore samples in a Ball Mill using a standard ball charge. Below describes in general terms the Bond Work Index […]

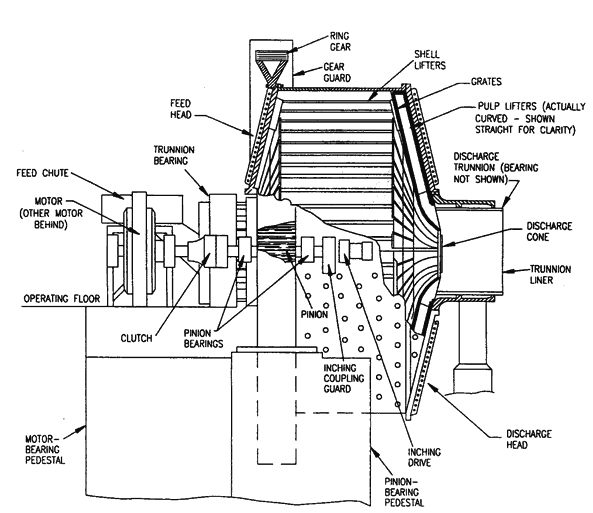

Grinding Mill Components

SAG Mill, Rod Mill or Ball Mill this is a typical grinding mill component list/assembly.

What Ore Testing is Required For Mill Selection

Beginners might ask what grinding test data is required in order to properly size a grinding mill. After the grind requirements are established, testing for the selection of comminution circuits and mill size can be initiated and can include the following: Primary Autogenous Media Competency Primary Autogenous and Semi-Autogenous Pilot Plant Secondary Autogenous (Pebble) Testing […]