Rods or Balls

Mill operators will not get to design too many mills, but this doesn’t mean that the information that has been compiled isn’t of interest to the operator. Knowing the ore body shape, size, and content will give the operator prior knowledge of operating conditions to be expected. It is also beneficial to know how this […]

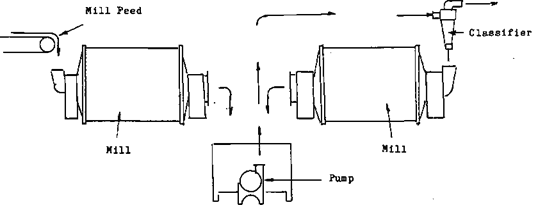

Simple Grinding Circuits & Flowsheets

To start the discussion on grinding circuits I would like to begin by showing you some simple Flowsheet SCHEMATICS of some sample circuits, but before I do there is one thing that I must explain for the schematics to make sense. When the ore is put into the first piece of equipment for grinding, water […]

Polyurethane Screen Panels

These Polyurethane Screen Panels are often installed on SAG discharge trommel screens or AG vibrating screens and even crusher circuits. Polyurethane Screen Panels are best when made of low “durometer” Polyurethane to allow a “bouncing” effect for the rocks and reduces wear.

THE BARRATT METHOD

Plants designed using The Barratt Method as published in the Book Mineral Processing Plant Design, Practice, and Control Proceedings, include: Alumbrera Batu Hijau Cadia (one consultant among others) Candelaria Clarabelle (Inco) Collahuasi (line 1 & 2) Dreifontein El Teniente SAG 1 Ernest Henry Esperanza Fimiston Freeport 95K expansion Lisheen Numerous benchmarking exercises to operating grinding […]

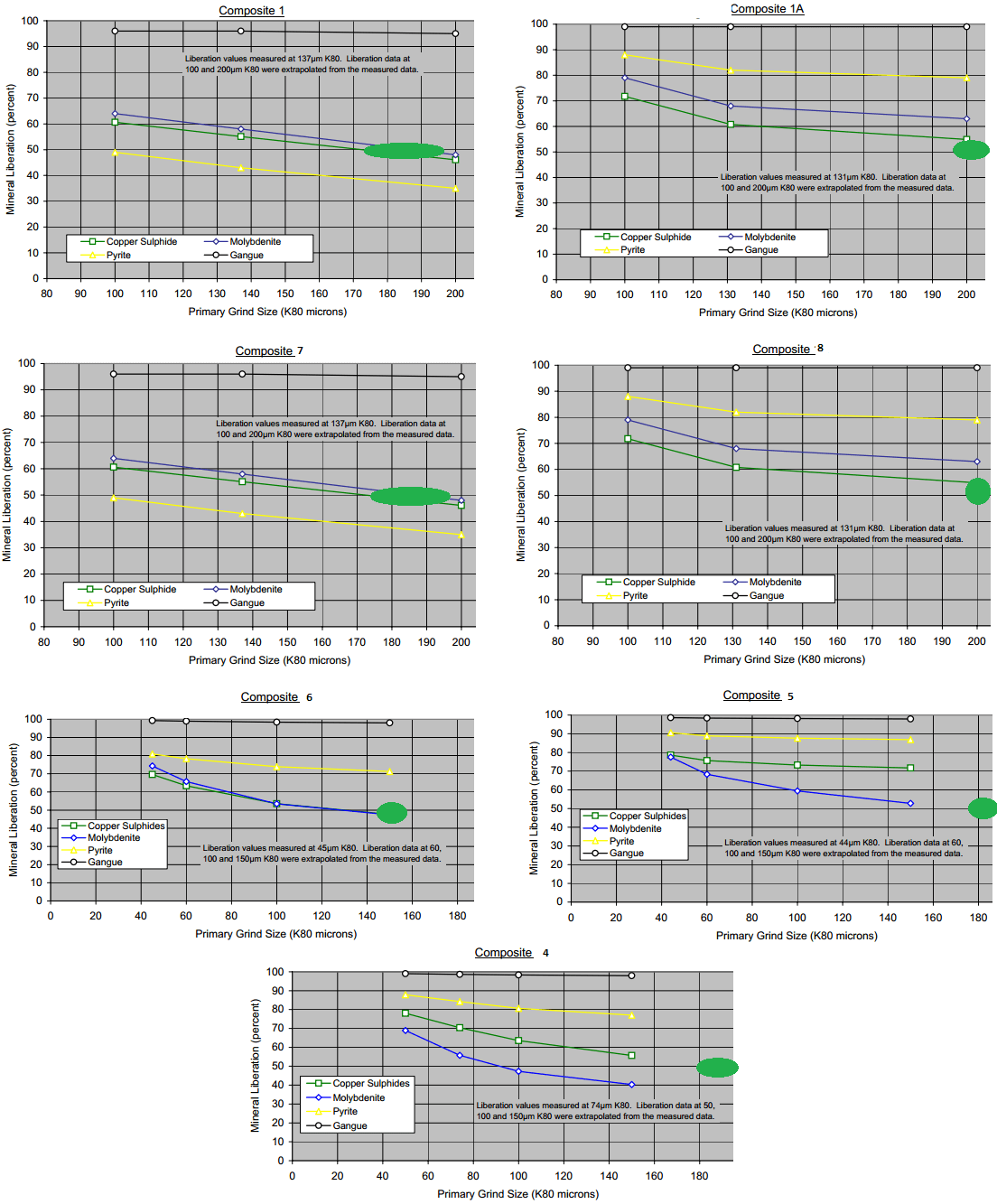

Effect Of Primary Grind Size On Mineral Liberation

The extrapolated ore fragmentation and copper sulphide liberation plots reveal that the liberation levels and hence the flotation responses of the minerals would be essentially constant across a broad range of flotation feed sizing. This observation would indicate that flotation feed sizing coarser than 200µm K80, the practical norm for copper porphyry ore processing worldwide, […]

Chilean Mill

The Quartz Mill AKA Chilean Mill is one of the more popular types of the original Chilean mill. Still used for certain grinding problems, this mill employs the convex-concave principle of crushing ores, resulting in a product surprisingly low in slime content and which has its particles, such as sulfides and gold, well polished and free of […]

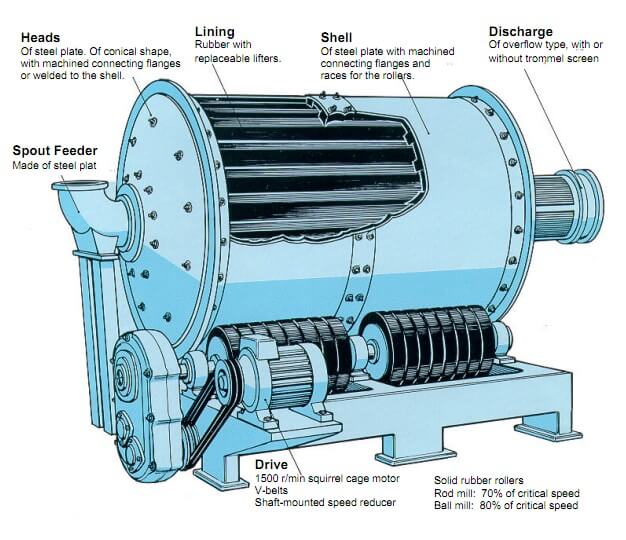

Rubber Tire Driven Ball Mill -Grinding Mill on Rollers

These very nice rubber tire driven grinding mills do not come cheaply priced. A small, 1 meter X 1.5 meter Rod mill OR Ball Mill cost approximately $160,000 US (in 2014) The small(est) mill starts at 600mm x 900mm and goes up to the large(est) 2100mm x 4200mm Options in the small “tyre” or Rubber roller grinding mills […]

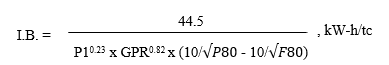

Indice de Trabajo de Bond y su Procedimiento

El índice de trabajo de Bond se ha usado por muchos años para indicar el consumo de energía de un molino de bolas para obtener un tamaño de partícula deseado, usualmente expresada como el pasante bajo una malla especifica como la 150 o la 200.el valor del índice de trabajo de trabajo es una característica […]

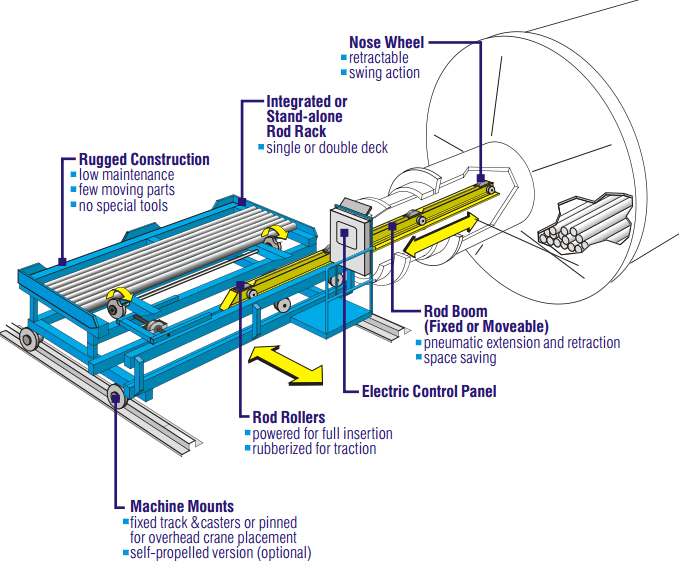

How to Charge Rods into a Rod Mill – The Charging Process Equipment

Rods are loaded or charged into a Rod Mill using a mechanised charger. The rod charger with extendable boom moves rods safely inside the trommel/trunnion before charging with a typical 30 seconds or less cycle time per rod. How you charging a rod mill is best explained by the video below. https://heathandsherwood64.com/products/mpe/grinding and https://www.mclellanindustries.com/rodcharger.html sells them.

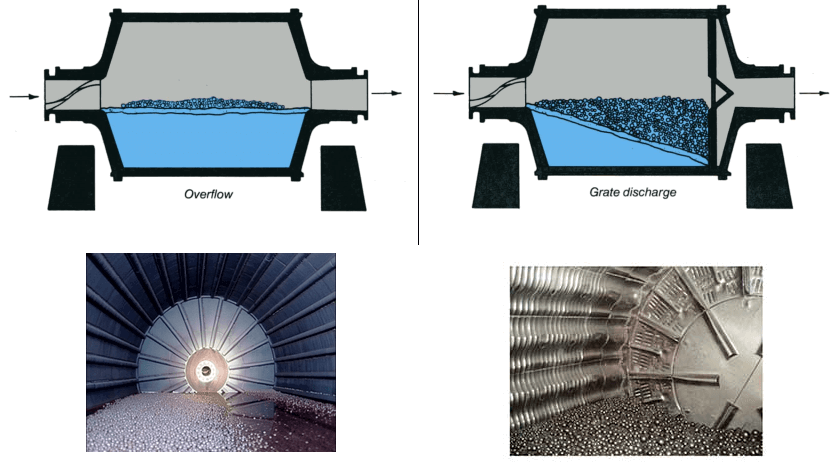

Overflow VS Grate Discharge Ball or Mill – Why Retrofit

Allow me to compare: Ball mills can be of the overflow or of the grate discharge type. Overflow discharge mills are used when a product with high specific surface is wanted, without any respect to the particle size distribution curve. Overflow discharge mills give a final product in an open circuit. Grate discharge mills are used when the […]