Rod and Ball Mill Discharge Housing

Most Marcy Rod/Ball Mills are provided with a discharge housing mechanism mounted independently of the mill. This unit consists of the housing proper, plug door, plug shaft, arm and various hinge pins and pivot and lock pins. The door mechanism is extra heavy throughout and is subject to adjustment as regard location. Place the housing […]

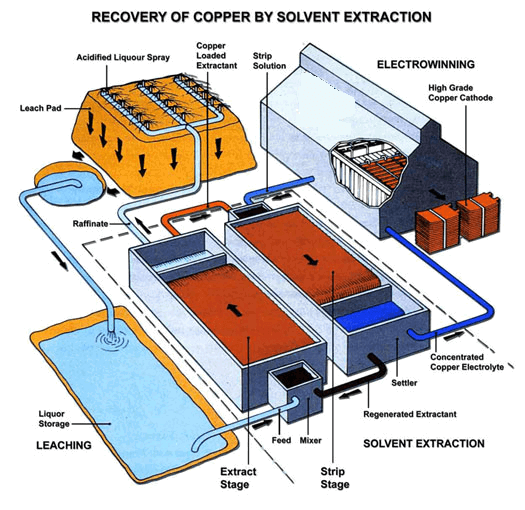

Solvent Extraction & Electrowinning (SX/EW) Plant Design

Cerro Verde began operations in April 1977, originally formed and operated by Minero Peru, as a state-run mining company. The electrowinning tankhouse was designed to produce 33,000 metric tonnes per year (mtpy) of copper cathode operating with current density of 184 amps per square meter (A/m2) and 88 percent (%) electrical current efficiency. In 1994 […]

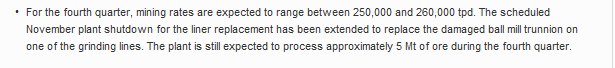

Typical Reason to Replace a Ball Mill Trunnion ‘unexpectedly’

What is the typical reason a ball mill trunnion needs to be replaced unexpectedly? It is unclear if the trunnion damage was known ahead of time and planned for a change-out during the shell reline or if it was discovered during the reline work. While, not knowing if this is the feed or discharge end trunnion, there […]

Methods to Estimate AG/SAG Mill Power Requirements

A linkedin.com group was recently discussing this by asking: I’ve tried to estimate AG/SAG Mill power requirements using several different methods: (1) Using the results of SMC data (2) Using SAG Power Index (SPI) data (3) Using the 1989 Barratt method updated on Alex Doll’s Web site (February 16, 2015) (3) Using Don Burgess’ method (11th […]

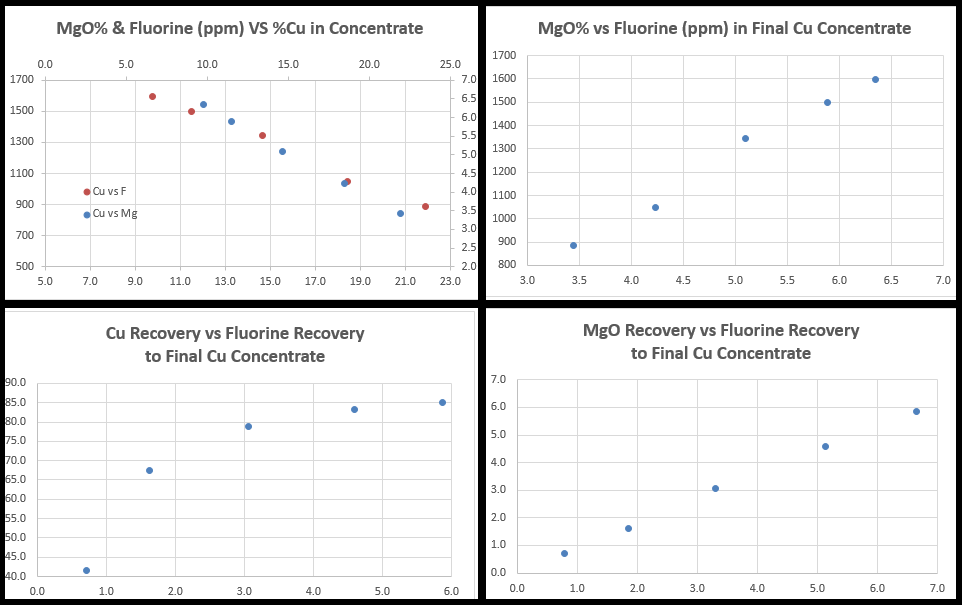

Understand Fluorine in Copper Concentrate (F in Cu Conc)

A copper flotation concentrate is over limit on Fluorine (F) content and Contamination. When assaying and plotting Copper (Cu) from times concentrates and the related fluorine and Magnesium Oxide (MgO) assays in various ways as shown below; one can see the obvious relationships. In the case, reducing Fluorine content and contamination of the copper conc […]

Bulk Density of Rod Mill Bars-Rods

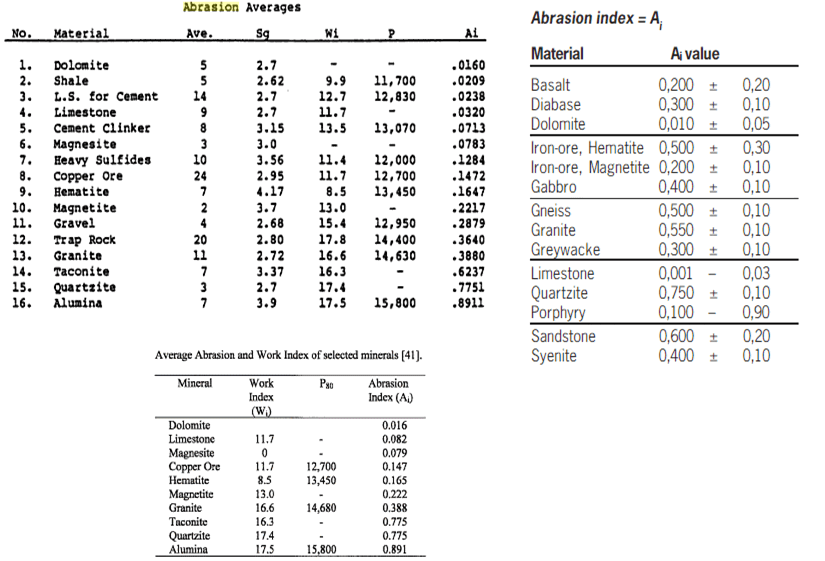

Table of Bond Abrasion Index for Varied Minerals-Materials

The Bond Abrasion Test determines the Abrasion Index, which is used to determine steel media and liner wear in crushers, rod mills, and ball mills. Bond developed the following correlations based on the wear rate in pounds of metal wear/kWh of energy used in the comminution process. Determining rock abrasivity in the laboratory ref

How Abrasion Index affects Wear Rates

What is the relationship between Abrasion Index affects Wear Rates of steel ball mill and rod mill liners as well as the wear life or consumption of grinding balls or rods. A little bit of data on crusher (gyratory and roll) liner wear life in also shown. Rubber wear data.

Bond Abrasion Index VS Bond Work Index

Compare and Understand Rod/Ball/Impact-Crushing/Abrasion BOND Work Index Ref

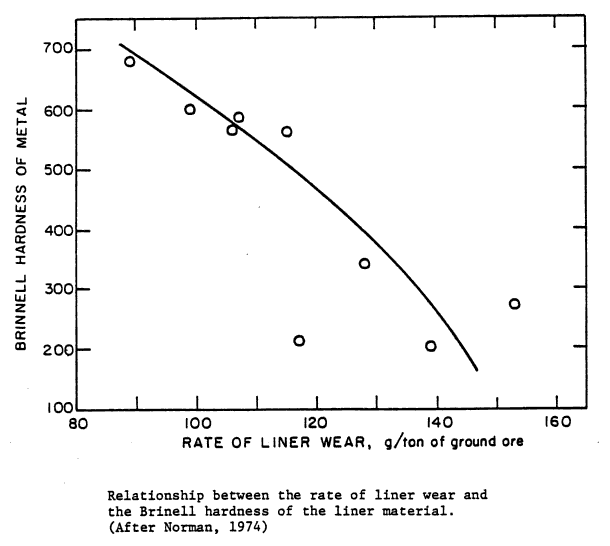

Estimated/Approximate Steel Liner Wear Life/Rate

A mill’ steel liner wear rate and total useful operating life is a function of its hardness (mostly). Here is a chart displaying Liner Hardness on the Brinell Scale as a function of the tonnage of ore/rock milled/processed. Not showed here is the impact a mill’s RPM has on the liner’s wear rate. Comminution and Energy Consumption: By […]