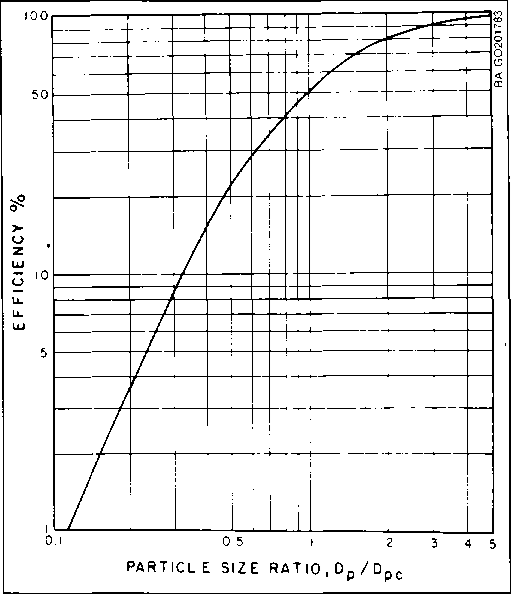

How to Improve Cyclone Separation

Good cyclone separation depends upon control of pressure drop, pulp density and apex size. The ‘pressure drop’ may vary but should not change rapidly, and is held at safe levels by keeping an adequate sump level. A falling sump level causes cavitation in the pump and reduction in feed rate; pressure drop in the cyclone […]

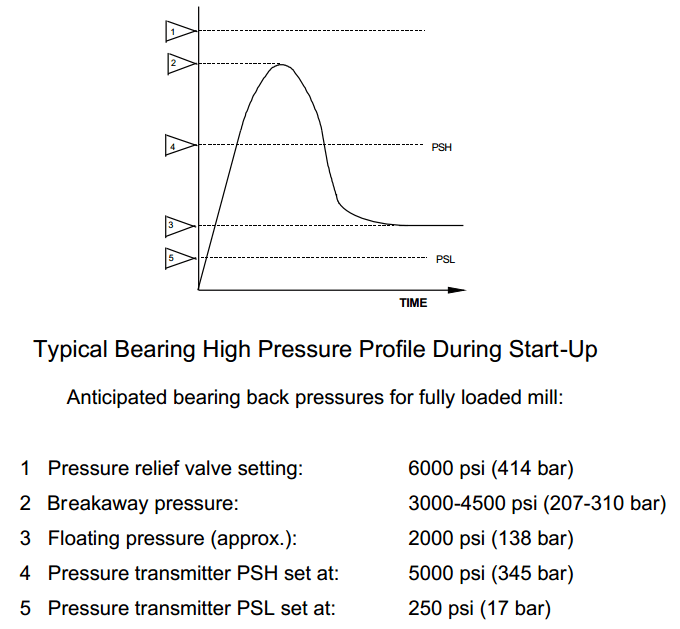

Ball Mill Trunnion Bearing Lube System

On a 11’-6” x 22’-0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during start-up of the mill. System monitors including pressure switches and flow monitors are provided, along with temperature […]

VertiMill Sizing Example

This was a case study for an expansion of a 2200 TPD SAG Mill operation. The client wanted to increase the plant to 2700 TPD @ 30um. Some plant samples were taken, work indexes obtained and data simulated. As it turns out a single 3000HP Vertimill would get that done. The applications of the VERTIMILL continue to […]

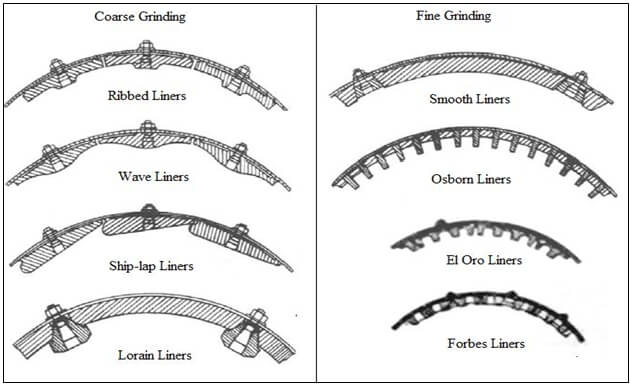

Ball Mill Liner Design

There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected. Based upon individual experience, mill superintendents develop preferences for liner designs. The following is given […]

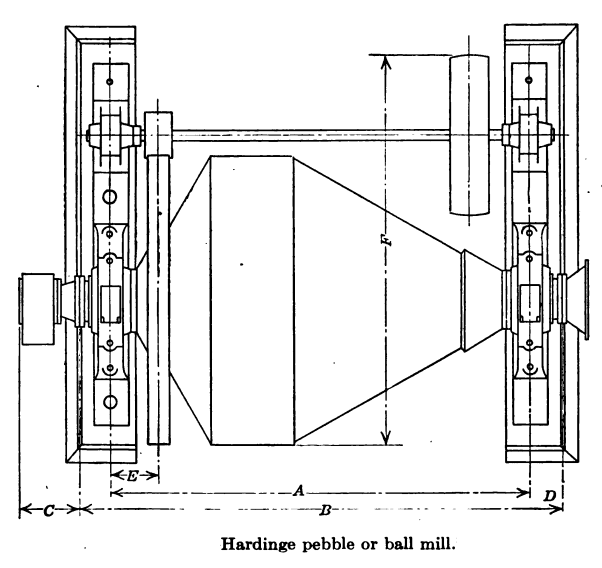

Hardinge Conical Ball Mill

The Hardinge Ball Mill consists of three sections. After the usual type of trunnion bearing the mill consists of a short conical section showing a sharp drop from feed entrance to maximum mill radius. A cylindrical section of varying length then follows and toward the discharge end connects with a comparatively long and conical section […]

Grinding Rule of Thumb

Here is a list of Rules of Thumb often used in Grinding Circuits: Fine ore bins (or stockpiles) that provide feed to the grinding circuit should have a capacity equal to 30 hours of processing. Source: Northern Miner Press Grinding is a low-efficiency, power-intensive process and typically can account for up to 40% of the direct operating […]

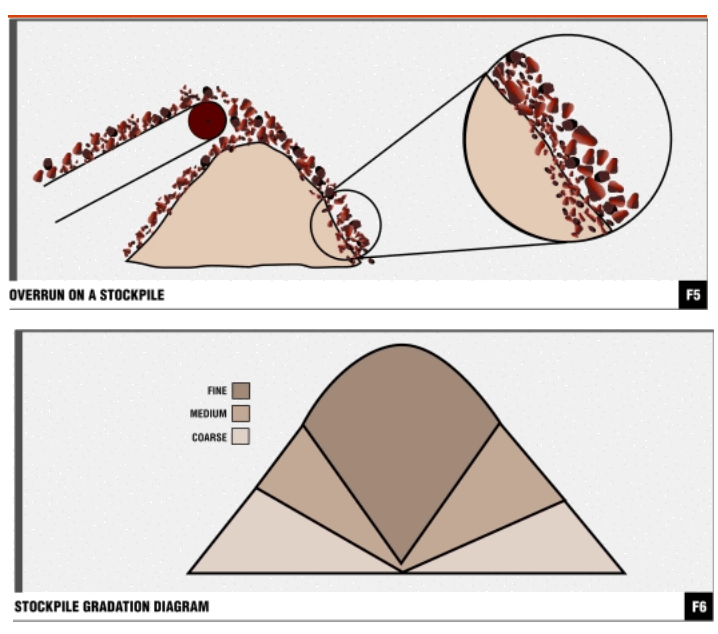

Stockpile Segregation

The video below graphically explains the common problem of Coarse Ore Stockpile Segregation. This topic relates to SAG Mill tonnage and the bad habit of putting bulldozers “dozers” on ore stockpiles. Stockpile-Segregation”>

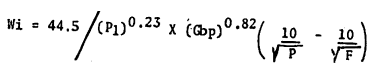

Standard Bond Ball Mill Grindability Test Method-Procedure

Here is the old Allis-Chalmers Bond Work Index Grindability Test Procedure. The standard feed is prepared by stage crushing to all passing a 6 mesh sieve, but finer feed can be used when necessary. It is screen analyzed and packed by shaking in a 1000-cc graduated cylinder, and the weight of 700 cc is placed […]

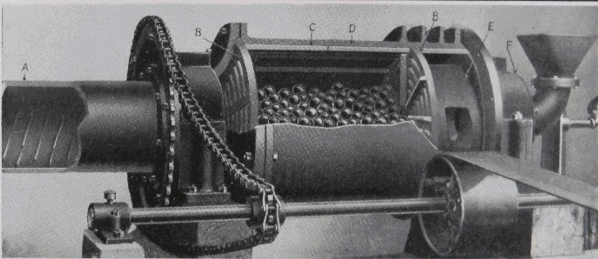

Gibson Roll Ball Mill

CRUSH, GRIND and CLASSIFY in a single pass! YOU Will save time, money and labor with the Gibson combination Elliptic Roll and Ball Mill.• It is the first successful mill put on the market that will take the mine run of ore. Crush grind and classify in a single pass. • Horsepower consumption over one […]

Marcy Overflow Rod Mills

Primary Grinding in open End ROD Mills successful since 1919 With MARCYS THE USE of MARCYS Open End Rod Mills for primary grinding is today receiving considerable attention – rightly so. The open end rod mill is an excellent primary grinder because it is efficient and economical for preparing food to tube or ball mills. Considering […]